Table of Contents

Advertisement

Available languages

Available languages

Quick Links

Owner's Manual

Comp,,anion

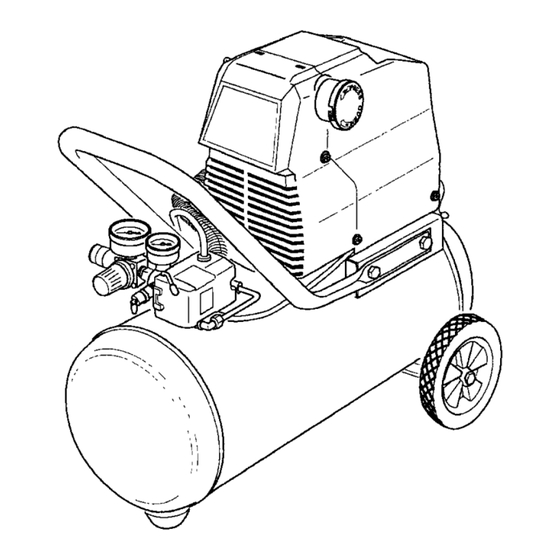

AIR COMPRESSOR

7-gallon

1.5 HP

Oil Free

Model No. 921.153501

CAUTION:

Before using this product,

read this manual and follow

all its Safety Rules and

Operating Instructions.

• Safety Instructions

• Installation & Operation

• Maintenance

& Storage

• Troubleshooting

Guide

• Parts List

• Espa_ol,

p. 12

Sears,

Roebuck

and Co., Hoffman

Estates,

IL 60179

U.S.A.

www.sears.com

?j'&t2005

Part No E101265

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for COMPANION 921.153501

- Page 1 Owner's Manual Comp,,anion AIR COMPRESSOR 7-gallon 1.5 HP Oil Free Model No. 921.153501 CAUTION: • Safety Instructions • Installation & Operation Before using this product, read this manual and follow • Maintenance & Storage • Troubleshooting Guide all its Safety Rules and •...

- Page 2 ON COMPANION AIR COMPRESSOR If this Companion Air Compressor fails due to manufacturer's defects in material or workmanship within one year of the date of purchase, RETURN IT TO THE NEAREST SEARS STORE IN THE UNITED STATES and it will be replaced free of charge. This warranty gives you specific legal rights and you may also have other rights which vary from state to state.

-

Page 3: Safety Symbols

Safety Symbols The information listed below should be read and understood by the operator. This information is given to protect the user while operating and storing the air compressor, We utilize the symbols below to allow the reader to recognize important information about their safety. - Page 4 Important Safety Instructions & Guidelines Risk from Always wear ANSI Z87,1 approved safety glasses with side shields when the air compressor is in use. Turn off the air compressor and drain the air tank before Flying Objects performing any type of maintenance or disassembly of the hoses or fittings. Never point any nozzle or sprayer toward any part of the body or at other peopfe or animals.

-

Page 5: Glossary

Glossary Cut-Out Pressure: The point at which the motor stops CFM: Cubic feet per minute. when the tank has reached maximum air SCFM: Standard cubic feet per minute; a unit of measure pressure. for air delivery. Code Certification: Products that bear one or more of PSlG: Pounds per square inch gauge;... -

Page 6: Installation & Assembly

Installation & Assembly Location of the Air Compressor The air compressor should always be located in a clean, dry, and well ventilated environment. The unit should have at The air compressor should be turned off and unplugged minimum, 12 inches of space on each side. The air intake filter from the power source before any installation and assembly should be free of any debris or obstructions. -

Page 7: Operating Procedures

Maintenance Operating Procedures Daily Start-Up Procedures NOTE; Any service procedure not covered in the 1. Set the Auto-On/Off lever to the Off position. maintenance schedule below should be performed by 2. Check the air compressor visually for any damage or qualified service personnel. -

Page 8: Troubleshooting Guide

Troubleshooting Guide compressor must be turned off and unplugged from power source before problem correction or task is performed. Release the air from the tank and allow the unit time to cool. Personal injuries could occur from moving parts, electrical sources, compressed air, or hot surfaces. -

Page 9: Notes

Notes... -

Page 10: Exploded View

Companion Compressor Model 921.153501 Exploded View... -

Page 11: Parts List

Companion Air Compressor Model 921.153501 Parts List Reference Part Description Number Nu e Number uantlty Description Quantity Reference _b t Part Number Number I Number E100023 Valve,Drain Screw,SHC$M6 x 1.0x 35ram Bolt,Hex Head M8x 1.25 x 25mm Washer, L ock6ram Nut,HexNylonLockMIOx 1.5... -

Page 12: Table Of Contents

DE AIRE COMPANION Si este compresor de aire Companion Ilega a fallar debido a defectos de manufactura o de materiales atribuiblas al fabricante en un plazo de un a_o desde la fecha de compra, DEVU_LVALO A LA TIENDA SEARS MAS CERCANA EN LOS ESTADOS UNIDOS, para que le sea reemplazado sin ningt_n cargo. -

Page 13: Simbolos De Seguridad

Simbolos de seguridad El operador debe leer y entender la informaciSn siguiente. Esta informaci6n se ofrece para proteger al usuario durante la operaci6n y el almacenaje del cempresor. Los simbolos siguientes son los que se utilizan para indicar al lector informaci6n que es importante para su seguridad. -

Page 14: Especificaciones

Instrucciones y peutas de seguridad importente$ (cont.) Riesgo de lanzamiento AI emplear el compresor, siempre utilice anteojos de seguridad con protectores laterales que cumplan con la norma ANSI Z87.1. Antes de llevar a cabo cualquier de objetos clase de mantenimiento y antes de desconectar [as mangueras y acopladores,... -

Page 15: Glosario

Glosario PreskSnde arranque: El compresor arranca automb4icamente CFM: Pies cQbicos per minute. cuando la presi6n baja a menos del minimo SCFM: Pies cObicos est&ndar per minute; unidad de prescrite. medici6n de suministro de aire. Presi6n de parada: Presi6n de aire que tiene que alcanzarse en el tanque para que se detenga el PSIG: Libras por pulgada cuadrada sobre la presibn motor. -

Page 16: Instalaci6N Y Ensamblaje

Instalaci6n y ensamblaje Ubicaci6n del compresor de aire El compresor de aire siempre debe estar en un medio ambiente limpio, seco y bien ventilado. La unidad debe Antes de dar instalaci6n y ensamblaje al compresor tener cuando menos 30 cm. de espacio libre en cada lado. de aire, se le debe apagar y desconectar de la fuente... -

Page 17: Procedimientos De Operaci6N

Mantenimiento Procedimientos de operaci6n NOTA: Procedimiento diario de arranque Cualquier procedimiento de servicio que no est6 1. Ponga el interruptor Auto-On/Off en la posici6n de cubierto en el programa de mantenimiento sigue apagado (OH. deber_ ser efectuado por personal de servicio ca[ificado. 2. -

Page 18: Diagn6Stico Y Correcci6N De Fallas

Diagn6stico y correcci6n de fallas !uiercorrecci6nde problemas o tare& el compresorde aire se debe apagar y desconectar del tomacorriente.Purgue el aire del tanque y perrnitaque la unidad se enffie. Las partes en movimiento,las fuentes elSctricas,el aire cornprimido y las superficies calJentes pueden provocar lesiones. -

Page 19: Apunte

Apunte... - Page 20 Your Home For repair - in your home - of all major brand appliances, lawn and garden equipment, or heating and cooling systems, no matter who made it, no matter who sold it[ For the replacement parts, accessories owner's manuals that you need to do-it-yourself. For Sears professional installation of home appliances...

Need help?

Do you have a question about the 921.153501 and is the answer not in the manual?

Questions and answers