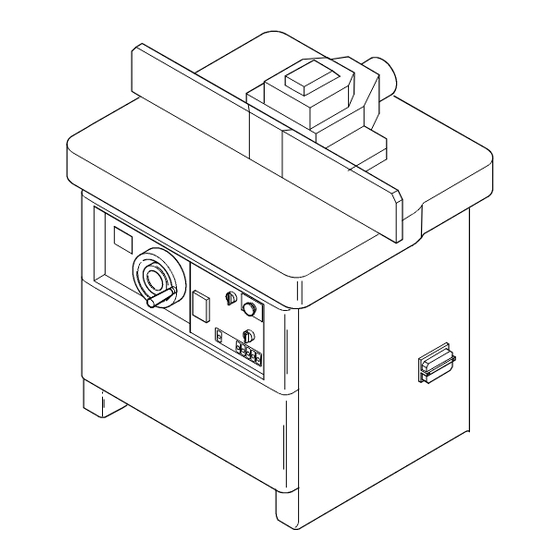

SAC T120 Heavy Duty Shaper Manuals

Manuals and User Guides for SAC T120 Heavy Duty Shaper. We have 1 SAC T120 Heavy Duty Shaper manual available for free PDF download: Use And Maintenance Instructions

SAC T120 Use And Maintenance Instructions (80 pages)

Brand: SAC

|

Category: Power Tool

|

Size: 1 MB

Table of Contents

Advertisement

Advertisement