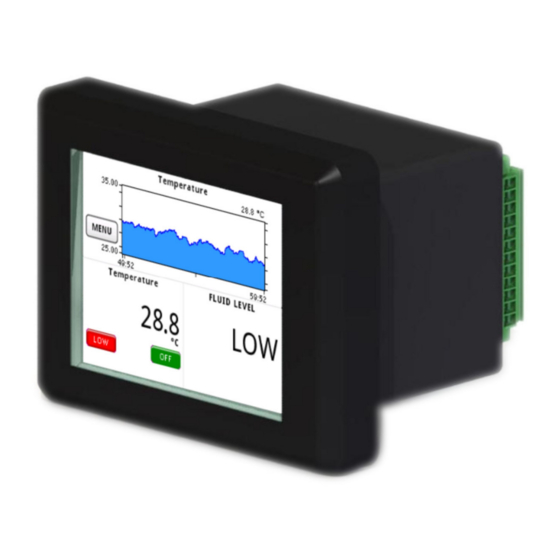

Dycor SmartVue Process Control Monitor Manuals

Manuals and User Guides for Dycor SmartVue Process Control Monitor. We have 1 Dycor SmartVue Process Control Monitor manual available for free PDF download: Operator's Manual

Dycor SmartVue Process Control Monitor Operator's Manual (138 pages)

Table of Contents

-

Figures8

-

Introduction11

-

Temperature25

-

SPN List72

-

File System101

-

Data Logging105

-

Monitor Data115

-

Date and Time115

-

Information116

-

Boot-Up Options118

-

LCD Brightness119

-

Load Application120

-

Color Bar120

-

Smartvue Remote121

-

Requirements121

-

Remote Settings124

-

Appendix127

Advertisement