Table of Contents

Advertisement

Quick Links

INSTALLATION AND

SERVICE INSTRUCTIONS

ECONOMITE MODEL RE32

Gas Conversion Burner

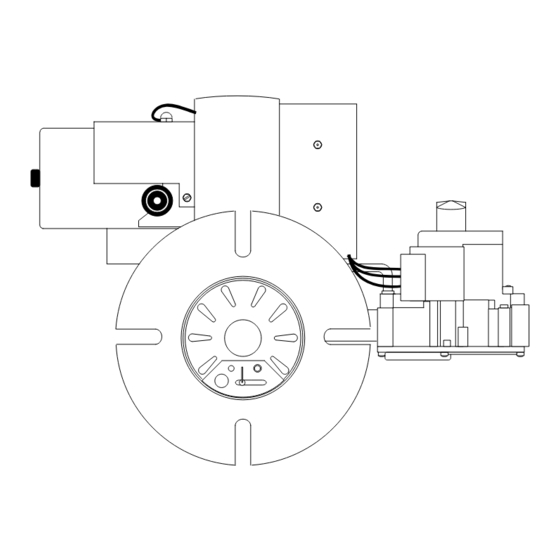

The ECONOMITE Model RE32 intermittent spark ignition conversion burner is adaptable to most gas utilization equipment,

including gravity and forced circulation furnaces and boilers, and is particularly recommended for horizontal and downdraft gas

utilization equipment since it needs no draft to maintain a pilot. Power burner design makes it perfectly suited for oil burner

replacement.

In the United States, installation must conform with local codes or,

in the absence of local codes, with Installation of Domestic Gas

Conversion Burners, ANSI Z21b-latest edition, and National

Fuel Gas

Code, ANSI Z223.1-latest edition, available from

American National Standard Institute. Further reference should

be made to the recommendation of your fuel supplier.

NOTE: Any additions, changes, or conversions required in order for

the gas utilization equipment to satisfactorily meet the application

needs must be made by a MIDCO distributor (or other qualified

agency) using factory specified and approved parts.

In Canada, installation must conform with local codes or, in the

absence of local codes, with Installation Codes for Gas Burning

Appliances and Equipment, CGA Standard CAN/CGA 1-B149.1

or 2. When the conversion burner is used on Forced Air Central

Furnace, the two yellow and black warning labels in the literature

envelope shall be attached in accordance with Installation Code,

CGA Standard CAN/CGA 1-B149,

reference should be made to the recommendation of

fuel supplier.

INSTALLER: Inform and demonstrate to the

user the correct operation and maintenance of

this gas utilization equipment. Inform the user

of the hazards of storing flammable liquids

and vapors in the vicinity of this gas utilization

equipment and remove such hazards.

this manual adjacent to the conversion burner.

CODE COMPLIANCE IS THE SOLE

RESPONSIBILITY OF THE INSTALLER.

USER: Retain this manual for future reference.

If other than routine service or maintenance

as described in this manual is required,

contact a qualified service agency.

ATTEMPT REPAIRS.

error could result in a dangerous condition.

SAFETY INFORMATION TERMS: The following terms are used to identify hazards, safety precautions or special notations and have

standard meanings throughout this manual. When you see the safety alert symbol and one of the safety information terms, as

shown below, be aware of the hazard potential.

DANGER: Identifies the most serious hazards which will result in severe personal injury or death.

WARNING: Signifies a hazard that could result in personal injury or death.

CAUTION: Identifies unsafe practices which would result in minor personal injury or product and property damage.

MIDCO International Inc.

4140 WEST VICTORIA STREET, CHICAGO, ILLINOIS 60646 / (773) 604-8700 FAX: (773) 604-4070 / http://www.midco-intl.com

PRINTED IN U.S.A.

ANSI Z21.17

CONVERSION

BURNERS

Clause 5.4.4.4.

Further

Affix

DO NOT

An inadvertent service

WARNING: If the information in

these instructions is not followed

exactly, a fire or explosion may

result, causing property damage,

personal injury, or death.

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

your

Do not try to light any appliance

Do not touch any electrical switch;

do not use any phone in your building.

Immediately call your gas supplier

from a neighborÕs phone. Follow the

gas supplierÕs instructions.

If you cannot reach your gas

supplier, call the fire department.

Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

197

8470-01

Advertisement

Table of Contents

Summary of Contents for Economite RE32

- Page 1 ECONOMITE MODEL RE32 Gas Conversion Burner The ECONOMITE Model RE32 intermittent spark ignition conversion burner is adaptable to most gas utilization equipment, including gravity and forced circulation furnaces and boilers, and is particularly recommended for horizontal and downdraft gas utilization equipment since it needs no draft to maintain a pilot. Power burner design makes it perfectly suited for oil burner replacement.

-

Page 2: Specifications

**All Ratings Based on 1000 BTU/Cu. Ft. NATURAL, 2500 usually not required for the ECONOMITE. However, a liner or BTU/Cu. Ft. PROPANE at Sea Level Derate burner for target wall may be necessary if the combustion chamber is... - Page 3 FIGURE 2 Dry Base Boiler With Combustion Chamber FIGURE 3 Wet Base Boiler with Unlined Liner (Furnace Construction is Similar) Combustion Chamber WARNING: BURNER CABINET MUST BE MOUNTED piping shall be fastened by sheet-metal screws or other IN ORIENTATION SHOWN IN FIGURES 2 approved means.

- Page 4 Set the thermostat heat anticipator for the total current draw pressure to the inlet of the combination valve when the burner handled by the thermostat. The current draw of the Economite and all other gas utilization equipment are on. For a firing rate 24V operating circuit is 0.9 amps.

- Page 5 11 turns from full closed (PROPANE 9 turns), to provide a lean gas/air mixture for initial start up. If a standard NATURAL gas Model RE32 is to be used with PROPANE gas, a conversion kit which contains a .025 Pilot Spud, a 1/8"...

- Page 6 control to OFF or thermostat below room temperature for Check the operation of the burner; start and stop it at least 60 seconds. If burner still fails to light, turn it off several times with the thermostat or operating control. and repeat from step 4.

- Page 7 FIGURE 8 Drawer Assembly manifold gas pressure of 2.0" W.C. If pressure adjustment is CAUTION: If the combination valve has been moved required for setting capacity, remove regulator cap for access or replaced, soap bubble test for leaks with the burner to slotted adjustment screw.

- Page 8 TROUBLE CHART Make sure the thermostat and operating controls are calling for heat. Defective wiring or loose connections can simulate the component defects outlined below. Check associated wiring before replacing a component. ELECTRICAL AND FLAME CHECKS MUST BE MADE IN THE ORDER LISTED. is faint and thread-like and may be overlooked in Shut off the manual gas control to the gas utilization equipment.

Need help?

Do you have a question about the RE32 and is the answer not in the manual?

Questions and answers