Table of Contents

Advertisement

Two-Stroke Engine For Airplanes

It is of vital importance, before attempting to operate

your engine, to read the general 'SAFETY

INSTRUCTIONS AND WARNINGS' section on

pages 2-6 of this booklet and to strictly adhere to the

advice contained therein.

Also, please study the entire contents of this

instruction manual, so as to familiarize yourself

with the controls and other features of the engine.

Keep these instructions in a safe place so that you

may readily refer to them whenever necessary.

It is suggested that any instructions supplied with

the aircraft, radio control equipment, etc., are

accessible for checking at the same time.

CONTENTS

RUNNING -IN, IDLING ADJUSTMENT CHART

2-6

7-8

9

10

11-14

15-17

18-19

ENGINE/ CARBURETOR EXPLODED

20-21

VIEWS & PARTS LIST

22

23

24-26

1

27-30

31

32

33

34-35

36-37

38-45

46-47

48-49

50

Advertisement

Table of Contents

Summary of Contents for O.S. engine MAX-25AX & MAX-35AX

-

Page 1: Table Of Contents

CONTENTS SAFETY INSTRUCTIONS AND WARNINGS RUNNING -IN, IDLING ADJUSTMENT CHART 27-30 ABOUT YOUR O.S. ENGINE MIXTURE CONTROL VALVE ADJUSTMENT ENGINE CONSTRUCTION, NOTES WHEN APPLYING AN ELECTTRIC STARTER REALIGNMENT OF MIXTURE CONTROL VALVE, SUBSEQUENT STARTINGPROCEDURE... -

Page 2: Safety Instructions And Warnings About Your O.s. Engine

As owner, you, alone, are responsible for the safe operation of your engine, so act with discretion and care at all times. If at some future date, your O.S. engine is acquired by another person, we would respectfully request that these instructions are also passed on to its new owner. - Page 3 NOTES This engine was designed for model If you remove the glowplug from the engine aircraft. Do not attempt to use it for any and check its condition by connecting the other purpose. battery leads to it, do not hold the plug with bare fingers.Use an appropriate tool or a Mount the engine in your model securely, folded piece of cloth.

-

Page 4: Engine Construction

NOTES Adjust the throttle linkage so that the engine For their safety, keep all onlookers stops when the throttle stick and trim lever (especially small children) well back (at on the transmitter are fully retarded. least 20 feet or 6 meters) when preparing Alternatively, the engine may be stopped by your model for flight. -

Page 5: Notes When Applying An Electtric Starter

NOTES WHEN APPLYING AN ELECTRIC STARTER Do not over-prime. This could cause a hydraulic lock and damage the engine on application of the electric starter. If over-primed, remove glowplug, close needle-valve apply starter to pump out surplus fuel. Cover the head with a rag to prevent pumped out fuel from getting into your eyes. -

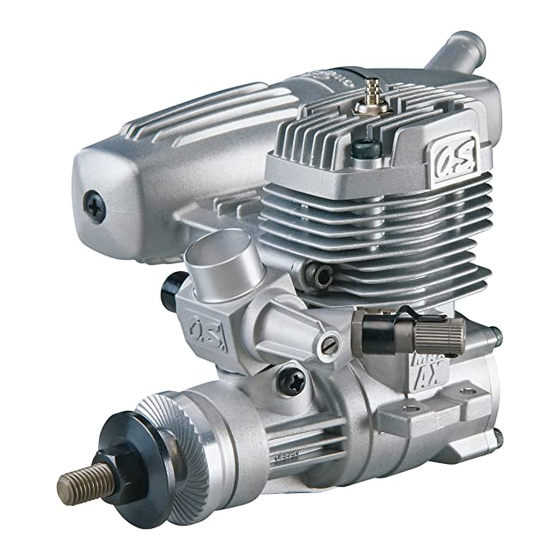

Page 6: Basic Engine Parts

BASIC ENGINE PARTS Glowplug Cylinder head Carburetor Type 21K (Type 21L For 25AX) Cover Plate Propeller washer Propeller nut Beam Mount Crankshaft Crankcase Drive Hub -35AX is shown. BEFORE STARTING Tools, accessories, etc. The following items Warning: are necessary for operating the engine. Make sure that the propeller is well balanced. - Page 7 FUEL Reminder! Model engine fuel is poisonous. Do not The 25AX and 35AX should be operated on a methanol allow it to come into contact with the eyes or based fuel containing not less than 18% (volumetric) mouth. Always store it in a clearly marked castor oil, or a top quality synthetic lubricant (or a container and out of the reach of children.

-

Page 8: Installation

LONG SOCKET WRENCH WITH PLUG GRIP TOOLS Recommended easy removal HEX Screwdriver replacement of the angled and recessed Necessary for engine installation. glowplug, the O.S.Long Socket Wrench 1.5mm, 2.5mm incorporates a special grip. Phillips Screwdriver No.2, etc. End Wrenches 10mm, etc. SCREWDRIVER Necessary for mixture control valve adjustments. - Page 9 How to fasten the mounting screws. Make sure that these mounting beams are ● Hardwood mounting beams accurately aligned and firmly integrated with Tighten second nut the airframe, reinforcing the adjacent 3mm steel nuts firmlydown onto first nut. structure to absorb vibration. Use 4mm or Tighten this nut first.

-

Page 10: Installation Of The Standard Accessories

INSTALLATION OF THE STANDARD ACCESSORIES NEEDLE-VALVE EXTENSION INSTALLING THE GLOWPLUG The needle-valve supplied with this engine is designed to incorporate an extension so that, when the engine is enclosed within the Install washer on glowplug fuselage, the needle-valve may be adjusted insert carefully into... -

Page 11: Fuel Tank Location

FUEL TANK LOCATION 25AX Position the fuel tank so that approximately Suggested fuel tank capacity is approx 1/3 of the tank height is above the center line 160cc. This will allow 10-12 minute flights. of the needlevalve. 35AX Suggested fuel tank capacity is approx Be sure to use a pressurized fuel system by 180cc. -

Page 12: Mixture Controls

MIXTURE CONTROLS Two mixture controls are provided on the Carburetor. Needle Valve The Needle Valve When set to produce maximum power at full throttle, this establishes the basic fuel/air mixture strength. The correct mixture is then Mixture Control Valve maintained by the carburetor's built-in Mixture Control Valve on the carburetor is set automatic mixture control system to cover at basic position ( a little on the rich side) at the... -

Page 13: Starting

STARTING Be sure to use an electric starter to Element glows when energized. start the engine. Pliers Never fail to check the tightness of screws and nuts, especially engine mounting and moving parts (e.g. throttle lever). Replace the plug when the element does not glow or is burnt out. - Page 14 Attention : How to stop the engine Do not choke the carburetor air intake when Pull down the throttle lever and trim lever on applying the starter. This could cause an the transmitter fully. excessive amount of fuel to be drawn into the Note: cylinder which may initiate a hydraulic lock and Make sure that the throttle linkage is set so...

- Page 15 Optimum needle setting(1) During subsequent flights, the needle-valve can be gradually closed to give more power. Slowly advance the throttle to its fully open However, if the engine shows signs of position, then gradually close the needle-valve running too lean, the next flight should be until the exhaust note begins to change.

-

Page 16: Mixture Control Valve Adjustment

MIXTURE CONTROL VALVE ADJUSTMENT With the engine running, close the throttle and In this case, turn the Mixture Control Screw allow it to idle for about five seconds, then counter-clockwise 90 degrees to positively open the throttle fully. If, at this point, the enrich the idle mixture, then turn the screw engine is slow to pick up and produces an clockwise gradually until the engine regains full... -

Page 17: Realignment Of Mixture Control Valve

REALIGNMENT OF MIXTURE CONTROL VALVE SUBSEQUENT STARTING PROCEDURE course making carburetor Once the optimum needle-valve setting has adjustments, it is just possible that the Mixture been established (see page 29, Needle-valve Control Valve may be inadvertently screwed in adjustment diagram) the procedure for starting or out too far and thereby moved beyond its may be simplified as follows. -

Page 18: Trouble Shooting When The Engine Fails To Start

TROUBLE SHOOTING WHEN THE ENGINE FAILS TO START Four key points For quick, reliable starting, the following four conditions are required. 1 Good compression. 2 Adequate "glow" at glowplug. 3 Correct mixture. 4 Sufficient electric starter rotating speed. If the engine fails to start, or does not keep running after being started, check symptoms against the following chart and take necessary corrective action. -

Page 19: Care And Maintenance

CARE AND MAINTENANCE Please pay attention to the matters Install an in-line fuel filter between the tank described below to ensure that your engine and carburetor to prevent foreign matter in serves you well in regard to performance, the tank from entering the carburetor. reliability and long life. - Page 21 21L CARBURETOR EXPLODED VIEW N.+M3x6 S.M3X3 N.+M3.5x5 Type of screw N...Round Head Screw S...Set Screw 21L CARBURETOR PARTS LIST Code No. Description 22081408 Throttle Lever Assembly 22582200 Carburetor Rotor 29181620 Mixture Control Valve Assembly 46066319 "O" Ring (L) (2pcs.) 22781800 "O"...

- Page 23 21K CARBURETOR EXPLODED VIEW N.+M3x6 S.M3X3 N.+M3.5x5 Type of screw N...Round Head Screw S...Set Screw 21K CARBURETOR PARTS LIST Code No. Description 22081408 Throttle Lever Assembly 23181200 Carburetor Rotor 29181620 Mixture Control Valve Assembly 46066319 "O" Ring (L) (2pcs.) 22781800 "O"...

-

Page 24: O.s. Genuine Parts & Accessories

O.S. GENUINE PARTS & ACCESSORIES O.S.GLOW PLUG RADIAL MOTOR MOUNT SPINNER NUT LONG PROPELLER NUT SET 1/4"-28 (71908410) No.6 (Fomer A3) (23024008) 1/4"-28 (71605300) (73101000) 1/4"-28(L) No.7 (23024009) (71607100) No.8 (71608001) PROPELLER NUT SET SILENCER EXTENSION SUPER FILTER FOR 2C SPINNER ADAPTORS ( L ) (72403050) -

Page 25: Three View Drawing

25AX THREE VIEW DRAWING 96.2 SPECIFICATIONS Displacement 4.07 cc / 0.248 cu.in. Bore 18.0 mm / 0.709 in. Stroke 16.0 mm / 0.630 in. Power output at 0.7 ps / 0.71 hp / 14,000 r.p.m. recommended R.P.M. range 33.6 Recommended R.P.M. range 2,500-15,000 r.p.m. -

Page 26: Memo

MEMO 6-15 3-Chome Imagawa Higashisumiyoshi-ku Osaka 546-0003, Japan URL : http://www.os-engines.co.jp 60092180 061101 Copyright 2009 by O.S.Engines Mfg. Co., Ltd. All rights reserved. Printed in Japan.