Summary of Contents for Mar Cor Purification M4-2200

- Page 1 M4-SERIES WATER PURIFICATION MACHINES M4-2200 – M4-13200 Operation and Maintenance Manual 1238160 Rev. D y 11...

- Page 2 This page intentionally left blank 1238160 Rev. D 23May11...

-

Page 3: Table Of Contents

OPERATION AND MAINTENANCE MANUAL M4-SERIES WATER PURIFICATION MACHINES M4-2200 – M4-13200 TABLE OF CONTENTS Page CHAPTER ONE: GENERAL INFORMATION Section General Information and Principles of Operation Machine Nomenclature Machine Permeate Quality Materials and Features Specifications for M4-Series Machines CHAPTER TWO:... - Page 4 CHAPTER FIVE: OPTIONAL ACCESSORIES Section Level Controls Conductivity Meter Autoflush Filters and Water Softeners CHAPTER SIX: TROUBLESHOOTING APPENDIX A: RETURN MATERIAL AUTHORIZATION (RMA) PROCEDURE 1238160 Rev. D 23May11...

-

Page 5: Chapter One

M-Series Water Purification Machines M-Series Water Purification Machines M4-2200 – M4-13200 CHAPTER ONE: DESCRIPTION 1238160 Rev. D 1 - 1 Description... - Page 6 M-Series Water Purification Machines This page intentionally left blank. 1238160 Rev. D 1 - 2 Description...

- Page 7 RO membrane, under sufficient pressure, allows passage of purified water while rejecting and concentrating dissolved and suspended solids. Mar Cor Purification manufactures a patented spiral-wound membrane package, with a turbulent flow design. The membrane module (i.e. sepralator), also called an element collects the purified water within a central tube (permeate tube), see Figure 1.

- Page 8 M-Series Water Purification Machines CONCENTRATION Concentration equals the Total Dissolved Solids (TDS) concentration of a solution expressed as milligrams per liter (mg/L) or conductivity (microSiemens/cm). Feed Concentration Permeate Concentration Concentrate Concentration Average Concentration in machine SALT (IONIC) REJECTION: This equals the percent of dissolved salt rejected by the membrane, calculated from an average concentration over the membrane.

- Page 9 M-Series Water Purification Machines Given the system case in Figure 2: Average Concentration (C ) = (C ) 100 mg/L + (C ) 146.9 mg/L ) = 123.5 mg/L TDS Rejection = (C ) 123.5 – (C ) 6.2 x 100 = 95% ) 123.5 Passage = (C ) = 6.2 x 100% = 5.0%...

- Page 10 M-Series Water Purification Machines Typical P&ID 1238160 Rev. D 1 - 6 Description...

-

Page 11: Machine Permeate Quality

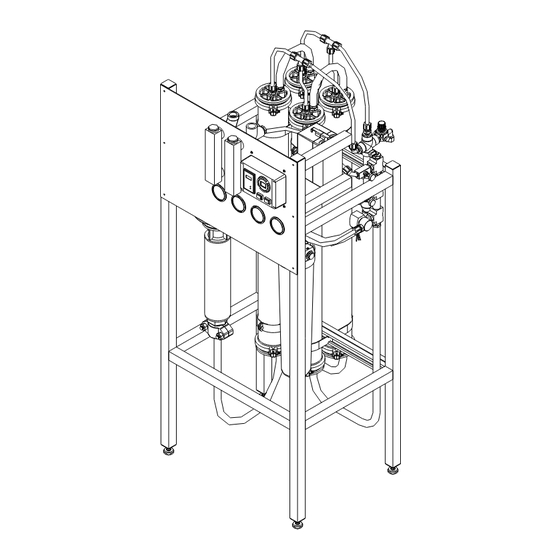

M-Series Water Purification Machines Machine Nomenclature M-Series water purification are numbered in such a way as to indicate the permeate flow and quality you can expect from the machine. Example: M4-6600, 208, 6, 50-75 • M4 indicates the machine series •... - Page 12 M-Series Water Purification Machines • Autoflush System – programmable, automated high velocity membrane flushing for the longest membrane life; set at the factory and adjustable in the field, includes a digital panel-mount timer, complete with push button Manual Flush • An electrical package that includes alarm delay shutdown for low inlet pressure condition to prevent pump damage should pressure fall below 15 psig (1 bar) •...

- Page 13 M-Series Water Purification Machines 1.5.2 Permeate (Product Water) Flow Rate Stated on the RO test report form (assumes no permeate back pressure, 2000 mg/L TDS maximum feed concentration, and rated temperature). To estimate permeate output with back pressure, use the formula below: Permeate Flow on Label x Operating Pressure –...

- Page 14 M-Series Water Purification Machines 1.5.6 Pump Multi-stage centrifugal, approximately primary operating pressure of 100 psig excluding line pressure. 1.5.7 RO Membrane Rejection FASTEK TLC Typical Ionic Rejection (TDS) 95-98% Average Molecular Weigh Cutoff* 150 MW *The molecular weight cutoff is based on the pore size of the membranes and the nature (shape/size) of the organic molecule.

- Page 15 M-Series Water Purification Machines NOTES: 1238160 Rev. D 1 - 11 Description...

- Page 16 M-Series Water Purification Machines This page intentionally left blank. 1238160 Rev. D 1 - 12 Description...

-

Page 17: Chapter Two

M-Series Water Purification Machines M-Series Water Purification Machines M4-2200 – M4-13200 CHAPTER TWO: INSTALLATION 1238160 Rev. D 2 - 1 Installation Guidelines and Instructions... - Page 18 M-Series Water Purification Machines This page intentionally left blank. 1238160 Rev. D 2 - 2 Installation Guidelines and Instructions...

-

Page 19: Plumbing

M-Series Water Purification Machines Mounting M-Series machines are equipped with a frame that supports the machine. Allow at least 45 inches (114 cm) of space at the top of the sepralator housing(s) for removal and loading of sepralators. If 45 inches (114 cm) are not available, the entire membrane element housing may have to be removed for element changes. -

Page 20: Electrical

M-Series Water Purification Machines Electrical M-Series models require two supply voltages, the control circuit voltage and a separate motor voltage. All field wiring must comply with applicable local and national electrical codes. All M4 models are supplied with a single-phase, 115 VAC 60 Hz or 230 VAC 50 Hz control circuit with an 8-foot cord with plugs into a three-prong grounded receptacle. - Page 21 M-Series Water Purification Machines 1238160 Rev. D 2 - 5 Installation Guidelines and Instructions...

- Page 22 M-Series Water Purification Machines NOTES: 1238160 Rev. D 2 - 6 Installation Guidelines and Instructions...

-

Page 23: Chapter Three

M-Series Water Purification Machines M-Series Water Purification Machines M4-2200 – M4-13200 CHAPTER THREE: PREPARATION AND START-UP 1238160 Rev. D 3 - 1 Preparation and Start-Up... - Page 24 M-Series Water Purification Machines This page intentionally left blank. 1238160 Rev. D 3 - 2 Preparation and Start-Up...

-

Page 25: Pretreatment For Water Purification

If the machine is to be run at a different location than was originally intended, a new water analysis is required for warranty consideration and should be sent to Mar Cor Purification for review and recommendations for operation of the machine. -

Page 26: Start-Up

M-Series Water Purification Machines Start-Up Re-check the function and integrity of your pretreatment equipment. Ensure that your water softener, activated carbon filters and iron filters (where applicable) have been leak checked, backwashed, and thoroughly rinsed for service, before starting up your RO unit. Attach the feedwater pipe work to the inlet of the machine. - Page 27 M-Series Water Purification Machines The proper adjustment of these valves is critical to the operation of the RO machine. The concentrate valve determines the amount of rejected water leaving the machine, and creates the operating pressure shown on the pressure gauge. The recycle valve returns unused reject flow back into the inlet stream to the RO pump.

- Page 28 M-Series Water Purification Machines Turn the ON/OFF switch to the ON position. The high-pressure pump will operate and the machine will begin to build pressure. As you are operating, make sure to watch the pressure gauge on the instrument panel. The machine is designed to operate at 115 psi (15.2 bar). NOTE: Do not allow the pressure to exceed 140 psi.

- Page 29 13200 models. Use this table in adjusting flow rates. NOTE: Permeate flow rates are dependent upon temperature and conditions at your site. Contact Mar Cor Purification if you have any questions. Table 1: Machine Recovery CONCENTRATE FLOW PERMEATE FLOW [GPM(LPM)]...

- Page 30 M-Series Water Purification Machines The system is now operational. Before putting the machine into final operation, continue to run the permeate and concentrate streams to drain for at least 60 minutes. This is done to ensure that all of the bactericide has been removed from the sepralators.

- Page 31 M-Series Water Purification Machines NOTES: 1238160 Rev. D 3 - 9 Preparation and Start-Up...

- Page 32 M-Series Water Purification Machines This page intentionally left blank. 1238160 Rev. D 3 - 10 Preparation and Start-Up...

-

Page 33: Operation And Maintenance

M-Series Water Purification Machines M-Series Water Purification Machines M4-2200 – M4-13200 CHAPTER FOUR: OPERATION AND MAINTENANCE 1238160 Rev. D Operation and Maintenance... - Page 34 M-Series Water Purification Machines This page intentionally left blank. 1238160 Rev. D Operation and Maintenance...

-

Page 35: Daily Log Sheets

(prefilter changes, flushing, cleaning, etc.), must be kept. Copies of the log can be made from the template. Mar Cor Purification will require a copy of this log sheet if a warranty question arises. -

Page 36: Flushing

We suggest cleaning at least every month to assure good membrane sepralator performance and long sepralator life. Mar Cor Purification offers a full line of chemical cleaners for specific cleaning needs. 4.4.1 Cleaning Procedure With the RO machine running, open the CIP Permeate valve. -

Page 37: Cleaning

M-Series Water Purification Machines With the machine off, close the feedwater inlet valve and open the CIP inlet valve. The permeate and concentrate streams must be diverted to the cleaning container for recirculation. Ensure that the prefilter is clean. A CIP pump is recommended to supply feed pressure in the machine. To circulate the cleaning solution through the machine with suction, the low-pressure switch must be bypassed. - Page 38 M-Series Water Purification Machines To flush the detergent from the machine, close the CIP inlet valve, open the feedwater valve, and divert the permeate and concentrate to drain by opening the CIP drain valve. Operate the machine as described in the flushing section for at least 1 hour.

-

Page 39: Sepralator Replacement

M-Series Water Purification Machines Sepralator Replacement As time progresses, the efficiency of the sepralator will be reduced. In general, the salt rejection does not change much until 2-3 years after installation, when operated on properly pretreated feedwater. The permeate flow rate will begin to decline slightly after one year of operation, but can be extended with diligent flushing and cleaning of the machine. - Page 40 M-Series Water Purification Machines NOTES: 1238160 Rev. D Operation and Maintenance...

- Page 41 M-Series Water Purification Machines M-Series Water Purification Machines M4-2200 – M4-13200 CHAPTER FIVE: ACCESSORIES 1238160 Rev. D 5 - 1 Accessories...

- Page 42 M-Series Water Purification Machines This page intentionally left blank. 1238160 Rev. D 5 - 2 Accessories...

- Page 43 M-Series Water Purification Machines Level Controls (Not Factory Installed) Wire float switches, pressure switches or other level controls into the control circuit line (prior to the switch as noted on the electrical schematic on the unit). The following assures that the inlet valve, instruments, and pumps are not powered when storage tanks are full: float switch assembly with cord, counter- weight, and plastic float (used with an atmospheric storage tank).

- Page 44 M-Series Water Purification Machines 5.3.1.3 Set Minute Press the clock key and the minute (min+) key simultaneously. The minutes will change. Hold the clock key and the minute (min+) key more than three seconds and the minutes will shift faster. Release both keys.

- Page 45 M-Series Water Purification Machines 5.3.4 To Select ON/AUTO/OFF Mode Press the MANUAL key to select the appropriate mode ON will turn on the timer. AUTO will set the timer to the Program Time. NOTE: Moving from ON to AUTO will turn on the timer according to the next Program’s turn-on time.

- Page 46 M-Series Water Purification Machines NOTES: 1238160 Rev. D 5 - 6 Accessories...

- Page 47 M-Series Water Purification Machines M-Series Water Purification Machines M4-2200 – M4-13200 CHAPTER SIX: TROUBLESHOOTING GUIDE 1238160 Rev. D 6 - 1 Troubleshooting...

- Page 48 M-Series Water Purification Machines This page intentionally left blank. 1238160 Rev. D 6 - 2 Troubleshooting...

- Page 49 M-Series Water Purification Machines TROUBLESHOOTING GUIDE Symptom Possible Causes Remedies Low operating Insufficient feedwater pressure or Open the feed pressure, pressure flow open the feedwater valve, check for restrictions. Clogged pre-filter Replace the cartridge High flow rates Close the concentrate valve, check the permeate and concentrate flow rates...

- Page 50 M-Series Water Purification Machines TROUBLESHOOTING GUIDE Symptom Possible Causes Remedies Low permeate Low operating pressure See the possible causes flow rate for low pressure Dirty or fouled sepralators Flush and clean the sepralators Operating on cold water less Install a hot/cold than 55°F (13°C) feedwater tempering valve if more permeate...

- Page 51 M-Series Water Purification Machines TROUBLESHOOTING GUIDE Symptom Possible Causes Remedies Concentrate valve plugged Remove the concentrate concentrate valve step and/or flow rate, disassemble the piping. normal or Concentrate outlet line Clean the valve. higher than restricted normal Examine the concentrate line pressure for obstructions or kinks;...

- Page 52 M-Series Water Purification Machines TROUBLESHOOTING GUIDE Symptom Possible Causes Remedies Excessive Restricted flow after pump Check for blockage of the pressure drop outlet concentrate flow at the inlets [over 50 psig and outlets of the sepralator (3.5 bar)] (high housings. primary pressure –...

- Page 53 Open the concentrate valve and flush. quality Test the water for pH hardness, TDS and iron content. A water analysis should be sent to Mar Cor Purification for review. Calibrated the monitor with a standard Inaccurate conductivity solution or check the range with another monitor fouled probe conductivity meter.

- Page 54 M-Series Water Purification Machines NOTES: 1238160 Rev. D 6 - 8 Troubleshooting...

- Page 55 M-Series Water Purification Machines M-Series Water Purification Machines M4-2200 – M4-13200 APPENDIX A: RETURNED MATERIAL AUTHORIZATION (RMA) PROCEDURE 1238160 Rev. D RGA Procedure...

- Page 56 M-Series Water Purification Machines This page intentionally left blank. 1238160 Rev. D RGA Procedure...

- Page 57 M-Series Water Purification Machines Returned Material Authorization Procedure If you wish to return good for repair, warranty evaluation and/or credit, please have your original sales order or invoice available when you call Mar Cor Purification. Call (800) 633-3080 and speak with Technical Support. A Mar Cor Purification Technical Support representative will provide instructions and a return authorization number which needs to be clearly written on the outside of the box used to ship your materials.

- Page 58 M-Series Water Purification Machines NOTES: 1238160 Rev. D RGA Procedure...

- Page 60 Call (800-633-3080) additional information or visit www.mcpur.com. 14550 28th AVE N Plymouth, MN 55447 Ph: 800-633-3080 FAX: 952-988-6661...

Need help?

Do you have a question about the M4-2200 and is the answer not in the manual?

Questions and answers