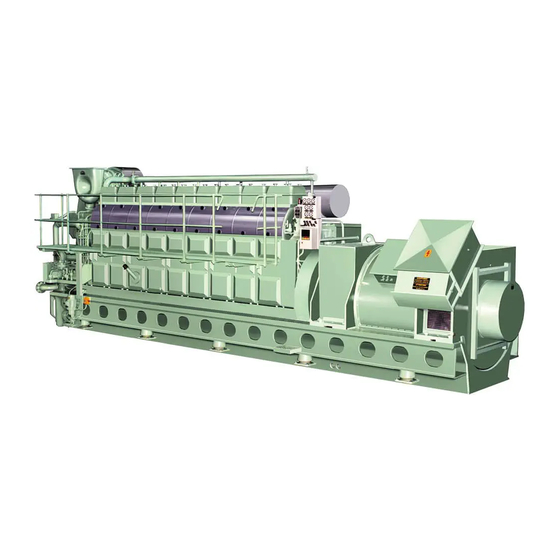

MAN Diesel & Turbo L28/32H Manuals

Manuals and User Guides for MAN Diesel & Turbo L28/32H. We have 1 MAN Diesel & Turbo L28/32H manual available for free PDF download: Instruction Manual

MAN Diesel & Turbo L28/32H Instruction Manual (466 pages)

Four-stroke GenSet compliant with IMO Tier II

Brand: MAN Diesel & Turbo

|

Category: Inverter

|

Size: 8 MB

Table of Contents

-

Index2

-

Warning12

-

Camshaft32

-

Camshaft33

-

Starting49

-

Stopping49

-

Air Cooler57

-

Fuel Valves58

-

Separator94

-

Viscosity97

-

Separators109

-

Settling Tank109

-

Homogeniser111

-

Vanadium/Sodium111

-

Ignition Quality112

-

Compatibility114

-

Sampling115

-

Tests115

-

Lubricity117

-

Distillate126

-

Slushing Oil128

-

Biocides129

-

Oil Sludge136

-

Cylinder Head141

-

Valve Rotator142

-

Valve Rotator152

-

Connecting Rod189

-

Roller Guides240

-

Governor251

-

Regulating Shaft251

-

Instrumentation254

-

Starting Box258

-

Tacho Fail259

-

Engine Run259

-

Overspeed Device285

-

Instrument Panel287

-

Thermometer293

-

-

Terminal Box312

-

Converter314

-

Vibration Damper317

-

Bearing Cap330

-

Crankshaft View334

-

Covers on Frame386

-

Compressor393

-

Steam Trap437

-

Starting System442

-

Control System442

-

Air Filter444

-

Drive Housing448

-

Gear Case450

-

Turbine Starter459

-

Muffler464

Advertisement

Advertisement