Table of Contents

Advertisement

Quick Links

Operator: Save these instructions for future use!

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY BEFORE

INSTALLING OR OPERATING THIS CONTROL COULD CAUSE PERSONAL

INJURY AND/OR PROPERTY DAMAGE.

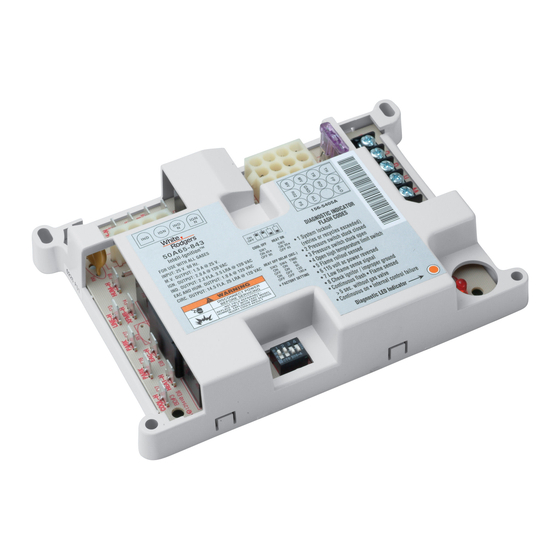

The 50A65-843 is an automatic gas interrupted ignition control that employs a

microprocessor to continually monitor, analyze, and control the proper opera-

tion of the gas burner, inducer, and fan.

Signals interpreted during continual surveillance of the thermostat and flame

sensing element initiate automatic ignition of the burner, sensing of the flame,

and system shut-off during normal operation.

These controls incorporate system fault analysis for quick gas flow shut-off,

coupled with automatic ignition retry upon sensing a fault correction.

Installation should be done by a qualified heating and air

conditioning contractor or licensed electrician.

If in doubt about whether your wiring is millivolt, line, or low

voltage, have it inspected by a qualified heating and air condi-

tioning contractor or licensed electrician.

Do not exceed the specification ratings.

All wiring must conform to local and national electrical codes and

ordinances.

This control is a precision instrument, and should be handled

carefully. Rough handling or distorting components could cause

the control to malfunction.

Following installation or replacement, follow manufacturer's

recommended installation/service instructions to ensure proper

operation.

CAUTION

Do not short out terminals on gas valve or primary

control. Short or incorrect wiring may damage the

thermostat.

CONTENTS

Description ........................................................ 1

Precautions ....................................................... 1

Specifications .................................................... 2

Installation ......................................................... 3

Operation .......................................................... 6

Mounting Hole Template .................................... 8

50A65-843

Universal Integrated Furnace Control

INSTALLATION INSTRUCTIONS

WARNING

Failure to comply with the following

warnings could result in personal injury

or property damage.

FIRE HAZARD

• Do not exceed the specified voltage.

• Protect the control from direct contact with water

(dripping, spraying, rain, etc.).

• If the control has been in direct contact with water,

replace the control.

• Label all wires before disconnection when servic-

ing controls. Wiring errors can cause improper

and dangerous operation.

• Route and secure wiring away from flame.

SHOCK HAZARD

• Disconnect electric power before servicing .

• Ensure proper earth grounding of appliance.

• Ensure proper connection of line neutral and line

hot wires.

EXPLOSION HAZARD

• Shut off main gas to appliance until installation is

complete.

DESCRIPTION

PRECAUTIONS

PART NO. 37-6270E

Replaces 37-6270D

0701

Advertisement

Table of Contents

Summary of Contents for White Rodgers UNIVERSAL INTEGRATED FURANCE CONTROL 50A65-843

-

Page 1: Table Of Contents

Operator: Save these instructions for future use! FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY BEFORE INSTALLING OR OPERATING THIS CONTROL COULD CAUSE PERSONAL INJURY AND/OR PROPERTY DAMAGE. The 50A65-843 is an automatic gas interrupted ignition control that employs a microprocessor to continually monitor, analyze, and control the proper opera- tion of the gas burner, inducer, and fan. -

Page 2: Specifications

SPECIFICATIONS ELECTRICAL RATINGS [@ 77°F (25°C)]: Input Voltage: 25 VAC 50/60 Hz Max. Input Current @ 25 VAC: 0.45 amp Relay Load Ratings: Valve Relay: 1.5 amp @ 25 VAC 50/60 Hz 0.6 pf Ignitor Relay: 2.0 amp @ 120 VAC 50/60 Hz (resistive) Flame Current Requirements: Minimum current to insure flame detection: 1 µa DC*... -

Page 3: Installation

WARNING FIRE HAZARD • Do not exceed the specified voltage. • Replace existing control with exact model and dash number. • Protect the control from direct contact with water (dripping, spraying, rain, etc.). • Label all wires before disconnection when servic- ing controls. -

Page 4: Typical System Wiring Diagram

(LINE) HUMIDIFIER ELECTRONIC AIR CLEANER FLAME SENSOR PROBE LEGEND Low Voltage (24 VAC) Line Voltage (120 VAC) N. C. = Normally closed switch N. O. = Normally open switch TYPICAL SYSTEM WIRING DIAGRAM 120 VAC 24 VAC CLASS II TRANSFORMER 24 VAC 50A65-843 COOL... -

Page 5: Typical System Wiring Table

TYPICAL SYSTEM WIRING TABLE 50A65 TERMINAL TERMINAL TYPE Terminal block with captive screws MV (2 terminals) 12-pin connector & harness (1 unused terminal) 4-pin connector IND N & harness IGN N COOL spade terminal HEAT spade terminal PARK (2 terminals) spade terminal LINE spade terminal... -

Page 6: Operation

OPERATION OPTION SWITCHES The option switches on the 50A65-843 control are used to determine the length of the cool delay-to-fan-off, heat delay-to- fan-on and heat delay-to-fan-off periods. The following table shows the time periods that will result from the various switch positions. - Page 7 SYSTEM LOCKOUT AND DIAGNOSTIC FEATURES SYSTEM LOCKOUT FEATURES When system lockout occurs, the gas valve is de-energized, the circulator blower is energized at heat speed, and, if flame is sensed, the inducer blower is energized. The diagnostic indica- tor light will flash or glow continuously to indicate system status. (System lockout will never override the precautionary fea- tures.) To reset the control after system lockout, do one of the...

-

Page 8: Mounting Hole Template

MOUNTING HOLE TEMPLATE MOUNTING HOLE TEMPLATE FOR MOUNTING HOLE LOCATIONS 4.172 ± .007 (2 plcs.) 6.402 ± .010 (2 plcs.) Refer to page 3 of the installation instructions for proper installation.