Summary of Contents for DUROMAX XP3100PW

- Page 1 Model: XP 3100 PW Gasoline Pressure Washer OPERATOR’S MANUAL Tel: 800-629-4329 Email: support@duromaxpowerequipment.com...

-

Page 2: Table Of Contents

TABLE OF CONTENTS Introduction ....................................3 Safety Rules .....................................4 Safety Symbols ................................4 Safety Instructions ...............................4 Pressure Washer Features ..............................7 Pressure Washer Parts Assembly............................7 Pressure Washer Parts List ..............................7 Assembly ....................................10 Packing List ................................10 Unpacking ...................................10 Attaching Foot Assembly............................11 Install Handle................................11 Attaching Upper and Lower Gun Hooks ........................11 Attaching Accessory Hook ............................11 Attaching Spray Gun..............................12 Adding Engine Oil and Fuel ............................13... -

Page 3: Introduction

This pressure washer operates at 3100PSI with a flow rate of 2.5 gallons per minute. This high end residential use system features a 208cc DuroMax engine, no flat foam filled tires, 30’ high pressure hose, and 5 quick-connect nozzles. The emissions control system for this pressure washer is compliant with all standards set by the Environmental Protection Agency. -

Page 4: Safety Rules

SAFETY RULES Safety Symbols Indicates a potentially hazardous WARNING! situation which could result in serious injury or death if not avoided. Indicates a potentially hazardous CAUTION! situation which could result in damage to equipment or property. Slippery surface Risk of explosion Risk of electric shock Hot surface Eye protection... - Page 5 SAFETY RULES To reduce the risk of injection, injury or possible amputation, never direct water pressure WARNING! towards people or pets. • The high pressure stream of water produced can cut through skin and underlying tissue. Never squeeze the trigger or point the spray gun at other people, animals, plants, or fragile objects such as glass, even if the engine is stopped.

- Page 6 SAFETY RULES WARNING! Stay alert and use common sense. Do not operate this unit if you are under the influence of alcohol, drugs, medication or you feel tired. Pull cord recoils rapidly and pulls arm towards engine faster than you can let go which WARNING! could result in injury.

-

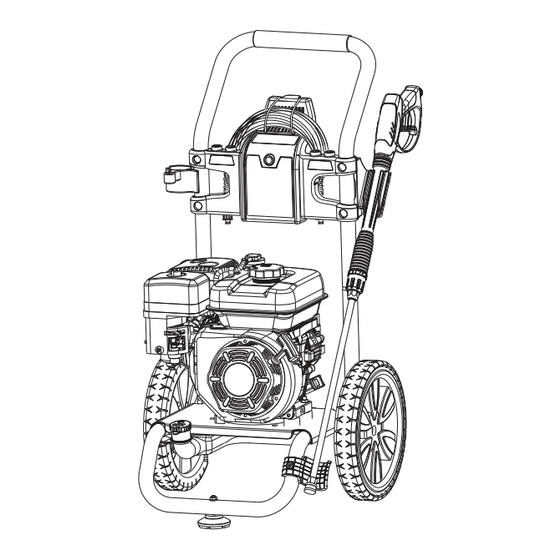

Page 7: Pressure Washer Features

PRESSURE WASHER FEATURES A - 30’ High Pressure Hose H - Locking Trigger B - Fuel Tank and cap I - Pull Cord C - Choke J - Engine On/Off Switch D - Fuel Valve Lever K - Oil Fill and Dipstick E - Soap Tank L - No Flat Foam Filled Tires F - Handle... - Page 8 PRESSURE WASHER PARTS ASSEMBLY...

- Page 9 PRESSURE WASHER PARTS LIST NUMBER ITEM NAME 208CC Engine XP 3100-P 1 Bolt M6 x 40mm XP 3100-P2 Cap, Soap Tank XP 3100-P3 Soap Tank XP 3100-P4 Lower "A" Frame assembly XP 3100-P5 M8 Self-Lock Nut XP 3100-P6 Rubber Feet XP 3100-P7 Round Head Bolt M6 x45mm XP 3100-P8...

-

Page 10: Assembly

ASSEMBLY Packing List • Pressure washer • Quick start guide • Operator’s manual and product registration card • Engine manual • Spray gun • Extension wand with quick-connect fitting • High pressure hose • Spray nozzles (5) - 0°, 15°, 25°, 40° and soap nozzle •... -

Page 11: Attaching Foot Assembly

ASSEMBLY Attaching Foot Assembly (See fig 1) • Parts needed - 1 foot, 1 M8 lock nuts. • Raise or tilt pressure washer so you can line up foot with the hole located at the centre of the frame. • Align the rubber foot with the hole in the frame where the foot is to be located. -

Page 12: Attaching Spray Gun

ASSEMBLY Attaching the Spray Gun (See fig 5 & 6) • Screw the spray wand and the trigger handle together until they are secure. • nut on by turning clockwise until it is hand tight. FIG 5 FIG 6... -

Page 13: Adding Engine Oil And Fuel

ASSEMBLY Adding / Checking Engine Oil (See fig 7) • Place pressure washer on a level surface. • • Carefully add between 520 ml (17.6 oz) of 4-Cycle engine oil (SAE10W30) to empty reservoir until oil reaches • Be sure to replace both dipsticks before attempting to start the engine. •... - Page 14 ASSEMBLY Connecting Garden Hose to Pressure Washer (See fig 9) • • Inspect inlet screen and remove any debris. • Connect hose to water inlet and tighten by hand. There must be a minimum of 10 feet of unrestricted hose between pressure washer and faucet or shut off valve.

-

Page 15: Operation

OPERATION Pre-Operation Check List • Read and understand this operator manual in its entirety before operating pressure washer. • Check oil level and add oil to the proper level if low. • Check fuel level and add fuel if needed. •... -

Page 16: How To Turn Off Pressure Washer

OPERATION Pull cord recoils rapidly and pulls arm towards engine faster than you can let go which WARNING! could result in injury. • Always relieve pressure from spray gun before pulling starter cord, including every failed attempt to start engine. •... -

Page 17: Using Spray Nozzle

OPERATION Using Spray Nozzle (See fig 16) • To connect or disconnect spray tip, pull back on the quick-connect collar. Insert or remove spray tip then release collar. • When spray tip is connected, pull on the spray tip to make sure it is secured. •... -

Page 18: Maintenance

MAINTENANCE Regular maintenance will extend the life of this pressure washer and improve its performance. The warranty does not cover items that result from operator negligence, misuse, or abuse. To receive full value from the warranty, operator must maintain the pressure washer as instructed in this manual, including proper storage. Before inspecting or servicing this machine, make sure the engine is off and no parts are WARNING! moving. -

Page 19: Changing Oil

MAINTENANCE Changing Engine Oil Engine oil will drain better if the engine is still warm, but not hot. • Shut off engine. • Clean the area around the oil fill cap/dipstick to keep out debris then remove oil fill cap/dipstick. •... -

Page 20: How To Store

MAINTENANCE Checking Spark Plug • Disconnect the spark plug wire from the spark plug. • Before removing the spark plug, clean the area around its base to prevent debris from entering the engine. • Clean carbon deposits off the electrode with a wire brush. •... -

Page 21: Troubleshooting

TROUBLESHOOTING PROBLEM CAUSE SOLUTION Engine does not start 1. Out of fuel 1. Fill fuel tank 2. Engine oil low 2. Add engine oil 3. Spark plug wire disconnected 3. Connect spark plug wire from spark plug 4. Replace spark plug 4.

Need help?

Do you have a question about the XP3100PW and is the answer not in the manual?

Questions and answers