Table of Contents

Advertisement

Owner's Manual

FOR YOUR SAFETY

READ AND UNDERSTAND THE ENTIRE MANUAL

BEFORE OPERATING MACHINE

MODLE NUMBER : □ LS5T-37

□ LS5T-52

SERIAL NUMBER :

Both model number and serial number may be found on the main label.

You should record both of them in a safe place for future use.

Save This Manual for Future Reference

Advertisement

Table of Contents

Summary of Contents for QCI LS5T-37

- Page 1 Owner’s Manual FOR YOUR SAFETY READ AND UNDERSTAND THE ENTIRE MANUAL BEFORE OPERATING MACHINE MODLE NUMBER : □ LS5T-37 □ LS5T-52 SERIAL NUMBER : Both model number and serial number may be found on the main label. You should record both of them in a safe place for future use.

-

Page 2: Table Of Contents

TABLE OF CONTENTS CONTENTS PAGE Safety Warnings & Cautions Application Conditions Specifications Electrical Requirements Contents of Shipping Container Set up and Preparation for Operation 6, 7 Wiring Diagram Plumbing Diagram Log Splitter Operation 8, 9 Freeing a Jammed Log Replacing Hydraulic Oil Sharpening Wedge Trouble Shooting Parts Schematic (1) -

Page 3: Safety Warnings & Cautions

SAFETY WARNINGS & CAUTIONS SYMBOL AFFIXED TO THE SAFETY WARNINGS & INSTRUCTIONS MACHINE UNDERSTAND YOUR LOG SPLITTER Read and understand the owner’s manual and labels affixed to the log splitter. Learn its application and limitations as well as the specific potential hazards peculiar to it. - Page 4 resistant lenses. They are not safety glasses. Do not put the log splitter on the ground for operations. This is awkward operating position that the operator has to bring his face close to the machine, and thus risks being struck by wood chips or debris EXTENSION CORDS Improper use of extension cords may cause inefficient...

- Page 5 protective hair covering to contain long hair, preventing it from get caught in machinery. DON’T OVERREACH Floor must not be slippery. Keep proper footing and balance at all times. Never stand on log splitter. Serious injury could occur if the tool is tipped or if the cutting tools is unintentionally contacted.

- Page 6 MAINTAIN YOUR LOG SPLITTER WITH CARE Keep splitter clean best safest performance. MAKE THE WORKSHOP CHILDPROOF Lock the shop. Disconnect master switches. Store the log splitter away from children and others not qualified to use...

-

Page 7: Application Conditions

C and for installation at altitudes no more than 1000m above M.S.L. The surrounding humidity should less than 50% at 40 It can be stored or transported under ambient temperatures between -25 C and SPECIFICATIONS Model Number LS5T-37 LS5T-52 Motor 230V~ 50Hz 1500W... -

Page 8: Set Up And Preparation For Operation 6

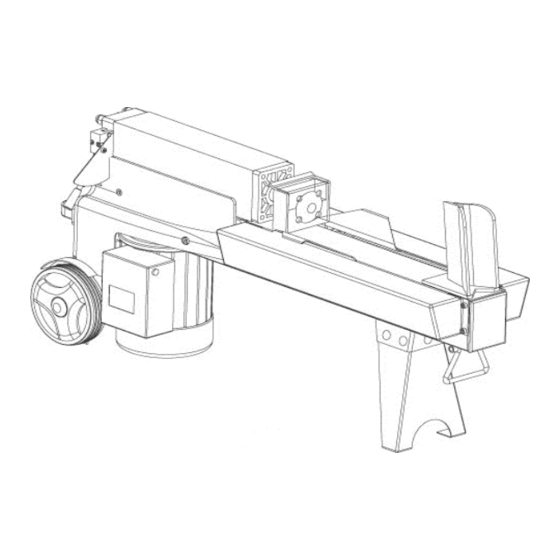

Connect the main leads to a standard 230V+10% (50Hz+1Hz) electrical supply which has protection devices of under-voltage, over-voltage, over-current as well as a residual current device (RCD) which maximum residual current rated at 0.03A. CONTENTS OF THE SHIPPING CONTAINER A. Log Splitter 1 set B. - Page 9 Oil Tank Log Pusher Work Table Wedge Lift Handle Support Leg Work Table Extension w/ Log Retaining Plates Switch Motor 10. Pushbutton Box 11. Wheels for Minor Moving ONLY. 12. Lift Handle 13. Hydraulic Control Lever 14. Control Lever Guard 15.

-

Page 10: Wiring Diagram

CAUSE PERMANT DAMAGE TO THE LOG SPLITTER. 17. Max Pressure Limiting Screw DO NOT ADJUST THE MAX PRESSURE LIMITING SCREW ! Max pressure was set before the log splitter work pressure limiting screw is sealed with glue to ensure the log splitter works under pressure no more than 5 tons. -

Page 11: Log Splitter Operation

LOG SPLITTER OPERATION... - Page 12 This log splitter is equipped with “ZHB” control system that requires to be operated by both hands of the user – Left hand controls the hydraulic control lever while right hand controls the pushbutton switch. The log splitter will freeze upon absence of either hand.

-

Page 13: Freeing A Jammed Log

on it to split excessively hard wood. After this time interval, the oil under pressure will be overheated and the machine could be damaged. For such extremely hard log, rotate it by 90 to see whether it can be split in a different direction. In any case, if you are not able to split the log, this means that its hardness exceeds the capacity of the machine and thus that log should be discarded to protect the log splitter. -

Page 14: Replacing Hydraulic Oil

Release both controls. After the log pusher moves back and completely stops at its starting position, insert wedge wood under the jammed log. Start the log splitter to push the wedge wood completely under the jammed one. Repeat above procedure with sharper slope wedge woods until the log is completely freed. - Page 15 Replace the Hydraulic oil in the log splitter after every 150 hours of use. Take following steps to replace it. Make sure all moving parts stops and the log splitter is unplugged. Unscrew Oil Drain Bolt with Dipstick to remove Turn the log splitter on the Support Leg side over an 4 liters capacity container to drain the hydraulic oil off.

-

Page 16: Sharpening Wedge

• ARAL Vitam GF 22 • BP Energol HLP-HM 22 SHARPENING WEDGE After using the log splitters for some time, sharpen the wedge of the log splitter using a fine-toothed file and smooth any burrs or crushed area along the cutting edge. - Page 17 unfamiliar noise vibrating Loosen Bleed Screw by 3 ~ 4 sealed hydraulic rotations before operating the system while operating. log splitter Bleed Screw Oil leaks around Tighten Bleed Screw tightened before moving cylinder ram or before moving the log splitter. the log splitter.

-

Page 18: Parts Schematic

PARTS SCHEMATIC (1) -

Page 19: Parts Schematic (2)

PARTS SCHEMATIC (2)

Need help?

Do you have a question about the LS5T-37 and is the answer not in the manual?

Questions and answers

Mitä hydrauliikka öljyä käytetään

The recommended hydraulic oils for the QCI LS5T-37 log splitter are:

- SHELL Tellus 22

- MOBIL DTE 11

- ARAL Vitam GF 22

- BP Energol HLP-HM 22

Or equivalent hydraulic oils.

This answer is automatically generated

какой сальник штока поршня стоит на дровоколе LS 5T - 37 и где можно купить ремкомплект для гидравлики этого дровокола?

The type of piston rod seal used in the QCI LS5T-37 log splitter is not specified in the provided context. For a hydraulic repair kit, the manual suggests contacting the dealer.

This answer is automatically generated