Table of Contents

Advertisement

Quick Links

Read through the Operation

instructions carefully.

NOTE: Instructions subject to change without notice.

Waterous Company, 125 Hardman Avenue South, South St. Paul, Minnesota 55075 USA (651) 450-5000

80-P, 80-SP PTO-Driven Compressor Kit

For Manual Auto-sync .............................................................................. 3

Multiple Uses ........................................................................................... 3

Water Pumping Operations ...................................................................... 3

Foam Solution Operations ....................................................................... 3

Compressed Air Foam Operations ........................................................... 4

Compressed Air Only Operation .............................................................. 4

Shut-Down Procedure .............................................................................. 6

SECTION 2.

How It Works ............................................................................................ 7

Maintenance Schedule............................................................................. 9

Maintenance Items ................................................................................... 9

Wye Strainer for Cooler .......................................................................... 10

Nozzles .................................................................................................. 11

Foam Concentrate Ratios ...................................................................... 11

Hose....................................................................................................... 11

1" (25 mm) Hose Diameter Jacketed ..................................................... 12

1-1/2" (38 mm) Hose Diameter .............................................................. 12

1-3/4" (44 mm) Hose Diameter .............................................................. 13

Master Stream ....................................................................................... 14

www.waterousco.com

Operation Guide

AIR COMPRESSORS ...............................................................

....................................................... 12

F-1031, Section 2416 (Revised: 02/02/10)

................................................ 3

............................... 8

............................................... 15

........................ 23

7

........ 11

Advertisement

Table of Contents

Summary of Contents for Waterous 80-P

-

Page 1: Table Of Contents

..........15 SECTION 6.TROUBLESHOOTING - CAFS ......23 SECTION 7.CONDITIONAL 1-YEAR WARRANTY POLICY NOTE: Instructions subject to change without notice. F-1031, Section 2416 (Revised: 02/02/10) Waterous Company, 125 Hardman Avenue South, South St. Paul, Minnesota 55075 USA (651) 450-5000 www.waterousco.com... - Page 2 Warnings, Cautions, and Notes Warning A warning alerts you to a procedure, practice or condition that may result in death or long term injury to personnel or destruction of equipment. Caution A caution alerts you to a procedure or condition that may result in serious damage to equipment or its failure to operate as expected Note: A note points out important information.

-

Page 3: Section 1. Operating Instructions

Figure 1 Manual Auto-sync panel B. Multiple Uses A pumper equipped with a Waterous compressed air foam unit can be operated in several pumping modes; water only, foam solution without compressed air, compressed air foam and compressed air only for support operations such as operating air tools, filling rescue air bags, etc. It is possible to pump foam solution from one discharge while pumping compressed air foam from another, or varying foam consistencies (expansion ratios) from different discharges simultaneously. -

Page 4: Compressed Air Foam Operations

E. Compressed Air Foam Operations Follow the instructions above for foam solution operations. Safe operations dictate the presence of foam concentrate in the water stream prior to the injection of compressed air. If foam concentrate is not present, a condition known as “slug flow” will occur. This is where unmixed water and air is discharged through a nozzle in an erratic manner. - Page 5 WARNINGS Compressed air can be dangerous. Read and understand the operating instructions for the Waterous compressed air foam unit and individual components prior to operating. • DO NOT use the compressed air foam unit as an air source for SCBA or any breathing air supply.

-

Page 6: Shut-Down Procedure

G. Shut-Down Procedure Close air valve(s) Turn off Foam proportioner Flow clear water through discharge hose(s) until no bubbles are present Close discharge valve(s) 5. Move Auto-Sync controls to AUTO / UNLOAD 6. Move the air compressor PTO switch to the “OFF” position After the compressor PTO is disengaged, the system will vent itself, creating an audible hiss as compressed air is evacuated from the pressure vessel / sump. -

Page 7: Section 2. Air Compressors

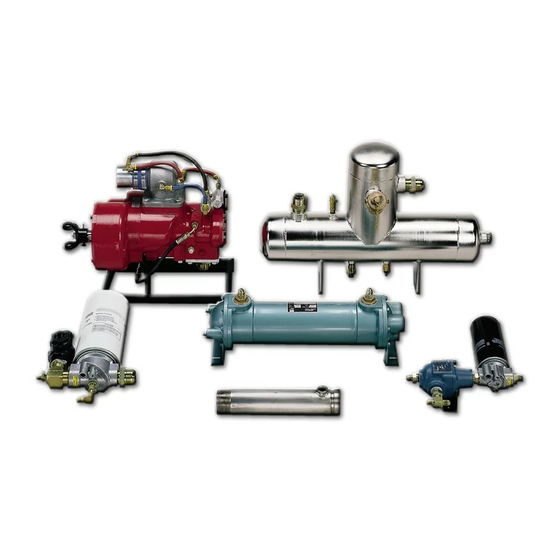

SECTION 2. AIR COMPRESSORS Figure 2 CE 55 G A. How It Works The air compressor used in this application is an oil flooded rotary screw type. Rotary screw air compressors are very common in industrial applications. This type of compressor injects oil into itself, where it lubricates, seals, cools, and silences the compressor. -

Page 8: Section 3. System Service And Maintenance

There is a drain plug located at the bottom of the sump. The oil fill cap is located on top of the unit. 3. Change the compressor system oil filter at the same time as the oil is changed. Call Waterous for replacement elements. -

Page 9: Maintenance Schedule

Each Use Weekly X- pg 5 Annually Every 24 Months Inspect the air compressor air intake filter monthly and change as necessary. B. Maintenance Items COMPRESSOR Waterous part# AIR FILTER: CO85005 2030043 HYDRAULIC FILTER: WD 920 2030058 SEPARATOR FILTER: -----------... -

Page 10: Wye Strainer For Cooler

Caution: Waterous is not responsible for damage due to plugged strainers. If the customer's water system contains excessive debris, or the vehicle relies on drafting for its water supply, it may be necessary to install a larger strainer and/or a clean-out valve on the wye-strainer. -

Page 11: Section 4. Cafs Nozzle / Flow Rate / Hose Combinations

SECTION 4. CAFS NOZZLE / FLOW RATE / HOSE COMBINATIONS A. Nozzles Compressed air foam can be discharged through various types and sizes of nozzles. Fog nozzles break down the bubble structure of the foam. This results in “wetter” or reduced expansion foam. The preferred way to make foam is utilizing smooth bore nozzles with a given hose diameter, smaller tips will discharge “wetter”... -

Page 12: Section 5.Suggested Guidelines For The Production Of Mid- Range Compressed Air Foam

SECTION 5. SUGGESTED GUIDELINES FOR THE PRODUCTION OF MID-RANGE COMPRESSED AIR FOAM A. 1” (25 mm) Hose Diameter Jacketed 1 GPM to 1 CFM ½” Tip Solution Flow: 15 GPM (56.78 LPM) Air Flow: 15 CFM (0.42 m /min) Disch. Pressure: 100-150 PSI (6.804 - 10.206 BAR) (689.5 - 1034.25 KPA) Min/Max Hose Length: 35’... -

Page 13: 1-3/4" (44 Mm) Hose Diameter

2 GPM to 1 CFM 1” Tip Solution Flow: 60-80 GPM (227.12 – 302.82 LPM) Air Flow: 30-40CFM (0.84 – 1.12 m /min) Disch. Pressure: 100-150 PSI (6.804 - 10.206 BAR) (689.5 - 1034.25 KPA) Min/Max Hose Length: 100’ to over 800’ (30.48 – 243.84 meters) 1 GPM to 1 CFM 1-3/8”... -

Page 14: Master Stream

It is possible to make the discharge stream wetter or drier by changing the amount of solution or air in the hose. The stream can also vary by changing the tip size at the nozzle. • The bigger the diameter tip, the drier the foam. •... -

Page 15: Section 6.Troubleshooting - Cafs

SECTION 6. TROUBLESHOOTING - CAFS Observed Probable Cause Suggested Remedy Symptom Lack of air supply to Lack of air pressure clutch (for air-clutch Repair air leak or re-establish air supply from compressor systems) Compressor not Confirm OK TO PUMP light is on, if not check wiring for damage or disconnected wire, No PTO engagement engaging check PTO. - Page 16 Observed Probable Cause Suggested Remedy Symptom Inadequate water flow Ensure adequate water flow through pump. Check Y strainer for obstruction, clean and through cooler reinstall Drain and flush cooler water tubes On-board tank used for cooling for a prolonged period - water too hot to effectively cool the compressor.

- Page 17 Observed Probable Cause Suggested Remedy Symptom Sump fire Check system and repair Low oil level or no oil Check system and repair Air flow meter stuck Magnet uncoupled in Turn air flow on and off to re-couple at "0" CFM meter Air flow meter stuck Move large amounts of air out discharge and turn air flow on and off to re-couple...

- Page 18 Observed Probable Cause Suggested Remedy Symptom High RPM engagement Engage in lower RPM Not allowing compressor to bleed down before Allow for bleed down engaging clutch again Contaminated clutch Clean or replace disc Auto-Sync system out of Adjust the Auto-Sync system, making sure to not open the trim valve on the balance compressor more than 3 turns.

-

Page 19: Figure 7 80-Sp

Figure 7 80-SP F-1031, Section 2416 Page 19 of 23... -

Page 20: Figure 8 Basic Cafs Schematic

Figure 8 Basic CAFS Schematic F-1031, Section 2416 Page 20 of 23... -

Page 21: Figure 9 Air Schematic W/ Manual Auto-Sync

Figure 9 Air Schematic w/ Manual Auto-sync F-1031, Section 2416 Page 21 of 23... -

Page 22: Figure 10 Hydraulic Schematic

Figure 10 Hydraulic Schematic F-1031, Section 2416 Page 22 of 23... -

Page 23: Section 7.Conditional 1-Year Warranty Policy

(1-1/2) years from the date of shipment by WATEROUS, whichever period shall be the first to expire; provided the Buyer notifies WATEROUS, in writing, of the defect in said product within the warranty period, and said product is found by WATEROUS to be nonconforming with the aforesaid warranty.

Need help?

Do you have a question about the 80-P and is the answer not in the manual?

Questions and answers