Table of Contents

Advertisement

Quick Links

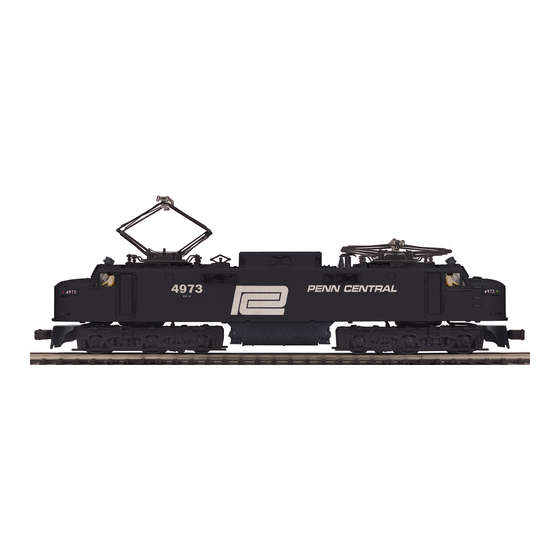

Premier EP-5

Electric Engine

OPERATOR'S MANUAL

Compatibility

3

This engine will operate on any

traditional O-Gauge track system,

including M.T.H.'s RealTrax® or

ScaleTrax™ or traditional tubular track

with O-42 curves. It is also compatible

with most standard AC transformers and

DC power packs. (See page 52 and 53 for

a complete list of compatible

transformers, power packs, and wiring

instructions.)

PFA

Passenger/Freight

Announcements

PLEASE READ BEFORE USE AND SAVE

Advertisement

Table of Contents

Summary of Contents for MTHTrains Premier EP-5

- Page 1 Premier EP-5 Electric Engine OPERATOR’S MANUAL Compatibility This engine will operate on any traditional O-Gauge track system, including M.T.H.’s RealTrax® or ScaleTrax™ or traditional tubular track with O-42 curves. It is also compatible with most standard AC transformers and DC power packs. (See page 52 and 53 for...

-

Page 2: Table Of Contents

Table of Contents Set Up Checklist ................3 Pantographs . -

Page 3: Set Up Checklist

WARNING: The Automatic Operating Pantographs must be unlatched or the on-off switch must be set to OFF before power is applied to the engine. Unlatch before power is applied Figure 3 Figure 2 Pantograph On-Off Switch Premier EP-5 Electric Engine... -

Page 4: Automatic Operating Pantographs

Automatic Operating Pantographs Your MTH electric type engine is equipped with Automatic Operating Pantographs. The Automatic Operating Pantographs must be unlatched before power is applied to the engine. To unlatch the pantographs, hold the base of the pantograph and gently pull up on the contact slider. -

Page 5: Command Mode-Automatic Operation

Command Mode- Automatic Operation The pantographs can be operated automatically or manually when using the M.T.H. DCS Digital Command System or DCC. The START UP function must be initiated for the pantographs to operate in command mode. After the startup function has completed, the pantographs will go through an orientation check. - Page 6 IMPORTANT – Ensure your pantographs are NOT locked down like they would be for shipment prior to pantograph operation. Manual operation using DCS requires DCS Software Version 3.1 or later which can be downloaded for free from www.mthtrains.com . DCS systems using software versions 3.0 or earlier will only have automatic pantograph operation when running under DCS command mode.

-

Page 7: Dcc/Dcs Switch

DCS/DCC Switch Your MTH PS3.0-equipped engine has a DCS/DCC selector switch (located underneath one of the Trucks on the undercarriage of the Enginer). To operate the engine in DCS mode, ensure the switch is set to DCS. If you wish to run the engine in DCC mode, ensure the switch is set to DCC. -

Page 8: Ps 3.0 Enhancements

PS 3.0 Enhancements Here are some of the exciting changes incorporated into your new MTH Proto- ® Sound 3.0 Locomotives. More advanced features such as Custom Speed Tables and Advanced Consisting can be found in the DCC section of this manual. Conventional (Analog) AC/DC Start-up/Shut-down Your new MTH PS3.0-equipped locomotive no longer has batteries. -

Page 9: Loading Engine Firmware

Loading Engine Firmware Your new MTH PS3.0-equipped O-Gauge engine affords you the ability to load Engine firmware. Loader version 2.30 or later will allow you to do this. Please refer to the Loader program’s instructions for more details. So, as MTH releases new features or updates you will be able to take full advantage without having to ship your favorite engine anywhere. - Page 10 When power is first applied to the track, the locomotive will be silent for 1-20 seconds and the headlight will be on, indicating the super capacitors are charging (The super capacitors provide power to the sound system during direction changes or intermittent drops in track power due to dirty track or on switches, when operating in...

-

Page 11: Proto-Sound 3.0 Conventional Ac Operating Instructions

® Proto-Sound 3.0 Conventional AC Operating Instructions ® Activating Proto-Sound 3.0 Conventional AC Mode Features Throttle - To increase or decrease track voltage, and therefore train speed, turn the throttle control knob. Turning clockwise will increase voltage and speed, while turning counterclockwise will decrease voltage and speed. -

Page 12: Manual Volume Control

Manual Volume Control To adjust the volume of all sounds made by this engine, turn the master volume control clockwise to increase the volume and counterclockwise to reduce the volume. Turning the master volume control completely counterclockwise will turn of all of the engine sounds and announcements. - Page 13 Your engine's lights will now look like this (Engine with Train): Rear Passenger/Freight Announcements (PFA) Your engine is equipped with a sound package of either passenger station announcements or freight yard sounds that you can play when you pull into a station or a yard. Each sequence described below will play as long as it is left on, randomly generating sounds, but be sure to allow approximately 30 seconds between the button pushes described below to allow the PFA sufficient time to run through each sequence.

-

Page 14: Proto-Coupler Operation

Tips on Using PFA •You can terminate PFA at any time by turning off power to the track for 15 seconds. •You do not have to be in Forward to use PFA. At the conclusion of the full sequence, the train will pull away from the station or yard in whatever direction you were going when you activated the feature. -

Page 15: Speed Control

Speed Control M.T.H. engines equipped with Proto-Sound 3.0 have speed control capabilities that allow the engine to maintain a constant speed up and down grades and around curves, much like an automobile cruise control. You can add or drop cars on the run, and the engine will maintain the speed you set. -

Page 16: Reset To Factory Default

Running in Wrong Direction Normal Operation Place Wrong Direction Running Lights Bell Bell Bell Bell Horn Engine in (Repeat to Return Neutral to Previous Lighting) Reset to Factory Default To override the settings you currently have assigned to the engine and reset it to its factory defaults, while in Neutral tap the Horn button quickly once, followed by five quick taps of the Bell button, allowing approximately ½... - Page 17 in the opposite direction. The electronics in your MTH Proto-Sound 3.0 locomotive are designed to slowly change direction without a need to change the throttle, if you so desire. Just change the polarity switch on your DC power pack and the engine will gradually come to a stop and then automatically begin traveling in the opposite direction.

- Page 18 For Train/No-Train Indicators: To set the Train/No-Train indicator Lights you want to press the LMK softkey so the DCS Remote displays “Marker Light ON”. By default your engine will be set to a No- Train indication. That means your engine has no string of cars being pulled. Your engine lighting will look like this: (Engine without Train) Just the engine running...

-

Page 19: Dcc / Digital Command Control

DCC - Digital Command Control DCC is a popular digital command scheme wherein the track power is also a digital control signal. That is, using a DCC controller, you can communicate with multiple engines and have all of them moving at different speeds and in varying directions on the same track at the same time. -

Page 20: Sounds

Note – You are actually able to move the engine in DCC without starting it up. Just increasing the throttle will cause the engine to move. In order for F3 to function correctly the engine must NOT be moving To shut your engine down, press the F3 button twice. This will play the shut down sounds and then turn the lights and smoke and sounds off. -

Page 21: Lights

Lights F0 – Headlight/Taillight This toggles your headlight/taillight on and off. It will also override F19 and F20 (Train/No-Train and Wrong Direction Running Lights). When F0 is disabled your Headlight, Taillight, Train/No-Train Indicators and Wrong Direction Running Lights are disabled as well. F5 –... -

Page 22: Crossing Signal

Grade Crossing Signal Again, just like a real engine, you can trigger the Grade Crossing Signal on your engine. This is two long, one short, one long whistle/horn blast. F11 – Grade Crossing Signal Pressing F11 twice (toggling on then off) will sound your Crossing Signal. Auto/Manual Pantograph Operation F12 –... - Page 23 F3 in that the engine will ultimately shut down, but in the case of Extended Shut Down you will hear the crew talking back and forth about how the engine ran, time schedules, etc. F19 – Train Marker This function will enable or disable the engine showing whether it is pulling a train or not. Please refer to page 12 for a visual description of how the train lights will behave by toggling F19 on/off.

-

Page 24: Engine Sounds

Function Chart Function Description Headlight Bell Horn Start-Up/Shut Down Lights Master Volume Front Coupler Rear Coupler Forward Signal Reverse Signal Grade Crossing Auto Panto On/Off Front Panto Up/Down Rear Panto Up/Down Idle Sequence 2 Idle Sequence 1 Extended Start-Up Extended Shut Down Train Marker Wrong Direction Running Lights On/Off One Shot Doppler... -

Page 25: Cv29

CV29 CV29 is the basic decoder setup CV that is used by all DCC decoder manufactures. So, if you are familiar with CV29 from other manufacturer's decoders MTH's is no different. The most important part of CV29 is the ability to switch between long and short addressing. -

Page 26: Feature/Factory Resetting

To change your engine's Long Address using PoM: 1. Call up the current engine's address on your DCC handheld 2. Enter Programming on the Main on your DCC handheld 3. In this step you have to tell the MTH engine that you want it to start looking at long addresses. - Page 27 unsure of the engine address you can apply the 55-55-55 reset (send a value of 55 to CV55 to engine address 55). In order for this to work correctly the engine's address must NOT be 55. The engine will need to be sitting at some address other than 55. Below is the method (55-55-55 Reset) you can employ to return an engine to its factory default short address of 3 (it will also set the engine's long address back to its default –...

-

Page 28: Advanced Dcc Operation

MTH PS3.0 Expanded DCC Functionality Advanced DCC Operation: This section of the manual provides more in-depth detail on how to set up and configure your MTH PS3.0-equipped engine using the NMRA-standard CV's as well as the manufacturer-specific CV's. It also explains some of the other F Functions not covered in the Basic DCC Operation section. - Page 29 Below is the table of Factory Default MTH supported DCC CV's. This table is specific to the engine in the title of this manual: Factory Default Values for MTH PS3.0 DCC Configuration Variables (CV’s) Default Value Function Function Decimal Description CV Description Short Address Function - Horn High Byte...

- Page 30 User-Settable F-Function List This feature allows you to take the 28 F-Functions that currently reside in each MTH Proto-Sound 3.0-equipped O-Gauge Engine and change the location of that function. For example: F4 is currently PFA and you'd like that placed down to F28 which is Feature Reset.

- Page 31 The above list includes ALL F functions that an MTH PS3 engine could have. You are free to change any of the above listed items to any F function position, 1-28. For example, if you your engine came from the factory without a smoke unit but you added one at a later date you could swap out any of the F functions, 1-28, for the Smoke On/Off and the Smoke Volume.

-

Page 32: Cv Programming - Marklin 6021 Controller

CV Programming – Marklin 6021 Controller Note: There are 4 DIP switches on the back of the Marklin 6021 Controller. For MTH engines you will want the DIP switches set to the following: 1 - OFF 2 - ON 3 - OFF 4 - OFF To enter programming mode using a Marklin 6021 controller, perform the following steps:... - Page 33 2. Briefly turn the speed knob counter clockwise to the direction change position. The headlight should shift to a short-short flash pattern. 3. Enter the units digit of the CV contents preceded by a zero. For the example of 128, enter 08. The state of the function LED does not matter.

- Page 34 27 Speed Step Mode maps directly to the 28 speed steps used in DCC but does not use the 28th speed step. It uses the odd steps on acceleration and the even steps on deceleration. 28 Speed Step Mode maps directly to the 28 speed steps used in DCC When the New Motorola format is used (DIP switch 2 in the ON position on the Marklin 6021 Controller), you can re-map F1-F4 using CV115-CV122.

-

Page 35: Advanced Consisting

Custom Speed tables Below is a table that shows the value to write to CV25 to achieve the desired speed curve. For example, if you would like to use speed curve 18 then: 1. Write a value of 1 to CV52 to enable PWM Mode 2. - Page 36 Engine 3 - Rear Engine 1 - Front Engine 2 - Middle Normal Forward Direction of Travel To set this consists up so that: The Headlight is ON in the Front engine when going Forward, OFF when the consist is in Reverse The Reverse light and headlight is OFF in the Rear engine when the consist is going Forward, headlight is ON, reverse light is OFF when the consist is in Reverse...

- Page 37 7. Set CV22 to a value of 2 to the Rear engine's address to tell the Rear engine that you want to control its FL control with the F0 button at the consist address. The engine will give you two horn blasts to announce that it received the CV change 8.

- Page 38 To do this: 1. Call up the Front engine on your DCC system 2. To set the Front engine to respond to the Bell (F1), Horn (F2), Start-Up/Shut Down (F3) and Front Coupler (F7) you will want to write a value of 71 to CV21. This is setting bits 0, 1, 2, and 6 ON.

-

Page 39: Programming Track

NOTE - CV21 is ONLY used when you have some value other than 0 written to CV19. If CV19 = 0 then the values of CV21, CV22, CV23, and CV24 are not used 1. Call up your Middle engine (address 2 in the example) 2. - Page 40 DCC Bit Value Decoder Example Value (bit 7 -> bit 0) 11011001 7(128) 6(64) 5(32) 4(16) 3(8) 2(4) 1(2) 0(1) (Decimal Value) Binary 1(on) 1(on) 0(off) 1(on) 1(on) 0(off) 0(off) 1(on) Example Decimal Value So, in the above example you simply add up the values in the “Decimal Value” row – 128+64+0+16+8 +0+0+1 = 217.

-

Page 41: Maintenance

Maintenance Lubricating and Greasing Instructions The engine should be well oiled and greased in order to run properly. Regularly lubricate all axles and pickup rollers to prevent squeaking. Use light household oil, such as that found in M.T.H.'s maintenance DO NOT DO NOT kit. -

Page 42: Cleaning The Wheels, Tires And Track

5. After repeating the procedure for the other motor, reassemble the chassis and body, being careful that the wire harnesses are not caught between the chassis and body, and reinstall the body mount screws. Cleaning The Wheels, Tires, and Track Periodically check the locomotive wheels and pickups for dirt and buildup, which can cause poor electrical contact and traction and prematurely wear out the neoprene traction tires. -

Page 43: Traction Tire Replacement Instructions

Traction Tire Replacement Instructions Your locomotive is equipped with two neoprene rubber traction tires on each powered truck block. While these tires are extremely durable, they may occasionally need replacement. 1. Locate the driver wheel set that has the traction tires. 2. -

Page 44: Troubleshooting Proto-Sound 3.0 Problems

Troubleshooting Proto-Sound® 3.0 Problems Although Proto-Sound® 3.0 has been designed and engineered for ease of use, you may have some questions during initial operation. The following table should answer most questions. If your problem cannot be resolved with this table, contact M.T.H. for assistance (telephone: 410-381-2580;... - Page 45 Lock-out Solution The engine maybe locked into the neutral I can't get the engine to run after I power position. Follow the procedure in the "Lock up the transformer. It sits still with the into a Direction" section to unlock the diesel and compressor sounds running.

- Page 46 Conventional DC Start-up Solution Check to see if that section of track has When I apply power to the track my power. Use a voltmeter or a lit passenger car. engine doesn't do anything. No lights, no sound, no nothing. Slide the engine a couple of feet in either direction, you may have a bad track section Have you got that section electrically isolated...

- Page 47 Lights Solution One of my lights is out. Most likely you had been running the engine in DCC or DCS mode and toggled that light off. Put it back into one of those modes and turn that light back on. The engine will remember that when you run it again in Conventional DC.

- Page 48 Start-up Solution When I apply power to the track my Did you press F3 yet? F3 on your DCC handheld will start your engine up. engine doesn’t do anything. No lights, no sound. Check to see if that section of track has power.

- Page 49 Lights Solution One of my lights is out. Check your F keys. F0 is the headlight (also controls the Back-up light) and F5 will toggle the Cab light and firebox light. F19 and F 20 will also toggle Train/No Train & Train Operation.

- Page 50 DCS (Remember, it's NOT DCC) Start-up Solution This is normal. You have to hit the Start-Up When I apply power to the track my button. engine doesn't do anything. No lights, no sound, no nothing. Check to see if that section of track has power.

- Page 51 Lights Solution One of my lights is out. Check that you haven't turned it off with the DCS controller. You have independent control over lights on your engine Could be the same reason as “One of my None of my lights are on. lights is out”...

-

Page 52: Transformer Compatibility And Wiring Chart

Transformer Compatibility and Wiring Chart Proto-Sound® 3.0 is designed to work with most standard AC transformers. The chart below lists the many compatible transformers. Note that many of the operational commands described in these instructions require a bell button, so if your transformer does not have its own bell button, you should consider adding one to get the full benefit of the system. -

Page 53: Dc Power Supply Chart

DC Power Supply Chart RECOMMENDED DC TRANSFORMERS Transformer Power Notes On Use Transformer Min/Max. Model Rating Type Voltage MRC 6200 0-18.5v 60-Watt Not Recommended For #70-3001-1 J3a Electronic 100-Watt 0-20v Electronic Controlmaster 20 PH Hobbies 0-20v 100-Watt Electronic PH Hobbies 0-20v 180-Watt Electronic... - Page 54 Additional Features Accessible With The DCS Remote Control System (Additional equipment required) While conventional mode operation of a Proto-Sound® 3.0 engine yields wonderfully realistic sound and several train control features, command mode operation allows the user to access a world of command functions never before accessible to O Gauge railroaders.

-

Page 55: Service & Warranty Information

Service & Warranty Information How to Get Service Under the Terms of the Limited One-Year Warranty When you suspect an item is defective, please check the operator's manual for standard operation and trouble- shooting techniques that may correct the problem. Additional information may be found on the M.T.H. Website. Should you still require service, follow the instructions below to obtain warranty service.

Need help?

Do you have a question about the Premier EP-5 and is the answer not in the manual?

Questions and answers