Advertisement

Quick Links

®

SAFETY INSTRUCTIONS

This is an industrial component. Only a qualified systems integrator should be allowed to

design it into a system. The integrator must determine proper plumbing, mounting, driveline

and guard components.

Improper installation or use could lead to a serious, even fatal, accident. The system

integrator must communicate all safe operation procedures to the end user(s).

Before operation, fully understand and follow the instructions shown in this manual and any

instructions communicated by the system integrator. No one should be allowed to operate or

maintain this pump who has not been fully trained to work safely according to the

configuration of the pump system and in accordance with all applicable government and

industry regulations.

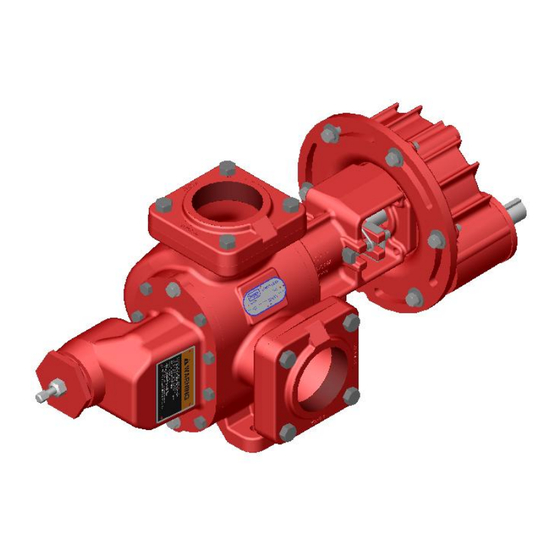

3611- 4722 GHB and BHB

Supplement to G12-209

OWNERS MANUAL

Roper Pump Company

P.O. Box 269

Commerce, GA 30529 USA

Telephone: (706) 335-5551

TeleFAX: (706) 335-5490

Email:

sales@roperpumps.com

www.roperpumps.com

G12-436

04/08/04

Advertisement

Summary of Contents for Roper G12-436

- Page 1 Roper Pump Company P.O. Box 269 Commerce, GA 30529 USA...

- Page 2 Injection Hazard: Do not try to ___________________________________________________________ stop a leak with your hand! Avoid Roper Pumps’ Close Coupled Drives any close contact with hydraulic fluid jets. Escaping fluid can Hydraulic drive units where the drive mounts directly to the pump penetrate skin, causing serious •...

- Page 3 WARNING Operating without guards could result in serious injury or death. Machinery in operation can grab, crush, cut, mangle and dismember. Do not operate without adequate guards in place.

-

Page 4: Installation

INSTALLATION Check Ports Versus Rotation: Make sure the inlet and discharge ports have been correctly plumbed corresponding to the direction of rotation and the relief valve, if present, is properly positioned. See following drawings for various configurations. Figure A... - Page 5 Figure B...

-

Page 6: Recommended Tool List

RECOMMENDED TOOL LIST NOTE: Tools not furnished with pump. Tools for all Pumps: (1) Safety Glasses (1) 9/16” Combination Wrench (1) ¾” Combination Wrench (1) 6” Adjustable Wrench (1) CG-45 Snap-On Tool Bearing Puller (1) 6” to 10” Three Square File (1) Pliers Additional Tools for GHB Pumps: (1) ½”... - Page 7 2. If you do not know which pump arrangement you have, collect nameplate data and refer to the Owners Manual for 3611-22 (G12-209), to determine what you have. Consult a Roper distributor or Roper Pump Company if you have any questions.

- Page 8 D.) For 3700/4700 “GHBO” and “BHB” pumps, follow steps 54 – 61. 3600/4600 ‘GHB” Gear Reduction Unit (See Figures 7.1 and 7.2) 21. Drain oil from gear reduction unit. 22. Remove drive key (A). Remove four hex head cap screws (U) and slide seal retainer (37) assembled with lip seal (39) off end of pinion shaft (42).

- Page 9 (20, 22, 25, if applicable, 38, 48, 50) and lip seals (5, 39) be installed when pump is being reassembled. • WARNING! Only use genuine Roper gaskets. Gasket thickness determines proper clearances. Always check quantity of gaskets removed and replace with exact quantity. Proper material must be used based on application.

- Page 10 6. A.) For 3600/4600 “GHBO,” “GHB,” and “BHB” pumps with shaft packing, follow steps 7 – 18. B.) For 3700/4700 “GHBO,” “GHB,” and “BHB” pumps with a standard mechanical seal, follow steps 28 – 38. C.) For 3700/4700 “GHBO,” “GHB,” and “BHB” pumps with a positive drive mechanical seal, follow steps 39 – 53. 3600/4600 “GHBO”...

- Page 11 3700/4700 “GHBO,” “GHB,” and “BHB” Pumps (Standard Mechanical Seal) (See Figure 7.1) 28. Place drive gear (34) into case bore. Install key (B) in keyway of drive shaft (32). Slide drive shaft into bore of drive gear. 29. Place appropriate number of case gaskets (20) on backplate side of case (19A, B, C, D). Align backplate (6A, B) on dowel pins (J).

- Page 12 50. Install antirotation pin (T) in locator ring (60). Position locator ring (60) with antirotation pin (T) toward seal face. Align antirotation pin (T) with slot in back of stationary seal face and push into counterbore of backplate (6A, B). 52.

-

Page 13: Gear Reduction Unit

INSTRUCTIONS FOR ASSEMBLY OF A TYPE “BHB” HYDRAULIC DRIVE 1. Refer to Section 3, INSTRUCTIONS FOR PUMP ASSEMBLY, steps 1 – 5. For installing packing, refer to steps 7 – 18. For installing mechanical seal, refer to steps 28 – 38. 2. - Page 14 14. Rotate pinion to desired position. Install and tighten six hex head cap screws (W) along with six flat washers (X) and six lockwashers (Y). 15. If necessary, reposition plugs (AA), petcock (AC), and oil cup (AB). Oil cup should be at uppermost point and petcock at second hole from bottom.

- Page 15 13. Refer to gear ratio chart to select desired gear ratio. 14. Slide drive gear (46) on drive shaft (32) securing in place using retaining ring (45). Make sure key (Z) and spacer (47) are in place. The number of teeth or part number is stamped on drive gear (46). On standard units, last two numbers of part number represent number of teeth on gear.

- Page 16 GEAR REDUCTION RATIOS AND CAPABILITIES Gear reducers are rated to transmit up to the horsepowers (kW) shown below. Three interchangeable gear ratios are available. 3611 THRU 4722 PUMPS 60 Hz OPERATION 50 Hz OPERATION NUMBER OF TEETH GEAR MOTOR PUMP MAX HP MOTOR PUMP...

-

Page 17: Parts List

PARTS LIST 2. Ball Bearing 3. Retaining Ring, Bearing Cage 4. Retaining Ring, Ball Bearing 5. Lip Seal (GHB) 6. Backplate A. Standard B. Jacketed 7. Bearing, Short 8. Bearing, Long 9. Seal Retainer 11. Mechanical Seal 12. Retaining Ring, Mechanical Seal 13. - Page 18 28. Spring Guide 29. Spring 30. Poppet 31. Adapter 32. Drive Shaft 33. Idler Shaft 34. Drive Gear 35. Idler Gear 57. Expansion Washer 58. Cam, Double Setting Relief Valve only 59. Operating Piston, Double Setting Relief Valve only 60. Locator Ring WRN2 Warning Plate, RV Style Relief Valve WRN3...

- Page 19 AP. O-Ring, Double Setting Relief Valve only Gear Reduction Assembly only 38. Bearing Retainer Gasket 39. Lip Seal 40. Retaining Ring, Ball Bearing 41. Ball Bearing 42. Pinion Gear and Shaft 43. Needle Bearing 44. Gear Case 45. Retaining Ring, Drive Gear 46.

- Page 20 Type BHB Hydraulic Drive Bracket Assembly only 51. Bracket Half, Pump 52. Bracket Half, Motor 53. Coupling Half, Pump 54. Coupling half, Motor 55. Spider Coupling AE. Socket Head Cap Screw, Bracket to Bracket AF. Lockwasher...

- Page 21 Figure 7.1...

- Page 22 Figure 7.2...

- Page 23 3611-4722 MBHB,F,RV HYDRAULIC DRIVE COUPLING ASSEMBLY Figure 7.3 FigFigure...

- Page 24 INDEX Aligning GHB Pinion Shaft Height, 13 – 14 Assembly Instructions All, 9 – 10 3600/4600 “GHBO,” 10 3600/4600 “BHB,” 10 3600/4600 “GHB” Gear Reduction Unit, 10 3700/4700 “GHBO” - Standard Mechanical Seal, 11 3700/4700 “GHBO” - Positive Drive Mechanical Seal, 11 – 12 3700/4700 “GHB”...

- Page 25 This agreement (this "Agreement"), consisting of these Terms and Conditions, and the associated Order Acknowledgement is binding upon Roper Pump Company, hereinafter "SELLER," and the customer, hereinafter "BUYER." By placing an order for a product with the Seller, the Buyer agrees to these Terms and Conditions of sale and acknowledges that the person placing the order has the authority to enter into the Order Acknowledgement on Buyer's behalf.

- Page 26 other documents necessary to perfect such interests and liens. If Buyer defaults in its obligations under the Order Acknowledgement before the price (including any notes given therefore) of the equipment has been fully paid in cash, Seller may take any and all actions permitted by law to protect its interests including, where permissible, repossession of such equipment.

- Page 27 or disclaim, (i) Seller's aggregate liability arising from or relating to this Order Acknowledgement or goods, regardless of the cause of action asserted, is limited to the amount paid by Buyer to Seller for the applicable goods and (ii) Seller shall not be liable for any special, incidental, consequential, indirect, or punitive damages, including without limitation, lost revenues, loss of use of the goods, loss resulting from improper storage, processing, padding/cushion, delay in delivery or shipment or errors in shipment or labeling, loss of data, or the cost of any substitute goods or related equipment, even if...

Need help?

Do you have a question about the G12-436 and is the answer not in the manual?

Questions and answers