Table of Contents

Advertisement

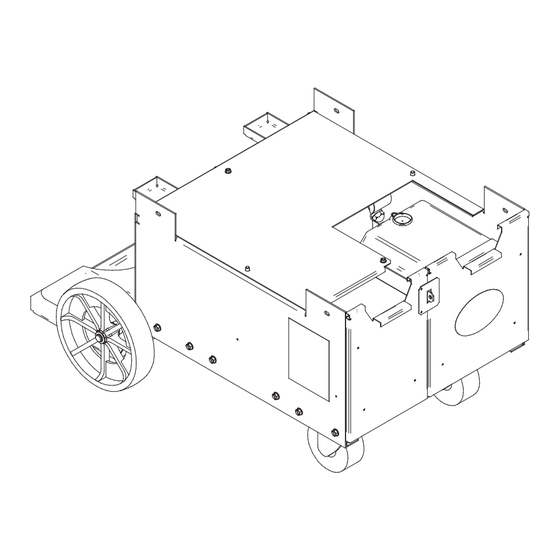

UNDER-COOLER CART

For use with machines having Code Numbers:

Safety Depends on You

Lincoln arc welding and cutting

equipment is designed and built

with safety in mind. However, your

overall safety can be increased by

proper installation ... and thought-

ful operation on your part. DO

NOT INSTALL, OPERATE OR

REPAIR THIS EQUIPMENT

WITHOUT

READING

THIS

MANUAL AND THE SAFETY

PRECAUTIONS CONTAINED

THROUGHOUT. And, most

importantly, think before you act

and be careful.

• Sales and Service through Subsidiaries and Distributors Worldwide •

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

RETURN TO MAIN MENU

10808, 11068

R

IP 21S

NTRL/C

OPERATOR'S MANUAL

• World's Leader in Welding and Cutting Products •

Copyright © 2004 Lincoln Global Inc.

IM723-A

January, 2004

Advertisement

Table of Contents

Summary of Contents for Lincoln Electric IM723-A

- Page 1 • World's Leader in Welding and Cutting Products • • Sales and Service through Subsidiaries and Distributors Worldwide • Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com RETURN TO MAIN MENU 10808, 11068 IP 21S NTRL/C Copyright © 2004 Lincoln Global Inc. IM723-A January, 2004...

-

Page 2: California Proposition 65 Warnings

351040, Miami, Florida 33135 or CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199. BE SURE THAT ALL INSTALLATION, OPERATION, MAINTENANCE AND REPAIR PROCEDURES ARE PERFORMED ONLY BY QUALIFIED INDIVIDUALS. -

Page 3: Electric Shock Can Kill

ELECTRIC SHOCK can kill. 3.a. The electrode and work (or ground) circuits are electrically “hot” when the welder is on. Do not touch these “hot” parts with your bare skin or wet clothing. Wear dry, hole-free gloves to insulate hands. 3.b. - Page 4 WELDING SPARKS can cause fire or explosion. 6.a. Remove fire hazards from the welding area. If this is not possible, cover them to prevent the welding sparks from starting a fire. Remember that welding sparks and hot materials from welding can easily go through small cracks and openings to adjacent areas.

- Page 5 PRÉCAUTIONS DE SÛRETÉ Pour votre propre protection lire et observer toutes les instructions et les précautions de sûreté specifiques qui parraissent dans ce manuel aussi bien que les précautions de sûreté générales suiv- antes: Sûreté Pour Soudage A L’Arc 1. Protegez-vous contre la secousse électrique: a.

- Page 6 The code number is especially important when identifying the correct replacement parts. - Register your machine with Lincoln Electric either via fax or over the Internet. • For faxing: Complete the form on the back of the warranty statement included in the literature packet accompanying this machine and fax the form per the instructions printed on it.

-

Page 7: Table Of Contents

TABLE OF CONTENTS Installation...Section A Technical Specifications ...A-1 Safety Precautions..A-2 Unpacking ...A-2 Filling Coolant Reservoir ...A-2 Coolant Connections ...A-3 Input Power Connection ...A-4 Assembly of Precision Tig ...A-4 Fastener Quick Reference ...A-5 Connection of Tig Torches ...A-5 ________________________________________________________________________________ Operation...Section B Safety Precautions. -

Page 8: Installation

TECHNICAL SPECIFICATIONS – UNDER- WATER COOLER Model / Make Input Rated Current Draw Operating Pressure Pump Hydraulic Rating No Flow No Pressure Pump Hydraulic Rating (Typical Operation) Reservoir Capacity Recommended Coolant Weight Shipping Reservoir Full (Water) Dimensions Length Width Height (Top Face) Height (TIG Interface) INSTALLATION Under-Cooler Cart K1828-1... -

Page 9: Safety Precautions

SAFETY PRECAUTIONS: WARNING ELECTRIC SHOCK Can Kill • Only qualified persons should per- form this installation. HOT COOLANT CAN BURN SKIN • Always be sure coolant is not hot before doing any work on cooler parts. R O TAT I N G FA N B L A D E S A R E HAZARDOUS •... -

Page 10: Coolant Connections

To replace the- ses hoses from Lincoln Electric ORDER (1) S18453- 19 (HOT) AND (1) S18453-20 (COLD). Hoses too long may be pinched when replacing the gas bottles and hoses too short may be damaged opening the cooler drawer. -

Page 11: Input Power Connection

INPUT POWER CONNECTION Plug the input power cord on the Under-Cooler cart into the standard bottom 115V NEMA circuit breaker protected receptacle, located on the back of the Precision TIG machine. Using this receptacle is taking advantage of the "cooler as needed" circuit incorporat- ed into the TIG machine and will prolong the life of the cooler. -

Page 12: Fastener Quick Reference

INSTALLATION FASTENER QUICK REFERENCE (FULL SCALE) SEE FIGURE A-2 Assembly for fastener placement. -12- -11- -10- CONNECTION OF TIG TORCHES Installation of TIG torches to be used with this Precision TIG Under-Cooler cart is explained in the Precision TIG machine literature. The torch does not directly attach to the cooler but through a connection box mounted on the TIG machine. -

Page 13: Operation

SAFETY PRECAUTIONS WARNING ELECTRIC SHOCK • Disconnect input power by remov- ing plug from receptacle before working inside Cooler. • Do operate removed. • Use only grounded receptacle. • Do not remove the power cord ground prong. • Do not touch electrically “hot” parts inside Cooler. -

Page 14: Turning The System On

TURNING THE SYSTEM "ON" CAUTION After connecting the Precision Tig and Tig Torches per Installation Section, plug the unit into a 115V NEMA electrical receptacle for start-up operation. Be certain that the power input into the unit matches the Cooler's rated input. The following should always be observed when operating the Under-Cooler Cart: •... -

Page 15: Maintenance

SAFETY PRECAUTIONS WARNING Have qualified personnel do the maintenance work. In some cases, it may be necessary to remove safety guards to perform required maintenance. Remove guards only when necessary and replace them when the mainte- nance requiring their removal is complete. Always use the greatest care when working near moving parts. -

Page 16: Reservoir Coolant Level

RESERVOIR COOLANT LEVEL The reservoir volume should be checked daily before using the cooler. Remove the reservoir fill cap and check the coolant level. The reservoir is full when the coolant level is just below the input elbow of the reser- voir (approximate. -

Page 17: Pump Inlet Filter

Disinfect the cooling system: • Prepare the disinfectant: Make a quantity of only is needed to avoid an excess. • Bulk preparation (for coolers serviced in quantity): 2.325 gals. (8.775 liters) of pure, fresh water per cooler 1.625 ml of additive per cooler •... -

Page 18: Additional Service Notes

Service the pump’s inlet strainer: a. Place absorbent towels underneath pump head to prevent stray coolant from wetting cooler’s electrical components. b. Hold pump head to apply counter torque when loos- ening strainers 7/8 acorn nut. Do not confuse with 3/4 acorn nut. -

Page 19: Troubleshooting

HOW TO USE TROUBLESHOOTING GUIDE Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual. - Page 20 Observe all Safety Guidelines detailed throughout this manual PROBLEMS (SYMPTOMS) Cooler does not operate Internal water leak. Torch or gun runs hot. Fan operates but there is low coolant flow. Fan operates but there is no coolant flow. Pump operates, but fan does not. If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

-

Page 21: Wiring Diagram

WIRING DIAGRAM UNDER-COOLER CART... - Page 22 DIAGRAM UNDER-COOLER CART...

-

Page 23: Dimension Print

DIMENSION PRINT UNDER-COOLER CART... - Page 24 NOTES UNDER-COOLER CART...

- Page 25 NOTES UNDER-COOLER CART...

- Page 26 NOTES UNDER-COOLER CART...

- Page 27 ● WARNING ● Spanish ● AVISO DE PRECAUCION ● French ● ATTENTION ● ● German WARNUNG ● Portuguese ● ATENÇÃO ● Japanese Chinese Korean Arabic ● ● ● ● ● ● ● ● ● ●...

- Page 28 ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● Spanish ● PRECAUCION French ● ATTENTION ● German WARNUNG Portuguese ● ● Japanese Chinese Korean Arabic WARNING AVISO DE ATENÇÃO...

- Page 29 • World's Leader in Welding and Cutting Products • • Sales and Service through Subsidiaries and Distributors Worldwide • Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com...

Need help?

Do you have a question about the IM723-A and is the answer not in the manual?

Questions and answers