Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for McCulloch MRT850

- Page 1 MRT850 Operator's Manual Gasoline containing up to 10% ethanol (E10) is acceptable for use in this machine. The use of any gasoline exceeding 10% ethanol (E10) will void the product warranty. 532 44 65-34 Rev.1...

-

Page 2: Safety Rules

SAFETY RULES Safe Operation Practices for Walk-Behind Powered Ro ta ry Tillers TRAINING • Never operate the tiller without proper guards, plates, or other safety protective devices in place. • Read the Manual care ful ly. Be thor ough ly fa mil iar with the controls and the proper use of the equip ment. -

Page 3: Table Of Contents

PRODUCT SPECIFICATIONS CUSTOMER RESPONSIBILITIES • Read and observe the safety rules. Gasoline Capacity: 3.2 Quarts (3.0L) • Follow a regular schedule in maintaining, caring for Unleaded Reg u lar and using your tiller. Oil (API:SG-SL): SAE 30 (Above 40°F/4°C) • Follow instructions under “Maintenance”... -

Page 4: Assembly

ASSEMBLY Your new tiller has been assembled at the factory with exception of those parts left unassembled for shipping purposes. To ensure safe and proper operation of your tiller all parts and hardware you assemble must be tightened securely. Use the correct tools as necessary to insure proper tightness. - Page 5 ASSEMBLY UNPACKING CARTON (See Fig. 2) • Grasp handle assembly. Hold in “up” position. Be sure handle lock remains in gearcase notch. Slide handle assembly into position. CAUTION: Be careful of exposed sta ples when handling or disposing of HANDLE ASSEMBLY carton material.

-

Page 6: Check Tire Pressure

ASSEMBLY CONNECT SHIFT ROD (See Fig. 6) • Insert end of shift rod into hole of shift lever indicator. • Insert hairpin clip through hole of shift rod to secure. SHIFT LEVER HAIRPIN INDICATOR CLIP SHIFT Fig. 6 REMOVE TILLER FROM CRATE •... -

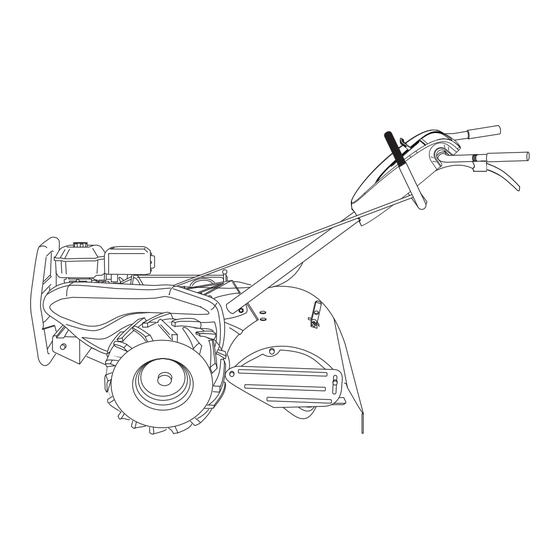

Page 7: Operation

OPERATION KNOW YOUR TILLER READ THIS MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TILLER. Compare the illustrations with your tiller to familiarize yourself with the location of various controls and adjustments. Save this manual for future reference. These symbols may appear on your Tiller or in literature supplied with the product. Learn and understand their meaning. - Page 8 OPERATION The operation of any tiller can result in foreign objects thrown into the eyes, which can result in severe eye damage. Always wear safety glasses or eye shields before starting your tiller and while tilling. We recommend a wide vision safety mask for over spectacles or standard safety glasses. 00155 HOW TO USE YOUR TILLER Know how to operate all controls before adding fuel and...

- Page 9 OPERATION TO TRANSPORT OUTER SIDE SHIELDS (See Fig. 10) The back edges of the outer side shields are slotted so CAUTION: Before lifting or trans port ing, that the shields can be raised for deep tilling and low ered allow tiller engine and muffler to cool. for shal low tilling to protect small plants from being buried.

- Page 10 OPERATION ADD GASOLINE • If engine fires but does not start, move choke control to half choke position. Pull recoil starter handle until • Fill to within 1/2" of top of fuel tank to prevent spills and engine starts. to allow for fuel expansion. Do not overfill. Use fresh, •...

- Page 11 OPERATION ADJUST WHEELS FOR CULTIVATING • Do not lean on handle. This takes weight off the wheels and reduces traction. To get through a really tough (See Figs. 15 and 16) section of sod or hard ground, apply upward pressure •...

-

Page 12: Maintenance Schedule

MAINTENANCE MAINTENANCE SCHEDULE FILL IN DATES AS YOU COMPLETE SERVICE DATES REGULAR SERVICE Check Engine Oil Level Change Engine Oil Oil Pivot Points Inspect Spark Arrester / Muffler Inspect Air Screen Clean or Replace Air Cleaner Cartridge Clean Engine Cylinder Fins Replace Spark Plug RH Gear Case Grease Fitting (1oz.) 1 - Change more often when operating under a heavy load or in high ambient temperatures. -

Page 13: Maintenance

MAINTENANCE Disconnect spark plug wire before performing any maintenance (except car bu re tor adjustment) to prevent accidental start ing of engine. Prevent fires! Keep the engine free of grass, leaves, spilled oil, or fuel. Re move fuel from tank before tipping unit for maintenance. -

Page 14: Spark Plug

MAINTENANCE COOLING SYSTEM (See Fig. 20) SPARK PLUG Your engine is air cooled. For proper engine performance Replace spark plugs at the beginning of each tilling sea- and long life keep your engine clean. son or after every 50 hours of use, whichever comes first. Spark plug type and gap setting is shown in “PRODUCT •... -

Page 15: Service And Adjustments

SERVICE AND ADJUSTMENTS CAUTION: Disconnect spark plug wire from spark plug and place wire where it cannot come into contact with plug. TILLER TO ADJUST HANDLE HEIGHT (See Fig. 21) Select handle height best suited for your tilling conditions. CLEVIS PIN Handle height will be different when tiller digs into soil. - Page 16 SERVICE AND ADJUSTMENTS GROUND DRIVE BELT ADJUSTMENT TO REPLACE GROUND DRIVE BELT (See Fig. 24) (See Fig. 24) • Remove belt guard as described in “TO REMOVE BELT For proper belt tension, the extension spring should have GUARD”. about 5/8" (16 mm) stretch when tine control is in “EN- •...

-

Page 17: Tine Replacement

SERVICE AND ADJUSTMENTS • To maintain the superb tilling performance of this TINE REPLACEMENT ma chine the tines should be checked for sharpness, (See Figs. 25, 26 and 27) wear, and bending, particularly the tines which are next to the transmission. If the gap between the tines CAUTION: Tines are sharp. - Page 18 SERVICE AND ADJUSTMENTS ENGINE TO AD JUST CARBURETOR The carburetor has been preset at the factory and ad just ment TO ADJUST THROTTLE CONTROL CABLE should not be necessary. However, engine per for mance (See Fig. 28) can be affected by dif fer enc es in fuel, tem per a ture, al ti tude or load.

-

Page 19: Storage

STORAGE Immediately prepare your tiller for storage at the end of the ENGINE OIL season or if the unit will not be used for 30 days or more. Drain oil (with engine warm) and replace with clean oil. (See “ENGINE” in the Maintenance section of this man ual). CAUTION: Never store the tiller with gasoline in the tank inside a build ing where fumes may reach an open flame... -

Page 20: Troubleshooting

TROUBLESHOOTING POINTS PROBLEM CAUSE CORRECTION Will not start 1. Out of fuel. Fill fuel tank. 2. Engine not “CHOKED” properly. See “TO START ENGINE” in Operation section. 3. Engine flooded. Wait several minutes before attempting to start. 4. Dirty air cleaner. Clean or replace air cleaner cartridge. - Page 21 SERVICE NOTES...

- Page 22 SERVICE NOTES...

- Page 23 SERVICE NOTES...

- Page 24 02.08.12 DH www.mcculloch.biz Printed in U.S.A.

Need help?

Do you have a question about the MRT850 and is the answer not in the manual?

Questions and answers