Table of Contents

Advertisement

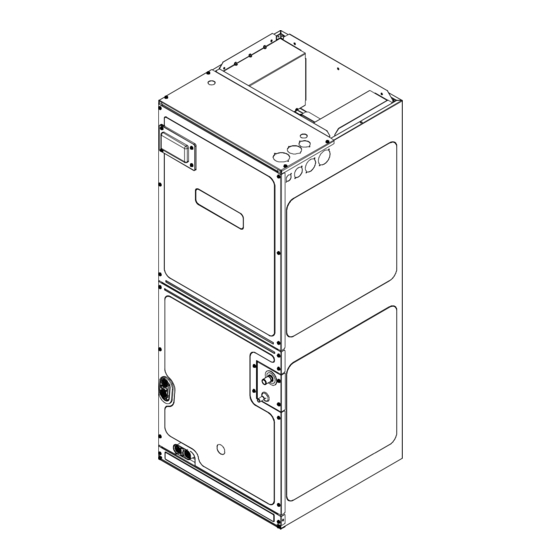

AVPEC

AIR HANDLERS

INSTALLATION & OPERATING INSTRUCTIONS

1 Important Safety Instructions --------------------------------------------------------- 2

2 Shipping Inspection ---------------------------------------------------------------------- 3

2.1 Parts ----------------------------------------------------------------------------------------- 3

2.2 Handling ------------------------------------------------------------------------------------ 3

3 Codes & Regulations -------------------------------------------------------------------- 3

4 Replacement Parts ----------------------------------------------------------------------- 3

5

Pre-Installation Considerations ------------------------------------------------------ 3

5.1 Preparation --------------------------------------------------------------------------------- 3

5.2 System Matches --------------------------------------------------------------------------- 3

5.3 Interconnecting Tubing ------------------------------------------------------------------ 3

5.4 Clearances ---------------------------------------------------------------------------------- 3

5.5 Horizontal Applications ------------------------------------------------------------------ 4

6

Installation Location -------------------------------------------------------------------- 4

6.1 Upflow Installation ----------------------------------------------------------------------- 4

6.2 Horizontal Left Installation ------------------------------------------------------------- 4

6.3 Downflow/Horizontal Right Installation --------------------------------------------- 4

7 Refrigerant Lines -------------------------------------------------------------------------- 7

7.1 Tubing Size ---------------------------------------------------------------------------------- 7

7.2 Tubing Preparation ----------------------------------------------------------------------- 7

7.3 Tubing Connections ----------------------------------------------------------------------- 7

8 Condensate Drain Lines ----------------------------------------------------------------- 8

9 Ductwork ----------------------------------------------------------------------------------- 9

9.1 Return Ductwork -------------------------------------------------------------------------- 9

10 Return Air Filters ------------------------------------------------------------------------ 9

11 Electric Heat ------------------------------------------------------------------------------ 9

12 Electrical and Control Wiring -------------------------------------------------------- 11

12.1 Building Electrical Service Inspection ----------------------------------------------- 11

12.2 Wire Sizing ------------------------------------------------------------------------------- 11

12.3 Maximum Overcurrent Protection (MOP) ----------------------------------------- 11

12.4 Electrical Connections - Supply Voltage ------------------------------------------- 12

12.4.1 Air Handler Only (Non-Heat Kit Models) ---------------------------------------- 12

12.4.2 Air Handler - Non-Circuit Breaker Heat Kits ------------------------------------ 12

12.4.3 Air Handler With Circuit Breaker Heat Kit -------------------------------------- 12

13 Achieving 1.4% & 2% Low Leakage Rate ------------------------------------------ 12

14 Miscellaneous Start-Up Checklist -------------------------------------------------- 12

14.1 Auxiliary Alarm Switch ----------------------------------------------------------------- 14

14.2 Circulator Blower ------------------------------------------------------------------------ 14

14.3 AVPEC Motor Orientation ------------------------------------------------------------- 14

14.4 Accessory Contacts ---------------------------------------------------------------------- 14

15 Troubleshooting -------------------------------------------------------------------------- 15

15.1 Electrostatic Discharge (ESD) Precautions ---------------------------------------- 15

15.2 Diagnostic Chart ------------------------------------------------------------------------ 15

15.3 Fault Recall ------------------------------------------------------------------------------- 16

15.4 Dehumidification ------------------------------------------------------------------------ 16

16 ComfortNet™ System -------------------------------------------------------------------- 17

16.1 Overview ---------------------------------------------------------------------------------- 17

16.2 Airflow Consideration ------------------------------------------------------------------ 17

16.3 CTK04 Thermostat Wiring ------------------------------------------------------------- 19

16.3.1 Two-Wire Outdoor and Four-Wire Indoor Wiring. ---------------------------- 19

16.4 ComfortNet™ System Advanced Features ---------------------------------------- 19

16.5 Network Troubleshooting ------------------------------------------------------------- 19

16.6 System Troubleshooting --------------------------------------------------------------- 20

17 Directions to ComfortNet System Advanced Feature Menus ----------------- 20

17.2 Diagnostics ------------------------------------------------------------------------------- 20

17.3 Identification ---------------------------------------------------------------------------- 20

17.4 Set-Up -------------------------------------------------------------------------------------- 20

17.5 Status -------------------------------------------------------------------------------------- 21

Troubleshooting ------------------------------------------------------------------------------- 23

setting the mode display -------------------------------------------------------------------- 24

Diagnostic Codes ------------------------------------------------------------------------------ 25

SETTING THE MODE DISPLAY -------------------------------------------------------------- 27

is a registered trademark of Maytag Corporation or its related companies and is used under license. All rights reserved.

®

© 2016-2018 Goodman Manufacturing Company, L.P.

5151 San Felipe, Suite 500, Houston, TX 77056

www.goodmanmfg.com - or - www.amana-hac.com

P/N: IOA-4018D Date: December 2018

O

NLY PERSONNEL THAT HAVE BEEN TRAINED TO INSTALL

(

, "

")

REPAIR

HEREINAFTER

SERVICE

. T

SHOULD SERVICE THE EQUIPMENT

FOR ANY INJURY OR PROPERTY DAMAGE ARISING FROM IMPROPER SERVICE OR

. I

SERVICE PROCEDURES

F YOU SERVICE THIS UNIT

FOR ANY INJURY OR PROPERTY DAMAGE WHICH MAY RESULT

JURISDICTIONS THAT REQUIRE ONE OR MORE LICENSES TO SERVICE THE EQUIPMENT

,

SPECIFIED IN THIS MANUAL

ONLY LICENSED PERSONNEL SHOULD SERVICE THE

. I

EQUIPMENT

MPROPER INSTALLATION

THE EQUIPMENT SPECIFIED IN THIS MANUAL

SERVICE OR REPAIR THE EQUIPMENT SPECIFIED IN THIS MANUAL WITHOUT PROPER

TRAINING MAY RESULT IN PRODUCT DAMAGE

.

INJURY OR DEATH

ATTENTION

INSTALLING PERSONNEL:

Prior to installation, thoroughly familiar-

ize yourself with this Installation Manual.

Observe all safety warnings. During instal-

lation or repair, caution is to be observed.

It is your responsibility to install the prod-

uct safely and to educate the customer

on its safe use.

,

,

ADJUST

SERVICE OR

THE EQUIPMENT SPECIFIED IN THIS MANUAL

HE MANUFACTURER WILL NOT BE RESPONSIBLE

,

YOU ASSUME RESPONSIBILITY

. I

N ADDITION

,

,

ADJUSTMENT

SERVICING OR REPAIR OF

,

OR ATTEMPTING TO INSTALL

,

,

PROPERTY DAMAGE

PERSONAL

,

IN

,

,

ADJUST

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Amana AVPEC Series

-

Page 1: Table Of Contents

AVPEC © 2016-2018 Goodman Manufacturing Company, L.P. 5151 San Felipe, Suite 500, Houston, TX 77056 AIR HANDLERS www.goodmanmfg.com - or - www.amana-hac.com INSTALLATION & OPERATING INSTRUCTIONS P/N: IOA-4018D Date: December 2018 1 Important Safety Instructions --------------------------------------------------------- 2 2 Shipping Inspection ---------------------------------------------------------------------- 3 2.1 Parts ----------------------------------------------------------------------------------------- 3... -

Page 2: Important Safety Instructions

1 IMPORTANT SAFETY INSTRUCTIONS CAUTION The following symbols and labels are used throughout this manual to indicate immediate or potential safety hazards. It is the owner’s When installing or servicing this equipment, safety clothing, including hand and eye protection, is strongly recommended. If installing in an and installer’s responsibility to read and comply with all safety area that has special safety requirements (hard hats, etc.), observe information and instructions accompanying these symbols. -

Page 3: Shipping Inspection

2 SHIPPING INSPECTION PRE-INSTALLATION CONSIDERATIONS Always transport the unit upright; laying the unit on its side or 5.1 Preparation top during transit may cause equipment damage. The installer Keep this document with the unit. Carefully read all instruc- should inspect the product upon receipt for shipping damage tions for the installation prior to installing product. -

Page 4: Horizontal Applications

5.5 Horizontal Applications Extension Horizontal Drip Shield If installed above a finished living space a secondary drain pan, as required by many building codes, must be installed under Drip Shield Bracket the entire unit and its condensate drain line must be routed to a location such that the user will see the condensate dis- charge. - Page 5 WIRE TIE LOCATION TO BE REMOVED Figure 2-1 Screw mount Screw wire tie (Side view) (Front view) Detail D Screw mount wire tie Sensor wires (15 mm ) Screw Screw mount 1.57 wire tie (40 mm ) Wire tie Center Insulation *Do not get the Support...

- Page 6 HORIZONTAL LEFT Figure 5 HORIZONTAL RIGHT Figure 6 UPFLOW DOWNFLOW Figure 3 Figure 4 Upper Tie Plate Control Deck Blower Access Panel Coil Tubing Access Downflow Panel Bracket Panel Center Support Filter Bracket Filter Access Knockout Panel INTERNAL PART TERMINOLOGY EXTERNAL PART TERMINOLOGY Figure 7 Figure 8...

-

Page 7: Refrigerant Lines

6. Reconnect the sensor wires and replace the insulation se- curing it with wire ties on both sides as shown in Figure 2-2. Then, secure the wire harness to the corner post using the Coil slideson screw mount wire ties provided. the downflow bracket 7. -

Page 8: Condensate Drain Lines

6. Insert suction line set into suction tube expansion and slide insulation and grommet about 18" away from braze joint. 7. Braze joints. Quench all brazed joints with water or a wet rag upon completion of brazing. 8. Replace access panels, suction line grommet, insulation and all screws. -

Page 9: Ductwork

9 DUCTWORK CAUTION If secondary drain is not installed, the secondary access must be plugged. Drain Connection This air handler is designed for a complete supply and return ductwork system. To ensure correct system performance, the ductwork is to be sized to accommodate 350-450 CFM per ton of cooling with the static Air Handler 2"... - Page 10 The heating mode temperature rise is dependent upon the system HEAT KIT NOMINAL Kw airflow, the supply voltage, and the heat kit size (kW) selected. 15 19/20 25 Use data provided in Tables 3,4 and 5 to determine the tempera- ture rise (°F).

-

Page 11: Electrical And Control Wiring

ELECTION Nominal Minimum Maximum For heat kit selection, see the Specification Sheet for each Input Voltage Voltage specific Air Handler. 208-240 ELECTRICAL VOLTAGE 12 ELECTRICAL AND CONTROL WIRING Table 7 IMPORTANT: All routing of electrical wiring must be made through provided electrical knockouts. -

Page 12: Electrical Connections - Supply Voltage

12.4 Electrical Connections – Supply Voltage Top of Cabinet IMPORTANT NOTE: USE COPPER CONDUCTORS ONLY. Knockouts are provided on the air handler top panel and sides of the cabinet to allow for the entry of the supply volt- age conductors, as shown in Figure 13. If the knockouts on the cabinet sides are used for electrical conduit, an adapter Side of ring must be used in order to meet UL1995 safety require-... -

Page 13: Auxiliary Alarm Switch

A UXA LA R M ACC-OUT (Accessory) ACC-IN (Accessory) RX LED X13A FUSE X12A CPU LED STATUS LED Micro Processor 7seg SEG2 7seg SEG1 X15A PR ESS URESE NSOR THER MIST OR COIL INDOORUNIT PCB COMMUNICATING BOARD Figure 14 14.1 Auxiliary Alarm Switch The control is equipped with two Auxiliary Alarm terminals, labeled TB4 and TB5 which are typically utilized in series with a condensate switch but could also be used with compatible... -

Page 14: Circulator Blower

14.2 Circulator Blower This air handler is equipped with a variable speed circulator blower. This blower provides several automatically-adjusted blower speeds. The Specification Sheet applicable to your model provides an airflow table, showing the relationship be- tween airflow (CFM) and external static pressure (E.S.P.). For MODEL DIP Switch Setting heater kit installation, it is important to set the capacity of... -

Page 15: Troubleshooting

IND: Humidifier will cycle with any active call for humidification from the thermostat (independent of a heat call). The relay will remain open during cooling operation. This mode also allows the user to select one of 4 fan speeds (25, 50, 75, and 100%). The fan speed will be used when the system is in an idol state and a call for humidification is made by Peripheral devices to be... -

Page 16: Fault Recall

8. From the Dehumidification Menu select A/C with Low Speed Each time FAULT RECALL button is pressed after that Fan and click the green Done button. segment display outputs next occurred fault. 9. Additional Dehumidification operational options can be se- 4. -

Page 17: Comfortnet™ System

16 COMFORTNET™ SYSTEM 16.2 Airflow Consideration Airflow demands are managed differently in a fully commu- 16.1 Overview nicating system than in a non-communicating wired system. The ComfortNet system is a system that includes a ComfortNet The system operating mode (as determined by the thermo- compatible air handler and air conditioner or heat pump with stat) determines which unit calculates the system airflow de- a CTK04 thermostat. - Page 18 Indication Possible Causes Corrective Action(s) Notes & Cautions Status None None None None Depres s once qui ckl y for Communi ca ti ons Communi ca ti ons Depres s Lea rn Button ...

-

Page 19: Ctk04 Thermostat Wiring

16.3 CTKO4 Thermostat Wiring System Airflow Demand System NOTE: Refer to section Electrical Connections for 208/230 Operating Mode Source volt line connections to the air handler. Cooling Air Conditioner Air Conditioner NOTE: Use thermostat model that is later than CTK04AB. Heating Air Handler + Air Handler... -

Page 20: System Troubleshooting

16.6 System Troubleshooting NOTE: Refer to the instructions accompanying the ComfortNet compatible outdoor AC/HP unit for unit specific troubleshooting information. Refer to the Troubleshooting Chart at the end of this manual for a listing of possible air handler error codes, possible causes and corrective actions. 17 DIRECTIONS TO COMFORTNET SYSTEM ADVANCED FEATURE MENUS DIAGNOSTICS... -

Page 21: Set-Up

17.4 Set-Up SET-UP Submenu Item User Modifiable Options Comments Choose the operation mode of Humidifier OFF*, ON, IND (This selection is only displayed if HUM is selected in ACC) Choose the indoor fan speed at the time of humidification HUM FAN SPD (%) 25%, 50%*, 75% , 100% (This selection is only displayed if IND is selected in HUM and HUM is selected in ACC) - Page 22 TROUBLESHOOTING...

-

Page 23: Troubleshooting

TROUBLESHOOTING... -

Page 24: Setting The Mode Display

DIAGNOSTIC CODES 7 SEGMENT LED DESCRIPTION OF CONDITION ERROR MESSAGE DISPLAY Normal Operation NO HTR KIT INSTALLED - SYSTEM CALLING FOR AUXILIARY HEAT (Minor Error Code) (No Display) HEATER KIT DIP SWITCHES NOT SET PROPERLY Check Heater Kit Dip Switches FUSE OPEN BLOWN FUSE AUXILIARY SWITCH OPEN... - Page 25 SETTING THE MODE DISPLAY MODE DISPLAY INTRODUCTION A 2-digit display is provided on the printed circuit board (PCB) as a backup tool to the thermostat for accessing error codes and erasing error code history of the indoor unit. Follow the information provided in this section to learn how to use the mode display DISPLAY The display consists of 2 digits.

-

Page 26: Diagnostic Codes

SETTING THE MODE DISPLAY <SCREEN ZERO> First Error Code Idle Release Fault Recall in less than 2 sec mins. Press Fault Recall for Error Code Second Error Code Hold Fault Recall for more than 2 sec Solid Display Press Fault Recall for Error Code Release Fault Last Error Code... - Page 27 WIRING DIAGRAM NOTE: THESE INSTRUCTIONS ARE SPECIFICALLY FOR AVPEC MODELS. DO NOT ATTEMPT TO APPLY THESE DIAGRAMS FOR ANY HIGH VOLTAGE! DISCONNECT ALL POWER BEFORE SERVICING. MULTIPLE POWER SOURCES MAY BE OTHER MODELS. PRESENT. FAILURE TO DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

- Page 28 AIR HANDLER HOMEOWNER’S ROUTINE MAINTENANCE BEFORE YOU CALL YOUR SERVICER RECOMMENDATIONS We strongly recommend a bi-annual maintenance checkup be performed before the heating and cooling seansons begin by a qualified servicer. REPLACE OR CLEAN FILTER IMPORTANT NOTE: Never operate unit without a filter installed as dust and lint will build up on internal parts resulting in loss of efficiency, equipment damage and possible fire.

- Page 29 THIS PAGE WAS LEFT BLANK INTENTIONALLY...

- Page 30 THIS PAGE WAS LEFT BLANK INTENTIONALLY...

- Page 31 THIS PAGE WAS LEFT BLANK INTENTIONALLY...

- Page 32 We are very interested in all product comments. Please fill out the feedback form on one of the following links: Goodman® Brand Products: (http://www.goodmanmfg.com/about/contact-us). Amana® Brand Products: (http://www.amana-hac.com/about-us/contact-us). You can also scan the QR code on the right for the product brand AMANA® BRAND GOODMAN®...