Summary of Contents for Ibex Dental Technologies SUMMIT

- Page 1 Operating Manual SUMMIT Porcelain & Press Furnaces Firmware V2012 Manufactured in the USA Ibex Dental Technologies 850 N. Dorothy Dr., Suite 502 Richardson, TX 75081 1-877-370-4242 972-918-0393 fax www.ibexdental.com...

- Page 2 Many furnaces do not allow for the programming of a specific vacuum level but instead provide for a “YES / NO” or a percentage of vacuum entry, typically 90% to 100%. The Summit furnaces allow for a more precise vacuum control. A simple rule for entering programs that do not state a specific vacuum level in cm or inches is to enter 72 –...

- Page 3 1. The revolutionary new “Long Life” open wire muffle with “Radiance Ring” provides unparalleled firing quality and consistency on all locations of the firing tray. 2. State of the art electronics and a high accuracy thermocouple make the Ibex SUMMIT a true “NO Temperature Calibration” furnace.

-

Page 4: Table Of Contents

Table of Contents Touch Screen operation …………………………….. Page 6 Oven Set-up and Connections …………………………….. Page 7 Furnace Set Up …………………………….. Pages 8 – 10 Cautionary Notes …………………………….. Page 11 Main Screen …………………………….. Page 12 I. Utilities Menu …………………………….. Page 13 Date &... - Page 5 Table of Contents II. Porcelain & Pressing Programs …………………………….. Page 25 The Program Select Screen ……………………………. Page 25 - 26 Create a New Porcelain Program …………………………….. Page 27 Program Name …………………………….. Page 27 Porcelain Program Parameters ………………………… Pages 28 - 29 Programming Vacuum ……………………………..

-

Page 6: Touch Screen Operation

TOUCH SCREEN OPERATION The touch screen of the Ibex SUMMIT is the control center of your furnace. All control functions and information to and from the user will be carried out through this screen. It is a high precision device that requires only a Light Touch of about a quarter of a second with the pad of your finger to select and activate the various controls and features of the Ibex SUMMIT. -

Page 7: Oven Set-Up And Connections

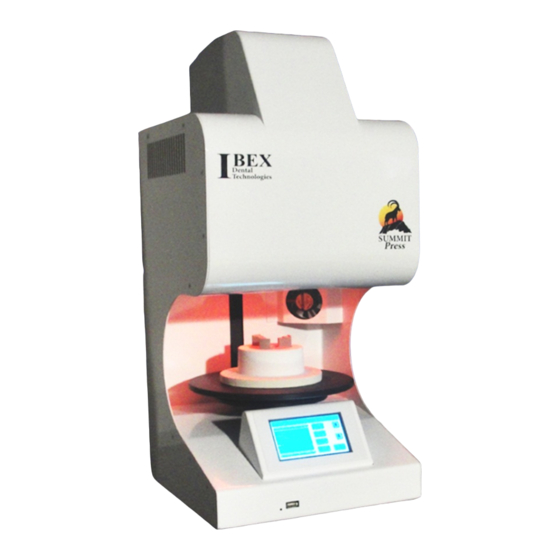

A1- One Ibex SUMMIT door brick (porcelain and pressing) A2- One door brick with ceramic press plate (pressing furnace only) B- One Ibex SUMMIT memory stick, (located inside the door brick box) C- One Ibex SUMMIT heat tray, black anodized... - Page 8 The footprint or area required by the Summit is 11ʺ on each side. The height of the Summit is 21ʺ while the Summit Press is 25 ½ʺ tall. Each requires at least 4ʺ of clearance to allow for proper ventilation of the heat from the muffle chamber.

- Page 9 NOTE! The regulator is preset to 60 - 65psi. Powering up the Ibex SUMMIT Now that your Ibex SUMMIT Furnace has been properly situated and all the required connections have been made, it is ready to be turned on. NOTE! Be sure to remove the platform lift block prior to powering the furnace on, as the platform motor will try to move the platform down as part of the power up tests.

- Page 10 Photo #3...

-

Page 11: Cautionary Notes

Many furnaces do not allow for the programming of a specific vacuum level but instead provide for a “YES / NO” or a percentage of vacuum entry, typically 90% to 100%. The Summit furnaces allow for a more precise vacuum control. A simple rule for entering programs that do not state a specific vacuum level in cm or inches is to enter 72 –... - Page 12 Night Mode Display Example #1 After powering up your Ibex SUMMIT for the first time, the Main Screen, as shown in Display Example #1 above, should be showing. If some other screen is displaying instead, touch the Cancel or OK button. This will bring you to the previous screen. Keep touching Cancel or OK until the above screen appears.

-

Page 13: Utilities Menu

Calibrate Display Example #2 The Utilities Menu is where the Ibex SUMMIT Porcelain Furnace can be customized to meet your particular needs. The Utilities Screen offers six menu picks as shown above in Display Example #2. 1. User Settings – Input user settings and operational parameters 2. -

Page 14: Date & Time

Utilities screen. The date and time will reflect your changes. The SUMMIT’s real time clock battery will maintain proper time for up to five years. All operational memory such as the user programs and utilities settings are stored in a non-volatile memory and will not be affected should the battery fail. -

Page 15: User Settings

User Settings Touch the User Settings button to proceed with entering the options settings 08/13/12 User Settings 450 C 0cmHg 04:15:45 Format Prefs Power Save Night Mode Set Defaults Features Volume Display Example #4 The User Settings Menu is where the user customizes the furnace operation. The menu picks are as follows: 1. -

Page 16: Power Save

2. Power Save – This feature will raise the platform and maintain the programmed temperature after a specified amount of time. The factory settings are 400° C and 90 minutes for the porcelain furnace and 700° C and 5 minutes for the Pressing Furnace. Touch the “Idle Time Until Power Save”... -

Page 17: Night Mode

Display Example #9 The Night Mode button on the Main Screen overrides this setting and places the furnace into NOTE! Night Mode immediately. When running a pressing program in the Summit Press, the Quick Cooling Fan is always NOTE! disabled. -

Page 18: Volume

Reset Display Example #10 The INFO screen displays the current software version that the SUMMIT is running. Additionally, the INFO screen provides the total number of hours that the furnace has been powered on, the number of hours and minutes that the door lift motor has been run and the total number of hours and minutes of power applied to the muffle. - Page 19 When an additional Ibex Summit furnace is being placed into service, you can quickly import all the original programs from the first furnace to the new furnace. It also allows an owner or manager to quickly restore programs to their original settings should they be altered by technicians.

- Page 20 Export The export function is a simple procedure. Simply insert the memory stick into the USB port and touch the EXPORT button. You will be prompted to either proceed with exporting or cancel the procedure. If you touch the EXPORT button prior to inserting the memory stick, you will receive the following message: “No Media Present”.

-

Page 21: Calibration

Calibration There is no requirement or ability to calibrate the temperature of your SUMMIT furnace. If you feel that your furnace is not firing at the proper temperature or if you have any other operating questions please call tech support at 877-370-4242 or email us at techsupport@ibexdental.com. -

Page 22: Touch Screen Calibration

Touch Screen Calibration The touch screen will require occasional recalibrating. This is a very quick and simple procedure. If you are noticing difficulty in the touch screen responding when touched, do not press harder or use a hard or pointed object to get the screen to respond. IMPORTANT. -

Page 23: Vacuum Calibration

Vacuum Calibration Vacuum Test Test Vacuum (mmHg) Actual Vacuum 0 mmHg Vacuum Adjust ± 5% Back Start Stop Display Example #17 This Vacuum Test utility’s primary function is to calibrate the vacuum transducer. The transducer’s worst case error is rated at + or – 5%, thus the ability to increase or decrease the Actual Vacuum value by +/- 5%. - Page 24 Plunger Press Test (Pressing Furnaces only) Press Test Press Dn Time 16.5 s Door Open Time: 2.0 s Plunger Up: High Plunger Down: Toggle Press Solenoid: Back Display Example # 18 The Plunger Press Test is used to test and adjust the rate at which the plunger moves down and back up.

-

Page 25: Porcelain & Pressing Programs

The left side of the Select Program Screen Located on the left half of the screen is the program list. The SUMMIT Porcelain Furnace and the Summit Press features 80 user programmable program locations. The numbers at the far left represents the program locations from 1 to 80. - Page 26 The right side of the Select Program Screen The right half of the display holds all the controls for creating, editing and manipulating the user programs. Located at the far right are the door control buttons for raising and lowering the platform. Located immediately below the door arrows is the Cancel button.

-

Page 27: Create A New Porcelain Program

Display Example #21 After touching the empty memory location #009 in Example Display #19, touch the CREATE button. If using a Summit Press, the next screen will ask “Porcelain or Pressing?” Touch Porcelain. NOTE! Example Display #20 will be displayed on the screen. At this screen you will enter the program name. -

Page 28: Porcelain Program Parameters

Porcelain Program Parameters Low Temp (° C or F) – The starting or entry temperature of the porcelain. 350°C min - 850°C max Preheat (minutes:seconds) - The time required to bring the porcelain into the muffle chamber. 00:20sec min – 99min:59 sec max Heat Rate (°C or F / min) - The rate of change (delta) in temperature per minute. - Page 29 Porcelain Data Entry Screen Porcelain Hold Time (mm:ss) Low Temp (C) 00:00 01:00 Preheat (mm:ss) 2ndHold Temp (C) 00:00 Heat Rate (C/min) 2nd Hold Time (mm:ss) 00:00 Vac Level (cmHg) Cool Time (mm:ss) High Temp (C) Start Vac (C) Vac Hold (mm:ss) 00:00 Release Vac (C) Cancel...

-

Page 30: Programming Vacuum

A special consideration has been made with regard to the vacuum parameters. A default value of zero (0) is programmed for all new programs. When the value of the vacuum is zero, all parameters regarding vacuum are lighted out in yellow and are not used, (see Display Example #25). When the vacuum box is touched, the vacuum boxes will appear and can be programmed. - Page 31 Many furnaces do not allow for the programming of a specific vacuum level, but instead provide for a “YES / NO” or a percentage of vacuum entry, typically 90% to 100%. The Summit furnaces allow for a more precise vacuum control. A simple rule for entering programs that do not state a specific vacuum level in cm or inches is to enter 72 –...

-

Page 32: Create A New Pressing Program

Create a New Pressing Program NOTE! This section assumes that the reader has read and understands the name and data entry via the touch screen as described in the “Create a New Porcelain Program” section. If not, please refer to the previous chapter for detailed instructions on how to create a new program. -

Page 33: Modify An Existing Program

Modify an Existing Program Porcelain or Pressing Porcelain SAMPLE 1 Hold Time (mm:ss) Low Temp (C) 01:30 05:00 Preheat (mm:ss) 2ndHold Temp (C) 00:00 Heat Rate (C/min) 2nd Hold Time (mm:ss) 03:00 Vac Level (cmHg) Cool Time (mm:ss) High Temp (C) Start Vac (C) Vac Hold (mm:ss) 00:00... -

Page 34: Copy A Program

Copying a Program There are 2 methods for copying a program: Method 1 Select program Sample 1 from the Select Program screen and touch the Modify button. A screen similar to Display Example #33 will be displayed. In the Modify Program screen, touch the Copy button. -

Page 35: Move A Program

program to be copied to. If necessary, use the Page Up or Page Down arrows to bring up the desired program page. Touch the appropriate program location box, and the copied program will be completed. The Select Program screen will appear with this copied program selected. The copied program, Sample 2, has been saved at the new location with all the modifications and can now be run. -

Page 36: Run A Program

Run a Program Once a program as been created and saved it is ready to run. From the Program Select screen, touch and highlight the program to be run. Touch the Run button. The display will change to the Run Program screen and the program will commence. -

Page 37: Edit A Running Program

Edit Touching the “Edit” button brings up full-function “On the Fly” edit screen. See display Example #36 below. Any parameter can be changed while the program is running. All rules and limits for creating and modifying a program apply to editing a program while it is running. NOTE! All edited values are valid for that cycle only. -

Page 38: Skip Step

Skip Step Skip Step is a powerful tool that allows the user to move or Skip ahead one or more steps from the current step in a program. NOTE! When starting a program, the processor runs several system checks before actually starting the program. -

Page 39: Metal Sintering

Metal Sintering Sintering Program Heat Rate (C/ min) High Temp (C) 1070 Hold Time (mm:ss) 10:00 Cancel Display Example #39 This special purpose screen is to facilitate the sintering of metal, (NOT Zirconia). This screen eliminates the need for using up a program memory location for this limited function. Programming is simple. -

Page 40: Error Codes And Troubleshooting

Error Codes The following is a listing of all the error codes by category. Programming Errors "Low Temp not within limits" "Preheat Time not within limits" "Heat Rate not within limits" "Vacuum Level not within limits" "High Temp not within limits" "Vac Hold Time not within limits"... - Page 41 Pressing Operational Errors "ROD LIMIT SWITCH FAILURE, Press Disabled" // Both limit switches are ON "ROD NOT EXTENDED, Check Pressure" "ROD FULLY EXTENDED, Check Ring" "ROD FAILED TO RETRACT, Press Disabled" System Errors "Door Failure: Motor Alert!" "Door Failure!: NO LIMIT IN STOP" // Door is stopped but cannot detect limit switch "Door Failure!: NO LIMIT IN MOTION"...

Need help?

Do you have a question about the SUMMIT and is the answer not in the manual?

Questions and answers