Alesis HR-16 Service Manual

Hide thumbs

Also See for HR-16:

- Instruction manual (73 pages) ,

- Instruction manual (31 pages) ,

- Instruction manual (31 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Alesis HR-16

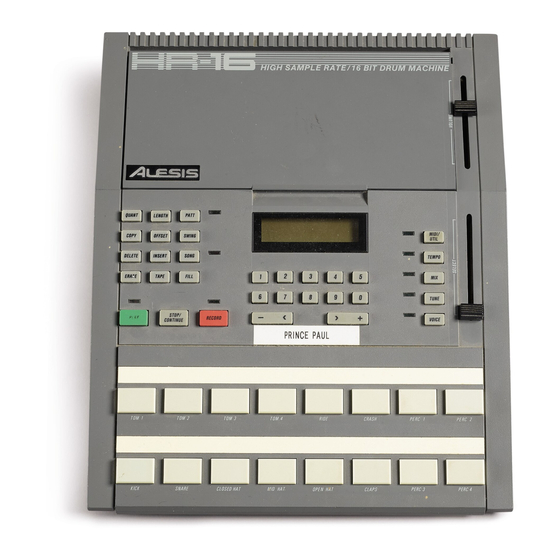

- Page 1 HR-16B Drum Machine Drum Machine SERVICE MANUAL © 1987 Alesis...

- Page 2 HR-16/HR-16B Drum Machines Service Manual V1.00 7/27/95 HR-16/HR16B Service Manual 1.00 03/31/06...

-

Page 3: Read This

As the owner of the copyright to the Manual, Alesis does not give you the right to copy the Manual, and you agree not to copy the Manual without the written authorization of Alesis. -

Page 4: Warnings

Battery Manufacturer: Tadiran Type: TL-5101 Rating 3.6V REPAIR BY ANY PERSON OR ENTITY OTHER THAN AN AUTHORIZED ALESIS SERVICE CENTER WILL VOID THE ALESIS WARRANTY. PROVISION OF THIS MANUAL DOES NOT AUTHORIZE THE RECIPIENT TO COMPETE WITH ANY ALESIS DISTRIBUTOR OR AUTHORIZED REPAIR SERVICE CENTER IN THE PROVISION OF REPAIR SERVICES OR TO BE OR MAKE REPAIRS AS AN AUTHORIZED SERVICE CENTER. -

Page 5: Safety Suggestions

The product is exposed to water or excessive moisture, c. The AC power supply plug or cord is damaged, d. The product shows an inappropriate change in performance or does not operate normally, or e. The enclosure of the product has been damaged. HR-16/HR16B Service Manual 1.00 03/31/06... -

Page 6: General Troubleshooting

(burnt, or loose components are a dead giveaway). 2. Self Test - Alesis products that utilize microprocessor control contain built in test software which exercises many of the units' primary circuit functions. Self test should always be done following any repair to ensure basic functionality. -

Page 7: Table Of Contents

7.19 Volume Slider Wiring............13 7.20 PUP Capacitor..............14 8.0 Common Solutions ................. 15 9.0 Service Parts List ................... 18 10.0 Software History ................... 20 11.0 MIDI Implementation ................23 12.0 Service Manual History ................ 31 INDEX......................32 HR-16/HR16B Service Manual 1.00 03/31/06... -

Page 8: General Description

2.0 Power Supply The power supply begins with the 9 Volt A.C., adapter (Alesis P2 [mini plug] or P3 [barrel] types). Input from J1 is R.F. filtered before on/off switch S1. From there it is split for the +12V, -12V, and +5V rails. -

Page 9: Battery Backup

Q10 lower. Q10 is now biased into saturation, allowing roughly +12V to be fed to the op- amps. C65 is provided for extra filtering. The - rail consists of R99, R100, R105, Q12-Q13, and C64. HR-16/HR16B Service Manual 1.00... -

Page 10: The 8031

SRAM during shutdown. Be aware that this can cause unusual unit lockups to occur if the circumstances are just right. For example, if an HR-16 was shut off while in record mode, it's possible the 8031 was put into reset in the middle of writing a two byte pointer into memory. If only one of those bytes is written before reset, then it may point to an incorrect location in memory (battery backup holds the incorrect data). -

Page 11: Memory Mapped I/O

MIDI in consists mostly of the opto isolator (U4), protection diode D6, pullup R7, and threshold resistor R5. Note that the threshold resistor may need to be changed in order to eliminate false MIDI triggers (see section 7.6). HR-16/HR16B Service Manual 1.00... -

Page 12: Dm3Ag Asic

However, a brief description of some of the important pins follows. NAME PIN#(s) Function MD0-MD7 27-34 8031 Data Buss Input. CLOCK Asic Clock Input (6MHz in HR-16). DAC0-DAC16 42-51, 53-60 Output to DAC. A0-A19 3-17, 19-23 Mask Address Buss D0-D7... -

Page 13: Analog Signal Paths

I/O needs of the HR-16. However, these cases should be rare, as the components chosen for the HR- 16 are based on the industry "standards" that most manufacturers adhere to. -

Page 14: Tape Output

6. Always verify tapes after saving them. This helps reduce the chances of bad saves. Note however that the HR-16 does not compare the tape to the contents of memory. It simply verifies that the information on the tape is valid HR-16 data. -

Page 15: General Testing

Enters DAC adjust mode (press stop to exit). 6.3 DAC Adjustments The only adjustment necessary in the HR-16 is the DAC adjustment. This is normally done at the end of the HR-16's internal diagnostics, however holding the "PATT" button and pressing the "VOICE"... -

Page 16: Updates And Corrections

Revisions A & CA. For a short time, glass package 1N5231B zener diodes were used instead of the more familiar metal package. These were found to be unreliable, and should be replaced with metal package zeners. Diagram 8 HR-16/HR16B Service Manual 1.00... -

Page 17: Dirty Cliff Jacks

74HC04 (U6) and the nearby feed through. The trace on the solder side of the PC board can then be cut (see diagram 12 for details). Diagram 11 HR-16/HR16B Service Manual 1.00... -

Page 18: Midi Resistor (R5)

• Revision A. In an effort to further reduce the R.F. emissions of the HR-16, a self sticking R.F. shield was introduced. Care should be taken when installing the shield, as wrinkles in the shield may easily cause shorts to the main PC board. The tab of the shield should... -

Page 19: Dac Drift

7.11 Old Keypad PC Boards • Revision A The original HR-16 came with standard PCB type contacts (tinned copper traces), but these were found to oxidize over time. This was especially evident when the unit was used in a moisture rich environment (such as near the ocean). -

Page 20: Tape Capacitors

(located between the 8031 and U6). 7.19 Volume Slider Wiring Note that the wiring of the volume slider changed between Revisions CA and AQ. Diagram 16 shows the correct wiring for each board style. Diagram 16 HR-16/HR16B Service Manual 1.00... -

Page 21: Pup Capacitor

When the PUP circuit first appeared, it was found that the circuit would occasionally oscillate on power up, causing noise. This was eliminated by adding a bypass capacitor (later incorporated as C62) across the power supply pins of U20 (pins 4 and 11). HR-16/HR16B Service Manual 1.00... -

Page 22: Common Solutions

A thorough knowledge of the software history can help solve a great many situations quickly. Also be aware that with devices as full of options as the HR-16(B), there are even more possibilities for user error (i.e. the user claims that MIDI out isn't working, but on checking the settings, the tech finds that both MIDI clock, and DRUM NOTES OUT are turned off). - Page 23 Possible Cause Solutions Unit "crashes" constantly. (cont.) Faulty I/O latch pulling down data buss. Troubleshoot and repair as necessary. Faulty front panel cable. Replace and retest. Incorrect data slider wiring. Check slider wiring. Repair as necessary. HR-16/HR16B Service Manual 1.00...

- Page 24 Check and replace if necessary. attempt to install the HR-16A/B EPROM into their new HR-16B. WRONG! This EPROM is intended to be used only in the HR-16, and does not have the correct MASK ROM addressing tables to play HR-16B sounds).

-

Page 25: Service Parts List

9-11-1010 ALPHA SWITCH CAP 9-11-1011 10K TRIMPOT 0-08-0103 MAIN 10KB SLIDE POT MONO 0-09-1009 10KB SLIDE POT STER 0-09-1010 100 1/8W 5% 0-00-0101 R75,120,133 MAIN GROUP DESCRIPTION PART # POSITION NOTES 1/8W 5% 0-00-0102 R23,29,35,36,48,49,50,51,64,67,69,72,91,92,112,114,115 MAIN HR-16/HR16B Service Manual 1.00... - Page 26 0-00-0562 R55-62 MAIN 820K 1/8W 5% 0-00-0824 MAIN 24K 8 PIN SIP 0-06-2438 MAIN 24K 9 PIN SIP 0-06-2439 MAIN TOP KEYPAD 9-21-1002 BOT KEYPAD 9-21-1004 ROUND RUBBER FEET 9-23-1004 68 PIN ASIC SOCKET 4-12-0068 MAIN HR-16/HR16B Service Manual 1.00...

-

Page 27: Software History

8051s that have indeterminate data in the UART on power up. 12/14/87 1.03 1) Fixes MIDI Song Pointer input bug that caused the HR-16 to continue from the wrong location if in song mode and a tempo was stored in the first step of the song. - Page 28 8/25/88 1.09 1) Fixes bug that caused the HR-16 to send out an incorrect MIDI song position pointer if any tempo change steps occurred in the song previous to the current song position. 2) Fixes bug that caused the HR-16 to send out an incorrect MIDI song position pointer if an empty pattern (8 beats, no drum events) was used in a step of a song previous to the current song position.

- Page 29 2) Fixed bug which caused sysex loading to be garbled if any real-time MIDI information was received during the sysex dump. This seemed to only be a problem with IBM MPU-401 interfaces. 3) All individual’s names have been removed from the software. HR-16/HR16B Service Manual 1.00...

-

Page 30: Midi Implementation

HR-16's memory. In order to optimize the data transfer, 8 MIDI bytes are used to transmit each block of 7 HR-16 data bytes. If the 7 data bytes are looked at as one 56-... - Page 31 0E6H Sysex enable (0=off, 1=on) 0E7H-0EBH Software version: 5 ascii bytes, starting with a space (20H) if an HR-16, or a "B" (42H) if an HR-16B, followed by a 4 digit version number (e.g., "2.00", or 32H, 2EH, 30H, 30H)

- Page 32 1) All pattern and song data must be in consecutive order, i.e., pattern 05 data cannot be before pattern 02's data. The order for the data should be pattern 00 through 99, followed by song 00 through 99. HR-16/HR16B Service Manual 1.00...

- Page 33 TOM 1 panning (bits 5-7: 0=L, 6=R) & pitch (bits 0-4:0=-16, 1FH=+15) TOM 2 sound number (0-30H) TOM 2 output assign (bit 7) and volume (bits 0-6: 0-63H) TOM 2 panning (bits 5-7: 0=L, 6=R) & pitch (bits 0-4:0=-16, 1FH=+15) HR-16/HR16B Service Manual 1.00...

- Page 34 LSB of number of bytes in song, including header. MSB of number of bytes in song, including header. Step 1 Step 2 Step 3 Step 4 etc..Pattern number 0FFH (end of song) Song data must follow these rules: HR-16/HR16B Service Manual 1.00...

- Page 35 0-99 = pattern or song number RECORD BUTTON This command is used to "press" or "release" the RECORD button. It will affect whether the HR-16 will go into play or record when it receives a MIDI START command. It does not affect what will happen when pressing play from the front panel.

- Page 36 When transmitting any copy function, it is recommended that a pause of one second be inserted between the copy mode byte and the data that follows it to insure that the receiving HR-16 has enough time to move memory around to make room for the new pattern or song.

- Page 37 MIDI information. For example, selecting a pattern, or copying a pattern can cause a delay in which the HR-16 will ignore incoming MIDI information if its input buffer overflows. By sending this command after a copy pattern command (command 5), and then waiting for the response before sending any additional commands, it can be insured that the HR-16 will not miss any information.

-

Page 38: Service Manual History

12.0 Service Manual History 7/27/95 V1.00 1st release. HR-16/HR16B Service Manual 1.00... -

Page 39: Index

C11, 13, 16, 18 hot glue, 13 power supply, 1, 13, 14, 15, 17 C16, 6, 18 HR-16, 3, 5, 6, 7, 8, 11, 12, 15, 17, 18, 20, program, 3, 20, 24 C2, 1 21, 22, 23, 24, 28, 29, 30... - Page 40 6, 7 R60, 12 stereo panning, 6 write, 3, 4 R63, 6, 19 STRES, 5 R68, 6 SYSEX, 22, 23, 24, 29 Z1, 3, 18 R7, 4, 11, 19 R73-R75, 6 tape backup, 6 HR-16/HR16B Service Manual 1.00...

- Page 41 NOTES HR-16/HR16B Service Manual 1.00...