Table of Contents

Advertisement

Quick Links

Models:

6000CF-OAK-IPI

6000CFLP-OAKIPI

•

Important operating

and maintenance

instructions included.

WARNING: If the information in these

instructions is not followed exactly, a fire

or explosion may result causing proper-

ty damage, personal injury, or death.

• Do not store or use gasoline or other flamma-

ble vapors and liquids in the vicinity of this or

any other appliance.

• What to do if you smell gas

- Do not try to light any appliance

- Do not touch any electrical switch. Do not

use any phone in your building.

- Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

- If you cannot reach your gas supplier, call

the fire department.

• Installation and service must be performed by

a qualified installer, service agency, or the gas

supplier.

This appliance may be installed as an OEM installation in

manufactured home (USA only) or mobile home and must

be installed in accordance with the manufacturer's instruc-

tions and the manufactured home construction and safety

standard, Title 24 CFR, Part 3280 or Standard for Installa-

tion in Mobile Homes, CAN/CSA Z240MH.

This appliance is only for use with the type(s) of gas indi-

cated on the rating plate.

CAUTION

DO NOT DISCARD THIS MANUAL

•

Read, understand and follow

these instructions for safe

installation and operation.

Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06

Owner's Manual

•

Leave this manual with

party responsible for

use and operation.

WARNING

HOT! DO NOT TOUCH.

SEVERE BURNS MAY RESULT.

CLOTHING IGNITION MAY RESULT.

Glass and other surfaces are hot during

operation and cool down.

• Keep children away.

• CAREFULLY SUPERVISE children in same room as

appliance.

• Alert children and adults to hazards of high

temperatures.

• Do NOT operate with protective barriers open or

removed.

• Keep clothing, furniture, draperies and other

combustibles away.

This appliance has been supplied with an integral barrier

to prevent direct contact with the fixed glass panel. Do

NOT operate the appliance with the barrier removed.

Contact your dealer or Hearth & Home Technologies if the

barrier is not present or help is needed to properly install one.

In the Commonwealth of Massachusetts:

• installation must be performed by a licensed plumber

or gas fitter;

• a CO detector shall be installed in the room where the

appliance is installed.

Installation and service of this appliance should be

performed by qualified personnel. Hearth & Home

Technologies suggests NFI certified or factory-trained

professionals, or technicians supervised

by an NFI certified professional.

Installation and Operation

1

Advertisement

Table of Contents

Summary of Contents for Heat&GloGlo 6000CF-OAK-IPI

- Page 1 Mobile Homes, CAN/CSA Z240MH. professionals, or technicians supervised This appliance is only for use with the type(s) of gas indi- by an NFI certified professional. cated on the rating plate. Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06...

- Page 2 Total Electrical Requirements: 000Vac, 00Hz., less than 00 Amperes IN CANADA Serial Number Model: XXXXXXXX ALTITUDE: 0-0000 FT. 0000-0000FT. (Modele): MAX. INPUT BTUH: 00,000 00,000 MIN. INPUT BTUH: 00,000 00,000 Serial XXXXXXXX ORIFICE SIZE: #XXXXX #XXXXX (Serie): Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06...

-

Page 3: Table Of Contents

C. Installing Heat Shield & Termination Cap . 25 D. Warranty ........... 53 D. Installing Roof Flashing and Vertical E. Contact Information ........54 Termination Cap ......... 26 = Contains updated information. Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... -

Page 4: Listing And Code Approvals

Heat & Glo Quality Systems and burn, whether flame proofed or not, or whether plastered registered by SGS ICS or unplastered shall be considered combustible materials. Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... -

Page 5: Getting Started

Safety glasses Level 1/2 - 3/4 inch length, #6 or #8 Self-drilling screws Manometer Voltmeter Tape measure Non-corrosive leak check solution One 1/4 inch female connection (for optional fan). Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... -

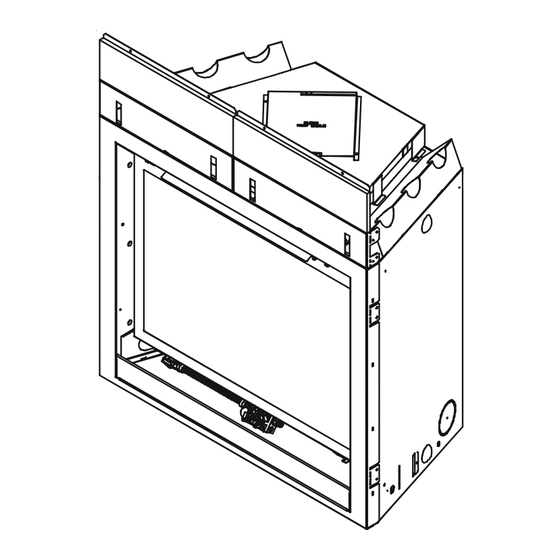

Page 6: Framing And Clearances A. Selecting Appliance Location

• Clearances and Mantel Projections (Section 3.C and 3.D) • Vent Clearances and Framing (Section 6). 38-7/8 Inches 1295 1295 1829 1067 1067 1067 Millimeters Figure 3.1 Appliance Locations Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... -

Page 7: Constructing The Appliance Chase

Sides of Opening Opening Opening Opening of Access to Ceiling Floor Flooring Appliance Appliance (Vent Pipe) (Height) (Depth) (Width) Panel Appliance 44-3/4 Inches 1137 1067 Figure 3.2 Clearances to Combustibles Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... -

Page 8: Mantel Projections

7-1/4 7-1/4 7-1/4 7-1/4 Figure 3.4 Clearances to Mantel Legs or Wall Projections (Acceptable on both sides of opening.) Figure 3.3 Clearances to Mantels or other Combustibles above Appliance Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... -

Page 9: Termination Locations

OIL TERMINATION 20 IN. (MINIMUM) TO PERPENDICULAR WALL (GAS ONLY) TERMINATION 18 IN. Gas Termination Wood & Fuel Oil Termination 6 in. 20 in. Figure 4.3 Multiple Vertical Termination Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... - Page 10 Figure 4.4 Minimum Clearances for Termination CAUTION: IF EXTERIOR WALLS ARE FINISHED WITH VINYL SIDING, IT IS SUGGESTED THAT A VINYL PROTECTOR KIT BE INSTALLED. Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06...

-

Page 11: Vent Information And Diagrams

3 to 6 pipe is allowed between two 45 elbows (see Figure 5.1). DVP12A 3 to 12 DVP12MI 3 to 12 DVP24MI 3 to 24 Figure 5.2 DVP Pipe Effective Length Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... -

Page 12: Vent Diagrams

1.8 m 4 ft 1.2 m 9 ft 2.7 m = 50 ft (15.2m) Maximum = 17 ft (5.2m) Maximum = 1-1/2 ft (457 mm) Minimum INSTALLED HORIZONTALLY Figure 5.4 Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... - Page 13 9 ft 2.7 m 6 ft 1.8 m 18 ft 5.5 m = 20 ft (6.1m) Max. = 50 ft (15.2m) Max. = 6 inches (152 mm) Min. Figure 5.5 Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06...

- Page 14 12 ft 3.7 m = 50 ft (15.2m) Max. *No specific restrictions on this value EXCEPT cannot exceed 50 ft (15.2m) = 6 inches (152 mm) Min. Figure 5.7 Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06...

- Page 15 1.2 m 12 ft 3.7 m 12 ft 3.7 m = 17 ft (5.2m) Maximum = 50 ft (15.2m) Maximum = 6 inches (152 mm) Minimum INSTALLED HORIZONTALLY Figure 5.8 Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06...

-

Page 16: Vent Clearances And Framing

4 inches. SCREW • Heat shield not required if distance is more than 4 inches. 3” (76mm) Figure 6.4 Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... -

Page 17: Wall Penetration Framing

Non-Combustible Wall Penetration If the hole being penetrated is surrounded by noncombusti- ble materials such as concrete, a hole with diameter one inch greater than the pipe is acceptable. Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... -

Page 18: Vertical Penetration Framing

• Field construct additional shield height if insulation is deeper than height of at- ATTIC SHIELD INSTALLED ATTIC SHIELD INSTALLED tic shield. ABOVE CEILING BELOW CEILING Figure 6.8 Installing the Attic Shield Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... -

Page 19: Appliance Preparation

The sheetrock ledges will attach to the top of the unit (see Figure 7.2). LOWER ACCESS PANEL Figure 7.3 SEE DETAIL B DETAIL B SHEETROCK UNIT LEDGE SURROUND CLEARANCE SLOT ATTACHMENT HOLES 6 PLACES Figure 7.2 Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... -

Page 20: Securing And Leveling The Appliance

• Do NOT notch into the framing around the appliance spacers. Failure to keep insulation, framing or other material away from the appliance may cause fire. Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... -

Page 21: Installing Flue Restrictor

Flue Restrictor FIBERGLASS (see Figure 7.7). GASKET - CHART - Top Vent Top Vent Vertical OUTERWRAP Restrictor Figure 7.9 Fiberglass Gasket Figure 7.7 Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... -

Page 22: Installing Vent Pipe

Use screws no longer than 1 inch. If predrilling screw holes, do NOT penetrate inner pipe. Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... - Page 23 If the slip section is too long, the inner and outer flues of the slip section can be cut to the desired length. Figure 8.7 Screws into Slip Section Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06...

-

Page 24: Disassembly Of Vent Sections

• Maintain all clearances to combustibles. • Do NOT allow vent to sag below connection point to appliance. Improper support may allow vent to sag or separate. Figure 8.11 Align and Disassemble Vent Sections Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... - Page 25 NOTE: Where required, an exterior wall flashing is it from the pipe section (see Figure 8.12). available. When penetrating a brick wall, a brick extension kit is available for framing the brick. Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06...

-

Page 26: Installing Roof Flashing And Vertical Termination Cap

Fire Risk. Explosion Risk. Inspect external vent cap regularly. • Ensure no debris blocks cap. • Combustible materials blocking cap may ignite. • Restricted air flow affects burner operation. Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... - Page 27 Slide the assembled storm collar down the pipe section until it rests on the roof flashing. Caulk around the top of the storm collar (see Figure 8.14). Figure 8.15 Assembling the Storm Collar Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06...

-

Page 28: Gas Information

Natural Gas Propane Minimum 5.0 inches 11.0 inches Inlet Pressure w.c. w.c. Maximum Inlet 14.0 inches 14.0 inches Gas Pressure w.c. w.c. Manifold 3.5 inches 10.0 inches Pressure w.c. w.c. Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... - Page 29 Fire hazard. Do NOT change the valve settings. • This valve has been preset at the factory. • Changing valve settings may result in fire hazard or bodily injury. Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06...

-

Page 30: Electrical Information

20 AWG through 14 AWG is acceptable. The wire needs a jacket with a temperature rating of 140 F (60 or higher. At the appliance connect the wire to the ON/OFF switch pigtails. Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... - Page 31 ON/OFF SWITCH NEUTRAL SIDE ON THE HOT SIDE TRANSFORMER 3 VAC PLUG IN VALVE *Note: Appliance will not operate unless properly grounded. Figure 10.1 Intellifire Pilot Ignition (IPI) Wiring Diagram Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06...

-

Page 32: Junction Box Installation

Figure 10.3 Junction Box Wired to Wall Switch face of the junction box, and connect to the top fan switch connector (1/4 inch male) as shown. Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... -

Page 33: Finishing

300 F minimum sealant. • Overhanging materials may ignite. • May interfere with proper operation of glass assembly. Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... -

Page 34: Appliance Setup

8 - Disconnect fan and remove it through the valve assem- bly cavity (see Figure 12.2). RHEOSTAT REMOVE FAN THROUGH VALVE ASSEMBLY CAVITY Figure 12.2 Figure 12.3 Rheostat Location Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... -

Page 35: Install The Refractory

Use this material to give the appliance a realistic ash bed. • Save the remaining ember materials for use during ap- pliance servicing. The embers provided should be enough for 3 to 5 applications. Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... -

Page 36: Positioning The Logs

LOG #2 (SRV385-724): Place this log so that the notches on the bottom of the log line up with the grate bars and slide it into the firebox until it hits the hump on the burner. 383-935B Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... - Page 37 LOG #5 (SRV385-722): Place this log so that the notch in the underside of this log is positioned onto the right grate bar, even with the grate leg. Swing the top portion of the log so it will rest on the dent of log #4. Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06...

-

Page 38: Glass Assembly

When finished tighten wing nut. LATCHES (BOTH BOTTOM AND TOP) GLASS ASSEMBLY Figure 12.16 Glass Assembly AIR SHUTTER WING NUT Figure 12.17 Shutter Settings Burner 1/8 in. 5/8 in. Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... -

Page 39: Operating Instructions

• Glass replacement should be done by qualified the appliance and to replace any part of the control system technician. and any gas control which has been under water. Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... -

Page 40: Lighting Appliance

For additional information on operating your Hearth & Home Technologies fireplace, please refer to www.fireplaces.com. Final Inspection by 593-913D _________________________________ Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... -

Page 41: After Appliance Is Lit

In an Intellifire ignition system it is normal to see the pilot flame, but it should turn off burn continually? when ON/OFF is turned off. In a standing pilot system the pilot will always stay on. Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... -

Page 42: Troubleshooting

The sensor rod may be contaminated. Clean sensor rod with emery cloth. c. Module is not Verify that module is securely grounded to metal chassis of appliance. Verify grounded. that wire harness is firmly connected to module. Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... - Page 43 5. Pilot will not stay a. Pilot plate out of Ensure pilot plate is in proper postion (see Section 7). lit after carefully position. following lighting instructions. Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06...

-

Page 44: Maintaining And Servicing Appliance

• Restricted air flow affects burner operation. control compartment • Burner, burner ports Risk of: • Fire • Delayed ignition or explosion • Exposure to combustion fumes • Odors Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... - Page 45 1. Verify operation of remote. 2. Replace batteries in remote transmitters and battery-powered receivers. 3. Verify batteries have been removed from battery back-up IPI systems to prevent premature battery failure or leaking. Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06...

-

Page 46: Appliance Dimension Diagram

GAS LINE ELECTRICAL ACCESS ACCESS 28-1/2 14-1/4 21-1/2 12-7/8 6-7/8 2-1/8 21-1/2 32-1/4 36-1/8 41-1/8 44-3/4 2-1/4 48-1/2 Inches Millimeters 1045 1137 127 1232 Figure 16. 1 Appliance Dimensions Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... -

Page 47: Vent Components Diagrams

DVP-FS (Ceiling Firestop) DVP-WS (Wall Shield Firestop) 10 in. 1-1/2 in. 10 in. 24 in. 12 in. 5 in. DVP-HVS (Vent Support) DVP-AS (Attic Shield) Figure 16.2 DVP vent components Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... - Page 48 Wall Shield Firestop DVP-TRAP2 Wall Shield Firestop DVP-TRAP1 DVP90ST DVP90ST Heat Shield Heat Shield DVP-TRAPK2 DVP-TRAPK1 Horizontal Termination Cap Kit Horizontal Termination Cap Kit Figure 16.3 DVP vent components Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06...

- Page 49 12-1/8 in. 7-1/8 in. 14 in. 5-3/4 in. DRC-RADIUS COOL-ADD Cap Shield Cap Shield (For use on Intellifire appliances only) PVK-80 Figure 16. 4 DVP vent components Power Vent Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06...

-

Page 50: Service Parts

3. HEAT & GLO reserves the right to make c h anges at any time, without notice, in design, material, speci fications and prices of the Product. HEAT & GLO also reserves the right to discontinue styles and products. © 2005 Hearth & Home Technologies Inc. 060-981D 3/05 Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06... -

Page 51: Contact Information

6875012, 6880275, 6908039, 6919884, D320652, D445174, D462436; (Canada) 1297749, 2195264, 2225408, 2313972; (Australia) 780250, 780403, 1418504 or other U.S. and foreign patents pending. Printed in U.S.A. - Copyright 2006 Heat & Glo • 6000CF-OAK-IPI • 2092-900 Rev. I • 1/06...

Need help?

Do you have a question about the 6000CF-OAK-IPI and is the answer not in the manual?

Questions and answers