Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Varitronics VariOuest Cutout Maker 1800

- Page 1 User’s Guide www.variquest.com...

-

Page 2: Copyright

LLC. While every precaution has been taken in preparation of this document, Varitronics assumes no liability to any party for any loss or damage caused by errors or omissions or by statements resulting from negligence, accident or any other cause. Varitronics further assumes no liability for incidental or consequential damages arising from the use of this document. -

Page 3: Standard Warranty

Varitronics will at its option repair, replace or refund the purchase price of any accessories, supplies or equipment found to be defective under this warranty. -

Page 4: Safety Information

Safety Information Warning Symbols Safety Information The instructions in this manual have been labeled with various types of caution and warning messages. The symbols preceding these messages indicate information that must be followed to avoid damage to property or injury to users of the Cutout Maker or people in the vicinity of the Cutout Maker. - Page 5 Safety Information Warning Symbols Warning • Always hold the plug firmly when removing it from the power socket. Do not simply pull on the cord. Pulling on the cord to remove the plug from the power socket or applying exces- sive force when doing so may damage the cord, which may in turn result in fire or electrical shock.

- Page 6 This page is intentionally left blank. ® VariQuest Cutout Maker 1800 User’s Guide...

-

Page 7: Table Of Contents

Contents Copyright ........................ii Trademarks .........................ii Standard Warranty ....................iii Safety Information ....................iv 1 - Features, Accessories and Materials Features ........................1-2 System Accessories ....................1-3 Materials ......................... 1-4 Paper Classifications ..................1-4 Classifications for Unspecified Paper Types ............. 1-4 2 - Components and Specifications Components ...................... - Page 8 5 - Maintenance Maintenance Summary ..................5-1 Replacing the Cutting Blade ................5-2 Replacing the Cutting Mat ................. 5-6 Oil Gantry Rails ....................5-10 Clean Tip Sensor ..................... 5-11 6 - Troubleshooting Process ........................6-1 Tips ........................6-1 Troubleshooting ..................... 6-2 Error Codes ......................

-

Page 9: Features, Accessories And Materials

Features, Accessories and Materials ® This chapter provides an overview of the VariQuest Cutout Maker 1800 features, accessories and materials. The following information is contained in this chapter: • “Features” on page 1-2 • “System Accessories” on page 1-3 • “Materials”... -

Page 10: Features

Features Features • The Cutout Maker is designed to allow even first-time users to quickly produce high quality cutout shapes from sheets of construction paper, cold laminated ® construction paper, card stock, bond paper, VariQuest Vinyl Sheets and ® VariQuest Magnetic Sheets. -

Page 11: System Accessories

System Accessories System Accessories The Cutout Maker comes with a Starter Maintenance Kit that contains: • Blades (3-pack) • Blade/Chad Removal Tool • Tweezers ® VariQuest Cutout Maker 1800 User’s Guide... -

Page 12: Materials

Materials Classifications for Unspecified Paper Types Materials CAUTION! CAUTION! Use of material other than that specified for use with the Cutout Maker may result in poor cut quality and damage to the blade. There is no direct correlation between paper weight and the classification of paper as “light weight”... -

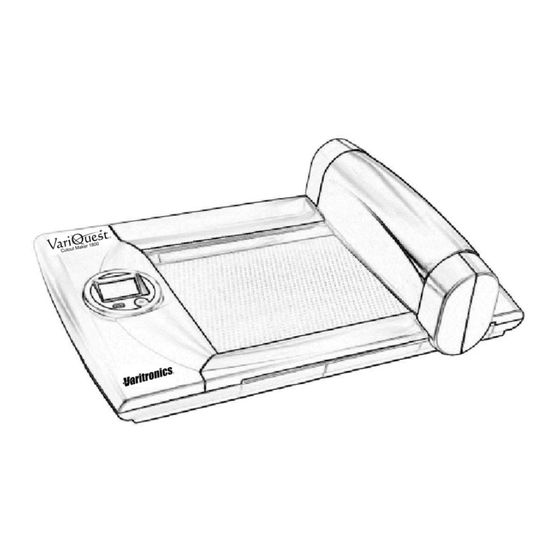

Page 13: Components And Specifications

Components and Specifications ® This chapter shows the locations of the major VariQuest Cutout Maker 1800 components and provides detailed system specifications. The following information is contained in this chapter: • “Components” on page 2-2 • “Perspective View” on page 2-2 •... -

Page 14: Components

Components Gantry Cover Open Components Perspective View Gantry Cover Open Name Gantry Control Panel Cutter Bed Blade Holder Assembly ® VariQuest Cutout Maker 1800 User’s Guide... -

Page 15: Side View

Components Side View Side View Name USB Cable Receptacle AC Power Cord Receptacle DC Power Supply Fuse (2 Amp) OFF (0) ON (1) Power Switch ® VariQuest Cutout Maker 1800 User’s Guide... -

Page 16: Control Panel

Components Control Panel Control Panel The control panel provides buttons to manually start and stop cutter operation. Pressing the GO button starts the cutter when all of the software selections are completed and the LCD display indicates a "Ready" condition exists. •... -

Page 17: Specifications

Specifications Control Panel Specifications Cutout Maker 1800 Technical Data Sheet Output • Maximum cutout size: 11-1/2” x 17-1/2”; up to 2’ x 3’ when tiling • Minimum scrap size: 4” x 6” (101.6 mm x 152.4 mm) Machine • Display: 4 line, 16 characters LCD graphical display •... -

Page 18: Getting Started

Getting Started ® This chapter provides instructions for unpacking and setting up the VariQuest Cutout Maker 1800. Keep this guide near the Cutout Maker so it can be available for reference. The chapter contains these sections: • “Unpacking and Positioning” on page 3-2 •... -

Page 19: Unpacking And Positioning

Unpacking and Positioning Unpacking the Cutout Maker Unpacking and Positioning Unpacking the Cutout Maker The Cutout Maker and accessories are packed in a cardboard carton with foam padding for protection during shipment. Carefully unpack the items and keep the packing materials. If you need to ship the Cutout Maker in the future, repack the system as shown in the figure. -

Page 20: Verifying Packaging Contents

Unpacking and Positioning Verifying Packaging Contents Verifying Packaging Contents After unpacking, verify that all of the following items have been included in the Cutout Maker box: Description Electrical Power Cord USB Cable Cutout Maker 1800 Maintenance Kit ® VariQuest Cutout Maker 1800 User’s Guide... -

Page 21: Positioning The Cutout Maker

Unpacking and Positioning Positioning the Cutout Maker Positioning the Cutout Maker To ensure proper functioning of the Cutout Maker on a work space, allow adequate space around the system as shown below. 2 in. / 51 mm 2 in. / 51 mm 2 in. -

Page 22: Setting Up The Cutout Maker

Setting up the Cutout Maker Connecting the Power Cord Setting up the Cutout Maker Connecting the Power Cord WARNING Never operate the Cutout Maker in an area where it can get wet CAUTION! CAUTION! Always connect the power cord to the Cutout Maker before inserting the plug into a wall socket Connect the power cord to the Cutout Maker. -

Page 23: Connecting The Cutout Maker

Connecting the Cutout Maker Connecting to a VariQuest® Design Center Connecting the Cutout Maker Important ® Use the USB cable supplied with the Cutout Maker to connect to the VariQuest Design Center or a PC. The USB cable complies with FCC “Rules and Regulations,”... -

Page 24: Connecting To A Personal Computer

Connecting the Cutout Maker Connecting to a Personal Computer Connecting to a Personal Computer The Cutout Maker provides a standard interface for connecting to a computer (USB connector). Connect one end of the cable provided to an available USB connector on the computer, and connect the remaining end to the USB connector on the Cutout Maker. -

Page 25: Operating The Cutout Maker

Operating the Cutout Maker This chapter provides instructions for operating the Cutout Maker. The following information is contained in this chapter: • “Loading Material” on page 4-2 • “Typical Operating Sequence” on page 4-3 • “Operating Example” on page 4-3 ®... -

Page 26: Loading Material

Loading Material Loading Material ® Before loading material on the VariQuest Cutout Maker 1800, you must choose ® the appropriate material type in the VariQuest Design Center Software. This ® software is installed on the VariQuest Design Center or on your PC. When you select the material type in the software, the Cutout Maker adjusts the output settings (blade depth, force and cutting speed) accordingly. -

Page 27: Typical Operating Sequence

Typical Operating Sequence Operating Example Typical Operating Sequence Important ® ® The VariQuest Cutout Maker 1800 can be used only with the VariQuest ® Design Center Software. The VariQuest Design Center Software is installed on ® ® your VariQuest Design Center or PC. Refer to the separate VariQuest Design Center User’s Guide for software installation. - Page 28 Typical Operating Sequence Operating Example To smooth paper/start cut job: 1. Smooth the paper on the cutting mat. Note: Smoothing paper on the cutting mat ensures a clean cut. 2. Press GO to start the cut job. Once cutting is complete, you can remove your cutout from the cutting bed.

-

Page 29: Maintenance

Maintenance This chapter describes the periodic maintenance procedures required during normal operation of the Cutout Maker. The chapter contains these sections: • “Maintenance Summary” on page 5-1 • “Replacing the Cutting Blade” on page 5-2 • “Replacing the Cutting Mat” on page 5-6 •... -

Page 30: Replacing The Cutting Blade

Maintenance Summary Replacing the Cutting Blade Replacing the Cutting Blade 1. Set the power switch [1] to 0 (OFF) to turn the machine off. 2. Open the gantry top cover [2a], locate the blade holder/motor assembly [2b] and move it toward the middle of the gantry track. 3. - Page 31 Maintenance Summary Replacing the Cutting Blade 4. Press blade release button [4a] at the rear of the blade holder to expose the blade. CAUTION! CAUTION! The cutter blade protrudes from the blade holder [4b] slightly even when retracted. Take care to avoid contact with the blade. Personal injury or equipment damage may result if the blade is touched.

- Page 32 Maintenance Summary Replacing the Cutting Blade 6. Carefully position the blade in the blade holder [6] and insert it until only 1/4 inch of the blade protrudes from the holder. CAUTION! CAUTION! The cutter blade protrudes from the blade holder slightly even when retracted. Take care to avoid contact with the blade.

- Page 33 Maintenance Summary Replacing the Cutting Blade 8. Rotate the blade holder assembly 90° [8a] back to its operating position [8b]. 9. Close the gantry top cover [9] on the Cutout Maker. ® VariQuest Cutout Maker 1800 User’s Guide...

-

Page 34: Replacing The Cutting Mat

Maintenance Summary Replacing the Cutting Mat Replacing the Cutting Mat 1. Set the power switch [1] to 0 (OFF) to turn the machine off. 2. Slide the gantry forward [2a] and grasp the rear edge of the cutting mat. Slide the mat out (to rear) [2b] from between the channels on each side of the bed [2c]. - Page 35 Maintenance Summary Replacing the Cutting Mat 3. With the gantry moved forward [3a], position the cutting mat soft side up [3b] so that the sides of the mat protrude into the channels on each side of the bed [3c]. 4. Guide the cutting mat forward between the channels [4] on each side of the bed.

- Page 36 Maintenance Summary Replacing the Cutting Mat 5. Continue sliding the mat forward until the guide slots [5a] on the leading edge of the mat are fully engaged with the guides on the front end of the bed [5b]. 6. With the leading edge of the mat secured, align the notches on the rear edge of the mat with the guide posts on the bed [6].

- Page 37 Maintenance Summary Replacing the Cutting Mat 7. Turn the machine on. 8. Ensure that the gantry returns to the home position [8]. Note: In some cases, you may rotate the protective mat to make use of surface area that is not worn. Either end of the mat may be inserted into the Cutout Maker. ®...

-

Page 38: Oil Gantry Rails

Maintenance Summary Oil Gantry Rails Oil Gantry Rails 1. Lift gantry top cover [1]. 2. Apply a small amount of general household oil (such as 3-in-1 oil) to a clean cloth and wipe on exposed edge of upper [2a] and lower [2b] gantry rails. Note: Take care not to apply too much oil. -

Page 39: Clean Tip Sensor

Maintenance Summary Clean Tip Sensor Clean Tip Sensor 1. Check that there are no obstructions, residue or paper debris covering the tip sensor. 2. Using the tweezers and chad removal tool from the maintenance kit, remove any debris from the tip sensor location plunger. 3. -

Page 40: Troubleshooting

Troubleshooting This chapter describes how to locate and solve problems that you may encounter while using the Cutout Maker. The following information is contained in this chapter: • “Process” on page 6-1 • “Troubleshooting” on page 6-2 • “Error Codes” on page 6-4 •... - Page 41 Troubleshooting Tips Troubleshooting Troubleshooting Diagnosis Required Action 1. Verify that power cord has been plugged in properly. Cutout Maker does not work even though the power switch has been 2. Verify that power switch is turned on. turned on. 1. Verify that power cord has been plugged in properly. LCD Display does not turn on.

- Page 42 Troubleshooting Tips Troubleshooting (Continued) Diagnosis Required Action 1. Adjust the cutting blade depth 1 step negative (see “Loading Paper scrunching during cutting. Material” on page 4-2). 2. Try cutting again. If condition persists, repeat step 1. 3. Clean tip sensor. See “Clean Tip Sensor” on page 5-11. 1.

-

Page 43: Error Codes

Error Codes Tips Error Codes The following table describes the Error Codes that may appear on the control panel and corrective action required to correct the problem. Note: Error codes contain a 2nd digit that the user does not have to be concerned with. - Page 44 Error Codes Tips Error Codes (Continued) Message Displayed Corrective Action ® Cut speed error. Select a 1. Select a different object size in the VariQuest Software on different object size and the Design Center touch computer or the PC. try again. 2.

-

Page 45: Servicing The Cutout Maker

Servicing the Cutout Maker Tips Servicing the Cutout Maker If you are unable to solve the problem, you need to have the Cutout Maker serviced. To service your Cutout Maker: 1. Write a description of the problem and a checklist of the steps you took when trying to fix the problem. - Page 46 © 2012 Varitronics, LLC All Rights Reserved. Cat #20144-03 11/12...

Need help?

Do you have a question about the VariOuest Cutout Maker 1800 and is the answer not in the manual?

Questions and answers