Siemens SINAMICS G120 Hardware Installation Manual

Hide thumbs

Also See for SINAMICS G120:

- List manual (1256 pages) ,

- Manual (732 pages) ,

- Operating instructions manual (550 pages)

Summary of Contents for Siemens SINAMICS G120

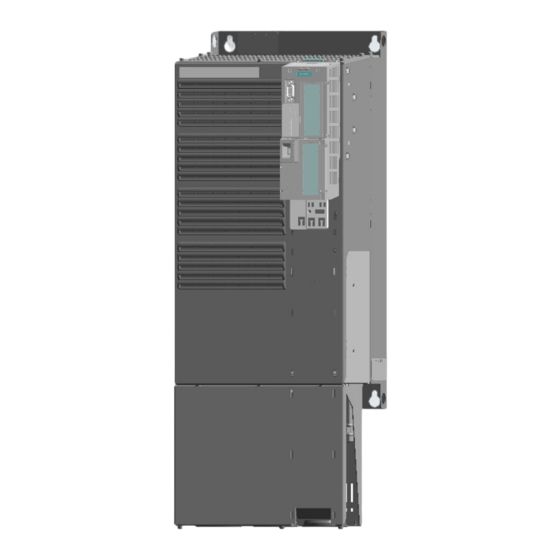

- Page 1 SINAMICS SINAMICS G120 inverters PM230 Power Modules, IP20 / push-through technology (PT) Hardware Installation Manual Edition 08/2016...

- Page 3 Changes in this manual Fundamental safety instructions Introduction SINAMICS Installing/mounting SINAMICS G120P Power Module PM230, IP20 / Push- Connecting through technology (PT) Service and maintenance Hardware Installation Manual Technical specifications Spare parts and accessories Appendix Edition 08/2016 08/2016 A5E34331322B AB...

-

Page 4: Edition

Note the following: WARNING Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems. -

Page 5: Table Of Contents

Table of contents Changes in this manual ..........................7 Fundamental safety instructions........................9 General safety instructions.......................9 Safety instructions for electromagnetic fields (EMF)..............13 Handling electrostatic sensitive devices (ESD)..............14 Industrial security........................15 Residual risks of power drive systems...................16 Introduction..............................17 Component specification according to UL................19 Permissible motors.........................20 Installing/mounting............................21 Installation conditions......................21 EMC-compliant installation of a plant or machine..............23... - Page 6 Table of contents Replacing the cooling fan.......................53 Technical specifications..........................57 Overload capability of the inverter..................58 Cable cross-sections and tightening torques.................60 Electromagnetic compatibility - overview ................61 Ambient conditions.........................62 General technical data......................63 Detailed technical data......................64 Restrictions for special ambient conditions................69 7.7.1 Current reduction depending on pulse frequency..............70 Electromagnetic compatibility of variable-speed drives............71 7.8.1 Inverter applications.......................72...

-

Page 7: Changes In This Manual

Changes in this manual Changes with respect to the manual, Edition 06/2014 The new PM230 FSA, FSB and FSC Power Modules support STO. How can you identify a Power Module of the new series? From the article number. The devices belonging to the new series have a "G" instead of an "L"... - Page 8 Changes in this manual Power Module PM230, IP20 / Push-through technology (PT) Hardware Installation Manual, 08/2016, A5E34331322B AB...

-

Page 9: Fundamental Safety Instructions

Fundamental safety instructions General safety instructions DANGER Danger to life due to live parts and other energy sources Death or serious injury can result when live parts are touched. ● Only work on electrical devices when you are qualified for this job. ●... - Page 10 Fundamental safety instructions 2.1 General safety instructions WARNING Danger to life when live parts are touched on damaged devices Improper handling of devices can cause damage. For damaged devices, hazardous voltages can be present at the enclosure or at exposed components;...

- Page 11 Fundamental safety instructions 2.1 General safety instructions WARNING Danger to life due to fire spreading if housing is inadequate Fire and smoke development can cause severe personal injury or material damage. ● Install devices without a protective housing in a metal control cabinet (or protect the device by another equivalent measure) in such a way that contact with fire is prevented.

- Page 12 Fundamental safety instructions 2.1 General safety instructions WARNING Danger of an accident occurring due to missing or illegible warning labels Missing or illegible warning labels can result in accidents involving death or serious injury. ● Check that the warning labels are complete based on the documentation. ●...

-

Page 13: Safety Instructions For Electromagnetic Fields (Emf)

Fundamental safety instructions 2.2 Safety instructions for electromagnetic fields (EMF) Safety instructions for electromagnetic fields (EMF) WARNING Danger to life from electromagnetic fields Electromagnetic fields (EMF) are generated by the operation of electrical power equipment such as transformers, converters or motors. People with pacemakers or implants are at a special risk in the immediate vicinity of these devices/systems. -

Page 14: Handling Electrostatic Sensitive Devices (Esd)

Fundamental safety instructions 2.3 Handling electrostatic sensitive devices (ESD) Handling electrostatic sensitive devices (ESD) Electrostatic sensitive devices (ESD) are individual components, integrated circuits, modules or devices that may be damaged by either electric fields or electrostatic discharge. NOTICE Damage through electric fields or electrostatic discharge Electric fields or electrostatic discharge can cause malfunctions through damaged individual components, integrated circuits, modules or devices. -

Page 15: Industrial Security

Siemens recommends strongly that you regularly check for product updates. For the secure operation of Siemens products and solutions, it is necessary to take suitable preventive action (e.g. cell protection concept) and integrate each component into a holistic, state-of-the-art industrial security concept. -

Page 16: Residual Risks Of Power Drive Systems

Fundamental safety instructions 2.5 Residual risks of power drive systems Residual risks of power drive systems When assessing the machine- or system-related risk in accordance with the respective local regulations (e.g., EC Machinery Directive), the machine manufacturer or system installer must take into account the following residual risks emanating from the control and drive components of a drive system: 1. -

Page 17: Introduction

Introduction Overview The Power Modules belong to the modular family of SINAMICS G120 inverters. A modular inverter comprises Control Unit and Power Module. PM230 Power Modules have been specifically designed for pump and fan drives in industrial HVAC applications for a line voltage range from 3 AC 380 V … 480 V. The Power Modules are available as built-in devices or in push-through technology. - Page 18 Introduction STO with PM230 and CU240 The PM230 FSA … FSC Power Modules have been technically revised. Together with CU240 Control Units from software version V4.7 SP3, they support the STO safety function. You can identify the new series of Power Modules as a result of the article number. The article numbers of the new Power Modules have a "G"...

-

Page 19: Component Specification According To Ul

You can find proof of the certification on the Internet UL certificates (http://www.ul.com) under "Tools / Online Certifications Directory" by entering the file number or the "Name". The UL file number for the Power Modules of the SINAMICS G120 product family is: ● E121068 for FSA, FSB and FSC The UL file number for the Power Modules of the SINAMICS G120 product family is: ●... -

Page 20: Permissible Motors

Introduction 3.2 Permissible motors Permissible motors Note Motors for inverter operation Only use motors that are suitable for operation with inverters with a DC link. Permissible motors For the Power Modules, induction motors are permissible in the range from 25 % … 150 % of the inverter power without any restrictions. -

Page 21: Installing/Mounting

Installing/mounting Installation conditions General installation conditions When installing the Power Modules, carefully observe the following sections in Chapter Technical specifications (Page 57) in order to guarantee reliable, continuous and disturbance-free operation. ● Cable cross-sections and tightening torques ● Electromagnetic compatibility ●... - Page 22 Installing/mounting 4.1 Installation conditions Frame sizes FSD … FSF ● Rated voltage 277 V (phase with respect to ground), 480 V (phase to phase) ● Suitable for overvoltage category III ● Terminal voltage VPR = 4000 V, Power Module PM230, IP20 / Push-through technology (PT) Hardware Installation Manual, 08/2016, A5E34331322B AB...

-

Page 23: Emc-Compliant Installation Of A Plant Or Machine

Installing/mounting 4.2 EMC-compliant installation of a plant or machine EMC-compliant installation of a plant or machine The inverter is designed for operation in industrial environments where strong electromagnetic fields are to be expected. Reliable and disturbance-free operation is only guaranteed for EMC-compliant installation. To achieve this, subdivide the control cabinet and the machine or system into EMC zones: EMC zones Figure 4-1... -

Page 24: Control Cabinet

Installing/mounting 4.2 EMC-compliant installation of a plant or machine 4.2.1 Control cabinet ● Assign the various devices to zones in the control cabinet. ● Electromagnetically uncouple the zones from each other by means of one of the following actions: – Side clearance ≥ 25 cm –... -

Page 25: Cables

Grounding and high-frequency equipotential bonding measures in the control cabinet and in the plant/system Further information Additional information about EMC-compliant installation is available in the Internet: EMC installation guideline (http://support.automation.siemens.com/WW/view/en/60612658) 4.2.2 Cables Cables with a high level of interference and cables with a low level of interference are connected to the inverter: ●... - Page 26 Installing/mounting 4.2 EMC-compliant installation of a plant or machine Cable routing inside the cabinet ● Route the power cables with a high level of interference so that there is a minimum clearance of 25 cm to cables with a low level of interference. If the minimum clearance of 25 cm is not possible, insert separating metal sheets between the cables with a high level of interference and cables with a low level of interference.

- Page 27 Installing/mounting 4.2 EMC-compliant installation of a plant or machine Routing cables outside the control cabinet ● Maintain a minimum clearance of 25 cm between cables with a high level of interference and cables with a low level of interference. ● Using shielded cables for the following connections: –...

-

Page 28: Electromechanical Components

Installing/mounting 4.2 EMC-compliant installation of a plant or machine 4.2.3 Electromechanical components Radio interference suppression ● Connect interference suppression elements to the following components: – Coils of contactors – Relays – Solenoid valves – Motor holding brakes ● Connect the interference suppression element directly at the coil. ●... -

Page 29: Power Losses And Air Cooling Requirements

Installing/mounting 4.3 Power losses and air cooling requirements Power losses and air cooling requirements Cooling requirements To protect the components from overheating, the control cabinet requires a cooling air flow, which depends on the power loss of the individual components. Formula for calculating the cooling airflow: airflow [l/s] = power loss [W] * 0.86 / ΔT [K] ●... - Page 30 Installing/mounting 4.3 Power losses and air cooling requirements The following losses occur in the cabinet when the device is operated with its rated data: ● FSA: 0.02 kW ● FSB: 0.045 kW ● FSC: 0.075 kW Power Module PM230, IP20 / Push-through technology (PT) Hardware Installation Manual, 08/2016, A5E34331322B AB...

-

Page 31: Mounting The Power Modules

Installing/mounting 4.4 Mounting the Power Modules Mounting the Power Modules Protection against the spread of fire The device may be operated only in closed housings or in control cabinets with protective covers that are closed, and when all of the protective devices are used. The installation of the device in a metal control cabinet or the protection with another equivalent measure must prevent the spread of fire and emissions outside the control cabinet. -

Page 32: Dimension Drawings And Drilling Dimensions For Ip20 Power Modules

Installing/mounting 4.4 Mounting the Power Modules If you do not use the optional mounting frames, then you must ensure that the required degree of protection is complied with using other appropriate measures. Mounting instructions are provided in the following section: Mounting frames for Power Module with push-through technology (Page 79) 4.4.1 Dimension drawings and drilling dimensions for IP20 Power Modules... - Page 33 Installing/mounting 4.4 Mounting the Power Modules Table 4-2 Depth with Control Unit and operator panel Depth (mm) with ... CU230P-2 CU240B/E-2 CU250S-2 … Control Unit: + 59 + 41 + 62 ... Control Unit and blanking cover / BOP-2: + 70 + 52 + 73 ...

- Page 34 Installing/mounting 4.4 Mounting the Power Modules Table 4-3 Drilling dimensions, cooling air clearances [mm] and fixing [Nm] Frame size Drilling dimensions Cooling air clearances Mounting Bottom Front Screws/torque 62.3 2 x M4 / 2.5 4 x M4 / 2.5 4 x M5 / 3.0 FSD without filter 4 x M6 / 6.0 FSD with filter...

-

Page 35: Dimension Drawings And Drilling Dimensions For Pt Power Modules

Installing/mounting 4.4 Mounting the Power Modules 4.4.2 Dimension drawings and drilling dimensions for PT Power Modules Table 4-4 Mounting dimensions without Control Unit (CU) [mm] Frame Width Height Depth size without shield plate with shield plate T1 +T2 Panel thickness of the control cabinet ≤ 3.5 mm The following dimension drawings and drilling patterns are not to scale. -

Page 36: Mounting The Shield Plate

Installing/mounting 4.4 Mounting the Power Modules Table 4-6 Drilling dimensions, cooling air clearances [mm] and fixing [Nm] Frame Section of the control cabinet Cooling air clearances Fixing size Bottom Front Screws/torque 8 x M5 / 3.5 34.5 8 x M5 / 3.5 30.5 10 x M5 / 3.5 You can mount the Power Modules without any lateral cooling air clearance. -

Page 37: Supplementary Components

Installing/mounting 4.5 Supplementary components Supplementary components Depending on the particular application, additional components may be required for your system. Information about additional components is provided in the following Sections: Connection overview (Page 46) Optional accessories (Page 79). Power Module PM230, IP20 / Push-through technology (PT) Hardware Installation Manual, 08/2016, A5E34331322B AB... - Page 38 Installing/mounting 4.5 Supplementary components Power Module PM230, IP20 / Push-through technology (PT) Hardware Installation Manual, 08/2016, A5E34331322B AB...

-

Page 39: Connecting

To protect against indirectly touching part of the motor circuit of an inverter and to automatically shut down in the case of a fault according to DIN EN 60364-4-41 (VDE 0100-410). (http:// support.automation.siemens.com/WW/view/en/103474630) WARNING Danger to life due to fire or electric shock when using unsuitable residual current protection devices The inverter can cause a current to flow in the protective conductor. - Page 40 Connecting CAUTION Risk of injury due to hot surfaces During operation and for a short time after the inverter shuts down, the surface of the device can reach a high temperature. ● During this time, avoid any direct contact with the surface of the inverter. Protection and monitoring equipment To provide protection against short-circuit, use the overcurrent devices listed in Technical data (fuses, circuit breakers etc.).

-

Page 41: Permissible Line Supplies

Connecting 5.1 Permissible line supplies Permissible line supplies Note Restrictions for installation altitudes above 2000 m Above an installation altitude of 2000 m, the permissible line supplies are restricted. Restrictions for special ambient conditions (Page 69) Note Line requirement The machine manufacturer must ensure that in operation the voltage drop between the transformer input terminals and the inverter when operated with its rated values is less than The inverter is designed for the following power distribution systems according to IEC 60364-1 (2005). -

Page 42: Tt Line System

Connecting 5.1 Permissible line supplies 5.1.2 TT line system In a TT line system, the transformer grounding and the installation grounding are independ‐ ent of one another. There are TT line supplies where the neutral conductor N is either transferred – or not. Inverter operated on a TT line system ●... -

Page 43: It System

Connecting 5.1 Permissible line supplies 5.1.3 IT system In an IT line system, all of the conductors are insulated with respect to the PE protective conductor – or connected to the PE protective conductor through an impedance. There are IT systems with and without transfer of the neutral conductor N. -

Page 44: Protective Conductor

Connecting 5.1 Permissible line supplies 5.1.4 Protective conductor WARNING Danger to life caused by high leakage currents for an interrupted protective conductor The drive components conduct a high leakage current via the protective conductor. Touching conductive parts when the protective conductor is interrupted can result in death or serious injury. - Page 45 Connecting 5.1 Permissible line supplies ① Additional requirements placed on the protective conductor ● For permanent connection, the protective conductor must fulfill at least one of the following conditions: – The protective conductor is routed so that it is protected against damage along its complete length.

-

Page 46: Connecting The Line And Motor Cable At The Inverter

Connecting 5.2 Connecting the line and motor cable at the inverter Connecting the line and motor cable at the inverter 5.2.1 Connection overview Figure 5-2 Connection overview Note Limit values for EMC classes, Category C2 or C1 In order to comply with limit values for EMC classes, Category C2 or C1, for certain Power Modules, ferrite cores must be installed when connecting to the line supply. -

Page 47: Length Of Motor Cable

Connecting 5.2 Connecting the line and motor cable at the inverter 5.2.3 Length of motor cable Always dimension the motor cable so that the ohmic losses are less than 5 % of the inverter power rating. The permissible length of the motor cable also depends on the quality of the motor cable and the inverter pulse frequency. - Page 48 Connecting 5.2 Connecting the line and motor cable at the inverter Connections for frame sizes FSA … FSC The Power Modules are equipped with withdraw‐ able plug connectors that cannot be inadvertently interchanged. To remove a plug connector, you must release it by pressing on the red lever.

-

Page 49: Connecting The Motor To The Inverter In A Star Or Delta Connection

Connecting 5.2 Connecting the line and motor cable at the inverter 5.2.5 Connecting the motor to the inverter in a star or delta connection Standard induction motors with a rated power of approximately ≤ 3 kW are normally connected in a star/delta connection (Y/Δ) at 400 V/230 V. For a 400‑V line supply, you can connect the motor to the inverter either in a star or in a delta connection. - Page 50 Connecting 5.2 Connecting the line and motor cable at the inverter Power Module PM230, IP20 / Push-through technology (PT) Hardware Installation Manual, 08/2016, A5E34331322B AB...

-

Page 51: Service And Maintenance

WARNING Danger due to incorrect repair Repairs may only be carried out by Siemens Service, by repair centers authorized by Siemens or by authorized personnel who are thoroughly acquainted with all the warnings and operating procedures contained in this manual. -

Page 52: Maintenance

Note The actual maintenance intervals depend on the installation and operating conditions. Siemens offers its customers support in the form of service contracts. For further information, contact your Siemens regional office or sales office. Power Module PM230, IP20 / Push-through technology (PT) -

Page 53: Replacing The Cooling Fan

Service and maintenance 6.2 Replacing the cooling fan Replacing the cooling fan Service life of the fan The average service life of the fan is 40,000 hours. In practice, however, the service life may deviate from this value. Especially a dusty environment can block up the fan. The fan must be replaced in good time to ensure that the inverter is ready for operation. - Page 54 Service and maintenance 6.2 Replacing the cooling fan ⑥ 7. Remove the fan from the device 8. Install the new fan in the inverse sequence. You have replaced the fan. Replacing the fan for inverters, frame size FSF Procedure 1. Switch-off the inverter, and wait 5 minutes until the DC link capacitors have been discharged. 2.

- Page 55 Service and maintenance 6.2 Replacing the cooling fan ⑥ 7. Swivel the fan sideways towards the outside and then remove it from the inverter 8. Install the new fan in the inverse sequence. ⑥ 9. Additionally secure the fan using four M3 nuts on the guide bolts You have replaced the fan.

- Page 56 Service and maintenance 6.2 Replacing the cooling fan Power Module PM230, IP20 / Push-through technology (PT) Hardware Installation Manual, 08/2016, A5E34331322B AB...

-

Page 57: Technical Specifications

Technical specifications Permissible motors For the Power Modules, induction motors are permissible in the range from 25 % … 150 % of the inverter power without any restrictions. Note Motors for inverter operation Only use motors that are suitable for operation with inverters with a DC link. Power Module PM230, IP20 / Push-through technology (PT) Hardware Installation Manual, 08/2016, A5E34331322B AB... -

Page 58: Overload Capability Of The Inverter

Low Overload. We recommend the "SIZER" engineering software to select the inverter. You will find additional information about SIZER on the Internet: Download SIZER (http:// support.automation.siemens.com/WW/view/en/10804987/130000). Load cycles and typical applications: "Low Overload" load cycle "High Overload" load cycle The "Low Overload"... - Page 59 Technical specifications 7.1 Overload capability of the inverter Typical inverter load cycles Figure 7-1 Duty cycles, "High Overload" and "Low Overload" Power Module PM230, IP20 / Push-through technology (PT) Hardware Installation Manual, 08/2016, A5E34331322B AB...

-

Page 60: Cable Cross-Sections And Tightening Torques

Technical specifications 7.2 Cable cross-sections and tightening torques Cable cross-sections and tightening torques Table 7-1 Connection, cross-section and tightening torque for PM230 Power Modules Inverters Connection Cross-section, tightening torque Stripped insulation Metric Imperial length Line supply, motor 1 … 2.5 mm , 0.5 Nm 16 …... -

Page 61: Electromagnetic Compatibility - Overview

Technical specifications 7.3 Electromagnetic compatibility - overview Electromagnetic compatibility - overview Electromagnetic compatibility according to EN61800-3 Property Version Interference immunity The inverters are suitable for use in the first and second industrial environments Interference emission - Category C2 for inverters with integrated radio interference suppression filter second environment Category C2 for inverters without filter with optional external radio interference suppression... -

Page 62: Ambient Conditions

Technical specifications 7.4 Ambient conditions Ambient conditions Property Version Ambient conditions for transport in the transport packaging Climatic ambient conditions ‑ 40 °C … + 70 °C, according to Class 2K4 to EN 60721‑3‑2 maximum humidity 95 % at 40 °C Mechanical ambient condi‐... -

Page 63: General Technical Data

Technical specifications 7.5 General technical data General technical data Property Version Line voltage 3 AC 380 V … 480 V ± 10 % Output voltage 3 AC 0 V … input voltage x 0.95 (max.) Input frequency 50 Hz … 60 Hz, ± 3 Hz Output frequency 0 Hz ... -

Page 64: Detailed Technical Data

Technical specifications 7.6 Detailed technical data Detailed technical data Note Values for Low Overload and High Overload The values for Low Overload (LO) are identical with those of the rated values. Power loss of the Power Modules The values specified for the power loss are typical values at 100% of the rated speed and 100% of the load corresponding to Low Overload. - Page 65 Technical specifications 7.6 Detailed technical data Article no. - without filter 6SL3210-1NE13-1UG1 6SL3210-1NE14-1UG1 6SL3210-1NE15-8UG1 Article no. - with filter 6SL3210-1NE13-1AG1 6SL3210-1NE14-1AG1 6SL3210-1NE15-8AG1 Weight without filter 1.4 kg 1.4 kg 1.4 kg Weight with filter 1.6 kg 1.6 kg 1.6 kg Table 7-4 PM230, IP20, frame size A, 3 AC 380 V …...

- Page 66 Technical specifications 7.6 Detailed technical data Table 7-6 PM230, IP20, frame size B, 3-phase 380 … 480 VAC Article no. - without filter 6SL3210-1NE21-0UG1 6SL3210-1NE21-3UG1 6SL3210-1NE21-8UG1 Article no. - with filter 6SL3210-1NE21-0AG1 6SL3210-1NE21-3AG1 6SL3210-1NE21-8AG1 LO base load power 4 kW 5.5 kW 7.5 kW LO base load input current...

- Page 67 Technical specifications 7.6 Detailed technical data Article no. - without filter 6SL3210-1NE22-6UG1 6SL3210-1NE23-2UG1 6SL3210-1NE23-8UG1 Article no. - with filter 6SL3210-1NE22-6AG1 6SL3210-1NE23-2AG1 6SL3210-1NE23-8AG1 Fuse according to IEC / UL 3NE1803-0 3NE1817-0 3NE1817-0 Fuse according to UL, Class J 35 A 45 A 50 A Power loss 0.3 kW...

- Page 68 Technical specifications 7.6 Detailed technical data Table 7-11 PM230, IP20, frame size E, 3 AC 380 V … 480 V Article no. - without filter 6SL3210-1NE27-5UL0 6SL3210-1NE28-8UL0 Article no. - with filter 6SL3210-1NE27-5AL0 6SL3210-1NE28-8AL0 LO base load power 37 kW 45 kW LO base load input current 70 A...

-

Page 69: Restrictions For Special Ambient Conditions

Technical specifications 7.7 Restrictions for special ambient conditions Restrictions for special ambient conditions Current de-rating depending on the ambient operating temperature The Control Unit and operator panel can restrict the maximum permissible operating ambient temperature of the Power Module. Current derating depending on the installation altitude Above 1000 m above sea level you must reduce the inverter output current as a result of the lower cooling capability of the air. -

Page 70: Current Reduction Depending On Pulse Frequency

Technical specifications 7.7 Restrictions for special ambient conditions 7.7.1 Current reduction depending on pulse frequency Current derating depending on the pulse frequency LO base Output base-load current at a pulse frequency of load 2 kHz 4 kHz 6 kHz 8 kHz 10 kHz 12 kHz 14 kHz... -

Page 71: Electromagnetic Compatibility Of Variable-Speed Drives

Technical specifications 7.8 Electromagnetic compatibility of variable-speed drives Electromagnetic compatibility of variable-speed drives EMC (electromagnetic compatibility) means that the devices function satisfactorily without interfering with other devices and without being disrupted by other devices. This is true when the emitted interference (emission level) and the interference immunity are matched with each other. -

Page 72: Inverter Applications

- and are not operated in the general public domain. For an EMC-compliant installation, observe the information provided in the Configuration manual: EMC installation guideline (http://support.automation.siemens.com/WW/view/en/ 60612658). The Power Modules described here are intended for operation in the first and second environments. - Page 73 When connected to IT line supplies, only filtered inverters are permissible. Use external filters without capacitors with respect to ground to limit symmetrical interference emission. When necessary, contact one of our Solution Partners (https://www.automation.siemens.com/ solutionpartner/partnerfinder/Home/Index? country=DE&program=1&technology=19&lang=en). Power Module PM230, IP20 / Push-through technology (PT)

-

Page 74: Operation In The First Environment

Technical specifications 7.8 Electromagnetic compatibility of variable-speed drives 7.8.1.2 Operation in the first environment Interference immunity You do not have to take any additional measures regarding interference immunity. Interference emission - operation in the first environment, Category C2 In order that you may operate the drive system in the first environment, Category C2, then in addition to the requirements for use in the second environment, you must also observe the limit values related to harmonic currents. -

Page 75: Harmonic Currents

Technical specifications 7.8 Electromagnetic compatibility of variable-speed drives ● Inverters with an LO base load input current > 16 A and ≤ 75 A The drive system is in compliance with IEC/EN 61000-3-12 under the following precondition: – Short-circuit power S at the connection point of the customer's system to the public grid, is not greater or is equal to the value according to the following formula: ≥... -

Page 76: Emc Limit Values In South Korea

In addition, measures for EMC-compliant configuration of the plant or system are described in detail in this manual and in the Configuration manualEMC installation guideline (http:// support.automation.siemens.com/WW/view/en/60612658). The final statement on compliance with the applicable standard is given by the respective label attached to the individual device. -

Page 77: Spare Parts And Accessories

Spare parts and accessories Product maintenance Inverter components are being continuously developed within the scope of product update. The product update includes, for example, measures to increase the ruggedness or hardware changes, which are necessary as components are being discontinued. These further developments are "spare parts-compatible"... -

Page 78: Spare Parts

Spare parts and accessories 8.2 Spare parts Spare parts Power Modules FSA Fan kit 6SL3200-0SF12-0AA0 for ● all FSA Power Modules Power Modules FSB Fan kit 6SL3200-0SF13-0AA0 for ● all FSB Power Modules Power Modules FSC Fan kit 6SL3200-0SF14-0AA0 for ●... -

Page 79: Optional Accessories

Spare parts and accessories 8.3 Optional accessories Optional accessories 8.3.1 Mounting frames for Power Module with push-through technology Order numbers for mounting frames ● FSA: 6SL3260-6AA00-0DA0 ● FSB: 6SL3260-6AB00-0DA0 ● FSC: 6SL3260-6AC00-0DA0 All of the necessary nuts and seals are included in the scope of delivery. Mounting instructions for the mounting frames Procedure Proceed as follows to correctly mount the Power Module:... - Page 80 Spare parts and accessories 8.3 Optional accessories Dimension drawings for mounting frames Power Module PM230, IP20 / Push-through technology (PT) Hardware Installation Manual, 08/2016, A5E34331322B AB...

-

Page 81: Line Filters

Spare parts and accessories 8.3 Optional accessories 8.3.2 Line filters With a line filter, the inverter can achieve a higher radio interference class. The line filters integrated in the inverter correspond to Category C2 according to EN 61800-3. External filters are available for Category C2 or C1 according to EN 61800-3. Details are provided in the following tables. -

Page 82: Sine-Wave Filter

Spare parts and accessories 8.3 Optional accessories Technical data Article number Power Connection (mm De‐ loss (W) gree Line supply Power Module at 50 Hz of pro‐ tec‐ tion 6SL3203-0BE17-7BA0 Screw terminals M5 studs Integrated, IP20 2.5 mm 450 mm 6SL3203-0BE21-8BA0 6 mm screw ter‐... - Page 83 Spare parts and accessories 8.3 Optional accessories The following applies when using a sine-wave filter: ● Operation is only permissible with pulse frequencies from 4 kHz to 8 kHz. ● The inverter power is reduced by 5%. ● The maximum output frequency of the inverter is 150 Hz at 380 V to 480 V. ●...

-

Page 84: Output Reactors

Spare parts and accessories 8.3 Optional accessories Table 8-2 Technical data Article number Connection Degree of loss protection Power Module / motor 6SL3202-0AE26-2SA0 Screw terminals 25 … 50 mm IP20 6SL3202-0AE28-8SA0 Screw terminals 25 … 95 mm IP20 6SL3202-0AE31-5SA0 Screw terminals 50 … 150 mm IP20 6SL3202-0AE31-8SA0 Screw terminals 50 …... -

Page 85: Output Reactors For Inverters Fsa

Spare parts and accessories 8.3 Optional accessories Clearances to other devices Keep shaded areas free of any devices and components. Minimum clearances of the output reactor to other devices, space-saving mounting examples 8.3.4.1 Output reactors for inverters FSA ... FSC Dimensions, drilling patterns and weights Power Module PM230, IP20 / Push-through technology (PT) Hardware Installation Manual, 08/2016, A5E34331322B AB... - Page 86 Spare parts and accessories 8.3 Optional accessories Table 8-4 Dimensions and weights Article number Overall dimensions (mm) Drilling dimen‐ Fixing/torque Weight sions (mm) (Nm) (kg) 6SL3202-0AE16-1CA0 4 x M4 / 3 Nm 6SL3202-0AE18-8CA0 4 x M4 / 3 Nm 6SL3202-0AE21-8CA0 4 x M5 / 6 Nm 10.1 6SL3202-0AE23-8CA0...

-

Page 87: Output Reactors For Inverters Fsd

Spare parts and accessories 8.3 Optional accessories 8.3.4.2 Output reactors for inverters FSD ... FSF Dimensions, drilling patterns and weights Figure 8-3 Dimensions and drilling patterns Table 8-5 Dimensions and weights Article number Overall dimensions Drilling dimensions (mm) Fixing/torque Weight (mm) (Nm) (kg) -

Page 88: Shield Connection Kit

– FSE: 6SL3262-1AD00-0DA0 – FSF: 6SL3262-1AF00-0DA0 The mounting instructions for the shield connection kits, frame sizes FSD … FSF are available in the Internet at (https://support.industry.siemens.com/cs/ww/de/view/23621093/en): Power Module PM230, IP20 / Push-through technology (PT) Hardware Installation Manual, 08/2016, A5E34331322B AB... -

Page 89: Appendix

Installing, commissioning and maintaining the inverter. Advanced commissioning ● CU240B/E-2 operating instructions (https://support.industry.siemens.com/cs/ww/en/view/ 109478828) Installing, commissioning and maintaining the inverter. Advanced commissioning ● CU230P-2 List Manual (https://support.industry.siemens.com/cs/ww/en/view/109477248) Parameter list, alarms and faults. Graphic function diagrams ● CU240B/E-2 List Manual (https://support.industry.siemens.com/cs/ww/en/view/ 109477251) Parameter list, alarms and faults. -

Page 90: Configuring Support

Catalog Ordering data and technical information for SINAMICS G inverters. Catalog D31 for download or online catalog (Industry Mall): All about SINAMICS G120 (www.siemens.com/sinamics-g120) SIZER The configuration tool for SINAMICS, MICROMASTER and DYNAVERT T drives, motor starters, as well as SINUMERIK, SIMOTION controllers and SIMATIC technology... -

Page 91: Product Support

A.1 Manuals and technical support Safety Integrated for novices technical overview Application examples for SINAMICS G drives with Safety Integrated Safety Integrated for novices (https://support.industry.siemens.com/cs/ww/en/view/ 80561520) A.1.3 Product Support You can find additional information on the product and more in the Internet under (http:// www.siemens.com/automation/service&support) -

Page 92: Directives And Standards

Appendix A.2 Directives and standards Directives and standards Relevant directives and standards The following directives and standards are relevant for the inverters: European Low Voltage Directive The inverters fulfil the requirements stipulated in the Low-Voltage Directive 2014/35/EU, if they are covered by the application area of this directive. European Machinery Directive The inverters fulfil the requirements stipulated in the Machinery Directive 2006/42//EU, if they are covered by the application area of this directive. - Page 93 Appendix A.2 Directives and standards Quality systems Siemens AG employs a quality management system that meets the requirements of ISO 9001 and ISO 14001. Certificates for download ● EC Declaration of Conformity: (https://support.industry.siemens.com/cs/ww/en/view/ 58275445) ● Certificates for the relevant directives, prototype test certificates, manufacturers declarations and test certificates for functions relating to functional safety ("Safety...

-

Page 94: Abbreviations

Appendix A.3 Abbreviations Abbreviations Abbreviation State Alternating current Communauté Européenne Control Unit Direct current Digital input DIP switch Digital output Equivalent circuit diagram European Economic Community ELCB Earth leakage circuit breaker Electromagnetic compatibility (EMC) Electromagnetic interference FS… Frame size ... Getting Started Guide High overload Input/Output... -

Page 95: Index

Index 87 Hz characteristic, 49 Getting Started, 89 Accessories, 89 Hardware Installation Manual, 89 Air barrier, 29 Harmonic currents, 75 High Overload, 58 Hotline, 91 Base load, 58 Base load input current, 58 Base load output current, 58 Industry Mall, 90 Base load power, 58 Installing, 31 IT system, 41... - Page 96 Index Parameter Manual, 89 Permissible motors, 20, 57 Power distribution systems, 41 Protective conductor, 41 Pulse frequency, 70 Questions, 91 Radio interference class, 81 Safety notes Electrical installation, 39 Service life of the fan, 53 Sine-wave filter, 82 SIZER, 90 Standards EN 61800-3, 92 Star connection (Y), 49...

-

Page 98: Further Information

Further information SINAMICS inverters: www.siemens.com/sinamics Siemens AG Subject to change Digital Factory © Siemens AG 2013 - 2016 Motion Control Postfach 3180 Scan the QR code for 91050 ERLANGEN further information GERMANY on SINAMICS G120P. www.siemens.com/drives...