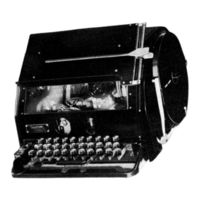

Teletype 14 Typing Reperforator Manuals

Manuals and User Guides for Teletype 14 Typing Reperforator. We have 2 Teletype 14 Typing Reperforator manuals available for free PDF download: Bulletin, Manual

Teletype 14 Bulletin (50 pages)

Brand: Teletype

|

Category: Typewriter

|

Size: 3 MB

Table of Contents

Advertisement

Teletype 14 Manual (41 pages)

Transmitter-Distributor

Brand: Teletype

|

Category: Typewriter

|

Size: 3 MB

Table of Contents

Advertisement