Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Lehman SP90

- Page 2 "hands off! Lehman has a world-wide Service Network of Distributors and Dealers. Get to know your local one through the Lehman Start Up Program and they will be on hand to help you, should you need it.

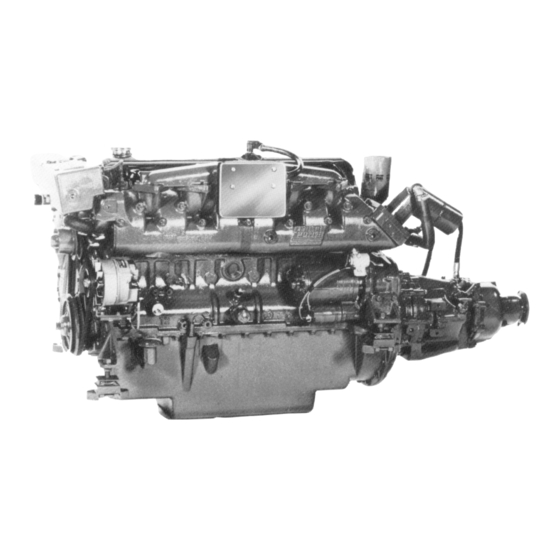

- Page 3 EXHAUST OUTLET 5 inch water cooled exhaust elbow. TRANSMISSIONS Twin Disc, PRM others available on request. Fuel consumption or typical Hull FINISH Lehman Red, with chrome rocker box, and filler caps APPROVAL STANDARDS Lloyds, RINA, DNV, ABS, JCI and others available.

-

Page 4: Specifications

254 cu/in. 4 Cyl. 380 cu/in. 6 Cyl. 363 cu/in 6 Cyl. Turbo. and 6 Cyl. TurboAnt. MODEL 4 CYCLE, OVERHEAD VALVE, DIRECT INJECTION MODEL (LEHMAN) 80 PSI between Cyl FIRING ORDER 1-2-4-3 1-5-3-6-2-4 CRANKSHAFT ROTATATION GOVERNED SPEED (Max) NO LOAD... - Page 5 T-Super SP275 6/82 Instructions for Ordering Parts Parts listed in this manual may be ordered through any Lehman distributor or dealer or. in areas not served by a Prices will be quoted upon request In order to prevent errors. please order any required items by exact part number and name of part When ordering parts.

-

Page 6: Engine Starts

LEHMAN DIESEL OWNER’S FAULT-FINDING GUIDE Starter does not Starter cranks crank engine engine slowly *Battery h n down *Battery partly run down Battery cable or switch *Battery terminals loose, Pump Injection pump **Air in fuel system **Air leak in fuel l i d... - Page 7 Controls, Starting & Stopping Engine No amount of engineering ingenuity or care in manufacture can substitute for the need of knowledge on the operation and avoidance of mis-use by the operator. It is important to be familiar with all controls so as to know how to properly operate your engine.

-

Page 8: Stopping All Engines

Stopping all Engines The engine should be allowed to slow idle for approximately 2 minutes before stopping, especially after extended periods of full load and full speed operation. This is particularly important in the case of turbocharged engines. Fuel System CAUTION: Your injection pump is a very accurately machined piece of equipment and requires careful handling and adjustment. -

Page 9: Bleeding The Fuel System

FIG. 4. TYPICAL FUEL SYSTEM, TURBO ENGINES Injection pump return tube Filter Press Relief Line Injector Leak Off Line *NOTE: “ON ENGINES MADE IN LATE 1985 ONWARDS FUEL RETURN LINES MAY BE INTERCONNECTED TO SIMPLIFY PIPING” (Return line to tank must be 10mm bore min.) Bleeding the Fuel System Bleeding air from the fuel system may well be one of the important procedures to be learned by the operator. -

Page 10: Fuel Lift Pump

Please contact your authorized Lehman Power distributor for this service. Warranty claims resulting from owner mishandling of the fuel injection pump will not normally be considered. - Page 11 While engine is hot, if there is liquid in tank, the system may be refilled with safety if not, allow engine to cool before refilling. Lehman Power recommends the use of anti-freeze at all times used in accordance with the manufacturer’s recommendations.

-

Page 12: Keel Cooling

The use of an efficient, full-flow raw water strainer is strongly recommended to prevent clogging of pump and exchangers by weeds, etc. Lehman part NO. EW-102 preferred. If hose is employed for intake, same should be reinforced type of extra heavy construction to prevent collapse under powerful suction of raw water pump Lehman can provide such hose if required. - Page 13 Electrics The standard electrical system for Lehman engines is 12 volt, NEGATIVE GROUND. Under no circumstances should polarity be reversed even for an instant for serious damage to alternator may result. For special applications, optional electrical systems are available in 12 volt insulated return, 24 volt negative ground and 24 volt insulated return configurations.

-

Page 14: Wiring Diagram

The filter is a full-flow, disposable “spin-on”type. It should be replaced at each oil change, and is readily available from your Lehman dealer. All marine installations should include an oil pressure gauge to register the lube system pressure and such gauge should be frequently checked to insure that system is functioning correctly. -

Page 15: Oil Viscosity Chart

of oil When engine is first installed, provide the proper quantity as indicated under “specifications” section. The oil cap is located on top of engine rocker cover. After pouring in oil, it will be necessary to wait several minutes before the oil level is checked in order to allow time for oil to flow to sump. -

Page 16: Borg Warner

Transmission As there is such a wide variety of transmissions available with Lehman diesels, it is not practical to cover all installations in this manual. However, due to the popularity of the Borg Warner, PRM/Newage and Twin Disc transmissions, the following information is offered for those models. -

Page 17: Routine Maintenance

Periodically inspect hoses for signs of leak, damage or sponginess, replacing where necessary. Pressure and temperature gages should be regularly inspected and replaced if found to be damaged or of suspect accuracy. If information on any other transmission is required, please contact Lehman and such information will be forwarded to you. -

Page 18: Maintenance

Maintenance The importance of correct lubrication, periodic inspection and adjustment cannot be over-emphasized. On it will depend, to a very large extent, the service which your engine will deliver. The heat exchanger of your engine is protected by a "zinc pencil" which should be inspected and replaced periodically as required. -

Page 19: Adjusting Valve Clearance

Rotate the engine and following the sequence in the following table, adjust each of the remaining valves. Replace rocker cover, making certain that gasket is unbroken and correctly positioned. After running engine for a short while, check rocker arm cover gasket for possible oil leaks. FIG. - Page 20 FIG. 20 INJECTION PUMP (All N.A. ENGINES) INJECTION PUMP (TURBO ENGINES) Max speed stop screw 2. Idling stop screw locknut TO ADJUST IDLING SPEED: When properly serviced and after the initial “break-in” period, your engine should idle as indicated on spec sheet. Engine must be at normal operating temperature when making adjustments.

- Page 21 It is common marine practice to utilize engine coolant passed through a hot water heater to provide domestic hot water. Connection to engine is made with Lehman Kit D1496. A coolant feed to the heater is made from the engine drain plug on the portside of block while the coolant return hose is attached to the forward, port side of the exhaust manifold.

- Page 22 Intercooler Assembly D I 128T Comprising Key 1-31 SP275 CODE PART No. DESCRIPTION INTERCOOLER BODY END RING INTERCOOLER CORE SUPPORT 1 c39 GASKET 1 C40 GASKET PLUG HOSE HOSE CLIP PIPE BOLT BOLT BOLT BOLT LOCK WASHER LOCK WASHER 1 D64 PIPE ASSEMBLY ADAPTOR PLUG...

- Page 23 SEE OVER...

- Page 24 Turbo Charger Assembly D l 51 5 Comprising Key 1-39 PART DESCRIPTION CODE TURBOCHARGER HOLSET 1456626 HOSE 1456620 AIR CLEANER SEE ALSO PAGE C42 5007673 CLAMP 1 C52 OIL RETURN GASKET WASHER SETSCREW OIL RETURN ELBOW CLAMP 5009881 60991 99 HOSE SLEEVE 6065031...

- Page 25 Turbo High Rise Exhaust Assembly 150 EXT. Comp Key (1 -1 7) Less 15 Comp Key (1 -1 7) Less 14 300 EXT. USE THE APPROPRIATE SUFFIX WHEN ORDERING ASSEMBLIES. CODE PART No. DESCRIPTION LOCK WASHER 1500785 STUD GASKET ADAPTOR )ALSO USED ON TOP CLAMP STEEL GASKET...

- Page 26 Thermostat Assembly D885 Comprising Key 1 -1 2 CODE PART No. DESCRIPTION HOSE CLAMP BOLT LOCK WASHER BOLT LOCK WASHER 1 A409 THERMOSTAT COVER 1 c47 GASKET 1 C46 RUBBER SEAL THERMOSTAT, SPl60/225/275 1 A41 0 THERMOSTAT HOUSING HOSE...

- Page 27 Header Tank Assembly D80O (Angled STD) Comp Key 1-1 7 Less (1 A) D801 (Horizontal) Comp Key (1-17) Less (1) CODE PART No. DESCRIPTION 1 A393 HEADER TANK (ANGLED) 1 A465 PRESSURE CAP VENT HOSE GASKET 1541 31 7 HOSE BARB CLAMP TUBE 1 D73...

- Page 28 Engine Oil Cooler Assembly DI97T Comprising >Key 1-22 PART No. DESCRIPTION CODE HOSE CLIP SPLIT FLOW RETURN GASKET PIPE RUBBER WATER HOSE RADIATOR HOSE HOSE CLIP LOCK WASHER OE307.5 SOCKET SCREW SETSCREW OILCOOLER ENGINE ADAPTOR OIL HOSE ASSEMBLY OIL HOSE ASSEMBLY HOSE PIPE BOLT...

- Page 29 c 2 2 Heat Exchanger Assembly D882 (Cupro) Comp Key (I A - I 8) D883 (Copper STD) Comp Key 1-18 (LESS I A ) N.B. 1854225 ARE ILLUSTRATED 275 END CAPS DIFFER CODE PART No. HEAT EXCHANGER (COPPER) SP185/225 SPARES ONLY HEAT EXCHANGER (CUPRO) SPl85/225 ONLY HEAT EXCHANGER (CUPRO) SP275 ONLY ID57...

Need help?

Do you have a question about the SP90 and is the answer not in the manual?

Questions and answers