Summary of Contents for Daewoo D1146

- Page 1 65.99897-8056 Feb. 2001 MAINTENANCE MANUAL Diesel Engine D1146 D1146TI DE08TIS PS-MMA0415-E1A...

- Page 2 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL FOREWORD This maintenance manual is designed to serve as a reference for DAEWOO Heavy Industries Ltd's (here after DAEWOO’s) customers and distributors who wish to gain basic product knowledge on DAEWOO's D1146, D1146TI and DE08TIS Diesel engine.

- Page 3 For the last, the content of this maintenance instruction may be changed without notice for some quality improvement. Thank you. DAEWOO Heavy Industries & Machinery LTD. Feb. 2001 Printed in Jan. 2001 PS-MMA0415-E1A...

-

Page 4: Table Of Contents

D1146/D1146TI/DE08TIS MAINTENANCE MANUAL CONTENTS 1. GENERAL INFORMATION 1.1 General Repair Instructions 1.2. Engine Specific Character 1.3. Engine Specifications 1.4. Engine Assembly 2. MAJOR MAINTENANCE 2.1. Preventive Maintenance 2.2. Diagnosis and Remedy 2.3. Engine Inspection 3. MAINTENANCE 3.1. Engine Disassembly 3.2. Inspection and Measurement on Major Parts 3.3. -

Page 5: General Information

4. The use of proper tools and special tools where specified is important to efficient and reliable service operation. 5. Use genuine DAEWOO parts necessarily. 6. Used cotter pins, gaskets, O-rings, oil seals, lock washer and self-lock nuts should be discarded and new ones should be prepared for installation as normal function of the parts can not be maintained if these parts are reused. -

Page 6: Engine Specific Character

1.2. Engine Specific Character 1.2.1. Toroidal combustion mode (D1146) The D1146 engine is operated in the toroidal combustion mode that was developed by this company with AVL Co. Australia. The feature of this mode in the fundamental structure is that there are combustion chambers in the centers of piston heads and swirling passages in the cylinder heads. - Page 7 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 1.2.3. Oil gallery cooling type piston (DE08TIS) Oil gallery cooling is used for the piston of DE08TIS diesel engine. When thermal loading is high, piston cooling by means of an oil gallery in the crown is normally necessary to prevent crown cracking and ring sticking. The design of the gallery, the design and location of the oil spray nozzle and the quantity of oil flowing in the gallery are critical in order to achieve the desired temperature reduction.

-

Page 8: Engine Specifications

D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 1.3. Engine Specifications 1.3.1. Specification Engine Model D1146 D1146TI DE08TIS Items 4 cycle in-line, 4 cycle in-line, Engine type Water-cooled type Water-cooled type Naturally aspirated Turbo charged & intercooled Combustion chamber type Direct injection type Cylinder liner type... - Page 9 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 1.3.2. Engine power Production tolerance : ±5% Engine model Performance Injection Power Torque Low idle High idle Model Suffix timing Remark (PS/rpm) (kg.m/rpm) (rpm) (rpm) (BTDC°) EACBA EACBB EACBE D1146 182/2,500 57.5/1,600 600-650 2750 EACBH EACBI EACBK...

- Page 10 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 1.3.3. Performance curve (DE08TIS – 225PS) Performance ISO 1585(SAE J1349) Output (max.) 165 kW (225PS) / 2,300 rpm Torque (min) 804 N.m (82 kg.m) / 1,200 rpm Fuel consumption (min) 192 g/kW.h (141 g / PS.h) Printed in Jan. 2001 PS-MMA0415-E1A...

- Page 11 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 1.3.4. Performance curve (DE08TIS – 240PS) Performance ISO 1585(SAE J1349) Output (max.) 176 kW (240PS) / 2,300 rpm Torque (max.) 882 N.m (90 kg.m) / 1,200 rpm Fuel consumption (min.) 192 g/kW.h (141 g / PS.h) Printed in Jan. 2001 PS-MMA0415-E1A...

-

Page 12: Engine Assembly

D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 1.4. Engine Assembly 1.4.1. Engine sectional view (longitudinal) Water pump Piston Air compressor Intake valve Exhaust valve Breather Cylinder head cover Exhaust valve spring Cylinder head Intake valve spring Cylinder block Push rod Flywheel housing Ring gear... - Page 13 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 1.4.2. Engine sectional view (cross) Fuel injection pipe Turbo charger Fuel filter Fuel injection pump Fuel injection nozzle Timing gear case Intake manifold Oil filler cap Air heater Connecting rod Rocker arm Oil spray nozzle Rocker arm bracket...

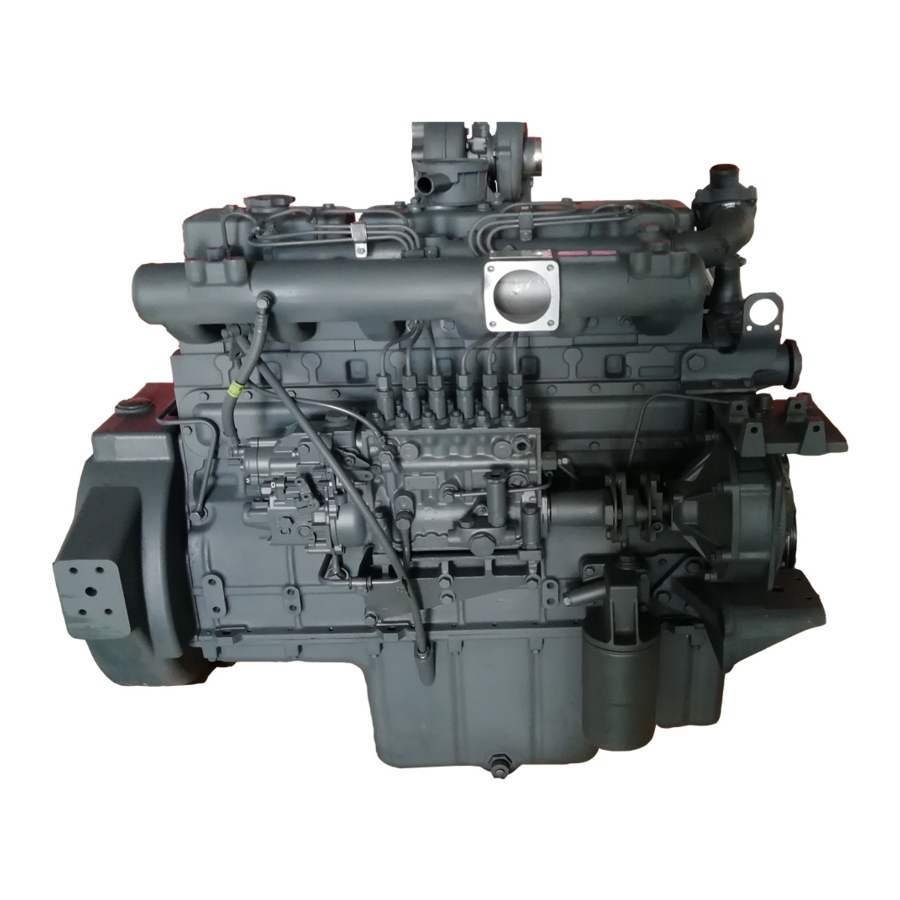

- Page 14 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 1.4.3. Engine Assembly Views (1) D1146 (bus) Flywheel housing Oil filler cap Water pump Intake manifold Oil level gauge Exhaust manifold Breather Oil pan Cylinder head cover Air pipe Oil drain plug Crank shaft pulley Oil filter...

-

Page 15: Fuel Injection Pipe

D1146/D1146TI/DE08TIS MAINTENANCE MANUAL (2) DE08TIS (Truck) 12 13 22 23 Magnetic pick-up sensor Cooling fan Exhaust elbow Flywheel housing Cooling fan guide Crank shaft pulley Intake manifold Air compressor pulley Vibration damper Fuel filter Thermostat Mounting bracket Air pipe Water pump... -

Page 16: Fuel Filter

D1146/D1146TI/DE08TIS MAINTENANCE MANUAL (3) DE08TIS (Bus) 19 20 12 13 14 15 16 22 23 Intake manifold Oil level gauge Water pump breather Flywheel housing Exhaust manifold Air pipe Drain plug Belt (Intercooler to intake manifold) Oil pan Mounting bracket... -

Page 17: Major Maintenance

For the improper control might give the fatal damage to the cooling water pump and cylinder liners, detail care is needed. Since D1146, D1146TI and DE08TIS (diesel engine of D1146 series) cylinder liner is dry type, particularly the cooling water control should be applied thoroughly. - Page 18 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL (3) Wait for about 45 sec. till the color change of test paper. NOTE : However, it should not elapse longer than 75 sec, and if it did, the hue would change. (4) Make the numerical value by comparing the test paper which hue has changed with the color list of label on storage bottle.

- Page 19 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 2.1.3. Engine oil Check oil level with the oil level gauge and replenish if necessary. Check the oil level with the engine cooled. If the engine is warm, allow time for 5 ∼ 10 minutes for oil drain into the crankcase before checking oil level. The oil level must be between Max and Min.

- Page 20 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 2.1.5. Fuel filter Drain water in cartridge with loosening cock under filter manually (6) from time to time. G1019 2.1.6. Air cleaner. In case that elements are deformed, damaged or if the air cleaner has a crack, replace it.

- Page 21 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Air/air intercooler with radiator (combined radiator) Air flow by cooling fan Hot air by turbo charger compressor Cooled air to intake manifold (max. 50°C) 2.1.8. Valve clearance adjust procedure After letting the #1 cylinder's piston come at the compression top dead center by turning the crankshaft, adjust the valve clearances.

- Page 22 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 3) Rotating the crankshaft by one revolution, #6 cylinder become the compression state of top dead center. 4) Thereafter adjust valve clearances corresponding to “ of lower figure. ” 5) After reinsuring valve clearances, retighten if necessary.

- Page 23 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Install the special tool (compression gauge adapter) at the nozzle holder hole, and connect the compression pressure gauge there. Standard value 28kg/cm over Limit value 24kg/cm Difference Within ± 10 % between each cylinder ♦ Condition : Water temperature 20°C,...

- Page 24 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Check if the idle operation and speed regulating lever's sealing is removed. The adjustment and testing of fuel injection pump should necessarily be done at the test bench. 2.1.12. Battery Inspect for any leakage of electrolytic solution owing to battery crack, and replace the battery in case of poor condition.

- Page 25 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL pipes, For leaking air will bring the overheat engine, an immediate repair must be done. During the operation that is surrounded by the dust and oil mixed air, frequent cleaning must be done on the impellers. Tear down the impeller casing (attention: be careful not to bend) and must clean with non-acid solvent solution.

-

Page 26: Diagnosis And Remedy

D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 2.2. Diagnosis and Remedy The following description summarizes the probable cause of and remedy for generall failure by item. Immediate countermeasures should be taken before a failure is inflamed if any symptom is detected. Printed in Jan. 2001 PS-MMA0415-E1A... - Page 27 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Operating state 1. Overload 2. Radiator core clogged 3. Continuous over-run Check fresh Radiator tank cap Inspect Radiator Printed in Jan. 2001 PS-MMA0415-E1A...

- Page 28 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Printed in Jan. 2001 PS-MMA0415-E1A...

- Page 29 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Printed in Jan. 2001 PS-MMA0415-E1A...

- Page 30 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Causes according to operating conditions 1. Overload 2. Freqent use of low geae position at high speed 3. Freqent use of high geae position at low speed 4. Clutch slip 5. Too low tire inflation pressure Printed in Jan. 2001 PS-MMA0415-E1A...

- Page 31 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Cause according to use conditions 1. Excessive oil infusing 2. continuous operation in low speed or extremely cold state Printed in Jan. 2001 PS-MMA0415-E1A...

- Page 32 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Printed in Jan. 2001 PS-MMA0415-E1A...

- Page 33 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Condition Causes Remedies 1) Starting difficult Valve's poor shut, stem Repair or replace Compression pressure lack distortion Valve spring damage Replace valve spring Cylinder head gasket's leak Replace gasket Wear of piston, piston ring Adjust or liner...

- Page 34 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Condition Causes Remedies 5) Engine noisy For noises arise compositely such as rotating parts, lapping parts etc., there is necessity to search the cause of noises accurately. (1) Crankshaft As the wear of bearing or Replace bearing &...

- Page 35 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Condition Causes Remedies 7) Oil Consumption Excessive (1) Oil level elevated Clearance between cylinder Replace liner & piston Wear of piston ring, ring Replace piston, groove piston ring Piston ring's damage, stick, Replace piston ring wear Piston...

-

Page 36: Engine Inspection

D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 2.3. Engine Inspection 2.3.1. Stopping engine After checking the engine for any unusual condition at the idling speed, then turn the key switch to stop the engine. 2.3.2. General engine inspection cycle О : Check & adjust ●... -

Page 37: Maintenance

D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 3. MAINTENANCE 3.1. Engine Disassembly 3.1.1. Heed at disassembly Before disassembly, the part shelf should be prepared for various tools and repair parts. When assembling, clean empty hand should be used and clean environment maintained. In case of storing the disassembled parts, each part should not touch each other. - Page 38 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 3.1.4. Engine oil Remove the oil drain plug of oil pan and pour the engine oil into the prepared vessel. Drain plug 3.1.5. Cooling fan Remove the flange fixing bolts, then take off the flange and cooling fan.

- Page 39 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 3.1.8. Starter Unscrew the starter fixing nuts and remove the starter being careful not to damage its gears. 3.1.9. Fuel filter Remove the hollow screws of filter and tear down fuel supply and discharge rubber hose. Remove fuel filter fixing bolts and disassemble the fuel filter.

- Page 40 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 3.1.12. Alternator Remove the alternator fixing bolts and take off the alternator. 3.1.13. Oil cooler Loosen the cooling water pump and the rubber hose clamps of connected pipes, and disassemble it. Remove the oil cooler fixing bolts and take off the oil cooler.

- Page 41 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 3.1.16. Air compressor Remove the oil pipe between cylinder block and air compressor. Unscrew the air compressor fixing bolts and take off the air compressor. 3.1.17. Idle pulley Unscrew the idle pulley fixing bolts and take off the idle pulley 3.1.18.

-

Page 42: Fuel Injection Nozzle

D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 3.1.20. Fuel injection nozzle Unscrew the fuel injection pipe between the injection pump and nozzle and take off the pipe. Install a special jig on the nozzle holder, and then pull out the nozzle as striking the hammer of the jig backwardly. -

Page 43: Intake Manifold

D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 3.1.23. Intake manifold Unscrew the intake manifold fixing bolts Air heater Intake manifold and remove the intake manfold from the cylinder head. Disassemble the intake manifold gasket and discard it. 3.1.24. Cooling water pipe Unscrew the cooling water pipe fixing bolts and remove the cooling water pipe from the cylinder head. - Page 44 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL CAUTION : When reassembling the bush, cool the bush in dry ice and press the bush while aligning the bush with the oil hole of the rocker arm. 3.1.26. Cylinder head Remove the cylinder head bolts in the reverse order of tightening but remove it step by step.

- Page 45 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL - For removal of the valve seat, apply arc welding work to two points of valve seat insert, and pull out the valve seat insert with inner extractor. M1072 3.1.27. Oil pan Unscrew the oil pan fixing bolts and remove the oil pan.

- Page 46 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 3.1.30. Oil pump Unscrew the bracket fixing bolts of the oil suction pipe. Unscrew the pipe fixing bolts of oil pump and disassemble the suction and supply oil pipe. Unscrew the oil pump fixing bolts, and disassemble the oil pump.

- Page 47 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL (2) Heat the piston with a electric heater, then take out the piston pin from the piston as tapping it with a round wooden bar. (3) Remove the piston ring with a plier. (4) Clean the piston thoroughly.

-

Page 48: Fuel Injection Pump

D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Unscrew two bolts fxing the idle gear, then remove the idle gear and its pin. 3.1.34. Fuel injection pump Disassembly the oil hose for lubrication. Remove the bolts and nuts of injection pump flange. Unscrew the injection pump fixing bolts and remove the injection pump by lifting it up. -

Page 49: Timing Gear Case

D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 3.1.37. Fly wheel housing Remove the flywheel housing fixing bolts and disassemble the flywheel housing. Disassemble the oil seal of flywheel housing. Oil seal 3.1.38. Injection pump drive gear Unscrew the drive gear housing fixing bolts remove... - Page 50 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 3.1.41. Crankshaft Assemble the bolts on the both side of crankshaft temporarily. Connect the rope to the bolts and lift the crankshaft by means of crane being careful not to give any damage on it. In order for the disassembled crankshaft to be prevented from bends or damage, put it on the special lathe and store.

-

Page 51: Oil Spray Nozzle

D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 3.1.43. Oil spray nozzle (D1146TI, DE08TIS only) Remove the valve screws of oil spray nozzle and disassemble it. Printed in Jan. 2001 PS-MMA0415-E1A... -

Page 52: Inspection And Measurement On Major Parts

D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 3.2. Inspection and Measurement on Major Parts 3.2.1. Cylinder block Clean the cylinder block thoroughly, and check for any crack or damage. If there is any crack or severe damage, replace it and if there is minor one, correct Check for any clogging or corrosion in the oil passage and water passage. - Page 53 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL (2) Inspection of cylinder head 1) Check for the cylinder head. Remove carbon from the cylinder head lower surface, and then should be careful not to scratch the surface. Check any crack or damage that can not found by naked eyes through the hydraulic or magnetic particle test.

- Page 54 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL (3) Inspection of valve and valve guide 1) Valve After cleaning valve with fuel, check it. Valve stem outer diameter Measure the valve stem outer diameter at 3 positions (top, middle, and bottom), and check for any wear and if beyond the limit value, replace the valve.

- Page 55 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL or valve guide. Valve stem end play Standard Limit 0.04 ∼ 0.07 mm Intake valve 0.2 mm Exhaust valve 0.06 ∼ 0.09 mm 0.25 mm Assemble the valve at cylinder head's valve guide and see if it is centered with the valve seat using a special tool.

- Page 56 (mm) M1078 Spring free Length Standard 64 mm Intake valve D1146/TI : 60 Inner DE08TIS : 73.8 Exhaust valve D1146/TI : 71 Outer DE08TIS : 77.7 Printed in Jan. 2001 PS-MMA0415-E1A...

- Page 57 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Valve spring inclination Use a surface plate and a square to M1079 measure the valve spring inclination. If the measured value exceeds the specified limit, the valve spring must be replaced. (unit : mm) Standard Limit Valve Spring Less than 1.8 mm...

- Page 58 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Install the lower seat of valve spring to the valve guide of cylinder head. After putting inner, outer springs, install the spring upper seat on it. Assemble the valve by inserting the valve cotter pressing the valve spring with a special tool.

- Page 59 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Rocker arm shaft diameter With an outside micrometer, measure the rocker arm shaft diameter at the point where the rocker arms have been installed. Replace the rocker arm if the amount of wear is beyond the specified limit.

- Page 60 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 3) Tappet and push rod Clearance Measure the clearance of the tappet and tappet holes of the cylinder block. If the value is beyond the specified limit, replace tappets. Standard Limit 0.035 ∼ 0.077 mm 0.15 mm...

- Page 61 Cam lobe height M1095 Standard Limit Intake 49.15 mm 48.85 mm Cam lobe height D1146/TI : 49.32mm Exhaust 49.00 mm DE08TIS : 49.35mm Cam journal diameter (A,B) φ57.86 ∼ φ57.88 mm φ57.52 mm Use a micrometer to measure the lobe...

- Page 62 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Inspect the cam face for scratch or damage. Slight step wear or damage on the cam face may be corrected with oil stone or oiled grinding paper. But, replace if severely damaged. (3) Cam shaft Clearance between camshaft journal and camshaft bush...

- Page 63 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 0.05 mm 0.2 mm 3.2.5. Crankshaft (1) Inspection of crankshaft 1) Defect check By naked eyes, check for any scratch damage crankshaft journal and crank pin. By means of magnetic particle test color check, check crankshaft for any crack and if found, replace it.

- Page 64 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL In case that pin's wear is more than the limit value, grind the crankshaft journal and crank pin, and use the undersized bearings. Be sure to use grinding paper which has been immersed in oil. <Undersize bearings available>...

- Page 65 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL (2) Crankshaft bearing and connecting rod 1) Visual check Visually check the crankshaft bearing and connecting rod bearing for scores, uneven wear or damage. 2) Oil clearance between crankshaft and bearing (Method 1 : dial gauge) Main bearing clearance...

- Page 66 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Compare the two values obtained through measurement of connecting rod bearing inside diameter with the outside diameters of crankshaft pins to determine the oil clearance. Standard Limit 0.034 ∼ 0.098 mm 0.25 mm If the clearance deviates from the...

- Page 67 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 4) Bearing spread and crush Inspection Check to see that the bearing requires a considerable amount of finger pressure reassembly operation. M1112 Spread Crankshaft bearing crush Install the bearing and cap in the cylinder block, retighten the bolts to...

- Page 68 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 5) Crank shaft end play Assemble the crankshaft to the cylinder block. With a dial gauge, measure crankshaft end play. Standard Limit 0.15 ∼ 0.325 mm 0.5 mm 3.2.6. Piston assembly (1) Disassemby of piston assembly Disassemble...

- Page 69 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Standard Limit φ111 ∼ φ111.022 mm φ111.122 mm clearance computed subtracting piston outside diameter from the cylinder liner inside diameter. Replace either piston or cylinder liner, whichever damaged more, if the clearance is beyond the specified limit.

- Page 70 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 3) Piston ring side clearance Fit the compression ring and oil ring in feeler gauge the piston ring groove. With a feeler gauge, measure side clearance of each ring, and replace either the ring or piston if the measured value is beyond the specified limit.

- Page 71 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 2) Clearance Measure the clearance between the piston pin and connecting rod bushing, and replace either of them, whichever damaged more, if the measured value is beyond the limit. M1106 Standard Limit 0.003 ∼ 0.015 mm 0.08 mm...

- Page 72 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 3) Wear Assemble the connecting rod to the crankshaft and measure connecting rod big end side clearance using a feeler gauge. Assemble the connecting rod to the piston and measure connecting rod small end side clearance. If the measured values are beyond the limit, replace the connecting rod.

-

Page 73: Reassembly

D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 3.3. Reassembly 3.3.1. General precautions Clean all the disassembled parts, particularly oil and water ports, using compressed air, then check that they are free from restrictions. Arrange the general and special tools in order for engine assembly operation. - Page 74 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 3.3.4. Tappet and cam shaft Undercool a new bush with dry ice about 2 hours and press it into position in the cylinder block using a bench press. After the pressing operation, measure the inside diameter of the cam bush to check if it is not deformed.

- Page 75 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 3.3.5. Crankshaft Install the main bearing (refer to assemble sequence : right figure) machined with two holes in the cylinder block so that the key is aligned with the key groove, then apply oil to the bearing surface.

- Page 76 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Install the bearing and thrust washers to the bearing cap and apply oil to the bearing and thrust washers. Install the bearing cap by matching the cylinder block No. with the bearing cap Apply oil to the entire part of the bearing cap bolts, then tighten in tightening sequence to specified torque.

- Page 77 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL torque. (30 kg.m). Tighten the bearing cap in the sequence of 4–3–5–2–6–1-7. Check to see that the assembled crankshaft turns smoothly with hand. 3.3.6. Flywheel housing Temporarily install the guide bar on the cylinder block. Apply gasket to the cylinder block.

- Page 78 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL shaft, then assemble the oil seal using an oil seal fitting jig. 3.3.8. Flywheel Installation of flywheel ring gear With a gas burner, heat the ring gear evenly until heat expansion takes place, then install it using a hammer.

- Page 79 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL specified torque. Torque 18 kg.m 3.3.9. Magnetic pick-up sensor Move the lock nut to hexagonal side of Lock nut sensor completely. Rotate (Clockwise) the pick-up sensor on fly wheel housing, until the end of it reach on fly wheel ring gear.

- Page 80 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL compressed air to prevent the entry of foreign substances. After the cleaning operation, make the cylinder liner dried up and push it into the cylinder block by hand. Wet the liner inside diameter with engine oil. 3.3.12. Piston and connecting rod Use a piston heater to heat the piston approximately 100 °C (212 °F) for 5...

- Page 81 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Install the snap rings and check to see that it is securely assembled. Install the piston ring in the piston using Piston piston ring pliers. Top ring Second ring Oil ring Identify the mark "Y" or "TOP" on the...

- Page 82 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Use care not to damage the cylinder liner and piston, and slightly lift and insert the piston into the cylinder so that the ring may not be damaged by the fillet of the liner. Install the bearing in the connecting rod cap and apply oil.

- Page 83 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL remove and reinstall or replace the connecting rod bearing cap. 3.3.13. Timing gear case Mount a new gasket using dowel pin on the cylinder block. Put the time gear case to the cylinder block by aligning the dowel pin hole of...

- Page 84 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Idler gear pin with oil hole is assembled toward cylinder block. Install the idle gear by coinciding the Mark “2” marks impressed on the crank gear, cam gear, fuel injection pump drive gear, and idle gear. Install a thrust washer on the idle gear and tighten to specified torque.

- Page 85 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL fixing bolts in the direction of fuel injection pump. 3.3.16. Fuel injection pump Install the injection pump bracket in the cylinder block. After measuring the amount of run-out with an alignment setting jig, disassemble the bracket, adjust the shims, then reassemble it.

- Page 86 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Operating the priming pump of supply pump, turn the crankshaft slowly in the direction of engine rotation until the fuel will drop at the rate of a drop for 6 ~ 8 sec. Confirm then whether the indication...

- Page 87 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Turn the coupling until the notch mark of the indicator plate attached to the fuel injection pump is aligned with the notch mark of the coupling. Tighten the coupling fixing bolts and nuts to specified torque. 6.0 ∼ 6.5 kg.m...

- Page 88 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL the oil pan fitting face. CAUTION : In the assembling, be careful not to be damaged by the crankshaft. 3.3.19. Front oil seal Apply lubricating oil to the outside of the oil seal and the oil seal hole of the timing gear case cover.

- Page 89 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 3.3.22. Oil pan Remove the gaskets thoroughly that project at the timing gear case, case cover cylinder block, contacting part of flywheel housing by means of a scraper. CAUTION : Be careful for the gasket pieces not fall into the engine during the work.

- Page 90 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Torque 2.2 kg.m Apply engine oil to the oil filter cartridge o-ring and assemble the cartridge using a filter wrench. 3.3.24. Oil cooler Install the gasket on the cylinder block. Assemble the oil cooler by tightening the assembling bolts.

- Page 91 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL valve guide. After installing valve springs and spring G1102 retainer, press the retainer with a jig, then install the cotter pin. Tap the valve stem lightly with a rubber hammer to check that the valve is assembled correctly.

- Page 92 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Check the inside of combustion chamber for foreign substances, and carefully mount the cylinder head assembly in the block by aligning the dowel pin with the dowel pin hole. G1089 CAUTION : Be careful not to damage the cylinder head gasket.

- Page 93 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL (1) First stage : Coat the bolts with engine oil. (2) Second stage : Tighten 1 ~2 threads with hands. (3) Third stage : Tighten at about 6 kg.m with a wrench. (4) Fourth stage : Tighten at rotating angle method 180° with a wrench.

- Page 94 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL <Guide for valve clearance adjustment> By turning the crankshaft, when the intake and exhaust of #6 cylinder (the fifth cylinder from the flywheel) overlap, that is, when #1 cylinder’s piston come at the compression top dead center (OT), adjust the valve clearances by .

- Page 95 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL As for the valve clearance, adjust it when in cold. Model Intake Valve Exhaust Valve D1146 D1146TI 0.3 mm 0.3 mm DE08TIS CAUTION : (1) Crankshaft revolution is done by hands without using a starting motor. (2) Turn it to the direction of engine rotation, but do not use the installing bolts at the turn.

- Page 96 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Install the exhaust manifold gasket over the stud bolts by aligning the gasket with the exhaust port on the cylinder head so that the face and back of the gasket can be positioned correctly. Semi-assemble the exhaust manifold and install the heat resisting plate.

- Page 97 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 3.3.33 Idle pulley Assemble the air compressor mounting bracket on the timing gear case. Install the idle pulley on the air compressor mounting bracket and tightening the fixing bolt. 3.3.34 Air compressor & power steering pump Couple the power steering oil pump to the air compressor with the driving dog engaged.

- Page 98 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL direction arrow impressed on the fuel filter head so that fuel can be fed in the sequence of FUEL FEED PUMP → FUEL FILTER → FUEL INJECTION PUMP. 3.3.37. Injection nozzle Install a new seal ring in the nozzle hole G1104 of the cylinder head.

- Page 99 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL screw. 3.3.39. Cylinder head cover Attach a new gasket on the cylinder head cover. Assemble the cylinder head cover to the cylinder head by tightening the cap bolts for fixing the cylinder head cover. Torque 1.2 kg.m Assemble the breather and breather hose.

- Page 100 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL bottom side of the guide tube. Then assemble the guide tube and oil level gauge on the oil pan. 3.3.43. Others Assemble by connecting the other oil and fuel hoses. Printed in Jan. 2001 PS-MMA0415-E1A...

-

Page 101: Breaking In

D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 3.4. Breaking in 3.4.1. Preparations for breaking-in Fill of new engine oil through the oil filler cap. When measuring the oil level with the oil level gauge with the engine mounted, the oil level must indicate about 10mm above the max. line. - Page 102 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Note : If you have a problem getting a good oil level reading on dipstick, rotate the level gauge 180° and re-insert for check. b) Watch the oil pressure warning lamp. If the lamp blinks, it may be the oil pick-up screen is not covered with oil.

-

Page 103: Maintenance Of Major Components

D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 4. Maintenance of Major Components 4.1. Cooling System 4.1.1. General information This engine is water-cooling type. Heat from the combustion chamber and engine oil heat are cooled down by coolant and radiated to the outside, resulting in the normal operation of the engine. - Page 104 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 4.1.3. Thermostat General descriptions and main data The thermostat maintains a constant temperature of coolant and improves thermal efficiency of the engine by preventing heat loss. Namely, when temperature coolant is low, the thermostat valve is closed to make the coolant bypass to directly enter the water pump;...

- Page 105 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL mm or more (full open) at temperature of 95 °C, the thermostat is normal. Replacing thermostat and precautions for handling (1) Precautions for handling The wax pallet type thermostat does not react as quickly as bellows type one to a variation of temperature of coolant.

- Page 106 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 4.1.4. Diagnostics and troubleshooting Complaints Possible causes Corrections 1. Engine overheating Lack of coolant Replenish coolant Radiator cap pressure Replace cap valve spring weakened Fan belt loosened or Adjust or replace fan belt broken Fan belt fouled with oil...

-

Page 107: Lubrication System

D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 4.2. Lubricating System 4.2.1. General descriptions and specifications General descriptions All the engine oil pumped up from the oil pan by the gear type oil pump is filtrated through the oil cooler and oil filter, and this filtrated oil is forced through the main oil... - Page 108 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 4.2.2. Oil pump Disassembly (1) Disassembly of oil pump drive gear a. Unscrew the screw and disassemble the oil relief valve. b. Unfold the washer for the oil pump drive gear fixing nut and remove the nut.

- Page 109 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL (3) Measuring clearance between drive shaft and bushing a. Measure the outside diameters of the drive shaft and driven shaft, and replace if the measured values are less than the limit (φ16.95mm) φ16.95 ∼ φ16.968 mm Standard b.

- Page 110 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 4.2.3. Diagnostics and troubleshooting Complaints Possible causes Corrections 1. Oil consumption Poor oil Use suggested oil excessive seal packing Replace leaky Pistons or piston rings Replace pistons and/or worn piston rings Cylinder liner worn Replace cylinder liner...

-

Page 111: Fuel Injection Pump

D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 4.3. Fuel Injection Pump 4.3.1. General information of fuel system The fuel system consists of the fuel tank, injection pump, injection nozzle, fuel filter, and fuel lines such as pipes and hoses necessary to connect those components. - Page 112 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 1) D1146 (1) Injection pump ass’y : 65.11101-7259A (101603-9981 ZEXEL) Injection pump : KP-PE6AD95B412RS2 (101060-6100) Governor : KP-EP/RLD250-1400AIFFL (105931-5901) Timer : KP-EP/SA900-1250B4DR (105644-0520) Fuel feed pump : KP-FP/KE-ADS (105210-5280) Coupling : 105662-1290 Micro switch : 153169-3320 Plunger & barrel...

- Page 113 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL (7) Governor adjustment (D1146) Injection pump speed (rpm) Printed in Jan. 2001 PS-MMA0415-E1A...

- Page 114 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 2) D1146TI (1) Injection pump ass’y : 65.11101-7298 (101701-9630 ZEXEL) Injection pump : KP-PE6AD100B412RS2 (101060-6541) Governor : KP-EP/RLD250-1400A1FXL (105932-3550) Timer : KP-EP/SA700-1100630DR (105644-0570) Fuel feed pump : KP-FP/KE-ADS (105210-5280) Coupling : 105662-1490 Micro switch : 153169-3320 Plunger & barrel...

- Page 115 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL (7) Governor adjustment (D1146T) a) Governor adjustment Injection pump speed (rpm) b) Boost compensator adjustment Boost pressure (mmHg) Printed in Jan. 2001 PS-MMA0415-E1A...

- Page 116 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 3) DE08TIS (225PS) (1) Injection pump ass’y : 65.11101-7331 (106671-9960 ZEXEL) Injection pump : NP-PE6P120/721RS3S (106067-6280 ZEXEL) Governor : NP-EP/RLD300-1100P5JXR (105923-4810) Timer : 105681-2670 Coupling : 105663-0470 Plunger & barrel : 134153 -2420 Delivery valve : 134180 - 0420 (2) Nozzle holder assembly : 65.10101-7087 (Y430 K02 049 BOSCH)

- Page 117 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL (7) Governor adjustment (DE08TIS-225PS) Printed in Jan. 2001 PS-MMA0415-E1A...

- Page 118 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 3) DE08TIS (240PS) (1) Injection pump ass’y : 65.11101-7331 (106671-9960 ZEXEL) Injection pump : NP-PE6P120/721RS3S (106067-6280 ZEXEL) Governor : NP-EP/RLD300-1100P5JXR (105923-4810) Timer : 105681-2670 Coupling : 105663-0470 Plunger & barrel : 134153 -2420 Delivery valve : 134180 - 0420 (2) Nozzle holder assembly : 65.10101-7087 (Y430 K02 049 BOSCH)

- Page 119 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL (7) Governor adjustment (DE08TIS-240PS) Printed in Jan. 2001 PS-MMA0415-E1A...

- Page 120 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 4.3.4. Fuel feed pump 1) General descriptions and construction The P-type injection pump is mounted with K-ADS or KP type feed pump. These pumps have the same basic construction and operation, and the general descriptions of the KP type...

- Page 121 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL In addition, a strainer is fitted into joint bolt on the inlet side of the fuel feed pump to filtrate any foreign substances possibly mixed in fuel. M1232 2) disassembly Strainer (50 mesh) Strainer bolt ass`y : 30, 31...

- Page 122 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 4) Reassembly Reassembly operation is performed in reverse order of disassembly. All the gaskets must be replaced with new ones at reassembly. 5) Testing (1) Suction capacity test Connect one end of a hose to the inlet...

- Page 123 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 4.3.5. Injection nozzle 1) General descriptions Pressurized fuel delivered from the fuel injection pump is sprayed into the combustion chamber past the injection nozzle at proper spray pressure and spray angle, then burnt completely to achieve effective engine performance.

- Page 124 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 5) Reassembly After removing carbon deposit, submerge the nozzle in diesel oil and clean it. Replace all the seal rings with new ones. Assemble the parts and tighten them to specified torque. 6) Adjustment After reassembly, install the nozzle on a tester.

- Page 125 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 4.3.6. Diagnostics and troubleshooting Complaints Possible causes Corrections 1. Engine won't start ① Fuel pipes clogged or air into 1) Fuel not being pumped Correct out from feed pump pipe fine ② Feed pump valve defective Replace ③...

- Page 126 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Complaints Possible causes Corrections ① supply of fuel insufficient 6. Engine output unstable Check feed pump ② Air in fuel Bleed ③ Water in fuel Replace fuel ④ Operation of plungers unsmooth Disassemble, correct ⑤ Movement of control rack...

-

Page 127: Turbocharger

D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 4.4. Turbocharger (D1146TI, DE08TIS) 4.4.1. Main data and specifications 1) Main data and specifications DE08TIS Specification D1146TI 225PS 240PS Allied Signal HOLSET Turbocharger Model 466721-12 WH1E-8284AX/H14EC8 Air pressure 1.26 kg/cm 1.33 kg/cm 1.40 kg/cm at maximum at compressor outlet... - Page 128 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 3) Construction Bearing housing O-ring Hex bolt Turbine housing Oil baffle Actuator ass`y Turbine wheel ass`y Inlet baffle Hose clamp Compressor wheel Thrust collar Actuator clip Compressor housing Heat protector cover Cover plate Journal bearing Oil seal plate...

- Page 129 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 3) Operating principle The turbocharger is a system designed to make use of the engine exhaust gas energy to charge high-density air into the cylinders, thereby to increase the engine output. 4.4.2. General descriptions The engine output is determined by the fuel delivery volume and engine efficiency.

- Page 130 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 4.4.3. Functions 1) Turbine Exhaust gas discharged from the combustion chamber distributes its own energy to the turbine blades while passing the inside of the turbine housing, with the result that the turbine shaft can get rotating force. This is the operating principle of 'turbine', which is mounted with seal rings and heat protector to prevent exhaust gas from affecting the bearings adversely.

- Page 131 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 4.4.4. Precautions for operation 1) Precautions for operation of engine The following precautions should be observed when starting, operating, or stopping the engine: Operations Precautions Reasons When starting 1) Check oil level the engine 2) Crank the engine with starter to...

- Page 132 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 4.4.5. Walk-around check and servicing As the condition of turbocharger depends greatly on how well the engine is serviced, it is very important to maintain the engine in accordance with the specified maintenance procedure. 1) Intake system Pay particular attention to the air cleaner when servicing the intake system.

- Page 133 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Recommend oil Engine Sulfated ash model content SAE No. API No. D1146 SAE 15W40 above CD or CE D1146TI SAE15W40 ACEA-E2 or ACEA-E3 DE08TIS Bellow 0.5 % SAE10W40 (API CH-4) * If long oil change intervals are to be used, ACEA-E3 oil must be used.

- Page 134 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL (2) Rotor radial play (3) If the measured axial and radial plays are beyond the limit of wear, replace or repair the turbocharger. 3) Guide for disassembling/cleaning and checking the turbocharger First, disassemble the turbocharger from the engine and clean/check it with the oil inlet and outlet plugged with tape and so on.

- Page 135 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL (2) Intake system Check the inside of the intake system for foreign matters. Assemble each joint on the intake duct and air cleaner securely to prevent air leaks. (3) Exhaust system Check the inside of the exhaust system for foreign matters.

-

Page 136: Special Tool List

D1146/D1146TI/DE08TIS MAINTENANCE MANUAL 5. Special Tool List Part No. Figure Tool Name Remark EF.123-014 D1146/TI Injection pump setting ass’y EF.123-015 DE08TIS CR : made USA EF.123-127 (up to 2000. Apr.) Oil seal insert ass’y (Front) NOK : made Japan EF.123-173 (From 2000. - Page 137 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Part No. Figure Tool Name Remark 10 EF.123.-065 Valve spring press EU.2-0647 Crankshaft gear punch D1146/TI EF.123-064 DE08TIS Piston sleeve EF.120-208 All engine 13 60.99901-0027 Feeler gauge 14 T7610001E Snap ring plier 15 T7621010E Piston ring plier...

-

Page 138: Appendix

D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Appendix Tightening torque for major parts Screw Strength Tightening Major Parts Remarks Torque (Diameter x pitch) (grade) 1st : 6.0 kg.m 2nd : 180。 M14 x 1.5 10.9T Cylinder head bolt 3rd : 150。 (Angle method) 1st : 10 kg.m M14 x 1.5... - Page 139 60% or so of the standard value. Tightening torque for hollow screw(4-hole) Material SM25C 13.0 18.0 30.0 SUM22L 11.0 16.0 20.0 35.0 STS304 11.0 16.0 20.0 35.0 : Adopted in DAEWOO engine Printed in Jan. 2001 PS-MMA0415-E1A...

- Page 140 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Maintenance specification table Stand value Limit Group Part Inspection Item Correction Remark for assembly for use Measure unworn Inside diameter φ111~φ111.022 φ111.122 Replace liner portion beneath the cylinder liner for wear rim of the upper side Need...

- Page 141 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Stand value Limit Group Part Inspection Item Correction Remark for assembly for use Measure In horizontal Radial run-out of journal Correct 0.01 and vertical directions and pin with a grinder (against axial direction) Outside diameter of Use under sized φ83.966~φ83.988...

- Page 142 67~73 66.5 Replace valve to 41mm)kg valve spring spring Squareness ° (along free length direction) Free length D1146/TI : 60 (mm) DE08TIS : 73.8 Valve Tension system force(when D1146/TI:26.9~30.3 pressed DE08TIS : 36~40 Replace Inner 38mm)kg valve spring Squreness (along free °...

- Page 143 D1146/D1146TI/DE08TIS MAINTENANCE MANUAL Stand value Limit Group Part Inspection Item Correction Remark for assembly for use Clearance between tappet & tappet hole of 0.035~0.077 0.15 Replace tappet cyl. block Valve φ19.944~φ19.965 Tappet Diameter of tappet Replace tappet system Replace Tappet face in contact...

- Page 144 & improper packing, etc. others Fuel filter cartridge for Replace cartridge damage or dimple Fuel D1146 : 210 Injection pressure of injection system D1146TI : 214 Adjust by shim DE08TIS: 1st 160 nozzle (kg/cm 2nd 220 Operating pressure of overflow 1.0~1.5...

-

Page 145: Worldwide Network

WORLDWIDE NETWORK...