Table of Contents

Advertisement

Quick Links

1/09/2008

®

VISIT THE LIFETIME WEB SITE:

WWW.LIFETIME.COM

**U.S. Canada and UK customers ONLY**

IF ASSISTANCE IS NEEDED,

DO NOT CONTACT THE STORE!

US and Canada customers call our customer service department at

1 (800) 225-3865

HOURS: 7:00 a.m. to 5:00 p.m. Monday through Friday (Mountain Standard Time)

UK customers call 01992 450333

**Call, or visit our Web site for Saturday hours**

**For customers outside the U.S., Canada, or UK, please contact the store for

assistance.**

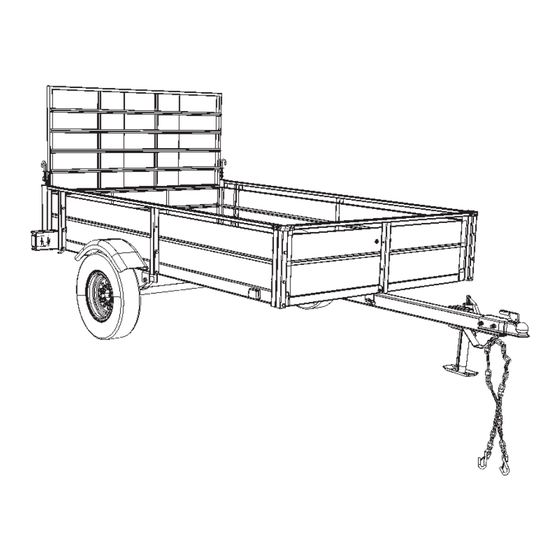

Metal Utility Trailer

MODEL #65004

User's Manual and Maintenance Guide

Warning: For safe operation of this trailer, be sure to read all

instructions and warnings. Failure to follow instructions and

warnings could result in property damage, serious injury and death.

Instruction #1029777 E

1

Advertisement

Table of Contents

Summary of Contents for Lifetime 65004

- Page 1 1/09/2008 ® VISIT THE LIFETIME WEB SITE: WWW.LIFETIME.COM **U.S. Canada and UK customers ONLY** IF ASSISTANCE IS NEEDED, DO NOT CONTACT THE STORE! US and Canada customers call our customer service department at 1 (800) 225-3865 HOURS: 7:00 a.m. to 5:00 p.m. Monday through Friday (Mountain Standard Time)

- Page 2 You could win $200! Register your product at www.lifetime.com and receive three important 1. You automatically will be entered to win $200 in our monthly drawing! immediately and directly. 3. You may choose to receive Preferred Customer Announcements and promotions regarding new Lifetime products.

- Page 3 Lifetime Products. You can also obtain other information about motor vehicle safety from http://www. safercar.gov. Lifetime Products, inc. Metal Utility Trailer Model 65004 WARNING precautions and instructions. Lifetime Products, Inc.

-

Page 4: Table Of Contents

Table of Contents SECTION 1: SAFETY INFORMATION SECTION 2: TRAILER PARTS & HARDWARE SECTION 3: PRE-TAKE-HOME ASSEMBLY SECTION 4: TRAILER ASSEMBLY 4.1 Secure Tongue 4.2 Attach Rear Floor Extension 4.3 Attach Front Panel 4.4 Attach Side Panels 4.5 Attach Rear Side Extension Panels 4.6 Attach Corner Guards 4.7 Attach Rear Gate 4.8 Attach State License Plate... - Page 5 7.4.11.2 Tire Safety Checklist 7.5 Changing a Flat Tire 7.6 Checking the Tire Pressure SECTION 8: LOADING THE TRAILER 8.1. Checking the Tongue Weight 8.1.1 Checking Tongue Weight — Using a lever and bathroom scale 8.2 Securing the Cargo 8.2.1 Loading Cargo 8.2.1.1 Preparing the Trailer for Loading 8.2.1.2 Loading the Trailer SECTION 9: CHECK TRAILER BEFORE &...

- Page 6 This Page Intentionally Left Blank...

-

Page 7: Section 1: Safety Information

Hazards or unsafe practices which COULD result in severe personal injury or death if the warning is ignored. Hazards or unsafe practices which could result in minor or moderate injury if the warning is ignored. Lifetime Products, Inc. or call... - Page 8 Lug Nuts and Tire Pressure WARNING Tire, wheel or lug nut failure can cause loss of control. Before towing, you must CHECK: 1. Tire pressure and tread. 2. Tires and wheels for damage. 3. Lug nuts for tightness. For new and remounted wheels, 10, 25 and 50 miles of driving.

- Page 9 Coupler, Load Weight and Distribution and Electrical Connections WARNING ADVERTENCIA Uncoupling will cause trailer to come loose from tow vehicle. You must: Attach hooks to tow vehicle Open Sujetar los ganchos al vehículo remolcador Abierto 1. CHECK that ball load rating is same or greater than coupler load rating. 2.

- Page 10 Always check tire pressure to ensure optimum life and performance from your tires. The tires that came with your trailer should have a tire pressure of 80 psi. Lifetime Products cannot be held responsible for damages caused by uneven tread wear and...

-

Page 11: Parts List

SECTION 2: TRAILER PARTS & HARDWARE Part # 1013280 1013282 1013252 1013274 1016242 Parts Bag (1024674) 1012273 Hardware Bag (1018013) Hardware Bag (1018014) Hardware Bag (1018015) Hardware Bag (1022647) TOOLS NEEDED (NOT INCLUDED) 1. Electric Drill 3. #2 Phillips Bit 6. -

Page 12: Hardware Identifier

HARDWARE IDENTIFIER the trailer. Call Lifetime Products at the number on the cover of this manual. Note: The hardware are in clear plastic bags within the plastic bag labeled *Note: Parts are actual size unless noted otherwise. (24) *Not to Scale... - Page 13 *AC (Right) *AD (Left) *AB (Right) *AI (Left)

-

Page 14: Section 3: Pre-Take-Home Assembly

PRE-TAKE-HOME ASSEMBLY Hardware Provided: Not actual size **At Least 2 Adults Required for the Following Steps** the tongue out and lock it in place before attaching the trailer to your tow vehicle. Note: If you’ve already towed your new trailer home, skip to the section “Trailer 3.1. - Page 15 • Lug nuts for the tires must be tightened by the user before each use. • Lifetime Products cannot be held responsible for damages caused by loosened lug nuts. • Before towing the Trailer, you must ensure the lug nuts are tightened to the proper torque.

- Page 16 Improper rigging of the safety chains can result in loss of control of the trailer and the tow vehicle, leading to death or serious injury, if the trailer uncouples from the tow vehicle. • Fasten chains to frame of tow vehicle. Do not fasten chain to any part of the •...

- Page 17 From Trailer Check the connection periodically to ensure tail and break lights function properly. Failure to follow this warning could result in property damage, serious personal injury and death. Note: Connecting Temporary License Plate If your state requires a temporary license on your trailer, secure the license to the license plate holder located on the left blinker before towing your trailer home.

-

Page 18: Section 4: Trailer Assembly

TRAILER ASSEMBLY Hardware Used: *AK (2) *Not actual size **At Least 2 ADULTS Required for the Following Steps** home. Refer to the section “P 4.1 Secure Tongue 4.1.1 Chock the Tires, front and rear, with bricks or wooden blocks. 4.1.2 the Bolts (AL) and Tongue (AA) in place. - Page 19 4.1.3 Replace the Cotter Keys 1/2”-13 Nylock Nuts (BH) to secure the Tongue in place. Discard Cotter Keys. Use upper hole...

-

Page 20: Attach Rear Floor Extension

Hardware Needed: Rubber Mallet Utility Knife **At Least Two ADULTS Required for Assembly** Before beginning this step, use a Utility Knife to cut the banding around Trailer. Important: carefully remove all loose parts from the bed of the Trailer. Inventory all parts and hardware to ensure you received all necessary pieces. - Page 21 4.2.3 Extension to the back of the Trailer Bed (BC) 3/8”-16 Nylock Nuts (BF). Note: If necessary, after aligning the holes gently tap the Bolt with a Rubber Mallet or Hammer to help pass the Bolts through the holes. DO NOT COMPLETELY TIGHTEN THE NYLOCK NUTS YET.

-

Page 22: Attach Front Panel

4.3 Attach Front Panel 4.3.1 Front Panel (AE) down between the two front Center Support Brackets of the Trailer Bed. WARNING: Watch for pinch points as serious injury could occur. Center Support Brackets Center Support... - Page 23 Hardware Needed: Rubber Mallet 4.3.2 3/8”-16 x 2 1/2” Hex Bolt (BB) (BF). Note: If necessary, after aligning the holes gently tap the Bolt with a Rubber Mallet or Hammer to help pass it through the holes. DO NOT COMPLETELY TIGHTEN THE NYLOCK NUTS YET.

-

Page 24: Attach Side Panels

4.4 Attach Side Panels 4.4.1 Left Side Panel (AI) WARNING: Watch for pinch points as serious injury could occur. Center Post Note: Lifetime logo goes towards the front of the Trailer. Brackets... - Page 25 Hardware Needed: Rubber Mallet Hardware Bag: 1022647 Hardware Bag: 1018015 4.4.2 3/8”-16 x 3 3/4” Hex Bolts (BE) 3/8”-16 Nylock Nuts (BF). 4.4.3 3/8”-16 x 2 1/2” Hex Bolts (BB) Nuts (BF). 4.4.4 Repeat steps 4.4.1 - 4.4.3 Note: If necessary, after aligning the holes gently tap the Bolts with a Rubber Mallet or Hammer to help pass them through the holes.

-

Page 26: Attach Rear Side Extension Panels

Hardware Needed: Hardware Bag: 1018014 Rubber Mallet 4.5 Attach Rear Side Extension Panels 4.5.1 Guard Rail Sleeve (BI) Left Rear Side Extension (AC) down into position, insert one Parts Bag: 1024674... - Page 27 4.5.2 Left Rear Side Extension Panel (AB) to the Bed Extension using 3/8”-16 x 2 3/4” Hex Bolts (BC) Note: If necessary, after aligning the holes gently tap the Bolts with a Rubber Mallet or Hammer to help pass them through the holes. WARNING: Watch for pinch points as serious injury could occur.

- Page 28 Hardware Needed: Rubber Mallet Hardware Bag: 1022647 4.5.3 Flat Washer (BD) Note: If necessary, after aligning the holes gently tap the Bolts with a Rubber Mallet or Hammer to help pass them through the holes. WARNING: Watch for pinch points as serious injury could occur.

- Page 29 Hardware Needed: Parts Bag: 1024674 4.5.4 Right Rear Side Extension Panel (AD) down into position, Guard Rail Sleeve (BI) WARNING: Watch for pinch points as serious injury could occur. DO NOT COMPLETELY TIGHTEN THE NYLOCK NUTS YET.

- Page 30 Hardware Needed: Rubber Mallet 4.5.5 3/8”-16 x 2 3/4” Hex Bolts (BC) Note: If necessary, after aligning the holes gently tap the Bolts with a Rubber Mallet or Hammer to help pass them through the holes. WARNING: Watch for pinch points as serious injury could occur.

- Page 31 Hardware Needed: Rubber Mallet Hardware Bag: 1022647 4.5.6 (BB) 3/8” Flat Washer (BD) Note: If necessary, after aligning the holes gently tap the Bolts with a Rubber Mallet or Hammer to help pass them through the holes. 4.5.7 Tighten all hardware from steps 4.2.3 - 4.5.6, but do not overtighten. Remember: Tighten all hardware before proceeding to the next step, but do not overtighten.

-

Page 32: Attach Corner Guards

Hardware Needed: 4.6 Attach Corner Guards Important: If you have not tightened all hardware, do so before beginning this step, but do not overtighten. 4.6.1 Corner Guard (BA) in place on the corner of the Front and Side Panels. Drill an 1/8” Pilot hole through the holes in the Corner Guard and into the Panels. -

Page 33: Attach Rear Gate

**Two People Required for These Steps** The trailer gate must be locked down during use and during stor age. Failure to lock gate securely could allow gate to open un expectedly resulting in serious property damage, personal injury and death. 4.7 Attach Tailgate 4.7.1 Lay Tailgate (AF) on the ground behind the trailer and lift bottom end up to wards the trailer as shown. - Page 34 4.7.2 Tailgate Sleeve over the Pin as shown. 4.7.3 Pull back on the right Pin and insert the Pin into the Sleeve. WARNING: Watch for pinch points as serious injury could occur. Sleeve 4.7.4 Rotate the Tailgate (AF) upwards to a vertical position and secure in place with the two Pins as shown.

-

Page 35: Attach State License Plate

4.8 Attach State License Plate 4.8.1 If your state requires a license plate on your trailer, bolt the license plate to the license plate holder located below the left blinker. Note: For all inquiries regarding trailer title and registration, please contact your towed must be tied to the side walls of the Trailer. -

Page 36: Section 5: Trailer Features

SECTION 5: TRAILER The trailer gate must be locked down during use and during stor age. Failure to lock gate securely could allow gate to open un expectedly resulting in serious property damage, personal injury and death. 5.1 Using Two-Way Tailgate 5.1.1 To open the Tailgate like a door, pull back on the Pins located on the right side of the gate and swing the door open. - Page 37 5.2 To lower the tailgate to a ramp position, pull up on the upper Pins located on both WARNING: Watch for pinch points as serious injury could occur. Do not play or hang on tailgate. If not secured properly, tailgate could open suddenly or fall.

- Page 38 5.3 USING THE TONGUE JACK 5.3.1 Pull the Locking Pin Locking Pin 5.3.2 Rotate Tongue Jack down to a vertical position and lock into place with Lock- ing Pin. Locking Pin...

- Page 39 5.3.3 Rotate Jack Handle Tongue. WARNING...

-

Page 40: Section 6: Coupling To The Tow Vehicle

SECTION 6: COUPLING TO THE TOW VEHICLE ATTACHING THE TRAILER TO YOUR VEHICLE You must follow all of the safety precautions and instructions in this manual to ensure safety of persons, cargo, and satisfactory life of the trailer. 6.1 Warning: Using an Adequate Tow Vehicle and Hitch death or serious injury. -

Page 41: Before Coupling The Trailer To The Tow Vehicle

Also, the ball size must be the same as the coupler size. If the hitch ball is too small, too large, is underrated, is loose or is worn, the trailer can come loose from the tow vehicle, and may cause death or serious injury. CAPACITY EQUAL TO OR GREATER THAN THE TRAILER marked on the hitch. -

Page 42: Rigging The Safety Chains

If the coupler cannot be secured to the hitch ball, do not tow the trailer. Call Lifetime Products at 1-800-225-3865 or your dealer for assistance. • Lower the trailer so that its entire tongue weight is held by the hitch. Push the safety latch downward to a horizontal position to lock it in place. -

Page 43: Connecting The Electrical Cables

Improper rigging of the safety chains can result in loss of control of the trailer and the tow vehicle, leading to death or serious injury, if the trailer uncouples from the tow vehicle. • Fasten chains to frame of tow vehicle. Do not fasten chains to any part of the hitch unless the hitch has holes or loops •... -

Page 44: Uncoupling The Trailer

From Trailer From Trailer Check the connection periodically to ensure tail and break lights function properly. Failure to follow this warning could result in property damage, personal injury and death. 6.2.1.6 Uncoupling the Trailer Follow these steps to uncouple your ball hitch trailer from the tow vehicle: 1. -

Page 45: Section 7: Tire & Safety Information

SECTION 7: TIRE & SAFETY INFORMATION CHECKING & CHANGING TIRES 7.1 Determining Correct Load Limit – Trailer 7.1.1 Trailers 10,000 Pounds GVWR or Less 3. Determine the combined weight of luggage and cargo being loaded on the vehicle. That weight may not safely exceed the available cargo and luggage load capacity. - Page 46 Carcass: bears the load. Chunking: The breaking away of pieces of the tread or sidewall. The pressure in the tire before you drive. Cord: The strands forming the plies in the tire. Cord separation: The parting of cords from adjacent rubber compounds. Cracking: Any parting within the tread, sidewall, or inner liner of the tire extending to cord material.

- Page 47 the roadway to the vehicle, generates the tractive forces that provide the directional providing those functions. Non-pneumatic tire assembly: a wheel or wheel center member, which can be mounted on a vehicle. Normal occupant weight: Occupant distribution: the third column of Table I of 49 CFR 571.110. Open splice: Any parting at any junction of tread, sidewall, or inner liner that extends to cord material.

-

Page 48: Tire Safety - Everything Rides On It

appropriate for use with that tire. Tread: That portion of a tire that comes into contact with the road. Tread rib: A tread section running circumferentially around a tire. Tread separation: Pulling away of the tread from the tire carcass. Tread-wear indicators (TWI): The projections within the principal grooves designed to give a visual indication of the degrees of wear of the tread. -

Page 49: Basic Tire Maintenance

• Fundamental characteristics of tires • Tire safety tips. Use this information to make tire safety a regular part of your vehicle maintenance routine. Recognize that the time you spend is minimal compared with the and other types of tire failure, you should maintain proper tire pressure, observe tire and vehicle load limits, avoid road hazards, and regularly inspect your tires. -

Page 50: Checking Tire Pressure

put in the tire under normal driving conditions. 7.4.4 Checking tire pressure It is important to check your vehicle’s tire pressure at least once a month for the following reasons: • Most tires may naturally lose air over time. • Tires can lose air suddenly if you drive over a pothole or other object or if you strike the curb when parking. -

Page 51: Tire Tread

original tires or another size recommended by the manufacturer. Look at the tire information placard, the owner’s manual, or the sidewall of the tire you are choose, consult with the tire dealer. 7.4.7 Tire tread The tire tread provides the gripping action and traction that prevent your vehicle from slipping or sliding, especially when the road is wet or icy. - Page 52 Ratio of height to width (aspect ratio) Nominal width of tire in millimeters Passenger car tire Max. permissable pressure Treadwear, traction and temperature grades Next number: from sidewall edge to sidewall edge. In general, the larger the number, the wider the tire.

-

Page 53: Utqgs Information

federal standards. The next two numbers or letters are the plant code where it was manufactured, and the last four numbers represent the week and year the tire was built. For example, the numbers 3197 means the 31st week of 1997. The other numbers are marketing codes used at the manufacturer’s discretion. -

Page 54: Additional Information On Light Truck Tires

Tires for light trucks have other markings besides those found on the sidewalls of passenger tires. Max. Load Dual kg (lb) at kPa (psi) Cold: This information indicates the maximum load and tire pressure when the tire is used as a dual, that is, when four Max. - Page 55 7.5.4 Place a Tire Jack 7.5.5 7.5.6...

- Page 56 Lug nuts for the tires must be tightened by the user before each use. Lifetime Products cannot be held responsible for damages caused by loosened lug nuts. WARNING WARNING...

-

Page 57: Checking The Tire Pressure

The tires that came with your trailer should have a tire pressure of 80 psi. Lifetime Products cannot be held responsible for damages caused by uneven tread wear and blow outs from an WARNING 80 psi. -

Page 58: Section 8: Loading The Trailer

SECTION 8: LOADING THE Improper trailer loading causes many accidents and deaths. To safely load a trailer, you must consider: To determine that you have loaded the trailer within its rating, you must consider the distribution of weight, as well as the total weight of the trailer and its contents. The trailer axles carry most of the total weight of the trailer and its contents (Gross vehicle hitch. - Page 59 tongue exerts an upward pull on the hitch, instead of pushing down on it (because lose traction or grip and cause loss of control. Also, even if there is some weight on the tongue, but not enough weight on the tongue, the trailer can suddenly become unstable at high speeds.

-

Page 60: Checking The Tongue Weight

8.1. Checking the Tongue Weight To check the tongue weight, the tow vehicle and trailer must be on level ground, as they will be when the trailer is being towed. If you know the weight on your tow vehicle’s axles when you are not towing a trailer, trailer tongue weight can be determined with the use of a truck axle scale. -

Page 61: Preparing The Trailer For Loading

motorcycle, etc. may be carried on your open trailer. dangerous materials in your trailer. Failure to heed this warning could result in property damage, serious injury and death. Exceptions: • Fuel in the tanks of vehicles that are being towed •... - Page 62 that it does not shift while the trailer is being towed. Load can suddenly move or topple, which can result in death or serious injury. Do not load or unload your open trailer unless it is prevented not move during transit. lead to death or serious injury.

-

Page 63: Section 9: Check Trailer Before & During Towing

SECTION 9: CHECK TRAILER BEFORE & DURING TOWING 9.1 Before Towing, Double Check All These Items: • Tires, wheels and lug nuts (see the section “Breaking in New Trailer“ and the • Cargo properly loaded, balanced and tied down (see the section “Loading the •... - Page 64 The tires must be maintained at the proper tire pressure before each use. Lifetime cannot be held responsible for damages caused by loosened lug nuts, or uneven tread wear and blow outs Failure to heed these warnings could result in personal injury, property damage and death.

-

Page 65: Section 10: Breaking In Anew Trailer

The lug nuts for the tires must be tightened by the user before each use. The tires must be maintained at the proper tire pres sure before each use. Lifetime cannot be held responsible for damages caused by loosened lug nuts, or uneven tread wear and Failure to heed this warning could result in property damage, serious injury and death. -

Page 66: Section 11: Maintenance

SECTION 11: MAINTENANCE INSPECTION, SERVICE & MAINTENANCE 11.1 Inspection, Service & Maintenance Summary Charts You must inspect, maintain and service your trailer regularly to insure safe and reliable operation. If you cannot or are unsure how to perform the items listed here, have your dealer do them. -

Page 67: Inspection And Service Instructions

Inspection and Service each 6 Months or 6,000 Miles Inspection and Service Each Year or 12,000 Miles Item • Frame members • Axle Attachment Bolts 11.2 Inspection and Service Instructions 11.2.1 Axle Bolts, Frame, Suspension, & Structure property damage, serious injury and death may result. Have trail er professionally inspected annually and after any impact. -

Page 68: Trailer Structure

11.2.2 Trailer Structure the trailer after each use. 11.2.2.1 Fasteners and Frame Members Inspect all of the fasteners and structural frame members for bending and other damage, cracks, or failure. Repair or replace any damaged fastener and repair the frame member. If you have any questions about the condition or method of repair of fasteners or frame members, get the recommendation of, or have the repair done by, your dealer. -

Page 69: Trailer Connection To Tow Vehicle

inspect the welds and fasteners for damage. To prevent severe damage to your trailer, inspect all of the welds for cracks or failure at least once a year. Improper weld repair will lead to early failure of the trailer struc ture and can cause serious injury or death. -

Page 70: Tires

11.2.6 Tires Before each tow, be sure the tire pressure is at the value indicated on the sidewall. Tire pressure must be checked while the tire is cold. Do not check the tire pressure immediately after towing the trailer. Allow at least three hours for a tire to cool, if the trailer has been towed for as much as one mile. -

Page 71: Lug Nuts (Bolts)

bearings. • After removing the grease cap, cotter pin, spindle nut and spindle washer, remove the hub and drum to inspect the bearings for wear and damage. pitting. Always replace bearings and cups in sets. The inner and outer bearings are to be replaced at the same time. - Page 72 Figure 11 - 2: Lug nut sequence of tightening Tighten the lug nuts to the proper torque for the axle size on your trailer, to prevent wheels from coming loose. Use a torque wrench to tighten the fasteners. If you do not have a torque wrench, tighten the fasteners with a lug wrench as much as you can, then have a service garage or dealer tighten the lug nuts to the proper torque.

- Page 73 Notes:...

- Page 74 Notes:...

-

Page 75: Section 12: Warranty Information

Lifetime Products, Inc. reserves the right to make substitutions to warranty claims if parts are unavailable or obsolete. 1. Lifetime utility trailers are warranted to the original purchaser to be free from de fects in material and workmanship for a period of two years from the date of origi use of the product. - Page 76 ALL TRAILER WARRANTY CLAIMS MUST BE ACCOMPANIED BY A SALES RECEIPT. REPORT PRODUCT DEFECTS IN WRITING TO: FOR TIRE WARRANTY CLAIMS REFER TO TIRE MANUFACTURER’S BROCHURE...

Need help?

Do you have a question about the 65004 and is the answer not in the manual?

Questions and answers