Summary of Contents for Velká Bíteš Turbojet Engine TJ20A

- Page 1 PP-42A OPERATION AND MAINTENANCE MANUAL GUARANTEE CERTIFICATE TURBOJET ENGINE TJ20A První brněnská strojírna Velká Bíteš, a.s. December 2014...

-

Page 2: Table Of Contents

Check-up of rotating parts ......................28 State of fuel filter pollution ....................... 28 Stocking instructions ......................... 28 CONTENT OF ENGINE IS PACKAGE ................28 EXHAUST PIPE FOR THE TJ20A TURBOJET ENGINE ..........29 TURBOJET ENGINE TJ20A DIMENSIONAL DRAWING ..........30... -

Page 3: Safety Instructions

PP-42A 1. SAFETY INSTRUCTIONS Definition In this manual relevant steps are preceded by WARNINGS or CAUTIONS. For WARNINGS and CAUTIONS contained at this manual apply these definitions: 1.1.1 Warning Caution! Operating procedures or maintenances jobs, methods, circumstances or instructions, whose non-observance could cause injury or death of personnel or can cause long-time health hazard. -

Page 4: Safety Warning

PP-42A Safety warning The operator of turbojet engine TJ20A (below only engine) must during engine testing and operation take into account the following safety risks: a) Aspiration of foreign objects The engine needs a large amount of air for its function, which may result in suction of foreign objects in the space of the compressor inlet, if are not fixed sufficiently. -

Page 5: Warning

Warning Turbojet engine TJ20A was designed purely for using inside aircraft model and it is not suitable for any other purpose. Never use this turbojet engine for persons, object or vehicles, only for well designed model of aircraft, every other using can cause hurt or death. -

Page 6: Guarantee

PP-42A Guarantee The guarantee relating purely to positive manufacturing or material defects arise during the guarantee period. Any other claims are eliminated. All costs regarding packing and transport will pay the seller. We will not guarantee waste during the transport. The guarantee is with no validity when is defect of the product caused by some accident, bad operating or modification of this product. -

Page 7: Technical Parameters

PP-42A 2. TECHNICAL PARAMETERS Technical parameters = 15°C, p * hold for standard conditions t = 101,325 kPa, v = 0 km/hod *Max. thrust Max. outsider diameter [mm] Length including starter [mm] 315±1 Engine weight [kg] < 2,2 (without battery) 35 000 ÷... - Page 8 PP-42A 2.1.3 Connection of engine with control electronic See picture at clause 3.5 2.1.4 Accessories of this engine which is delivery separately: - Fuel filter fuel input to hose Js 4 fuel output to hose Js 4 - Engine Data Terminal - Hose D6,5 0,4 m - Engine clamp...

-

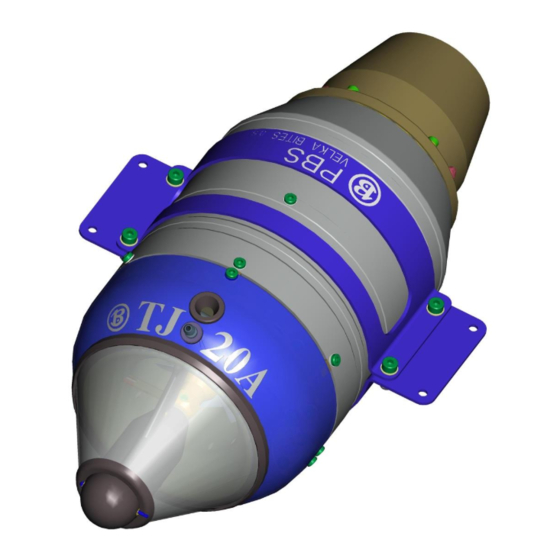

Page 9: Description

3. DESCRIPTION Description of engine Turbojet engine TJ20A is single-shaft engine with single-stage radial compressor, annular combustion chamber, single-stage axial turbine and output nozzle. At the compressor suction is located booster with break-in clutch enabling starting of this engine from the cockpit net. -

Page 10: Starting Instructions

PP-42A Attention! Fire hazard! Observe all applicable regulations for the transport and storage of fuels (kerosene /jet fuel /etc.). Don't use open fire when mixing fuels with oil or handling the fuels (refuelling, draining, etc.). Ensure that the fuel does not spill or leak into the soil. Starting instructions After connection of engine with EDT, RC, fuel supply and power supply must be made record of control instructions (stop, idle thrust, maximum) send out from superior system (acceptor) -

Page 11: Connection Scheme

PP-42A Connection scheme ORANGE Input for RC signal from the control auxiliary power +4,8 VDC for RC Control BROWN 20 ms 0,852,1 ms Switch Connector Battery core 12V 2500 mAh Input Signal of RC Control Connector Engine Data Terminal Connector service ORANGE Data Power supply +4,8VDC for EDT... - Page 12 PP-42A ENGINE CONNECTOR PC CONNECTOR OR SWITCH FUEL TANK ENGINE DATA TERMINÁL THROTTLE BATTERY FUEL FILTER...

-

Page 13: Recommended Accessories

PP-42A Recommended accessories 3.6.1 Suction screen The engine can be provided with a suction screen to prevent suction of foreign objects into the compressor. Put the suction screen on the engine starter in such way, so that the grooves on the screen fit onto the protrusions on the starter. -

Page 14: Edt Status Display (Engine Data Terminal)

PP-42A 4. EDT STATUS DISPLAY (ENGINE DATA TERMINAL) EDT (Engine Data Terminal) Control and Monitoring Panel Main Display: EGT a RPM Menu A E G T 9 9 9 ° C T H : 1 0 0 % R P M 1 2 0 . 0 U b 1 2 . -

Page 15: Menu A - Control Unit Modes

PP-42A Menu A – Control Unit Modes → Setting upon battery switch-on and after COOL mode LOCK (without RC signal) → Setting upon battery switch on and after COOL mode STOP (RC signal set to STOP) → RC signal set to IDLE (displayed in idle speed) IDLE →... - Page 16 PP-42A Menu SETUP: EGT999°C TH:100% RPM120.0 Ub12.6V 1: INFO >>> 2: STATISTICS >>> 3: LIMITS >>> 4: R/C-SETTINGS >>> 5: TEST-DEVICES >>> 6: RESET-ENGINE >>>...

- Page 17 PP-42A Menu - 1: INFO (only for reading) 1: INFO >>> 10: R/C-FAILS 11: JET-ENGINE TJ20A S/N:0000 12: FIRMWARE Version v06.16 13: LIFE-TIME 0 hour 14: ERROR-CODES No Error 15: ERROR-STD 0x00000000 16: ERROR-EXT 0x00000000 10: R/C-FAILS Number of RC connection fails during the last engine run 11: JET-ENGINE Engine type and serial number 12: FIRMWARE...

- Page 18 PP-42A RC FAILS Loss of RC signal during engine run will set 45:FAILS-THROTTL speed for the 44:FAILS-TIME period and, after this period lapses, the engine switches off. TIME Failure to reach idle speed (IDLE) since the engine start beginning. If the engine fails to reach IDLE within 60 s after the start, starting is terminated.

- Page 19 PP-42A Menu – 2: STATISTICS (only for reading) 2: STATISTICS >>> 20: RUNS-TOTAL 21: START-ABORT 22: RUNS-ABORT 23: HOUR-METER 000:00´0 24: EGT-AVG/PEAK 0°C/0°C 25: FUELPMP-MIN 0 mV/ 0 mV 26: FUELPMP-MAX 0 mV/ 0 mV 27: RPM-MIN/MAX 0 / 0...

- Page 20 PP-42A 20: RUNS-TOTAL Total number of engine starts and runs 21: START-ABORT Total number of engine failed starts 22: RUNS-ABORT Total number of engine failed runs 23: HOUR-METER Total hours worked by the engine (total time of the fuel pump operation) Units –...

- Page 21 PP-42A Menu - 3: LIMITS (for reading and setting) 3: LIMITS >>> 30: ENGINE-IDLE 35000rpm 31: ENGINE N100% 120000rpm 32: FUELPMP-MAX 9.6V 33: UP 4,0s 34: DOWN 4.0s 35: EGT-MAX 880°C 36: START-EGT-OFF 950°C 37: RUN-EGT-OFF 900°C...

- Page 22 PP-42A 30: ENGINE-IDLE Engine idle speed. Setting range from 33,000 to 40,000 rpm in 100 rpm steps. 35,000 rpm by default 31: ENGINE N100 % Maximum reduced engine speed. Setting range from 100,000 to 120,000 in 100 rpm steps. The maximum speed can be lowered or raised by the engine manufacturer, because of the setting of engine parameters.

- Page 23 PP-42A Menu - 4: R/C SETTINGS (for reading and setting) 4: R/C SETTINGS >>> 40: RC-MONITOR 41: RC-TRIM.OFF 900us 42: RC-IDLE 1000us 43: RC-100% 2000us 44: FAILS-TIME 5.0s 45: FAILS-THROTTL 46: THROTTLE-TYPE THRUST 47: CONTROL-TYPE...

- Page 24 PP-42A 40: R/C-MONITOR Current value of RC signal 41: RC-TRIM.OFF RC signal value for STOP. Push the SET push-button (the > and < starts flashing). Set the RC transmitter signal for STOP and confirm it by the SET push-button (the > and < stops flashing and it is entered in the engine memory).

- Page 25 PP-42A Меnu - 5: TEST-DEVICES (for controlling engine devices only) 5: TEST-DEVICES >>> 50: STARTER-OFF RPM 0.0 ST 0.0A 51: FUELPUMP CLOSED 52: FUELVALVE CLOSED 53: STARTVALVE CLOSED 54: DRAIN-FUEL CLOSED 55: FUEL-PUMPING CLOSED 56: ENGINE-RUN 50: STARTER OFF Starter test. The starter is spun to a defined speed and then switched off. 51: FUELPUMP Fuel pump test.

- Page 26 PP-42A Procedure of engine actuating by EDT: Set 56: ENGINE-RUN in EDT Menu. Press the push-button and the OFF inscription will start flashing in the display. Set ON using the push-button and confirm it by the push-button. The EDT display will indicate "EDT ST?" in the top right corner. Actuate the engine start by pressing the push-button.

- Page 27 PP-42A Schema menu: EGT999°C TH:100% RPM120.0 Ub12.6V 1: INFO 2: STATISTICS 3: LIMITS 4: R/C SETTINGS 5: TEST-DEVICES 6: RESET-ENGINE >>> >>> >>> >>> >>> >>> 10: RC-FAILS 20: RUNS-TOTAL 30: ENGINE-IDLE 40: RC-MONITOR 50: STARTER OFF 6: RESET-ENGINE 35000rpm RPM 0.0 ST 0.0A 11: JET-ENGINE 21: START-ABORT...

-

Page 28: Maintenance Of Engine

This engine mustn´t be stocked right on the floor, at esplanade and at places with higher humidity. 6. CONTENT OF ENGINE IS PACKAGE Engine is packaged in transport box containing: Turbojet engine TJ20A 1 piece Engine Data Terminal 1 piece... -

Page 29: Exhaust Pipe For The Tj20A Turbojet Engine

PP-42A 7. EXHAUST PIPE FOR THE TJ20A TURBOJET ENGINE The manufacturer of the TJ20A engine recommends to use an exhaust pipe with the engine, to protect the model against damage caused by the high temperature of the engine output nozzle. The exhaust pipe must be designed in accordance with the following figure. -

Page 30: Turbojet Engine Tj20A Dimensional Drawing

PP-42A 8. TURBOJET ENGINE TJ20A DIMENSIONAL DRAWING...

Need help?

Do you have a question about the Turbojet Engine TJ20A and is the answer not in the manual?

Questions and answers