Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Woods RD6000-2, RD7200-2, RD8400-2

- Page 1 REAR DISCHARGE MOWERS RD6000-2 RD7200-2 RD8400-2 Tested. Proven. Unbeatable.

- Page 2 Dealer Check List items have been completed. The dealer is to return the prepaid postage portion to Woods, give one copy to the customer, and retain one copy. Failure to complete and return this card does not diminish customer’s warranty rights.

-

Page 3: Table Of Contents

TABLE OF CONTENTS INTRODUCTION ....... . .Inside Front Cover SPECIFICATIONS..........2 GENERAL INFORMATION . -

Page 4: Introduction

3-Point Hitch Cutting Width Cutting Height Range Operating Weight with Chain Shielding Blade Speed (feet per minute) Blade Speed (RPM) Blade Spindles Number of Blades Universal Drive Series Caster Wheels Tractor PTO Speed RPM Recommended Maximum Tractor Horsepower Mower Frame Thickness GENERAL INFORMATION ARNING ■... -

Page 5: Safety Rules

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED! Safety is a primary concern in the design and manufacture of our products. Unfortunately, our efforts to provide safe equipment can be wiped out by an operator’s single careless act. In addition to the design and configuration of equipment, hazard control and accident preven- tion are dependent upon the awareness, concern, judgement, and proper training of personnel... - Page 6 ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED! Never direct discharge toward people, animals, or property. Keep bystanders away from equipment. Never go underneath equipment (lowered to the ground or raised) unless it is properly blocked and secured. Never place any part of the body under- neath equipment or between moveable parts even when the engine has been turned off.

-

Page 7: Safety Rules

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED! Always wear relatively tight and belted clothing to avoid getting caught in moving parts. Wear sturdy, rough-soled work shoes and protective equipment for eyes, hair, hands, hearing, and head; and respirator or filter mask where appropriate. Make sure attachment is properly secured, adjusted, and in good operating condition. -

Page 8: Safety Decals

Replacement safety decals can be ordered free from your Woods dealer. To locate your nearest dealer, check the Dealer Locator at www.WoodsEquipment.com, or in the United States and Canada call 1-800-319-6637. - Page 9 SAFETY & INSTRUCTIONAL DECALS ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED! Replace Immediately If Damaged! WARNING O NOT EXCEE PTO SPEE OF 540 RPM PTO speeds higher than 540 RPM can cause equipment failure and personal injury. 5 - 18866 DANGER ROTATING DRIVELINE CONTACT CAN CAUSE DEATH...

-

Page 10: Operation

The operator is responsible for the safe operation of the mower. The operator must be properly trained. Operators should be familiar with the mower, the trac- tor, and all safety practices before starting operation. Read the safety rules and safety decals on page 3 to 7. This mower is designed for lawn and grass mowing. - Page 11 ATTACHING MOWER TO TRACTOR ARNING Make sure spring-activated locking pin or collar slides freely and is seated firmly in tractor PTO spline groove. The standard 1-3/8" 6B-spline driveline with a QD yoke is used to connect the mower to the tractor. 1.

-

Page 12: Front Caster Arm Configuration

Table 1: Cutting Height Chart SPACERS REQUIRED UNDER CASTER ARM PIVOT TUBE 1/2" 3/4" Height Spacer Spacer 1" 1-1/2" 2" 2-1/2" 3" 3-1/2" 4" 4-1/4" 4-1/2" 5" 5-1/2" * RD6000 and RD7200 only Figure 5. Height Adjustment with Caster Arm Spacers TRACTOR TOP LINK ADJUSTMENT When the cutting height is set, adjust tractor top link until mower top link attachment point A is aligned verti-... -

Page 13: Front Caster Wheel Interference Check

R - Right Offset RIGHT L - Left Offset OFFSET A - Mounting Holes B - Pivot Tube CD4990 Figure 8. Front Caster Arm Configuration for RD6000-2 & RD7200-2 Only FRONT CASTER WHEEL INTERFERENCE CHECK IMPORTANT ■ Do not operate tractor and mower until this interference check has been performed. - Page 14 If mower becomes plugged causing belt to slip for over two seconds follow these steps: 1. Maneuver equipment into a previously cut area and allow mower to clear accumulated material. 2. Continue running at least two minutes, allowing pulleys to cool. Stopping the mower in contact with a very hot pulley will bake and ruin belt.

- Page 15 OWNER PRE-OPERATION CHECK LIST (OWNER'S RESPONSIBILITY) ___ Review and follow all safety rules and safety decal instructions on pages 3 through 7. ___ Check that all safety decals are installed and in good condition. Replace if damaged. ___ Check that all shields and guards are properly installed and in good condition.

-

Page 16: Blocking Method

The information in this section is written for operators who possess basic mechanical skills. If you need help, your dealer has trained service technicians available. For your protection, read and follow the safety informa- tion in this manual. CAUTION Always wear relatively tight and belted clothing to avoid entanglement in moving parts. - Page 17 Use SAE 90W gear lube in the gearbox. Fill to plug on side of gearbox. Check gearbox daily for evidence of leakage at both seals and the gasket between the housing and cover. If leakage is noted, repair immediately. There may be a small amount of lube emitted from the vent plug;...

-

Page 18: Belt Replacement/Installation

BELT SERVICE Belt Replacement One of the major causes of belt failure is improper installation. Before installing a new belt, check the fol- lowing: 1. Check pulley shafts and bearings for wear. 2. Check pulley grooves for cleanliness. 3. Make sure spindles turn freely and without wobble. If grooves require cleaning, moisten a cloth with a non- flammable, non-toxic degreasing agent or commercial detergent and water. -

Page 19: Chain Shielding

Inspect machine and replace worn or damaged parts. ● Sand down scratches and the edges of areas of missing paint and coat with Woods spray paint of matching color (purchase from your Woods dealer). ● Replace any safety decals that are missing or not readable (supplied free by your Woods dealer). -

Page 20: Trouble Shooting

PROBLEM Grass cut higher in center of swath than at edge Grass cut lower in center of swath than at edge Streaking conditions in swath Material discharges from mower unevenly; bunches of material along swath 18 Owner Service TROUBLE SHOOTING MOWING CONDITIONS POSSIBLE CAUSE Height of mower higher at front... -

Page 21: Belt Conditions

PROBLEM Belt slippage Frayed edges on belt cover Belt rollover Damaged belt Belt breakage * Check belt for damage by laying it flat on the floor. A belt that does not lie flat (has humps or twists, indicating broken or stretched cords) must be replaced. MAN0180 (Rev. -

Page 22: Dealer Service

The information in this section is written for dealer ser- vice personnel. The repair described here requires special skills and tools. If your shop is not properly equipped or your mechanics are not properly trained in this type of repair, you may be time and money ahead to replace complete assemblies. - Page 23 1. 7/8 NF Jam nut 2. 1/4 NC x 1 HHCS 3. .929 x 1.66 Lock 4. 1/4 Lock washer 5. Bushing, H 1 6. Sheave, H 1 BK 19. 1/2 NF x 1-1/4 21.Grease fitting Figure 17. Sheave and Blade Assembly Spindle Disassembly 1.

-

Page 24: Seal Replacement

Refer to Figure 19. 12. Apply a thin coat of Permatex to shaft area where sleeve will seat. 13. Install sleeve on shaft and press sleeve and bearing into housing until all free play is removed and there is a very light drag on bearings (similar to adjusting front wheel bearings on an automobile). -

Page 25: Vertical Shaft Seal Replacement

1. Seal 2. Pipe or tube 3. Seal seat 4. Casting Pipe or tube must press at outer edge of seal Incorrect Installation CD1092 Figure 20. Seal Installation Vertical Shaft Seal Replacement 1. Disconnect and remove the driveline from the gearbox. - Page 26 Remove Gearbox from Mower Refer to Figure 22. 1. Disconnect and remove the rear driveline from the gearbox. 2. Remove vent plug and siphon gear lube from housing through this opening. 3. Remove gearbox stand (20) from mower deck by removing four flanged lock nuts (56).

- Page 27 1. Crown gear 2. Gearbox housing 3. Input shaft 4. Output shaft 5. Gear pinion 6. Bearing 7. Bearing 8. Protective flat washer 9. Cotter pin 10. Snap ring 11. Snap ring 12. Spacer 13. Shim kit 14. Castle nut 15.

- Page 28 Install Gearbox NOTE: Gearbox is heavy: do not attempt to move with- out mechanical assistance. 1. Set gearbox on gearbox stand and fasten with bolts and nuts. Torque bolts to 175 lbs-ft. 2. Attach drive sheave to output shaft. Secure using castle nut and hardware previously removed.

- Page 29 3. Clamp cup in vise as shown in Figure 28 and tap on yoke to completely remove cup from yoke. Repeat Step 2 and Step 3 for opposite cup. CD1387 Figure 28 4. Place universal cross in vise as shown in Figure 29 and tap on yoke to remove cup.

-

Page 30: Assembly

ASSEMBLY INSTRUCTIONS DEALER SET-UP INSTRUCTIONS Assembly of this mower is the responsibility of the Woods dealer. If should be delivered to the owner com- pletely assembled, lubricated, and adjusted for normal cutting conditions. Complete Dealer Check Lists on page 32 when you have completed the assembly. - Page 31 Install Rear Offset Links 1. Loosen nut (56) at rear frame lug and attach offset link (13) as shown in Figure 33. 2. Repeat for opposite side. 3. Do not tighten at this time. 13. Link, rear offset 56. Nut, flanged lock 1/2 NC Figure 33.

- Page 32 Install Driveline Shield (RD8400-2) The counter-cone drive shield is factory installed on models RD6000-2 and RD7200-2. On the RD8400-2 model, attach counter-cone shield (22) to gearbox (21) with cap screws (43) and flat washers (42). Orient chain attachment lug as shown. CD5064 A.

- Page 33 Install Quick Hitch Kit (Optional) NOTE: Figure 38 shows RM660, other models use the same assembly instructions. NOTE: This kit allows mower to fit only Cat. 1 standard ASAE quick hitch. 10 0 1/2" x 4-3/4" HHCS 1. Offset link, .38 x 2 x 25.88 (A-frame bars) 2.

-

Page 34: Dealer Check List

DEALER CHECK LISTS DEALER PRE-DELIVERY CHECK LIST (DEALER’S RESPONSIBILITY) Inspect the equipment thoroughly after assembly to ensure it is set up properly before delivering it to the customer. The following check lists are a reminder of points to inspect. Check off each item as it is found satisfactory or after proper adjustment is made. -

Page 35: Parts Lists

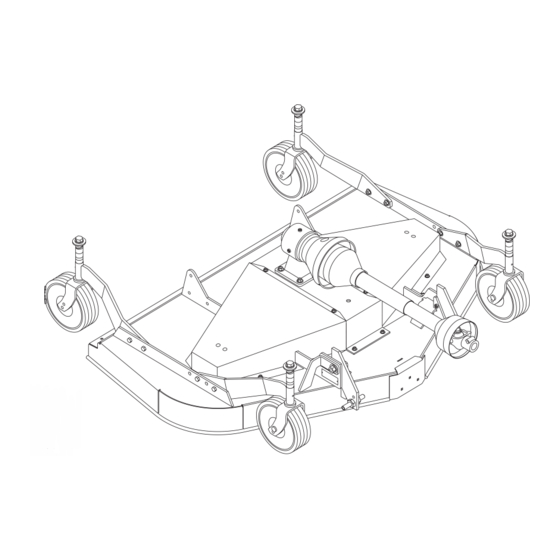

Rear Discharge Mowers: RD6000-2 RD7200-2 RD8400-2 MAIN FRAME ASSEMBLY ....... 34 - 35 GEARBOX ASSEMBLY . - Page 36 RD6000-2, RD7200-2 & RD8400-2 MAIN FRAME ASSEMBLY CD4986C REF PART DESCRIPTION – – – – Main Frame (not sold separately) 67407 Spring, Comp 1.40 x .19 x 2.1, 257 53562 Caster Arm Asy, Right RD6000-2 & RD7200-2 -or- 53563 Caster Arm Asy, Left -or- 52883 Caster Arm Asy RD8400-2 67318...

- Page 37 RD6000-2, RD7200-2 & RD8400-2 MAIN FRAME ASSEMBLY PART – – –– – CW Spindle Assembly (see page 38) 1001244 1 V-Belt W99 (used on RD6000-2 only) 18879 1 V-Belt W112 (used on RD7200-2 only) -or- 53418 1 V-Belt W157 (used on RD8400-2 only) 53567 1 Guide, Belt 8 GA Formed 64555...

- Page 38 RD6000-2, RD7200-2 & RD8400-2 GEARBOX ASSEMBLY REF PART DESCRIPTION 1002499 Gearbox Repair Assembly 57458 Gear Crown Z25 M5.3 Gearbox Housing 1005320 Shaft, Input 1-3/8 -6 1005321 Shaft, Output 1-1/4 57491 Pinion Gear Z13 M5.3 57476 Bearing 57462 Bearing 20888 Washer, Protective Flat Pin, Cotter B4 x 50 57466 Snap Ring...

- Page 39 RD6000-2, RD7200-2 & RD8400-2 DRIVESHAFT WALTERSCHEID (TWO-LOBE SHAFT) PART DESCRIPTION 40551 Complete Drive Shaft 40571 Yoke, 1-3/8-6 Spline Q U-Joint Repair Kit L14R 40775 Pin, Spring 10mm x 65mm 40572 Yoke, Inner Profile 40583 Drive Tube, Inner Profile 40584 Drive Tube, Outer Profile 40573 Yoke, Outer Profile 40776...

- Page 40 RD6000-2, RD7200-2 & RD8400-2 BLADE & SPINDLE ASSEMBLY PART DESCRIPTION 37009 Nut, Jam 7/8 NF 10378 Screw HHCS 1/4 NC x 1 GR5 52898 Washer, Lock .929 x 1.66 1985 Washer, Lock 1/4 34440 Bushing, H 1 Straight bore w/key 66694 Sheave, H 1 BK 4.17 PD (RD6000-2) -or-...

- Page 41 REAR CHAIN SHIELDING ASSEMBLY (OPTIONAL) PART 55348 Chain Shield Assembly (RD6000-2) 53566 Chain Shield Assembly (RD7200-2) 52856 Chain Shield Assembly (RD8400-2) 1007854 Pin, 40 to 42 Chains (for RD6000-2 only) -or- 1007856 Pin, 52 to 54 Chains (for RD7200-2 only) -or- 1007850 Pin, 31 to 33 Chains (for RD8400-2 only) 4763...

- Page 42 1/2 x 4-3/4 HHCS 40 Parts QUICK HITCH KIT (OPTIONAL) PART DESCRIPTION 1003692 Link, Offset .38 x 2.0 x 15 1005401 Chain 3/8 Proof Coil 38 Link 38214 Sleeve, .91 x 1.44 x 1.25 13563 Screw, HHCS 1/2 NC x 6 GR5 Washer, Flat 1/2 ZP 29368 Sleeve, .50 x .75 x 3.38...

-

Page 43: Bolt Torque Chart

Always tighten hardware to these values unless a different torque value or tightening procedure is listed for a specific application. Fasteners must always be replaced with the same grade as specified in the manual parts list. Always use the proper tool for tightening hardware: SAE for SAE hardware and Metric for metric hardware. Make sure fastener threads are clean and you start thread engagement properly. -

Page 44: Bolt Size Chart & Abbreviations

NOTE: Chart shows bolt thread sizes and corresponding head (wrench) sizes for standard SAE and metric bolts. SAE Bolt Thread Sizes 5/16 Metric Bolt Thread Sizes 10MM AG ...Agriculture ATF ... Automatic Transmission Fluid BSPP... British Standard Pipe Parallel BSPTM ... British Standard Pipe Tapered Male CV ... -

Page 45: Index 43

ASSEMBLY Dealer Set-Up Instructions 28 DEALER CHECK LISTS Delivery (Dealer’s Responsibility) 32 Pre-Delivery (Dealer’s Responsibility) 32 DEALER SERVICE Blade Spindle Assembly 21 Disassembly 21 Installation 22 Removal 20 Service 20 Blocking Method 20 Drive Sheave Installation 26 Gearbox Disassembly 24 Horizontal Shaft Seal Reoplacement 23 Installation 26 Reassembly 24... -

Page 46: Product Warranty

9180RD-2, 9204RD-2 Under no circumstances will this Warranty apply in the event that the product, in the good faith opinion of WOODS, has been subjected to improper operation, improper maintenance, misuse, or an accident. This Warranty does not apply in the event that the product has been materially modified or repaired by someone other than WOODS, a WOODS authorized dealer or distributor, and/or a WOODS authorized service center. - Page 47 WOODS’ obligation under this Warranty is limited to, at WOODS’ option, the repair or replacement, free of charge, of the product if WOODS, in its sole discretion, deems it to be defective or in noncompliance with this Warranty. The product must be returned to WOODS with proof of purchase within thirty (30) days after such defect or noncompliance is discovered or should have been discovered, routed through the dealer and distributor from whom the purchase was made, transportation charges prepaid.

- Page 48 © 2002 Woods Equipment Company. All rights reserved. WOODS, the Woods logo, and "Tested. Proven. Unbeatable." are trademarks of Woods Equipment Company. All other trademarks, trade names, or service marks not owned by Woods Equipment Company that appear in this manual are the property of their respective companies or mark holders.