Advertisement

Quick Links

Advertisement

Summary of Contents for Niko Caterpillar HY 60

- Page 1 Operating instructions Caterpillar HY 60...

- Page 2 Foreword Dear customer, We would like to thank you for your confidence in purchasing a NIKO-product and we would like to assure you, that we have done the best to deliver you an efficient and reliable product. We kindly ask you to read this operating instruction as well as to observe all other instructions before starting the machine.

-

Page 3: Table Of Contents

Contents • Product description • EG-Conformity Declaration • General safety instructions • Transport • Installation • Operation • Help with breakdowns • Maintenance • Warranty... -

Page 4: Product Description

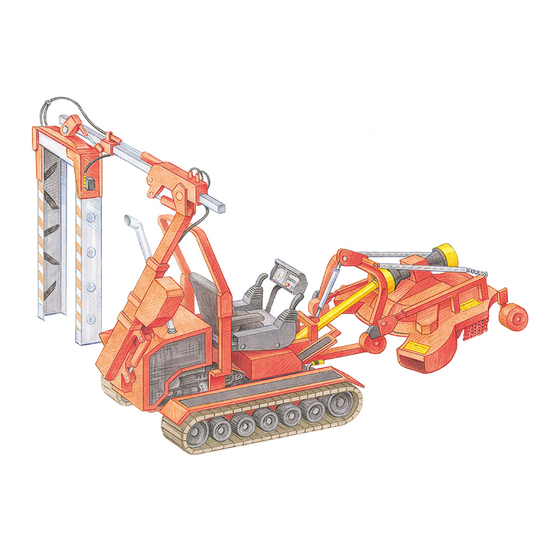

The hydrostatic caterpillar HY 60 is only affected for riding in pathless and steeply terrain. The caterpillar may not be driven in the ambit of the StVZO (in the open road traffic). - Page 5 2. Construction...

- Page 6 3. Functional description The NIKO caterpillar HY 60 is a equipment rack especially designed for driving in steeply and pathless terrain. Several accessory equipments can be attached on the basic device as well as rear or front extension. The caterpillar is equiped with a 4 cylinder diesel engine. This engine powers a total of two axial piston pumps and two geared pumps.

-

Page 7: Eg-Conformity Declaration

EG-Conformity Declaration according to II A of EG- machines guidelines (89/392/EWG) NIKO Maschinen- & Fahrzeugbau The manufacturer: Im Mühlgut 1 D-77815 Bühl-Weitenung Germany declares that the machine described as Caterpillar HY 60 follows: Complies with the safety and health EG-Maschine Guideline 89/392/EWG... - Page 8 General Safety Information 1. Care of the operator and general safety measures The caterpillar HY 60 were constructed and manufactured according to an endangerment analysis after careful selection of harmonized norms to be observed, as well as further technical specifications. It fulfils state of the art requirements and ensures a maximum of safety.

- Page 9 The driving speed must be always adapted to the environmental conditions Attend on the overhang and the oscillating weight of the machine while driving curves with attached or positioned equipment! Protect the caterpillar by leaving the machine against scrolling, switch off the engine (By the use of switching off the engine, the hydraulic brake will be activated.) detract the ignition key While the engine is in use, do not leave the caterpillar uncontrolled...

-

Page 10: Transport

Transport The caterpillar HY 60 can be shipped by means of a fork-lift truck or by shipping planks on trailer, truck etc. Consider dimensions and weight of the crawler-type vehicle. Secure the caterpillar by bands on means of transport. As points of notice for this the draft links of the three point linkage at front and tail serve. -

Page 11: Installation

The caterpillar HY 60 is completely installed and handed over with all fuels filled (for reasons of security in the case of transport only little Diesel is filled in). Nevertheless the filling conditions in engine and hydraulic system should be examined the first start, as well as later ago in regular intervals. -

Page 12: Operation

Operation The job of the driver of the caterpillar is excluding the driver's seat. Pay attention to it that no persons are in the danger area of the caterpillar and their attachments. 1. Start the caterpillar - Press the locking button (activate the brake and switch the Joystick off). - If you ascend, you sat down and you adjust the driver's seat with the help of the lever at the front of the seat. - Page 13 Speed indicator Fuel gage Switching button for speed indicator Fuse box engine - temperature ignition Switch Test port Additonal control function Brake light Working hydraulic pump On - Out Joystick - turnaround Power take-off On-Out Attention: Power take-off 540 U/min = Engine speed 1850 U/min!!! Operation of the instrument panel: At the instrument panel are all important function announcements and switching functions of the caterpillar.

- Page 14 Temperature indicator of the motor: Shows the working temperature of the diesel engine (Please pay attention to the manufacturers` instructions in the provided manual book!!!) By excessive temperature you should first check, if the radiator is free of smutt!!! Power take-off: This is operarted electrically over the lever key (white).

- Page 15 Drive joystick – change of direction: Switch for speed function Joystick solenoid with disk If the seat will be turned the activity of the joystick should also be assimilated with the driving direction. To turn the seat, you have to work out the clamp bolt at the black rotating assembly. Therefore push the red lever key.

- Page 16 2. Driving with the caterpillar -Arise the rotation speed through operating the throttle lever a little bit. -Push the joystick in the direction you would like to drive. - You can determine the driving speed by switching the button for the speed control to position "1".

- Page 17 Working Joystick: Release guider Red function lamp Switching Guider function Shift button 1. If the red functions lamp is activated, she is in the first section. By opearting the joystick forwards and backwards the guider raises or drops. The green hydraulic clutches are activ by operating left or right. Attention: Through operating the brown switch on the cockpit an extra control function is activated in the first joystick level.

- Page 18 3. Put down and leaving the caterpillar Lower the accessory equipment completely via joystick For turning the caterpillar of lower the rotational speed via hand throttle lever on “condition gas” Push the Stop-button above for activating the wedging brake and to switch of the joystick Turn the ignition key left against clockwise (into vertical) Attention:...

- Page 19 4. Extension of accessory equipment Please take exact details from the operating instructions of the attachments: • fix the devices only with the required appliances • When coupling devices to the caterpillar danger of injury exists • In the area of the three point leverage risk of injury through crimp and rubbing exists. Do not step between caterpillar and attachment.

-

Page 20: Help With Breakdowns

Help with breakdowns Only dispose a breakdown if you posses on the declared qualification Sichern Sie zunächst die Maschine gegen unbeabsichtigtes Wieder-Anlaufen, indem Sie die Batterie abklemmen. Gewährleisten Sie jederzeit die Sicherheitsabschaltung der Maschine durch eine zweite Person. Reason Remedy Motor doesn`t start Check the batterie Check the status of the diesel... - Page 21 Caterpillar HY 60 Seat poistion 2 Seat in roll function 12 Volt accessory Connector...

- Page 22 Diesel filler Bonnet Border (equipment rack) with attachment for weights. Guard plade Chain 230x72x52 Fat nippels for chain tension...

- Page 23 Roll bar – fold-away Flue gas pipe Air cleaner – aspiration hole with protective cap Seat position 1 (Front) Dome fastener (rubber) Ports for control - funtion (direction bonnet)

- Page 24 Guide over Ports for working hydraulic (direction bonnet) Bonnet fastener...

- Page 25 Power take-off Hydraulic filter Adjustment - pendular of the guide Guide adjusting screw - sideways Guide under Catch for guide under Ports for control - function (direction guide under)

-

Page 26: Maintenance

Maintenance Secure first the range for the maintenance work spaciously. Cut off all power supply units and secure the power supply units against accidental resetting Switch all printer units depressurized Use only the indicated fuels. Use excluding spare parts, which are specified in our parts catalogs 1. - Page 27 Electric equipment • With work on the electric system pinch off the battery in principal (negative pole) • Attend to correct connection – at first the plus pole and then the minus pole • Attention with battery gases – they are very explosive •...

- Page 28 Brake • Check the brakes each time before starting to drive! • You should check the brake systems efficient and regularly! • Adjusting and repairs on the brake system may be only conducted by repair shop or approved brake services! Caterpillar chains + maintenance •...

- Page 29 4. Maintenance after ca. 50 operating hours • After-image all connections • Check hydraulic lines and connections after leak tightness and after-image or pack them if necessary • Change the hydraulic oil filter, later ca. all 500 working hours • Check the tension of the chain and clamp them if necessary •...

- Page 30 5. Gearbox for power take-off Pump drives with clutch “BD” or “BDS” The clutch must be engaged only with the engine idling or, however, not more tjem 1000 rpm. The engagement must be quickly effected. The same recommendations must be applied for disengagement. Maintenance Pump drives are supplied without oil.

- Page 35 By acting without authority or changes of the original state the guaranty slips. The claim for compensation will be lost if you had not used original NIKO spare parts. Please consider attentively the operating instruction. Please contact by all questions you don’t know our dealer or the movement.

Need help?

Do you have a question about the Caterpillar HY 60 and is the answer not in the manual?

Questions and answers