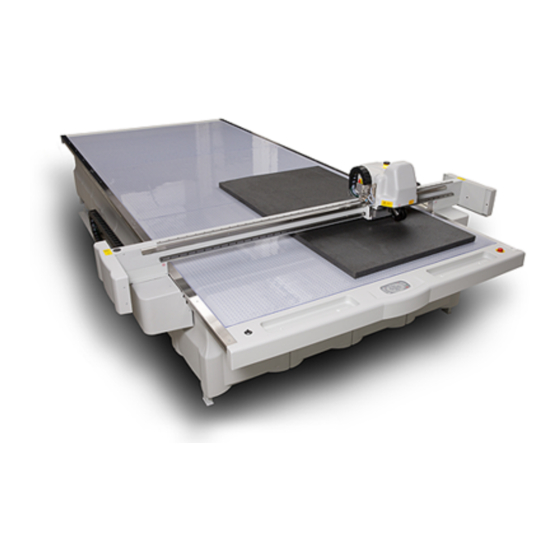

Esko Kongsberg XN IPC 2.0 Cutter Manuals

Manuals and User Guides for Esko Kongsberg XN IPC 2.0 Cutter. We have 1 Esko Kongsberg XN IPC 2.0 Cutter manual available for free PDF download: User Manual

Advertisement

Advertisement