Advertisement

Quick Links

SERVICE MANUAL

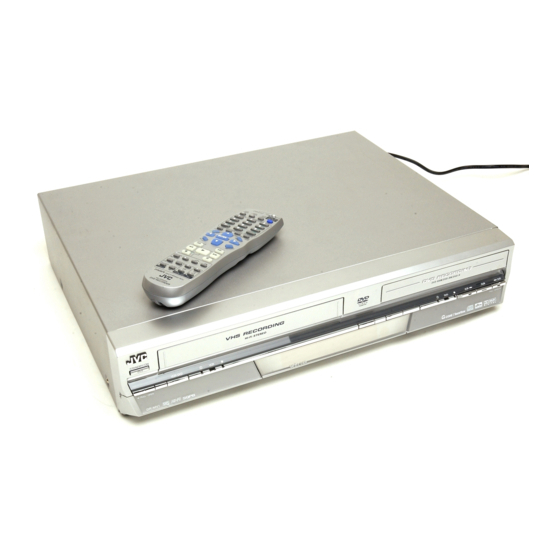

DVD VIDEO RECORDER & VIDEO CASSETTE RECORDER

YD006

4

2004

DR-MV1SUC, DR-MV1SUS

CABLE/DBS

TV

DVD

TV/CBL/DBS

VCR

DVD

VCR

/DVD

TIMER

TIMER

/DVD

NUMBER / TV CH / DVD CH

NUMBER / TV CH / DVD CH

1

2

3

ABC

DEF

4

5

6

GHI

JKL

MNO

7

8

9

PQRS

TUV

WXYZ

0

CANCEL

AUX

MEMO/MARK

PROG/CHECK DISPLAY ON SCREEN

VCR PLUS+

PROGRESSIVE

SCAN

ENTER

PREVIOUS

NEXT

SLOW

PLAY/SELECT

SLOW

STOP/

CLEAR

PAUSE

REMAIN

REC

REC MODE

POWER

ANGLE

SUBTITLE

LIVE CHECK

T V

CH

VOL.

TV/VCR

AUDIO

VCR EJECT

TV/DVD

TV/CBL/DVD

TV

PULL-OPEN

DVD

S-VIDEO

For disassembling and assembling of MECHANISM ASSEMBLY, refer to the SERVICE MANUAL No.86700(MECHANISM ASSEMBLY).

1

PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2

SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3

DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

4

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

5

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

VCR/DVD

TIMER

VCR

REC

F-1

VIDEO

(MONO) L - AUDIO - R

DR-MV1SUC, DR-MV1SUS [D3RV21]

TABLE OF CONTENTS

COPYRIGHT © 2004 VICTOR COMPANY OF JAPAN, LIMITED

OPEN/CLOSE

STOP

PLAY

TIMER

DVD

REC

VCR

DUBBING

DVD

PULL-OPEN

REMAIN

REC

PAUSE

REW

FF

REC LINK

CH

DV IN

REC MODE

<<

SLOW

>>

DVD

Preliminary

No.YD006

2004/4

Advertisement

Summary of Contents for JVC DR-MV1SUC

-

Page 1: Table Of Contents

S-VIDEO VIDEO (MONO) L - AUDIO - R DR-MV1SUC, DR-MV1SUS [D3RV21] For disassembling and assembling of MECHANISM ASSEMBLY, refer to the SERVICE MANUAL No.86700(MECHANISM ASSEMBLY). TABLE OF CONTENTS PRECAUTION............... . . 1-3 SPECIFIC SERVICE INSTRUCTIONS . - Page 2 SPECIFICATION DR-MV1SUC DR-MV1SUS GENERAL Power requirement AC 120 V, 60 Hz Power consumption Power on 43 W Power off 16.5 W Temperature ° ° ° ° Operating C to 35 C (41 F to 95 ° ° ° ° Storage...

-

Page 3: Precaution

SECTION 1 PRECAUTION SAFTY PRECAUTIONS Prior to shipment from the factory, JVC products are strictly in- Consequently, when servicing these products, replace the spected to conform with the recognized product safety and elec- cathode ray tubes and other parts with only the specified trical codes of the countries in which they are to be parts. - Page 4 1.1.2 Safety Check after Servicing Examine the area surrounding the repaired location for damage (4) Leakage current test or deterioration. Observe that screws, parts and wires have been Confirm specified or lower leakage current between earth returned to original positions, Afterwards, perform the following ground/power cord plug prongs and externally exposed ac- tests and confirm the specified values in order to verify compli- cessible parts (RF terminals, antenna terminals, video and...

-

Page 5: Specific Service Instructions

SECTION 2 SPECIFIC SERVICE INSTRUCTIONS 2.1 Service position This unit has been designed so that the Mechanism and Main Main board assy board assemblies can be removed together from the bottom Regulator board assy chassis. Before diagnosing or servicing the circuit boards, take TP111 D.FF TP106 PB FM out the major parts from the bottom chassis. - Page 6 2.2.1 Changing Remote Control Code (2) To clean the parts of the tape transport system other than (1) Slide the TV/CABLE/DBS/DVD switch to DVD. the upper drum, use a piece of closely woven cloth or a cot- (2) Press the numeric button "1" of the remote control unit ton swab soaked with alcohol.

-

Page 7: Disassembly

SECTION 3 DISASSEMBLY Removing the major parts 3.1.1 Destination of connectors P= Spring, W= Washer, S= Screw, L= Locking tab, SD= Solder, CN**(WR**)= Remove the wire (WR**) from the Two kinds of double-arrows in connection tables respectively connector (CN**). show kinds of connector/wires. Note: : Flat wire : Wire... - Page 8 <Note 3a> • When reattaching the Mechanism assembly, secure the screws (S3a to S3b) in the order of 1,2,3. <Note 3b> • When reattaching the Mechanism assembly, be sure to align the phase of the Rotary encoder on the Main board assembly. •...

- Page 9 NOTE (S1a) 1.Insert direction of FCC WIRE as follows. [4]DVD unit [1]Top cover right side back side supporting side (S1a) electrode side 2.FFC WIRE and DRUM FPC WIRE should be insert as follows. (S1a) (S1a) [4]Bracket (S4a) 3.Insert the wire to even the root of connector completely at the same time as inserting each wire.

-

Page 10: Adjustment

SECTION 4 ADJUSTMENT Before adjustment 4.1.5 Switch settings When adjusting this unit, set the VCR mode and switches 4.1.1 Precaution as described below. • The adjustments of this unit include the mechanism com- • When using the Jig RCU, it is required to set the VCR to the patibility and electrical adjustments. - Page 11 Digit-key TENSION ARM Code • As the counter indication and remaining tape indication are not displayed FDP during the EVR adjustment CONTROL PLATE mode, check them on the TV monitor screen. Stamping(a) Stamping(b) • When performing the EVR adjustment, confirm that the FDP indication is changed to the EVR mode.

- Page 12 4.2.4 A/C head phase (X-value) Proper waveform variation Signal (A1) • Alignment tape(SP, stairstep, NTSC) [MHP] (A2) • Alignment tape(EP,stairstep,NTSC) [MHP-L] Mode • PB Equipment • Oscilloscope Measuring point (D) • TP106 (PB. FM) External trigger (E) • TP111 (D.FF) Improper waveform variation Down Adjustment part (F)

- Page 13 4.3 Electrical adjustment Note: (1) Record the signal (A2) in the mode (B1), and play back The following adjustment procedures are not only necessary the recorded signal. after replacement of consumable mechanical parts or board (2) Set the VCR to the manual tracking mode. assemblies, but are also provided as references to be referred (3) Set the VCR to the FWD slow (+1/6x) mode.

- Page 14 4.3.2.2 EE Y level Signal (A1) • Ext. input (A2) • Color (colour) bar signal Mode • EE PB/CB level Equipment • Oscilloscope Measuring point (D) • Y OUT (S terminal) EVR mode (F1) • Jig code “95” Fig.4-3d EE component PB/CB level EVR address (F2) •...

-

Page 15: Troubleshooting

SECTION 5 TROUBLESHOOTING Manually removing the cassette tape sion arm assembly free from tension, pull out the tape on the pole base assembly. Take the spring(a) of the If you cannot remove the cassette tape which is loaded because pinch roller arm assembly off the hook, and detach it of any electrical or mechanical failures, manually remove it by from the tape. - Page 16 EMG display of FDP display mode (1) Transmit the code “59” from the Jig RCU. The FDP shows the EMG content in the form of “E:**:**”. <Example 1> E : 01 Latest EMG <Example 2> E : - - No EMG record (2) Transmit the code “59”...

- Page 17 DD : Capstan motor control status EE : Loading motor control status : Sensor information (See sensor information details.) GG : Capstan motor speed HH : Key code (JVC code) Encoder data : Supply reel winding diameter data higher 8 bits. (See Mechanism mode sequence.) : Supply reel winding diameter data lower 8 bits.

- Page 18 5.3.4 EMG content description Note: EMG contents “E09” are for the model with Dynamic Drum (DD). CONTENT CAUSE If the mechanism mode does not change to the next mode within 4 sec- E01: Loading EMG 1. The mechanism is locked in the middle of the mode transition during a tape loading operation. onds after the loading motor starts rotating in the loading direction, while 2.

- Page 19 5.3.5 EMG detail information <1> *2 : Mechanism operation mode The status (electrical operation mode) of the VCR and the status [Table of MN*] (mechanism operation mode/sensor information) of the mecha- Display Mechanism operation mode nism in the latest EMG can be confirmed based on the figure in Command standby (No command to be executed) EMG detail information <1>...

- Page 20 3- : Mechanism sensor information *5 : Cassette tape type <1> [Common table of MN* and HD*] Display Cassette tape type <1> Cassette type not identified Mechanism sensor informatio n Large reel/small reel (T-0 to T-15/T-130 to T-210) not classified Display Mechansim Small reel, thick tape (T-120) identified/thin tape (T-140) identified...

- Page 21 Display function of DVD section 5.4.1 Displaying SYSTEM INFO SYSTEM INFO contains information on firmware version of the unit and the mechanism drive, and an initialize execution menu. (1) Set the unit to the Jig RCU mode. (2) Transmit "8b" from the JIG RCU. (3) SYSTEM INFORMATION menu is displayed in the screen.

- Page 22 5.4.3 The exchange method of a tray fitting When DVD unit is exchanged, please transplant a tray fitting from an old drive, or change for a new tray fitting. 5.4.4 Initialization method Since the information on internal is as follows if it initializes, before enforcement, it is required to surely obtain the approval of a cus- tomer.

- Page 23 (No.YD006)1-23...

- Page 24 JVC SERVICE & ENGINEERING COMPANY OF AMERICA DIVISION OF JVC AMERICAS CORP. www.jvcservice.com(US Only) JVC CANADA INC. Head office : 21 Finchdene Square Scarborough, Ontario M1X 1A7 (416)293-1311 (No.YD006) Printed in Japan...

Need help?

Do you have a question about the DR-MV1SUC and is the answer not in the manual?

Questions and answers