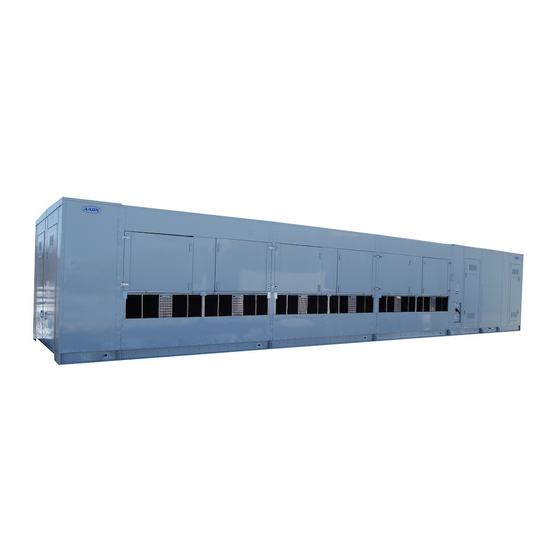

AAON LZ Series Manuals

Manuals and User Guides for AAON LZ Series. We have 1 AAON LZ Series manual available for free PDF download: Installation Operation & Maintenance

AAON LZ Series Installation Operation & Maintenance (104 pages)

Chillers and Outdoor Mechanical Rooms

Table of Contents

Advertisement

Advertisement