Summary of Contents for MIGHTYLAM 2700

- Page 1 OPERATING INSTRUCTIONS MIGHTYLAM 2700 ROLL LAMINATOR READ BEFORE OPERATING MACHINE FAILURE TO LOAD FILM CORRECTLY WILL VOID ALL WARRANTIES...

-

Page 2: Table Of Contents

TABLE OF CONTENTS Safety Messages and Electrical Safeguards ......3 - 4 Introduction ..................Laminator Features ..............5 Specifications ..................5 Intial Set-up ..................6 Operating Instructions…………………………………………7 - 8 Operation ..................Loading Laminating Film ............8 Threading Laminating Film ..........8 - 9 Adjusting Mandrel/Film Tension..........10 Heat Shoe Temperature ............10 Laminating .................. -

Page 3: Important Safety Messages And Electrical Safeguards

IMPORTANT SAFETY MESSAGES AND ELECTRICAL SAFEGUARDS For your protection, do not connect the laminator to electrical power or attempt to operate it until you read these instructions completely. Keep these instructions in a convenient location for future reference. This instruction manual and labels affixed to the laminator are important safety messages. Read these messages carefully. - Page 4 If the below conditions exist do not attempt to service or repair the laminator yourself. Unplug the laminator from the electrical outlet and contact an authorized service representative. • When the power supply cord or plug is damaged or frayed. •...

-

Page 5: Introduction

Congratulations on your purchase of the MightyLam 2700 Roll Laminator. This unit is designed to provide years of trouble-free service. The MightyLam 2700 will accept rolls of laminating film up to 27” wide in all film thicknesses. Paper and card stock up to 3/16” (4.8mm) thick may be laminated without adjusting the rollers. Your MightyLam 2700 is preset at the factory for most applications so any adjustments should be minor. -

Page 6: Intial Set-Up

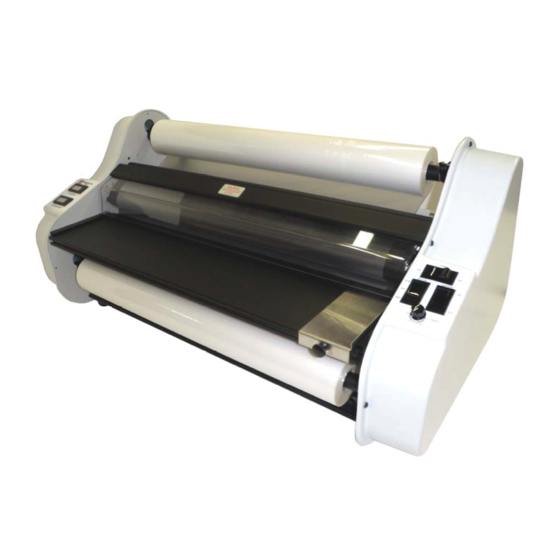

Before unpacking the unit, inspect the shipping container for signs of damage. Notify the carrier and your dealer immediately if any damage is noted. Components... Figure 1 below shows the location of the major components and controls of the MightyLam 2700. You should become familiar with these before operating the laminator. Figure 1... -

Page 7: Operating Instructions

OPERATING INSTRUCTIONS Heat Control Your new MightyLam 2700 has digital heat controllers for each heat shoe. Users can easily adjust the set temperature for each heat shoe individually to achieve the best quality lamination. Both controllers have been calibrated to accurately display the heat shoe temperature in the laminating range. -

Page 8: Operation

OPERATION This section describes the operation of your MightyLam 2700. This laminator is designed for all widths of plastic up to 27”. However, if narrower widths are used the Heat Shoes must be cleaned before using a wider roll. Refer to the MAINTENANCE section for cleaning instructions. - Page 9 4. Pull 6”-12” of film from the bottom roll. Pass it under the lower idler bar. Drape the film from the bottom roll over the film from the top roll. See figure 5. FIGURE 5 NOTE: The shiny side of the film must always go against the heat shoes. The heat shoes reach a temperature of up to 350°F.

-

Page 10: Adjusting Mandrel/Film Tension

7. When the feed card has completely exited the pull rollers at the rear of the laminator turn the motor switch off. 8. Replace the feed table. 9. If you are ready to laminate, the heat switch should be in the on position. Adjusting Mandrel/Film Tension….. -

Page 11: Laminating

Adjusting Slitter Blades The slitter (figure 8) may be set to trim the web to the desired width as it exits the laminator. If an additional slitter blade is installed (optional), two pages (side-by-side) may be laminated and trimmed in a single operation. (As the web exits the unit, these pages may then be separated with the additional slitter blade). -

Page 12: Coating Mount Board

If at any time you have adhesive going through the machine without mount board, be sure to pull the adhesive on the exit side of the machine to prevent a wrap-around. Mounting & Laminating The MightyLam 2700 is capable of simultaneously mounting and laminating a print on up to 1/4” mount board. Preparing your print for mounting:... - Page 13 1. Peel back about 2” of release liner on your pre-coated mount board. 2. Align the top edge of your print with the top edge of the mount board (see figure 9). Mounting your print: 1. Be sure all laminator parts (i.e. safety shield, feed table, etc.) are in their proper positions and the laminating film is loaded correctly on top and bottom mandrels.

-

Page 14: Troubleshooting

TROUBLESHOOTING PROBLEM: Laminator is inoperative. Motor does not run, indicator lights are out. ACTION: Unit may be unplugged. Connect power supply. Ensure that your circuit breaker has not tripped. Fuse may have blown. Replace 15 amp power fuse. PROBLEM: Laminating film and item being laminated move through laminator erratically. ACTION: Check thickness of item to be laminated. -

Page 15: Maintenance

ACTION: Adjust tension. If laminated item curls upwards, reduce top roller film. If item curls downward, reduce bottom film tension. Clean heat shoes of residual adhesives as it may be causing “drag” on one side. Refer to MAINTENANCE section for cleaning instructions. MAINTENANCE This section contains instructions for cleaning and maintaining your laminator. -

Page 16: Warranty & Return Policy

WARRANTY AND RETURN POLICY Warranty Your laminator is warranted to be free of defects in material and workmanship for a period of 1 year from the original purchase date. In the event of a defect in material or workmanship, the manufacturer or its authorized dealer, will repair or replace (at their option) the laminator. This does not cover rollers that have been damaged due to improper usage. -

Page 17: Parts List And Illustrations

BACKING,IDLER,BLOCK,EZII 10085 MOTOR, EZII, 80mm 10815 SPROCKET, IDLER,MIGHTYLAM 2801 SPROCKET, FRONT ROLLER, 22T 10371 SPROCKET, REAR ROLLER, 21T 10500 SPROCKET, MOTOR, MIGHTYLAM 10814 CHAIN, MIGHTYLAM 10356 HEAT SINK 8288 RELAY, SOLID STATE 25A DC 10357 TERMINAL BLOCK, 10 STA 10393... - Page 18 FUSE HOLDER, POWER 11327 FUSE, MAIN POWER 15AMP ABC-15 11532 FUSE, MOTOR, ¾ AMP AGC3/4 10386 HEX KEY, ROLLER PRESSURE ADJUSTMENT 10389 LABEL, RIGHT MIGHTYLAM 10387 LABEL, LEFT MIGHTYLAM 8279 SENSOR, K TYPE 2856 SHAFT COLLAR, FR12, 1/2" 11611 SLITTER BLADE ASSEMBLY...

Need help?

Do you have a question about the 2700 and is the answer not in the manual?

Questions and answers