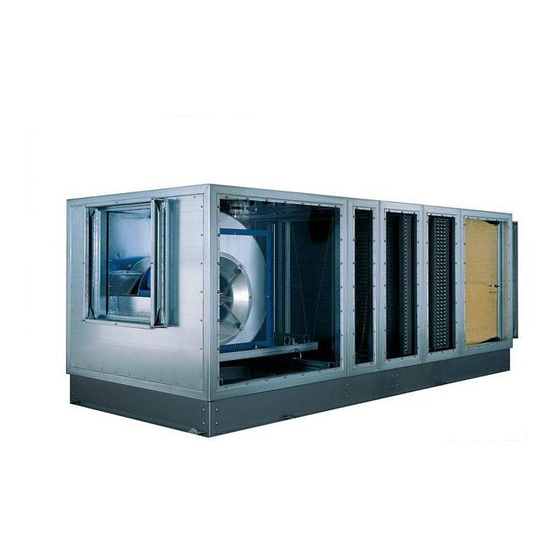

Summary of Contents for Wolf KG Gigant Series

- Page 1 Gigant Installation and maintenance instructions Air-conditioning units KG/KGW Gigant Wolf GmbH · 84048 Mainburg · Postfach 1380 · Telefon 08751/74-0 · Telefax 08751/741600 Art.-Nr. 30 40 549 10/00 TV...

-

Page 2: Table Of Contents

Contents Gigant Contents ..................Page Information signs / Safety information ..........3 Standards .................... 4 Delivery / Transportation ..............5 Installation information ..............6-12 Electrical connection ..............13-14 Commissioning of the unit ............15-17 Maintenance ................. 18-19 Maintenance / Frost protection ............19... -

Page 3: Information Signs / Safety Information

Information signs / Safety information Gigant General These installation and maintenance instructions apply exclusively to WOLF KG/KGW Gigant air-conditioning units. Before installation, commissioning or maintenance, these instructions must be studied by the personnel responsible for the respective operations. The specifications contained in these instructions must be complied with. -

Page 4: Standards

Standards Gigant Standards The following standards and regulations apply to the air-conditioning units of the KG/KGW Gigant series: - EC Directive 89/392/EEC incl. amendment 93/44/EEC (Ninth Regulation relating to the Safety of Equipment Act) - EC Directive 89/336/EEC incl. amendment 92/31/EEC (Electromagnetic Compatibility of Equipment Act) - EC Directive 73/23/EEC (Low-Voltage Directive) (First Regulation relating to the Safety of Equipment Act) - Page 5 In case of damage or suspected damage, this must be specified on the shipping note by the recipient and countersigned by the forwarder. The recipient must relay the respective details directly to WOLF. Units may only be transported in their fitting position.

- Page 6 The whole underside of the equipment frame must be in contact with the supporting surface; gaps underneath the frame are not permissible. WOLF base frames are supplied either pre-fitted to the unit or as separate modules (shipped in advance). Separately supplied base frames are supplied as individual sections and must be assembled, aligned and fixed to the installation surface on site, according to the instructions supplied with the base frame.

- Page 7 Installation information Gigant For units with washers, a base frame or foundation base must be used for KG and KGW units, as the washer protrudes from the bottom of the unit. The required height of the base frame depends on the type of washer and will be separately specified during the design of the housing.

-

Page 8: Installation Information

Installation information Gigant Unit connection The cubical unit sections are connected to one another with M8 screws. For this purpose, the cubes contain bore holes at respective locations. All small assembly parts and loosely supplied accessory are packed in a component fitted with an inspection door (preferably fan component). - Page 9 Installation information Gigant The joints between two unit cubes are covered, as far as possible, with a double frame capping section. In some instances, however, double frame capping sections cannot be used for design reasons. In these cases, single frame capping sections are used and the gap remaining on all sides, is covered with a plastic cover strip or a plastic sealing section.

- Page 10 Installation information Gigant Piggyback units For piggyback units, where the top and bottom units are supplied separately, the units must be secured to each other on site. The manufacturer makes provisions for the connections to be made with self- tapping screws. The required number of self-tapping screws are supplied with the air-conditioning unit.

- Page 11 Installation information Gigant The fan shaft must remain horizontal at all times. Fan section Caution Remove transportation fastening from fans seated on anti-vibration struts. Transportation fastening Remove transportation fastening. Canvas couplers When installing, it should be noted that the gap between the connecting flanges is permitted to be up to 100 mm, thus enabling full movement of the canvas couplers.

- Page 12 It is not permissible to join several drain sections onto a common drain trap. WOLF supplies the drain trap as an accessory. The required drain trap height must, in this case, be determined on site. If the drain trap is provided by the customer, the drain trap height must be determined according to the adjacent illustration.

- Page 13 Electrical connection Gigant Electrical connection The electrical connection may only be carried out by a qualified electrician in accordance with the valid regulations (VDE, EVU, etc.)! In case of switch-off or breakdown o the supply or exhaust fan, all control valves, the warm/cold water and the washer pump must be shut off automatically! Only use control valves which are closed, when contact is interrupted, and frost protection thermostats without reclosure preventing...

-

Page 14: Electrical Connection

Electrical connection Gigant Circuit for single speed Circuit for 3 speeds (2 separate windings - 1 of which being a Dahlander winding) Motors up to 2.2 kW are generally started directly on line, Design for fan drives 500/1000/1500 min or 8/6/4 poles; from 3 kW star delta starting is used. - Page 15 Commissioning of the unit Gigant Wait until the fan(s) has (have) stopped before opening the inspection doors. Check for correct installation of safety and control equipment. Fan section - The unit may only be started once the ductwork is connected and the inspection doors are closed.

- Page 16 Commissioning of the unit Gigant Before starting the unit, check pipework for possible leaks. Heater - Bleed heat exchanger and pipework. (Warm water/hot water/steam) - For steam registers, ensure that a condensate drainage is provided to avoid damage of the register by steam impact. - Switch on the heating water pump or open the water/steam valve only whilst the fan is running to avoid overheating due to insufficient heat dissipation.

-

Page 17: Commissioning Of The Unit

Commissioning of the unit Gigant Cooler Before filling the cooling circuit with refrigerant, take appropriate measures to (Direct evaporator) ensure that the pipework contains no residual moisture (i.e. by evacuating or flushing with dry nitrogen). Check evaporation temperature: the evaporation temperature may not fall below +2°C, as there is the danger that at evaporation temperatures of <... -

Page 18: Maintenance

Maintenance Gigant Before starting any maintenance work, the main switch of the system and the repair switch must be switched off and safeguarded against reactivation! The inspection doors may only be opened once the fan has stopped moving. Fan bearings requiring lubrication must be greased with saponified lithium- Fan section based grease every 2500 operating hours. -

Page 19: Maintenance/Frost Protection

Maintenance/frost protection Gigant Washer The washer and drop eliminator must be cleaned regularly. The cleaning frequency depends on the operation, air condition and water quality. For maintenance, the trough must be emptied and flushed with clear water or a pressure-jet cleaner. Caution Spray-clean pipes and nozzle connector only with reduced water pressure, as they may otherwise break! - Page 20 Structural measures for explosion protection in fans (explosion-proof devices) We hereby declare that the electrical equipment for Wolf airconditioning units type KG, KGW and KG/WO including the special control cabinets for said products and the control accessories: room thermostats, room-thermostat timers, remote-control units, actuating motors, valves, valve drives, channel...