Table of Contents

Advertisement

Quick Links

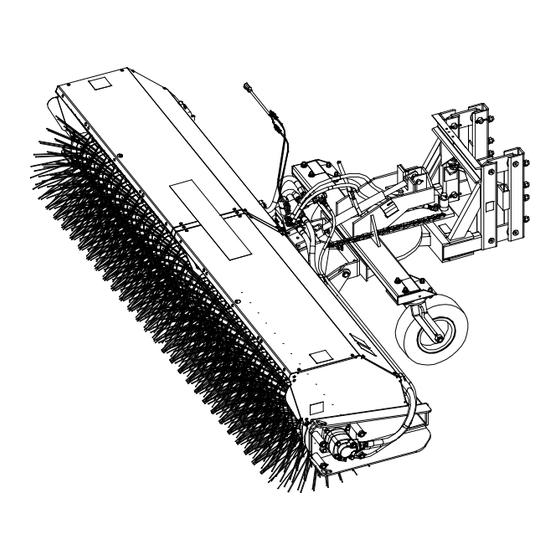

OPERATOR'S AND PARTS MANUAL

Hydraulic Windrow Sweeper

Serial Number: ___________________

Model Number: ___________________

800-456-7100 I www.paladinattachments.com

WLA 213 Series

for Loaders

2800 N. Zeeb Rd., Dexter, MI. 48130, United States of America Copyright ©

Manual Number: 51-4005

Release Date: January 2014

Serial Number: 0733001 & Up

Rev. 1

1

Advertisement

Chapters

Table of Contents

Summary of Contents for Sweepster WLA 213 Series

- Page 1 OPERATOR’S AND PARTS MANUAL WLA 213 Series Hydraulic Windrow Sweeper for Loaders Serial Number: ___________________ Manual Number: 51-4005 Release Date: January 2014 Model Number: ___________________ Serial Number: 0733001 & Up Rev. 1 800-456-7100 I www.paladinattachments.com 2800 N. Zeeb Rd., Dexter, MI. 48130, United States of America Copyright ©...

- Page 3 Table of Contents Section 1 ... Installation............ 5-13 Section 2 ... Operation and Maintenance ..... 15-22 Section 3 ... Service ............23-33 Section 4 ... Parts............35-46 Section 5 ... Options ............47-55 Section 6 ... Appendix ............ 57-61...

-

Page 5: Table Of Contents

Installation Manual Table of Contents Introduction ............... 6 Safety Information ..........7-13 General Safety Information ........7-8 Safety Signs & Labels ........10-11 Product Information Section ........12 Installation/Storage ..........13... -

Page 6: Introduction

Due to continuous product improvement, specifications and features may change without notice. Warranty To validate the warranty for this unit, fill out the warranty card or warranty pages located at the back of this manual. Then, send this information to SWEEPSTER. -

Page 7: Safety Information

SAFETY SECTION GENERAL SAFETY INFORMATION Safety Information •Check prime mover tire pressure before sweeping. Read this manual •Check tire ratings to be sure they match the prime mover load. Weigh the sweeper end of the prime mover, if necessary, to insure proper tire rating. Read all safety information in this manual. - Page 8 Repair loose lines, loose tubes, and loose hoses. Repair damaged lines, damaged tubes, and damaged hoses. Leaks can cause fires. See your SWEEPSTER dealer for repair or replacement parts. Replace the parts if any of the following conditions are present: •The end fittings are damaged or leaking.

- Page 9 Notes...

-

Page 10: Safety Signs & Labels

• Apply the safety sign to the position shown in the diagram Safety signs are available, free of charge, from your dealer above and smooth out any bubbles. or from SWEEPSTER. Serial Number ... - Page 11 SAFETY SECTION SAFETY SIGNS AND LABELS Safety Signs and Labels 50-0643 41043 Serial Number Tag 50-0722 50-0721 50-0726 50-0775 50-0724...

-

Page 12: Product Information Section

OPERATION SECTION PRODUCT SPECIFICATIONS Product Information Section Specifications and Model Views Maximum Width at 0° Articulation Maximum Width at Full Articulation Range of Hydraulic Oil Flow and Pressure Dual Motor 11.9 CI 12-30 gpm 4500 max psi Dual Motor 11.9/23.9 CI 18-45 gpm 4000 max psi Dual Motor 23.9 CI 24-60 gpm 4000 max psi... -

Page 13: Installation/Storage

NOTICE - Do not store the sweeper with weight on the have been successfully completed. Contact SWEEPSTER brush. Weight will deform the bristles, for instructions if the limiting stops do not contact properly. - Page 14 Notes...

- Page 15 Operation and Maintenance Manual Table of Contents Operation .............16-17 Operation ................16 Leveling Sweeper .............17 Maintenance............18-22 Brush Pattern Adjustment ..........18 Maintenance Schedule .............19 Maintenance Record ............20 Replacing Brush Sections ..........21 Lubrication Points ............

-

Page 16: Operation

OPERATION SECTION SWEEPING/OPERATING TIPS Before Each Use 4. Engage the brush and then lower it to the ground. Perform daily maintenance as indicated in Maintenance 5. Increase prime mover engine rpm to sweeping speed. Schedule. 6. Travel forward at 5 mph (8 kph) or less. Run the prime mover and sweeper at a slow idle. -

Page 17: Leveling Sweeper

OPERATION SECTION LEVELING THE SWEEPER Aligning Mounting The mounting incorporates a four-bar linkage system that allows the sweeper to move up and down independently of the loader arms. This feature is very important because it permits the sweeper to follow the contours of the ground, offering a good sweep. -

Page 18: Maintenance

MAINTENANCE SECTION BRUSH PATTERN/SPRING CHAIN/TRANSPORT CHAIN Setting Brush Pattern A properly adjusted brush offers the best sweeper performance. To check the brush pattern: Move the sweeper to a dusty, flat surface. Engage the parking brake and shut down the prime mover. Be sure to relieve pressure to the auxiliary hydraulic lines. -

Page 19: Maintenance Schedule

MAINTENANCE SECTION MAINTENANCE SCHEDULE Maintenance Schedule Procedure Before After See Prime Each Use Each Use Hours Hours Mover Brush head assembly - Level Brush pattern - Check (See Pattern Adj. Section) Cylinders - Retract rods - Grease threaded and ball ends to prevent rust Filter, air, prime mover - Clean Fittings/hoses, hydraulic - Check for leaks/tighten... -

Page 20: Maintenance Record

MAINTENANCE SECTION MAINTENANCE RECORDS Maintenance Record Use this log to record maintenance performed on the sweeper. Maintenance Performed Date Comments Procedure Performed... -

Page 21: Replacing Brush Sections

MAINTENANCE SECTION REPLACING BRUSH SECTIONS 1. Remove lynch pins and bushings. Retain hardware for reinstallation. Remove motor. 2. Remove core from brush head assembly. 3. Remove lynch pins, bushings and motor from the other side of brush head. 4. Remove idler bearing shaft mounting plate, retaining hardware. -

Page 22: Lubrication Points

MAINTENANCE SECTION LUBRICATION POINTS Lubrication Points The following grease fittings should be greased before each use. See figure for locations. Parallel Link Pins (8 fittings) Caster Assembly (2 fittings) Hydraulic Angle Cylinder (1 fitting) Not Shown: Center Mounted (1 fitting) - Page 23 Service Manual Table of Contents Troubleshooting ..........23-33 Brush Head ...............24 Lift & Swing ...............25 Hydraulic System ............26-29 Wiring Harness ............30--33...

-

Page 24: Troubleshooting

SERVICE SECTION TROUBLESHOOTING Brush Head Problem Possible Cause Possible Solution Brush rotates wrong direction Hoses installed incorrectly Switch hoses at brush head tubes Brush slows or stops when sweeping Brush pattern too wide Adjust brush pattern to 2-4 inches (51-101mm) wide: see Maintenance: Adjusting Brush Pattern Travel speed too fast Travel no more than 5 mph (8 kph) while... -

Page 25: Lift & Swing

Hoses or fittings loose or Tighten hoses or fittings disconnected Restriction in hoses Remove bends in hoses, remove obstructions inside hoses Hydraulic cylinder only extends or Dirt or debris in spools Contact Sweepster Technical Service only retracts... -

Page 26: Hydraulic System

Contact host manufacturer for proper maximum rate of broom flow control method Hydraulic motor seals leak Back pressure exceeds 1000psi Contact Sweepster Motor is failing High number of hours on motor; Contact dealer to rebuild or replace Motor Port Identification... - Page 27 SERVICE SECTION TROUBLESHOOTING 03-5215 12 Volt Manifold Hydraulic Schematic...

- Page 28 SERVICE SECTION TROUBLESHOOTING 03-5835 12 Volt Manifold Hydraulic Schematic .082 HYDRAULIC SCHEMATIC 213 SERIES...

- Page 29 SERVICE SECTION TROUBLESHOOTING 03-5836 24 Volt Manifold Hydraulic Schematic .082 HYDRAULIC SCHEMATIC 213 SERIES...

-

Page 30: Wiring Harness

SERVICE SECTION TROUBLESHOOTING Wiring Harness... - Page 31 SERVICE SECTION TROUBLESHOOTING Wiring Harness...

- Page 32 SERVICE SECTION TROUBLESHOOTING Wiring Harness WIRE NO. GUAGE WIRE NO.

- Page 33 SERVICE SECTION TROUBLESHOOTING Wiring Harness...

- Page 34 Notes...

-

Page 35: Parts Lists

Parts Manual Table of Contents Parts Lists ..............35-45 Brush Head Frames ............36 Core Assemblies ...............37 Motor Assembly ..............38 Hydraulic Assembly ............39 Manual Assembly ..............40 Swing Mountings ............41-44 Brush Head Labels ............45 Brush Head Stand ............46... -

Page 36: Brush Head Frames

PARTS SECTION BRUSH HEAD FRAME Brush Head Frame 12 19 NOTE: ASSEMBLE ITEM WITH CROSS HOLES HORIZONTAL. Item Part Description Item Part Qty Description 13-14817 2 Sheet, Hood, 5 Ft 07-2032 Clevis, Double Link, Gr80, 9/32 07-2952 Screw, HFH, CL10.9, M6-1 x 20 13-14079 2 Sheet, Hood, 6 Ft 13-14550-10... -

Page 37: Core Assemblies

PARTS SECTION CORE ASSEMBLIES Core Assemblies DETAIL B DETAIL A 01-1211-10 Set, Section, 36, Mixed, 10 ft 01-1211-12 Set, Section, 36, Mixed, 12 ft 01-1212-10 Set, Section, 36, Poly, 10 ft 01-1212-12 Set, Section, 36, Poly, 12 ft Item Part Qty Description 07-3279 Washer, Flat, Gr8, 3/8... -

Page 38: Motor Assembly

PARTS SECTION MOTOR ASSEMBLY Motor Assembly Hydraulic Motor Requirements Model 21319 and 21343 Require 2 03-4430 Model 21321 and 21344 Require 1 03-4430 (Right) and 1 03-5192 (Left) Model 21321 and 21345 Require 2 03-5192 Replacement Parts for 03-4430 : 03-5043... -

Page 39: Hydraulic Assembly

PARTS SECTION HYDRAULIC ASSEMBLY Hydraulic Assembly RETURN TOP PORT ON MOTOR PRESSURE BTM PORT ON MOTOR DETAIL A CASE DRAIN DIRECTION OF FLOW RETURN TOP PORT ON MOTOR PRESSURE BTM PORT ON MOTOR Replacement Parts for 03-5724: Replacement Parts for 03-4887: 45617 Seal Kit 03-4888 Seal Kit... -

Page 40: Manual Assembly

PARTS SECTION MANUAL ASSEMBLY Manual Assembly RETURN TOP PORT ON MOTOR PRESSURE BOTTOM PORT ON MOTOR RETURN TOP PORT ON MOTOR RETURN PRESSURE BOTTOM PORT PRESSURE ON MOTOR Item Part Qty Description 03-5238 Hose, .75 x 82, 12FF-12FF45, 3K, TC (10 Ft) 03-4119 Hose, .75 x 102, 12FF-12FF, 3K, TC (12 Ft) 03-5160... -

Page 41: Swing Mountings

PARTS SECTION SWING MOUNTING Bolt-On Swing Mounting 3 23 Item Part Qty Description Item Part Qty Description 07-0119 Bolt, Carriage, Gr5, 5/8-11 x 1 3/4 07-3066 Nut, Hex, Gr8, 3/4-10 07-0206 Pin, Cotter, Gr2, 3/16 x 2 07-3120 Washer, Flat, Gr8, 5/8 07-0223 Fitting, Zerk, 1/8NPT 07-3544... - Page 42 PARTS SECTION SWING MOUNTING Weld-On Swing Mounting Item Part Qty Description Item Part Qty Description 07-0119 Bolt, Carriage, Gr5, 5/8-11 x 1 3/4 07-3066 Nut, Hex, Gr8, 3/4-10 07-0206 Pin, Cotter, Gr2, 3/16 x 2 07-3120 Washer, Flat, Gr8, 5/8 07-0223 Fitting, Zerk, 1/8NPT 07-3544...

- Page 43 PARTS SECTION SWING MOUNTING Swing Mounting 3 Point Category II Serial # 0943100 and Lower Item Part Qty Description Item Part Qty Description 07-3066 Nut, Hex, Gr8, 3/4-10 07-0119 Bolt, Carriage, Gr5, 5/8-11 x 1 3/4 07-3120 Washer, Flat, Gr8, 5/8 07-0206 Pin, Cotter, Gr2, 3/16 x 2 07-3544...

- Page 44 PARTS SECTION SWING MOUNTING Swing Mounting 3 Point Category II Serial # 0943101 and Higher Item Part Qty Description Item Part Qty Description 07-3941 Caster, Assembly, Swivel 07-0119 Bolt, Carriage, Gr5, 5/8-11 x 1 3/4 07-5075 Screw, HHC, Gr8, 1/2-13 x 2 07-0206 Pin, Cotter, Gr2, 3/16 x 2 13-17196...

-

Page 45: Brush Head Labels

Qty Description 41043 Decal, Warning, Hazardous Dust 50-0185 Label, Logo, Medium, White 50-0252 Label, Logo, Large, White 50-0634 Label, Serial Number, Sweepster 50-0643 Label, Tie Down Point 50-0721 Label, Warning, Crush Hazard 50-0722 Label, Warning, Misuse Hazard 50-0724 Label, Warning, High Pressure Fluid Hazard 50-0726 Label, Warning, Flying Objects &... -

Page 46: Brush Head Stand

PARTS SECTION BRUSH HEAD STAND Brush Head Stand Item Part Qty Description 07-0260 Pin, Clevis, Gr2, 3/8 x 2 3/4 07-0699 Pin, Cotter, Gr2, 1/8 x 1 1/4 07-4748 Pin, Lock, 3/8 x 2 13-13898 Weld, Stand... -

Page 47: Options

Options Section Table of Contents Options ..............47-55 Hood Kits............48-49 Dust Suppression ............ 50 Water Tank ............51-52 Sight Indicator Kits ..........53 Case Drain Kit ............54 Hydraulic Angle ............55... -

Page 48: Hood Kits

OPTION SECTION HOOD KITS 180° Hood with Drape 28-9927-10 10 Ft 28-9927-12 12 Ft Item Part Qty Description 07-2952 Screw, HFH, CL10.9, M6-1 x 20 07-3617 Nut, Insert, Hex, M6 x 1 07-3736 Washer, Flat, CL8.8, M8 07-3737 Nut, Hex, CL10, M8-1.25 07-3738 Washer, Lock, Split, Medium, M8 07-3739... - Page 49 OPTION SECTION HOOD KITS 180° Hood 28-9932-10 10 Ft 28-9932-12 12 Ft Item Part Qty Description 07-2952 Screw, HFH, CL10.9, M6-1 x 20 07-3617 Nut, Insert, Hex, M6 x 1 07-3761 Screw, HHC, CL10.9, M12-1.75 x 45mm 07-4610 Nut, Hex, Lock, CL10.9, M12-1.75 13-14575 Sheet, Hood, 5 ft, 180°...

-

Page 50: Dust Suppression

DETAIL C OPTIONS SECTION DUST SUPPRESSION Dust Suppression DETAIL B Kit: 28-9928 DETAIL A DETAIL C DETAIL C NOTE 1: MOUNT SPRINKLER KIT DETAIL B IN THIS POSITION WHEN USING 180 DEGREE HOOD AND DEFLECTOR «««¦¦¦¦ Replacement Parts for 03-1326 : 07-6565 Fan Shroud 07-6566... -

Page 51: Water Tank

OPTIONS SECTION WATER TANK 85 Gallon Water Tank Kit: 28-4318 DETAIL A Item Part Description Item Part Description 13-10074 Weld, Mounting, Water Tank 03-0714 Barb, 10, 8MP90 03-1068-9 1 Fitting, 8FP-12MP 13-10075 Rubber, Neoprene, Tank, Pad 13-10081 Weld, Bolt, Tee, 3 1/2 07-1716 Bolt, Carriage, Gr5, 3/8-16 x 1 07-1734... - Page 52 OPTIONS SECTION WATER TANK 85 Gallon Water Tank 3 Point Kit: 28-10217 Replacement Parts for 07-4682 : 07-6088 07-7168 Drain Assembly Item Part Description Item Part Description 07-1716 Bolt, Carriage, Gr5, 3/8-16 x 1 07-4037 Nut, Hex, Nylock, Gr8, 1/2-13 07-1734 Clamp, Rubber, Vinyl, Coat, Hose, 1 07-4682...

-

Page 53: Sight Indicator Kits

OPTIONS SECTION SIGHT INDICATOR KITS Sight Indicators Kit: 28-9965 Item Part Qty Description 07-3279 Washer, Flat, Gr8, 3/8 07-5839 Nut, Hex, Nylock, 3/8-24 07-6597 Screw, HFH, CL10.9, M6-1 x 30 13-14857 Weld, Sight Indicator 13-9567 Ball, 2 1/8, Red, with Hole Kit: 11-5897... -

Page 54: Case Drain Kit

OPTIONS SECTION CASE DRAIN Case Drain Assembly REUSED FROM LEFT SIDE OF STANDARD HYDRAULIC ANGLE PACKAGE. Item Part Qty Description 03-3135 Tee, 12MB-12MF-12MF 03-3344 Fitting, 4MB-4MF 03-5245 Hose, .25 x 104, 4FF-4FF45, 3K, AR 03-5247 Hose, .25 x 120, 4FF-4FF90, 3K, AR 03-5249 Tee, 4MF-4MF-4MF, BHD, R... -

Page 55: Hydraulic Angle

OPTIONS SECTION HYDRAULIC ANGLE HYDRAULIC ANGLE ASSEMBLY Item Part Qty Description Replacement Parts for 03-5724 : 03-2092 2 Elbow, 90º, 6MB-6MF 45617 Seal Kit 03-2155 2 Hose, .25 x 72, 6FF-6FF, 3.25K 03-2159 2 Fitting, 6MF-4MP 03-5724 1 Cylinder, 2.5 x 1.25, 3.5K (09/24/09 and Up) Replacement Parts for 03-4887 : 03-4887 1 Cylinder, 2.5 x 1.38 x 7.5, 3.5K (09/23/09 and Down) - Page 56 Notes...

- Page 57 Appendix Table of Contents Bolt Torque Specifications ........58 Hydraulic Fittings Torque Specifications ....59-60 Warranty Information ..........61...

- Page 58 APPENDIX TORQUE SPECS. Foot-pounds may be converted to Newton Meters by multiplying by 1.35582 Foot-pounds may be converted to Inch-pounds by multiplying by 12. If the nut and screw are not the same grade, the lower grade will always be used. NOTE - Nylock nuts are utilized when greater resistance to vibrating loose is required, and greater operating temperatures are not a factor.

- Page 59 APPENDIX TORQUE SPECS Hydraulic Torque Specifications Face Seal: Assembly, Tube to Fitting Note - Face seal fittings have the most reliable sealing method and therefore, should be used whenever possible. Installation 1. Make sure threads and sealing surfaces are free of burrs, nicks, scratches, or any foreign materials. 2.

- Page 60 APPENDIX TORQUE SPECS. Hydraulic Torque Specifications Straight Thread O-ring Fitting: Assembly, Fitting to Port NOTE - Straight thread o-ring fittings are utilized to adapt hydraulic systems to motors, pumps, cylinders, and valves. Installation (Adjustable Fitting) 1. Make sure threads and sealing surfaces are free of burrs, nicks, scratches, or any foreign materials. 2.

-

Page 61: Limited Warranty

APPENDIX WARRANTY INFORMATION Limited Warranty Except for the Excluded Products as described below, all new products are warranted to be free from defects in material and/or workmanship during the Warranty Period, in accordance with and subject to the terms and conditions of this Limited Warranty.

Need help?

Do you have a question about the WLA 213 Series and is the answer not in the manual?

Questions and answers