Summary of Contents for Protectowire 2000 FireSystem

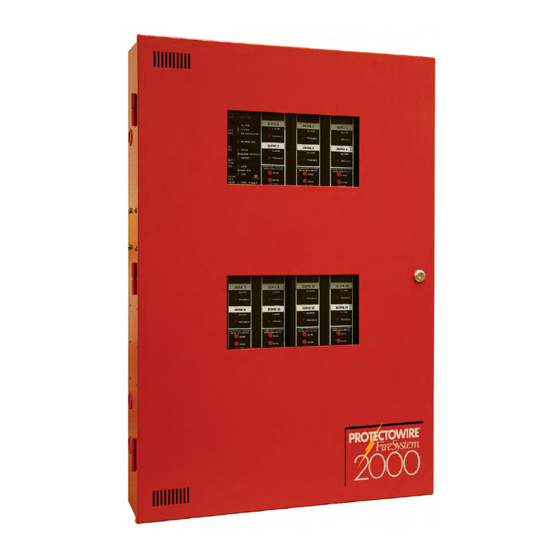

- Page 1 FIRE DETECTION CONTROL PANEL OPERATING & MAINTENANCE MANUAL An ISO 9001 Registered Company APPROVED...

- Page 2 Model Number, Drawing Number and Serial Number. This product information is recorded on the Panel Identification Label located inside the control panel. Please have this information available before call- ing your Authorized Protectowire Distributor or the Factory.

- Page 3 60 Washington Street, Pembroke, MA 02359-1833 USA Tel. (781) 826-3878 Fax (781) 826-2045 Visit us on the World Wide Web at: www.protectowire.com FS2000 Series Fire Detection Control Panel Operating & Maintenance Manual Part Number MAN-2000 Revision Date: June 1, 2011...

-

Page 4: Table Of Contents

Protectowire Alarm Point Location Meter (PDM) ........ - Page 5 Table of Contents (continued) OPTION Page No. “H” Intrinsic Safety Barrier for Special Hazard Applications ........39 “H”...

- Page 6 Caution The Protectowire Co. Inc. designs and manufactures fire protection systems to meet both UL and FM Global criteria for electrical transients introduced on both the power supply side of the system and into the panel from field wiring for initiating device circuits, notification applaince circuits, and other external field routed wiring.

-

Page 7: Information And Specifications

Deluge/Preaction Control Panel Information and Specifications The FS2000 Series of multiple zone fire protection panels is the latest in fire protection from The Protectowire Company, Inc. The standard model provides, as a minimum, 2 (Class A or B) initiating device circuits and the following standard features:... - Page 8 TYPICAL DETECTION CIRCUIT FIELD WIRING (ELR-HD-4-QC) INITIATING DEVICES Use the following compatible devices approved by The Protectowire Company, Inc.: - Up to 5,000 ft. of PROTECTOWIRE per circuit - Any combination of normally open contact devices. Note: Maximum feed cable resistance = 100 ohms Feed cable may consist of any combination of PROTECTOWIRE or copper wire.

-

Page 9: Standard Enclosure Mounting Dimensions

FS2000 Standard Enclosure Dimensions (all dimensions in inches) Enclosure Back Box Dimension Reference Table TYPE ROWS COLUMNS SPACES 17” 21” 4.75” 15” 19” 6” 31” 21” 4.75” 29” 19” 6” 31” 26” 4.75” 29” 24” 42” 26” 4.75” 40” 24” EN12 53”... -

Page 10: Lti2X Enclosure Mounting Dimensions

FS2000 LTi2X Enclosure Dimensions (all dimensions in inches) Enclosure Dimension Reference Table TYPE ROWS COLUMNS SPACES LTi2X 17.5” 19.5” 9” 12” 18.85” Note: Enclosure shown represents the LTi2X only. For LTi4 - LTi9 dimensions reference the LTi4 -LTi9 dimensions page of this manual. Caution: Do not drill through the top of the enclosure for conduit entry. -

Page 11: Lti4 - Lti9 Enclosure Mounting Dimensions

FS2000 LTi4 - LTi9 Enclosure Dimensions (all dimensions in inches) COLUMNS Enclosure Dimension Reference Table TYPE ROWS COLUMNS SPACES LTi4 35.25” 24” 6.85” 34” 18” LTi6 35.25” 29” 6.85” 34” 23” LTi9 46.25” 29” 6.85” 45” 23” Note: Enclosure shown represents the LTi4, 6 and 9 only. For LTi2X dimensions reference the LTi2X dimensions page of this manual. -

Page 12: Alarm Notification Appliance Circuit - Wire Size Estimator (Ds-9066)

FS2000 Series Alarm Circuit Installation Guide DS-9066A Issued 3-1-05 Alarm Notification Appliance Circuit Wire Size Estimator To ensure that all alarm notification appliance circuits will be supplied with adequate power to operate, it is necessary to use the correct size feed cable for the distance and current requirement of each circuit. Follow the steps below to calculate the correct wire size for your application. -

Page 13: Standby Battery - Size Calculation

FS2000 Series Fire Alarm Control Panel Battery Size Calculation Sheet Use this form to calculate the required battery size for your system. You must first determine the duration the panel will need to function on batteries in hours. The installation wiring diagram for your system includes a factory calculat- ed battery size in the specification section. -

Page 14: Typical Panel Field Wire Routing Detail

FS2000 Series Fire Alarm Control Panel Typical Panel Wire Routing Detail DS-9079B When bringing field wires to and from the control panel you must maintain segregation between Power Limited and Non-Power Limited wiring. Use the illustration below as a guideline for routing wire within the system enclosure. Also reference the field wiring sections of this manual to determine which field connections are Power Limited and which are Non-Power Limited. -

Page 15: Installation And System Power-Up Outline

FS2000 Series Fire Detection - Preaction/Deluge Control Panel Operation Installation Test and Maintenance Installation and System Power-Up. 1. Carefully unpack the system and inspect for any visible damage from shipping. 2. Mount the system in a clean, easily accessible, stable area with four (4) 1/4” screws. The system enclosure should be mounted to allow clear visibility of the systems control indicators and easy access to the systems control switches. -

Page 16: Test And Maintenance Outline

FS2000 Series Fire Detection - Preaction/Deluge Control Panel Operation Installation, Test and Maintenance Testing and Maintenance Quarterly testing is advised to help ensure system controls are functioning properly. Testing should be performed by competent personnel having jurisdiction over the protective signaling system. The following instructions should be observed in conjunction with the System Operational Outline contained in this manual when testing this equipment. -

Page 17: System Operational Outline

FS2000 Series Fire Detection - Preaction/Deluge Control Panel Operation Installation Test and Maintenance Operational Outline: 1. Normal Standby Condition a) “AC ON” Indicator (Green) illuminated. 2. Power Supervision AC power source failure: a) “AC ON” Indicator (Green) OFF. b) System trouble buzzer ON (Pulsing) - Press “SUP./TRO. SIL.” button to silence. c) “SYS. - Page 18 FS2000 Series Fire Detection - Preaction/Deluge Control Panel Operation Installation Test and Maintenance Operational Outline Continued: 6. Ground Fault Detection Circuit (Not available with Option “H”) When undesirable current flows to ground from the system DC power supply, either positive or negative: a) “SYSTEM TROUBLE / SUP”...

-

Page 19: Troubleshooting - Basic Troubleshooting Guide

FS2000 Series Fire Detection - Preaction/Deluge Control Panel Operation Installation Test and Maintenance Basic Troubleshooting Guide for The FS2000 Series Fire Alarm Control Panel Indicator Status Fault Condition Course of Action Alternate Action “A.C. ON” Indicator OUT AC Power source failure Check AC power source Check AC voltage across “SYS. - Page 20 FS2000 Series Fire Detection - Preaction/Deluge Control Panel Operation Installation, Test and Maintenance Continued from previous page Basic Troubleshooting Guide for The FS2000 Series Fire Alarm Control Panel Indicator Status Fault Condition Course of Action Alternate Action “A.C. ON” Indicator OUT Short in zone circuit field Class B –...

-

Page 21: Parts Replacement - Instructions

FS2000 Series Fire Detection - Preaction/Deluge Control Panel Part Replacement Instructions DS-9038 Rev. B Initial Steps 1. Notify the applicable local fire department and/or alarm receiving station that the system is being serviced. 2. Inform all personnel in the facility that testing is in progress, from the start of servicing to its completion. 3. -

Page 22: System Main Board - Description, Controls And Field Wiring

Main Board - MB-91A Sys. Test feature is available on special orders only and is not provided on systems with solenoid releasing. ELR-4.7K ELR-4.7K 1/2 W 1/2 W MAIN BOARD DISPLAY PANEL PROGRAMMABLE N.O. / N.C. TROUBLE MAIN BOARD CONTACTS COM. - Page 23 Lamp and trouble test button. Press to test indicator lamps and system trouble signaling. TEST METER Meter read switch. Press and hold to read distance (ft/m) to alarm actuation point of Protectowire zone SWITCH in alarm. See Option A – Protectowire alarm point location meter Note: The MB-91A/M (main board) is a host to the CC-91A/NT (Control Card) and ZC-91A (Zone Card).

-

Page 24: Transformer Connections

Main Board MB-91A/M - Field Wiring Common Trouble 1 amp @ 24 VDC, Resistive load 2 sets available. Contacts See Option “S” page for silencable & non- silenceable operation Main Board Common Supervisory 1 amp @ 24 VDC, Resistive load 1 set available MB-91A/M Contacts (non-silenceable) -

Page 25: Initiating Device Circuits

Protectowire or copper feed Ground Fault Impedance rating Less than 2.2K ohms impedance Use the following compatible devices or devices approved by The Protectowire Company, Inc. - Up to 5,000 ft. of PROTECTOWIRE per circuit. - Any combination of normally open contact devices. -

Page 26: 4-Wire Detector Power Supervision

4-Wire Detector Power Supervision Description - Supervision of power to 4-wire detectors is necessary to ensure their operation. Supervision is accomplished by installing a Power Supervisory Relay (PSR), Model PSR-2040 or its equivalent after the last detector. The relay contacts are nor- mally closed when power is present at the last detector. -

Page 27: Expander Board - Description, Accommodations And Field Wiring

Expander Board - EB-91A/M The zone expander board can accommodate up to (4) initiating device zones. Two zone cards per expander board with (2) initiating device zones per card. Zones can be implemented as Class A/B detection, waterflow or switch supervisory circuits depending on the card type being utilized. - Page 28 Expander Board - EB-91A/M The zone expander board can accommodate up to (4) initiating device zones. Two zone cards per expander board with (2) initiating device zones per card. Zones can be implemented as Class A/B detection, waterflow or switch supervisory circuits depending on the jumper configuration of the ZC-91A card.

- Page 29 100 ohms. Feed cable may consist of any combination of resistance PROTECTOWIRE or copper feed Use the following compatible devices or devices approved by The Protectowire Company, Inc. - Up to 5,000 ft. of PROTECTOWIRE per circuit. - Any combination of normally open contact devices.

-

Page 30: Control Card - Description, Variations And Controls

Control Card Module - CC-91A The Control Card CC-91A provides system controls and indicator for the FS2000 Series system. This card plugs into the Main Board MB-91A/M printed circuit board left side card slot. System control switches, lamp indicators and signal monitoring are managed with this module. - Page 31 Control Card Module - CC-91A The Control Card CC-91A provides system control and indicators for the FS2000 Series system. This card plugs into the Main Board MB-91A/M printed circuit board left side card slot. System control switches, lamp indicators and signal monitoring are managed with this module.

-

Page 32: Zone Card - Description, Variations And Controls

Zone trouble indicator: Activates in respect to each zone in TROUBLE condition ZC-91A Control Switches: Meter Switch Meter read switch Zone 1: Press and hold to read distance (ft/m) to alarm actuation point of Protectowire zone in alarm: Zone 1 See Option A - Protectowire alarm point location meter... - Page 33 Zone trouble indicator: Activates in respect to each zone in TROUBLE condition ZC-91A Control Switches: Meter Switch Meter read switch Zone 1: Press and hold to read distance (ft/m) to alarm actuation point of Protectowire zone in alarm: Zone 1 See Option A - Protectowire alarm point location meter...

-

Page 34: Protectowire Alarm Point Location Meter (Pdm)

PROTECTOWIRE run has an inherent resistance. This resistance although small compared to that of the PROTECTOWIRE, will introduce an error in the digital meter reading. The longer the feed wire, the greater the error . Adjust the meter per the following procedure to compensate for field wiring resistance. -

Page 35: Zone Alarm Scanner (Nds-91-16)

The NDS-91-16X Sixteen Zone Alarm Scanner identifies the zone number in conjunction with linear alarm point identification of a PROTECTOWIRE heat sensitive cable detection zone. In the automatic (AUTO) scan mode this device continually steps through all active (not bypassed) detection zones until an alarm input signal is received. Once received, the zone is identified and displayed with the alarm point location for approximately six (6) seconds;... -

Page 36: D" Waterflow Detection Card (Zc-91Aw)

Option “D” - Waterflow Detection Card -ZC-91AW The zone card ZC-91AW provides two Class A or Class B alarm initiating device circuits for waterflow detection monitoring. Both waterflow alarm circuits are equipped with alarm and trouble indicators for immediate off normal status identification. The waterflow card must be programmed per jumper settings noted below and plugs into the Main Board MB-91A/M and/or Expander Boards EB-91A/M printed circuit board card slots. - Page 37 Option “D” - Waterflow Detection Card -ZC-91AW The zone card ZC-91AW provides two Class A or Class B alarm initiating device circuits for waterflow detection monitoring. Both waterflow alarm circuits are equipped with alarm and trouble indicators for immediate off normal status identification. The waterflow card must be programmed per jumper settings noted below and plugs into the Main Board MB-91A/M and/or Expander Boards EB-91A/M printed circuit board card slots.

-

Page 38: E" Switch Supervisory Card (Sc-91A)

Option “E” - Switch Supervisory Card - SC-91A DESCRIPTION: The supervisory card SC-91A provides two Class A/B alarm initiating supervisory circuits to recognize the activation of a normal- ly open switches (tamper, low air, temperature, etc.) Each zone is equipped with individual alarm (yellow) and trouble (yellow) LED’s for diagnostic ease. -

Page 39: F" Solenoid Release/Switch Supervisory Board - Field Wiring

A meter read switch is provided to activate alarm point location on the circuit when used in systems employing the Protectowire Alarm Point Location Meter. Release Circuit Activation Operation: Trip - When the releasing output circuit is triggered by the appropriate pro- grammed zone/s, the solenoid coil is energized opening the control valve allowing the extinguishing agent to be expelled. -

Page 40: Solenoid Release / Detection Zone Field Wiring

Solenoid Release/Initiating Device Card Field Wiring, Electrical Specifications & Jumper Settings Electrical Requirements: Electrical - Initiating Device Cirucit Voltage Standby 22VDC Current to Insure Alarm 11mA Less than 1.5K Ohm loop resistance maximum to insure alarm End-of-Line Resistor (detection zone) ELR-4.7K 1/2 Watt, 5% Electrical - Solenoid Release Circuit Voltage Standby 0.87VDC @ 1K Ohm... -

Page 41: Solenoid Release Card Jumper Settings

Solenoid Release/Initiating Device Card Field Wiring, Electrical Specifications & Jumper Settings Electrical Requirements: Electrical - Initiating Device Circuit Voltage Standby 22VDC Current to Insure Alarm 11mA Less than 1.5 K Ohm loop resistance maximum to insure alarm End-of-Line Resistor ELR-4.7K, 1/2 Watt, 5% FM approved Solenoid Groups Groups A thru K Fuse (F1) used with Star D (Group C valve only... -

Page 42: Intrinsic Safety Barrier For Special Hazard Applications

Option “H” - Intrinsic Safety Barrier for Special Hazard Applications DESCRIPTION: Some applications of PROTECTOWIRE linear heat detection circuits require energy limiting to prevent explosions in areas classified as hazardous locations. One method used to accomplish this “Intrinsic Safety” is to utilize diode shunt barriers. -

Page 43: H" Intrinsic Safety Barrier Field Wiring Illustration (Il-1008)

~ 40 ~... -

Page 44: Intrinsic Safety Dc Isolator For Special Hazard Applications

With this segregation spikes and other circuit abnormalities that occur in the non-safe (primary side) areas are eliminated due to the transformer isolation from the safe (secondary side) area circuit. When the secondary loop is shorted by a Protectowire activation, the primary attempts to compensate for the additional current drain of the secondary by drawing more current from the initiating circuit activating it into an alarm. -

Page 45: K" Intrinsic Safety Dc Isolator Field Wiring Illustration (Il-1008-2)

~ 42 ~... -

Page 46: L" "Ll" Auxiliary Zone Alarm Relays

Option “L” AND “LL” - Auxiliary Zone Alarm Relays DESCRIPTION: Auxiliary zone alarm signaling relays (AS) are often needed to provide an interface to other systems for annunciation and/or to pilot electrical shutdown. Also, (AS) relays may be used for cross zoning initiating circuits or various panel control functions. Reference the Installation Wiring Diagram (IWD) for specific function of installed relays. -

Page 47: Battery Charger Status Meters (Pwm-V-A)

Option “P” - Battery Charger Status Meters DESCRIPTION: An available numerical indication of battery status may be provided with Battery Charger Status Meters. These meters supply an easy-to-read accurate display of both the charger current draw and the charging/standby voltage level. OPERATION: The ammeter continuously displays battery charger current draw. -

Page 48: Common Alarm Signaling Relay (Cas)

Option “R” - Common Alarm Signaling Relay DESCRIPTION: The Common Alarm Signaling (CAS) Relay provides two sets of contacts for interfacing to other control equipment upon the initiation of any alarm condition. This relay is normally non-silenceable but can be field modified to provide silenceable contacts. OPERATION: The relays positive terminal (18/24) is sourced with 24V FWR. -

Page 49: Rr" Auxiliary Relay Module (Rb-98)

Option “RR” - Auxiliary Relay Module - RB-98 DESCRIPTION: Auxiliary signaling relays are often needed to provide an interface to other systems for annunciation and/or to pilot electrical shut- down. Auxiliary signaling relays may be used for “cross zoning” initiating circuits or other various panel control functions. The RB-98 Relay Module provides (8) individually activated sets of Form “C”... -

Page 50: Class A Alarm Notification Appliance Circuit Adapter (Am-91)

Option “T” - Class A Alarm Notification Appliance Circuit Adapter DESCRIPTION: The AM-91 Alarm Notification Appliance Circuit Adapter Module converts the two Class B system Alarm Notification Appliance Circuits of the Main Board MB-91 to Class A type circuits. This provides 4 wire alarm notification appliance circuits in lieu of the standard 2 wire circuits. -

Page 51: Alarm Expander Card (Ae-91)

Option “U” - Alarm Expander Card DESCRIPTION: The AE-91 Alarm Expander Card provides one alarm notification appliance circuit which may be wired in a Class A or Class B configuration (NFPA styles X and Z or W and Y). The module plugs into an expander board (EB-91A) expansion slot and can be factory programmed for general alarm activation or for selective activation by up to (4) individual detection zones. -

Page 52: V" Zone Voting Module (Zv-91)

Option “V” - Zone Voting Module DESCRIPTION: The ZV-91 Zone Voting Module is designed to supply an output signal upon the receipt of multiple zone alarm signals. The standard configuration produces a single output signal after receipt of (2) input signals. The module is also available in a (3) input version. -

Page 53: Preaction Double Interlock Deluge Cross-Zoning - Applications Data Sheet

FS2000 Series Control Panel Preaction Double Interlock Deluge Cross Zoning Applications Data Sheet Double Interlock Sprinkler Systems are designed to prevent accidental release of water. When the solenoid is energized, depressur- ization of the air filled pipes (loss of air) is required to obtain water at the sprinkler heads. This beneficial feature becomes a con- cern when the system is operating under battery backup power. -

Page 54: X" Dual Temperature Zone Card (Zc-95)

Alarm Point Location Meter (Option “A”). ZC-95 Control Switches Meter SW. Meter read switch Zone #1: Press and hold to read distance (ft/m) to alarm actuation point of Protectowire zone ZONE 1 in alarm. See Option “A” - Protectowire Alarm Point Location Meter. -

Page 55: X" Dual Temperature Zone Card Field Wiring

Option “X” - Dual Temperature Zone Card - ZC-95 Field wiring for Main Board (MB-91) and Expander Board (EB-91) PROTECTOWIRE TYPE "TRI" POWER LIMITED DUAL COMMON (BLACK) TEMPERATURE THREE (3) ALARM (CLEAR WIRE) TRIP @ 200° F WIRE LINEAR HEAT DETECTION CIRCUITS (2) PRE-ALARM (RED/PINK WIRE) TRIP @ 155°... -

Page 56: Power Conditioning Module (Ps-95)

INDICATOR INDICATOR RESET SWITCH TO CONTROL PANEL PS-95 ZONE MODULE EOL (PSR) POWER SUPERVISORY DET. RESET PROTECTOWIRE AC ON BK-UP ON RELAY P/N INPUTS PSR-2040 SELF RESETABLE FUSE POWER ON BUSS (REF. SIG.) 26Vdc OUTPUT FS2000 AL. RESET BUSS REMOTE AL. RESET TRO. -

Page 57: External Key Operated Switches

Option “Z” - External key Operated Switches DESCRIPTION: Option “Z” consists of four (4) externally mounted key operated switches. These switches are used to duplicate the main control functions normally operated by the push buttons mounted on the Control Card (CC-91) located inside the FS2000 system enclo- sure. -

Page 58: Preaction Manual Release Station And Releasing Agent Dead Man Abort

Preaction Manual Release Station DESCRIPTION: When solenoid releasing is employed, a means of manually activating the solenoid must also be provided for each release circuit as required by Underwriters Laboratories. The SG-32SK1 non-coded double action manual release station can provide this capability. The SG-32SK1 “Fire System Release”... -

Page 59: Fs2000 Series Alarm Control Panel Instructions - To Be Mounted Adjacent To The System Enclosure

Lamp and trouble test button: Press to test indicator lamps and system trouble signaling. TEST Meter read switches: Press and hold to read distance (ft/m) to alarm actuation point of Protectowire zone in alarm. MS-Z# See Option A - Protectowire alarm point location meter. -

Page 60: Listed Solenoids, Notification Appliance Devices, Listed Smoke Detectors

APPENDIX A The following Smoke Detectors/ Solenoids / Notification Appliance Circuits (NAC’s) are all approved by UL for use in the FS2000 panel Unless DET. MODEL IDENTIFIER BASE MODEL IDENTIFIER SLR-24V HD-3 NS6-220 HB-3 SLR-24H HD-3 NS6-220 HB-3 SIJ-24 HD-3 NS6-220 HB-3 Compatible 24 Volt Solenoids:... - Page 61 APPENDIX A (continued) The following 24 Volts DC Notification Appliancel Circuits (NACs) are all UL approved for use on the FS2000 Fire Control Panel. Note Wheelock Synch module DSM-12/24-R must be used for synchronization of Horn / Strobes. - Indicates Field Selectable Device Important: consult manufacture cut-sheet for actual current draw NAC type...

- Page 62 APPENDIX A (continued) Important: consult manufacture cut-sheet for actual current draw - Indicates Field Selectable Device NAC type Model / Series Average Current * RSD24-75110 .250 Amps * RSD24-153075 Strobe Light Retrofit .114 Amps * RSB24-153075 Amesco RSD24-110 .200 Amps Temporal Module TMP1-3A .025 Amps Synchronization Module...

- Page 63 The Protectowire Company, Inc. 60 Washington Street, Pembroke, MA 02359 U.S.A. p:781-826-3878 f:781-826-2045 web: www.protectowire.com email: pwire@protectowire.com M N 2000H-0313 (100) SPECIAL HAZARD FIRE DETECTION SYSTEMS...

Need help?

Do you have a question about the 2000 FireSystem and is the answer not in the manual?

Questions and answers