Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Brooks Stairlift

- Page 1 BROOKS STAIRLIFTS SUPERGLIDE 120 INSTALLATION PROCEDURES...

-

Page 2: Table Of Contents

CONTENTS Health And Safety Hazards Unpacking the Stairlift Carriage Pre-Installation Procedure Box Contents Installation Tools Required Optional Installation Installation Procedure 1.2.1 Preparation on Site 1.2.2 Joining the Rail 1.2.3 Installing the Rail 1.2.4 Installing the Stairlift Carriage 1.2.5 Setting Seat Angle 1.2.6... -

Page 3: Health And Safety Hazards

IMPORTANT! READ THESE PROCEDURES THOROUGHLY PRIOR TO STAIRLIFT INSTALLATION Health And Safety Hazards The following health and safety hazards should be considered when installing the stairlift: The risk of loose clothing Correct manual handling or body parts getting procedure. trapped... -

Page 4: Unpacking The Stairlift Carriage

WARNING! Take care when handling the carriage assembly, as this is a heavy component. Before unpacking carriage it is recommended if possible to unpack box at Top of Stairway using Brooks PACKING/ UNPACKING INSTRUCTIONS provided. PLEASE READ PACKAGE INSTRUCTIONS BEFORE REMOVING THE CARRIAGE FROM BOX... -

Page 5: Pre-Installation Procedure

Pre-Installation Procedure ���������������������������������� �������������������������������������������������������������� ������������������������������������������������������ ������������������������� ���������������������������� �� �� � � Open the bag that ������������������ �������������������������������� � � contains the remotes, �� ���������������������� ������ ��������������������������������� batteries and keys. � �������������������� � ���������������������������� � � ��������������������� � ������������ � ������� �... -

Page 6: Box Contents

Box Contents CARRIAGE BOX � �������� � �� ���� ����� � ������ � ����� ����� �������� � �� ��������� � � ���� � � ������� � ������� �� ��������� ������������ � ������� ���� � ��� ������ � �������� � �����... - Page 7 SEAT BOX � ���� � � ����������� � � ���� � �������� �� ���������� � ������ ���� � ��� ���� � � ����� ����� �� ���� ������ �� ��� ����...

- Page 8 RAIL BOX...

-

Page 9: Installation Tools

Installation Tools Required Open / ring Flat electrical Nº2 / Nº3 Spanner terminal Philips screwdriver screwdriver Socket 10mm 13mm 17mm Socket Socket ratchet extension Spirit Knife Level Tape Measure... -

Page 10: Optional

Optional Wire Side strippers cutters Hammer Drill Torch Philips masonry Screwdriver bits drill bit... -

Page 11: Installation Procedure

INSTALLATION PROCEDURE 1.2.1 Preparation on Site It is recommended that the following examinations be carried out prior to taking the rail into the end users’ property: Visually check the site making sure that all obstructions such as window sills, pipes, bulkheads, newel posts etc have been allowed for. -

Page 12: Joining The Rail

1.2.2 Joining the Rail The stairlift rail is shipped in two pieces that are spliced together during installation. The upper and lower charge points and upper and lower stopping limit ramps are installed on the rail sections at the factory. -

Page 13: Installing The Rail

The two rail sections now need to be fixed together. IMPORTANT! Make sure that the wiring isn’t trapped between the edges of the rail preventing a flush join. Re-tighten the pinch bolts to hold the joint-bar securely in place, using 2 x 10mm spanners. Replace the screw into the gear rack and back into the upper rail. - Page 14 Position the stair brackets underneath the rail - one on the first step, one on the very top step or on the landing and the middle two either side of the join in the rail. The stair brackets clamp to the underside of the rail and are secured by tightening the long 13mm nut / bolt, which runs right through each bracket.

-

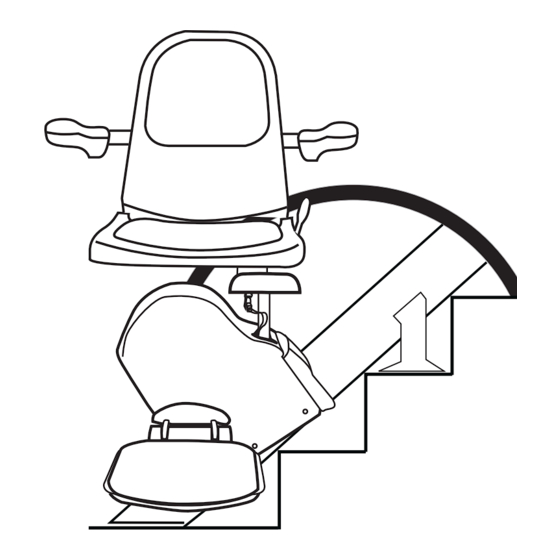

Page 15: Installing The Stairlift Carriage

� 1.2.4 Installing the Stairlift Carriage Remove the adjustable upper stopping limit ramp moulding from the top end of the rail. � WARNING! Take care when handling the carriage assembly, as this is a heavy component. Insert plastic end pieces to Rail top for Carriage installation. - Page 16 Switch on Battery isolation switch. Hold down seat switch, and drive Carriage onto Rail using a remote control. Remember to remove the plastic end pieces from the top of the rail. Remove yellow warning labels and transit screws attached to both upper and lower carriage safety edges then fi...

-

Page 17: Setting Seat Angle

1.2.5 Setting Seat Angle The following procedure must be STRICTLY adhered to, to avoid damage to the chassis plates. Remove the footrest hinge cover by removing the screw. To remove main cover, remove the 2 screws that are located along the front bottom edge. - Page 18 Loosen the 6 horizontal bolts (3 either side) until the post can just move. Adjust the seat to the correct angle by placing a spirit level on the seat post platform. Ensure that the anti-slip clamps (butterfly brackets) are in the correct horizontal position.

-

Page 19: Setting Footrest Angle

Replace the carriage cover and replace the two screws. 1.2.6 Setting Footrest Angle Loosen the centre bolt and adjust to the correct level using the spirit level. Once level, tighten the bolt back up. Return the footrest hinge cover by replacing the screw. -

Page 20: Installing The Seat

1.2.7 Installing the Seat The seat assembly now needs to be fitted to the seat post on the carriage. Carry this out as follows: Fold up the seat arms and seat base. Fit Seat Index Plate Cover. Ensure that all wires are clear and will not become trapped. - Page 21 With the seat facing across the stairs, hold the swivel locking handle down, and gently twist the seat from side to side, easing it downwards. Do this until the seat will not lower any more, and check that the seat post appears flush with the top of the seat frame.

- Page 22 If other codes are displayed refer to the error codes in the User Manual. The stairlift can now be ‘driven’ downwards to locate the motor drive pinion on to the toothed rack on the rail.

-

Page 23: Setting Top Stopping Point

Slide the stopping ramp up or down to a suitable position. Run the stairlift back to the top of the stairs and check to see if the footrest is level with the landing. If not, repeat until correct. -

Page 24: Fixing Down The Rail

There should be approximately 25mm between seat back and the wall to avoid trapping hazards. Adjust the clearance between the stairlift and the wall by moving the rail in or out appropriately. Once checked and final position verified, screw the rail brackets down to the stairs using the screws provided (four per bracket). - Page 25 fitting kit over the end of the rail. Ensure that the transformer wire is neatly routed so it will not cause a tripping hazard or get caught by the moving stairlift. Plug in the transformer only...

-

Page 26: Safety Checks

1.3.2 Check Remote Controls Press the GREEN button on the remote and the stairlift will descend. By releasing the button the stairlift will stop travelling. Pressing the RED button on the remote and the stairlift will travel in upwards. By releasing the button the stairlift will stop... -

Page 27: Check Safety Sensors

1.3.3 Check Safety Sensors Footrest ‘top’ side sensor - with the lift ascending, push top-side spring-loaded edge of footrest - lift should stop immediately. LED Display will show Footrest ‘bottom’ side sensor - with the lift descending, push bottom-side spring-loaded edge of footrest - lift should stop immediately. -

Page 28: Check Stopping Limits

- lift should automatically come to a ‘soft’ stop at the top of the staircase. 1.3.5 Check Seat Swivel Turn the seat toward the top of the stairs away from the riding position. The LED display should show and the stairlift will not operate... -

Page 29: Labelling

1.3.9 Labelling Check all labels are fi xed to the stairlift. 1.3.10 Check Correct Fixing of Carriage to Rail Ride the stairlift up and down once, ensuring the ride is smooth and... -

Page 30: Demonstrate Stairlift To User

AT LEAST until you are certain that they are able to use it safely. If the user is unable to operate the stairlift correctly and safely, the stairlift should be removed, unless it is to be operated by an attendant. In this case, the attendant should be present at the installation. - Page 32 REGISTER YOUR BROOKS STAIRLIFT AT www.brooksstairlifts.com/register © 2006 Brooks Stairlifts...

Need help?

Do you have a question about the Stairlift and is the answer not in the manual?

Questions and answers

Is there a wiring diagram somewhere in the manual or on line??