Table of Contents

Advertisement

Safe Operation Practices • Set-Up • Operation • Maintenance • Service • Troubleshooting • Warranty

O

'

M

peratOr

s

anual

Tank M48-KW

WARNING

READ AND FOLLOW ALL SAFETY RULES AND INSTRUCTIONS IN THIS MANUAL

BEFORE ATTEMPTING TO OPERATE THIS MACHINE.

FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

CUB CADET LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

Printed In USA

Form No. 769-05007

(November 19, 2009)

Advertisement

Table of Contents

Summary of Contents for Cub Cadet Commercial Tank M48-KW

- Page 1 Safe Operation Practices • Set-Up • Operation • Maintenance • Service • Troubleshooting • Warranty ’ peratOr anual Tank M48-KW WARNING READ AND FOLLOW ALL SAFETY RULES AND INSTRUCTIONS IN THIS MANUAL BEFORE ATTEMPTING TO OPERATE THIS MACHINE. FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

-

Page 2: Table Of Contents

To The Owner Thank You Thank you for purchasing a Cub Cadet Commercial Zero-Turn We reserve the right to change product specifications, designs tractor. It was carefully engineered to provide excellent and equipment without notice and without incurring obligation. performance when properly operated and maintained. -

Page 3: Important Safe Operation Practices

Important Safe Operation Practices WARNING! This symbol points out important safety instructions which, if not followed, could endanger the personal safety and/or property of yourself and others. Read and follow all instructions in this manual before attempting to operate this machine. Failure to comply with these instructions may result in personal injury. - Page 4 Mow only in daylight or good artificial light. Do not operate machines that have been damaged or have not been properly maintained. If the machine has been Never carry passengers. damaged, then have it repaired. Back up slowly. Always look down and behind before and When looking for oil leaks, never run your hand over while backing to avoid a back-over accident.

- Page 5 Do not mow on wet grass. Reduced traction could cause If ramps are used, they must be full width, and secured to sliding. the trailer or truck. Do not tow heavy pull behind attachments (e.g. loaded Machines must be secured onto trailers and trucks with dump cart, lawn roller, etc.) on slopes greater than 5 straps, chains, cables, ropes, or other means deemed degrees.

- Page 6 could come in contact with the ROPS and OPDs. Contact • Hydrau lic controls are actuated to release pressure on pumps, cylinders, etc. If “float” positions are available, they of ROPS and OPDs by items such as tree limbs, clothes should be used.

- Page 7 Never operate/store the machine or fuel container Do not change the engine governor settings or over-speed inside where there is an open flame, spark or pilot the engine. The governor controls the maximum safe light as on a water heater, space heater, furnace, operating speed of the engine.

-

Page 8: Safety Symbols

Safety Symbols This page depicts and describes safety symbols that may appear on this product. Read, understand, and follow all instructions on the machine before attempting to assemble and operate. Symbol Description READ THE OPERATOR’S MAnUAL(S) Read, understand, and follow all instructions in the manual(s) before attempting to assemble and operate WARnInG—... - Page 9 2 — s ectiOn peratiOn ractices...

-

Page 10: Assembly & Set-Up

One Deck Wash Hose Coupler • One Lawn Tractor • One Oil Drain Hose • One Tank M48-KW Operator’s • One Engine Operator’s Manual Manual Tractor Preparation Install Roll Over Protective System (ROPS) The Roll Over Protective System (ROPS) has not been installed Remove the upper crating material from the shipping pallet, and on your unit for shipping purposes. - Page 11 Install the upper ROPS section onto the lower ROPS posts. Move the upper ROPS section to the upright position, and Install the (1⁄2-13 x 3.25) HHCS bolts, nuts and washers. See insert the locking pins with their retainer hairpin clips. See Fig.

- Page 12 Adjusting Drive Control Levers To adjust the front-to-rear angle of the control levers: Loosen the nuts on the control lever mounting bolts, The RH and LH drive control levers can be adjusted up or down leaving the bottom one fairly snug. The top hole is slotted, and fore-and-aft for the comfort of the operator.

- Page 13 Connecting the Battery Cables CALIFORNIA PROPOSITION 65 WARNING! Battery posts, terminals, and related accessories contain lead and lead compounds, chemicals known to the State of California to cause cancer and reproductive harm. Wash hands after handling. CAUTION: When attaching battery cables, always connect the POSITIVE (Red) wire to its terminal first, followed by the nEGATIVE (Black) wire.

-

Page 14: Controls And Features

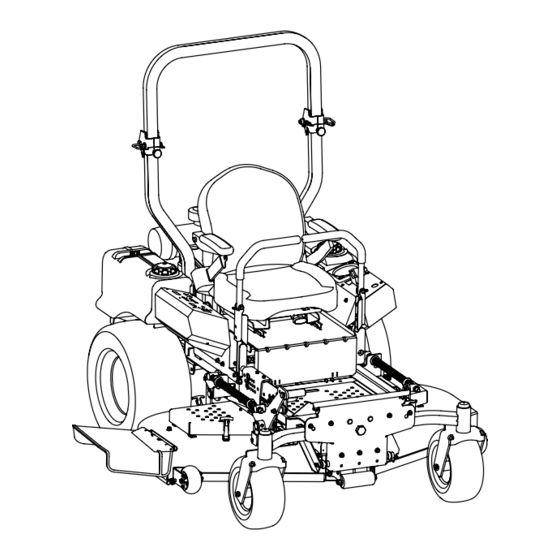

Controls and Features ROPS (Roll Over Protective System) WARNIN Fuel Shut-Off Valve R DEAT Digital Tachometer & Hour Meter Choke Cup Holder Lever Switch Fuel Tank Cap Parking Brake RH Drive Control Lever LH Drive Control Lever Throttle Control Ignition Deck Height Switch Index... -

Page 15: Ignition Switch

Ignition Switch Throttle Control The ignition switch is located on the RH console to the right of the operator’s seat. The ignition switch has three positions as follows: The throttle control is located on the LH console to the left of the operator’s seat. - Page 16 Fuel Shut-Off Valve The fuel shut-off valve is located on top of the fuel tank(s). When turned in a clockwise direction until it stops, it will shut off the flow of fuel to the engine. When turned in a counterclockwise direction it will open and allow fuel to flow to the engine.

-

Page 17: Operation

Operation General Safety • Watch for holes, sprinkler heads, and other hidden hazards. • Avoid dr iving too close to trees, creeks, ditches, sand traps, • RECEIVE InSTRUCTIOn — Entirely read this operator’s and other obstacles. manual. Learn to operate this machine SAFELY. Do not risk •... -

Page 18: Safety Interlock System

Examine the belts for cuts, fraying, and excessive Engage the parking brake. wear. Replace if any of these are detected. Make certain the PTO switch is in the disengaged (down) Replace the deck cover. position. Check if deck is level. When correctly adjusted the mower Push the choke lever to the on position. -

Page 19: Driving The Tractor

Stopping the Engine Move the RH and LH drive control levers inward in the neutral position. Refer to Figure 5-1. Place the PTO switch in the “OFF” position. Move the RH and LH drive control levers fully outward in the neutral position. Engage the parking brake. - Page 20 Driving the Tractor Forward To turn to the left, move the left drive control lever rearward of the right lever. See Fig. 5-3. WARNING! Keep all movement of the drive control levers slow and smooth. Abrupt movement of the control levers can affect the stability of the tractor and could cause the tractor to flip over, which may result in serious injury or death to the operator.

- Page 21 Driving the Tractor In Reverse Turning While Driving Rearward WARNING! To turn the tractor while driving rearward, move the control Always look behind and down on both levers as necessary so that one lever is forward of the other. The sides of the tractor before backing up.

- Page 22 Executing a Zero Turn Stopping the Tractor WARNING! Move both drive control levers to the neutral position to When executing a zero turn, the tractor stop the motion of the tractor. MUST BE STOPPED. Executing a zero turn while the tractor is moving can significantly reduce your Push the PTO switch downward to the disengaged control of the tractor and will cause severe turf...

- Page 23 Using the Mower Deck Sitting in the tractor seat with both drive control levers opened fully outward, disengage the parking brake and WARNING! Make certain the area to be mowed is momentarily turn the ignition switch to the start position. free of debris, sticks, stones, wire or other objects The engine should not crank.

- Page 24 Reconfigurable Mower Inner Discharge Cutting Gauge Front Rear Front Skirt Baffle Baffle Blades Wheels Roller Rollers Low = 3 Low = 3 Low = 3 Standard set-up Installed Installed Hi-lift to 5” to 5” to 5” High = 1 to High = 1 to High = 1 to 2-1⁄2”...

-

Page 25: Maintenance & Adjustments

Maintenance & Adjustments Maintenance Schedule Before Every Every Every Every After Yearly Each use 25 Hours 50 Hours 100 Hours 500 Hours Mowing Check Engine Oil/Gasoline Level Check Hydraulic Hoses For Leaks Check Tires & Tire Pressure Check Deck, Mower & Hydro Drive Belts Check Blades &... - Page 26 OIL CHART Apply a few drops of SAE engine oil, grease, or use a spray lubricant. Apply the oil to both sides of pivot points. Wipe off any excess. Start engine and operate mower briefly to insure that oil spreads evenly. number of Oil Points Description DAILY...

- Page 27 LUBRICATION CHART Use a grease-gun filled with nO. 2 Multipurpose Lithium Base Grease number of Grease Fittings Description EVERY 25 HOURS Blade Spindle Bearings WEEKLY Front Caster Wheels Front Caster Wheel Spindles Mower Deck Ball Wheels number of Grease Points Description WEEKLY Mowing Deck Pivots...

-

Page 28: Maintenance (Engine)

Maintenance Clean the area around the Hydraulic Oil fill neck. See Fig. 6-1. WARNING! Before performing any maintenance or repairs, disengage the PTO, move the drive control levers fully outward in the neutral position, engage the parking brake, stop the engine and remove the key to prevent unintended starting. -

Page 29: Hydraulic System

Place a small pan under the pump motor frame. Remove fill Fill the replacement filter with a good grade of 15W-40 oil oil cap from hydraulic reservoir for faster drainage. Remove and lubricate the sealing surface. nut caps and drain oil from both left and right pumps. Screw the filter onto the filter base until it seats and then Replace and retighten nuts. -

Page 30: Tire Maintenance

• As a further precaution, only charge the battery in a well wheel and jack up the tire that leaks about an inch ventilated area. off the ground. • Always shield eyes and protect skin and clothing when Loosen and remove the lug nuts and remove the working near batteries. - Page 31 Using the Transmission Bypass Valves Pull back the lock collar of the nozzle adapter and push the adapter onto one of the deck wash nozzles at either end of If for any reason the tractor will not drive or you wish to move the mower deck.

-

Page 32: Tractor Storage

Battery Storage • Prior to putting the tractor in storage, monitor fuel consumption with the goal of running When storing the tractor for extended periods, disconnect the fuel tank empty. the negative battery cable. It is not necessary to remove •... - Page 33 Start the engine and allow to idle for a few minutes to The right front blade tip height is fixed so you must adjust ensure engine is operating properly. the left front tip to match it. See Fig. 6-5. Drive the tractor without a load to make certain all the tractor systems are functioning properly.

- Page 34 Start at the rear right to raise the rear of the deck, tighten Remove the lock nut securing one of the front gauge wheel the rear outer jam nut to raise the deck or loosen the rear shoulder screws to the deck. Remove the gauge wheel and outer jam nut to lower the rear of the deck.

- Page 35 Adjusting the Front Skirt Removing/Installing the Inner Baffle The front skirt can be raised or lowered depending on the The inner flow-control baffle can be removed depending on mowing conditions. The skirt has three settings; low, medium the mowing conditions. The baffle controls discharge and can and high.

-

Page 36: Service

Service Battery Removal Jump Starting WARNING!: Failure to use this starting procedure WARNING! Battery posts, terminals and related can cause sparking, and the gases in the battery to accessories contain lead and lead compounds. Wash explode. hands after handling. Attach the end of the red jumper cable to the positive The battery is located on the right/rear of the tractor beneath the terminal (+) of the charged battery. -

Page 37: Deck Removal

Seat Switch NOTE: There is a certain amount of spring tension due to the weight of the deck. When removing the lift linkage • With the speed control pedals in the neutral position, the from the deck the tension of the springs will go from the parking brake engaged and the PTO switch in the “OFF”... - Page 38 the idler pulley so that a ten-pound pull with a spring scale Use a 1- 1⁄8” socket wrench on the pulley side of the spindle between two pulleys deflects the belt about 1⁄2”. bolt. See Fig. 7-5. Replacing the Blades Hex Screw WARNING! Before performing any maintenance,...

- Page 39 Changing the Spindle Assembly Tractor High Speed Tracking Jack up the front of the mowing deck about one foot and If the tractor tracks to one side with both drive control levers fully block it in that position. forward, adjust the control levers as follows: Make sure the blade clutch is disengaged.

-

Page 40: Troubleshooting

Troubleshooting Problem Cause Remedy Engine fails to start PTO/Blade Engage knob engaged. Place knob in disengaged (OFF) position. Parking brake not engaged. Engage parking brake. Drive control levers not fully outward in Move drive control levers fully outward in neutral position. neutral position. - Page 41 Problem Cause Remedy Engine overheats Engine oil level low. Fill crankcase with proper amount and weight of oil. Air flow restricted. Clean grass clippings and debris from around the engine’s cooling fins and blower housing. Engine hesitates at high Spark plug(s) gap too close. Remove spark plug(s) and reset the gap.

-

Page 42: Replacement Parts

Replacement Parts Component Part Number and Description KM-BPR4ES Spark Plug KM-11013-7020 Outer Air Filter KM-11013-7019 Inner Air Filter KM-49019-7001 Fuel Filter KM-49065-2078 Oil Filter 01005374 Deck Belt 01005378 PTO Belt 01007015 Drive Belt 02005017 Hi-Lift Blade, 17.0 01003532P Deck Spindle... - Page 43 Component Part Number and Description 634-3159 Deck Wheel 925-1707D Battery 951-3124E Gas Cap 02003421 Throttle Control 02003422 Choke Control 725-1341B Ignition Key 01006693 Discharge Chute Assembly 02002666 Wheel Assembly 02002821 Caster Wheel Assembly 9 — r ectiOn eplaceMent arts...

-

Page 44: Attachments & Accessories

Attachments & Accessories The following attachments and accessories are compatible with your TAnK tractor. See your dealer or the retailer from which you purchased your tractor for information regarding price and availability. Part Number Part 59A30025150 Striper Kit 59A30020150 Snow Blade Kit 59A30017150 Spreader Kit 59A30021150... -

Page 45: Specifications

Specifications NOTE: Specifications subject to change without notice. Engine: 23HP Kawasaki Type: Vertical air cooled V-Twin Air Cleaner: Dual Paper element with rain cap Lube System: Pressurized with oil filter Hydraulic System: In tank filter, 3 quart capacity Starter: 12-volt electric Traction Drive: Engine to two variable-output hydraulic pumps each connected to individual wheel motors Cutter Deck Drive:... -

Page 46: Warranties

CALIFORNIA EMISSION CONTROL WARRANTY STATEMENT YOUR WARRANTY RIGHTS AND OBLIGATIONS The California Air Resources Board and MTD Consumer Group Inc are pleased to explain the evaporative emission control system warranty on your 2008 lawn mower. In California, new lawn mowers must be designed, built and equipped to meet the State’s stringent anti-smog standards. MTD Consumer Group Inc must warrant the EECS on your lawn mower for the period of time listed below provided there has been no abuse, neglect or improper maintenance of your lawn mower. - Page 47 WARRANTED PARTS: The repair or replacement of any warranted part otherwise eligible for warranty coverage may be excluded from such warranty coverage if MTD Consumer Group Inc demonstrates that the lawn mower has been abused, neglected, or improperly maintained, and that such abuse, neglect, or improper maintenance was the direct cause of the need for repair or replacement of the part.

- Page 48 CUB CADET LLC MANUFACTURER’S LIMITED WARRANTY FOR TANk ZERO-TURN COMMERCIAL RIDING MOWER IMPORTANT: To obtain warranty coverage owner must present an In the U.S.A.: original proof of purchase and applicable maintenance records to the Check your Yellow Pages, or contact Cub Cadet LLC at P.O. Box servicing dealer.

Need help?

Do you have a question about the Tank M48-KW and is the answer not in the manual?

Questions and answers