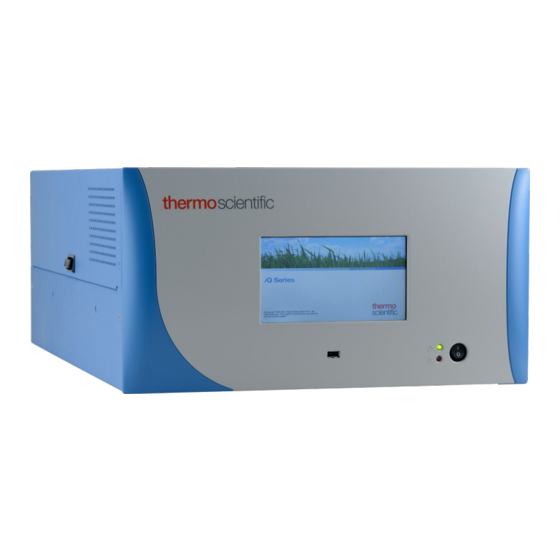

ThermoFisher Scientific 43iQHL Manuals

Manuals and User Guides for ThermoFisher Scientific 43iQHL. We have 1 ThermoFisher Scientific 43iQHL manual available for free PDF download: Instruction Manual

ThermoFisher Scientific 43iQHL Instruction Manual (278 pages)

High Level Sulfur Dioxide Analyzer

Brand: ThermoFisher Scientific

|

Category: Measuring Instruments

|

Size: 15 MB

Table of Contents

Advertisement

Advertisement

Related Products

- ThermoFisher Scientific Ozone Primary Standard 49iQPS

- ThermoFisher Scientific Applied Biosystems Veriti 4375305

- ThermoFisher Scientific Applied Biosystems Veriti 4375786

- ThermoFisher Scientific Applied Biosystems Veriti 4388444

- ThermoFisher Scientific Applied Biosystems Veriti 4384638

- ThermoFisher Scientific Wellwash 4Mk2

- ThermoFisher Scientific 4483636

- ThermoFisher Scientific 4483638

- ThermoFisher Scientific 44840714

- ThermoFisher Scientific 4484073