Table of Contents

Advertisement

Quick Links

Operating Instructions

Digital IGBT controlled

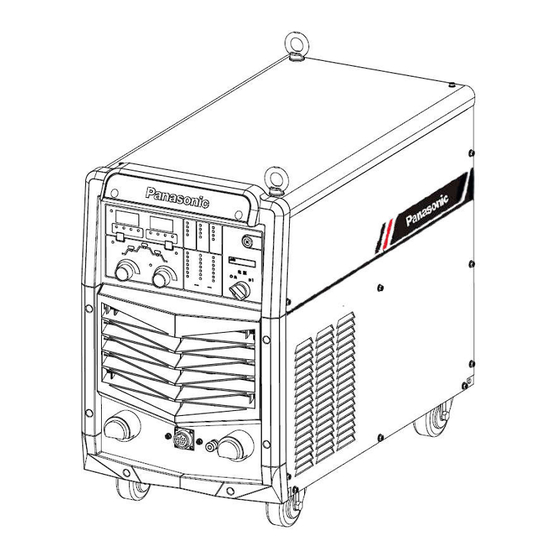

MIG/MAG Arc Welding Power Source

YD-350/500GL(R)5

Model No . :

● Thank you for your purchase of Panasonic welding power source.

● Before operating this product, please read the instructions carefully and save this manual

for future use.First of all, please read "Safety precautions" or "Safety manual".

● SPEC. No.:YD-350GL5HGY, YD-350GR5HGY, YD-500GL5HGY,YD-500GR5HGY.

Panasonic Welding Systems (Tangshan) Co., Ltd.

WTD032TE0PAA02

Advertisement

Table of Contents

Troubleshooting

Summarization of Contents

Safety

1.1 Warning symbols for safe usage

Explains symbols indicating hazardous conditions or damages.

1.2 Safety precautions

Lists essential safety measures to prevent hazards during operation.

Rated Specifications

2.1 Specifications table

Details the technical specifications of the welding power source.

2.2 Specifications table

Lists further technical specifications for different models.

2.3 Rated duty cycle

Explains the duty cycle performance and limitations of the machine.

2.4 Thermal protection

Details the thermal protection features and operation.

2.5 Dimensions

Provides the physical dimensions of the welding power source.

Installation and Power supply facility

3.1 Installation site

Guidelines for selecting a suitable installation location for the machine.

3.2 Installation transportation

Instructions for safely transporting the welding machine.

3.3 Power supply equipment

Requirements and precautions for the power supply equipment.

Configuration

4.1 Equipment necessary for welding

Lists the essential equipment required for welding operations.

4.2 Connecting cable

Information on connecting cables and their usage.

4.2.1 About connecting cable

Details about the connecting cable and its use.

4.2.2 Cautions about using connecting cable

Important warnings and precautions for using connecting cables.

Names and functions

5.1 The power switch

Explains the function and operation of the power switch.

5.2 The output terminal area

Describes the output terminals and their connections.

5.3 rear side

Identifies and explains components on the rear panel of the machine.

5.4 Front panel

Details the controls, indicators, and functions on the front panel of the welding machine.

Connection

6.1 The connection of output cable

Instructions for connecting the output cable.

6.2 The connection of the grounding wire

Procedure for connecting the grounding wire.

6.3 The connection of input cable

Steps for connecting the input power cable.

6.4 Connecting jig(s)

Information on connecting jigs and their terminal layout.

Preparation and termination processings

7.1 Preparation

Steps and precautions for preparing the welding operation.

7.2 Termination processing (steps after welding operation)

Procedures for shutting down the machine after welding.

Settings

8.1 FUNCTION settings

Overview of function settings and parameter adjustments.

8.1.1 "F. ADJ"

Details the "F. ADJ" menu for fine parameter adjustments.

8.1.2 "CALL" and "RECORD"

Functionality for calling and recording welding conditions.

8.2 The welding machine factory defaults reset

Procedure to reset the machine to factory default settings.

8.3 Robot welding system

Information on connecting and using the robot welding system.

8.4 Robot/manual welding switch

How to switch between robot and manual welding modes.

8.5 Welding preparation

Steps and precautions before starting the welding operation.

8.6 Checking shield gas

Procedure for checking the shield gas supply.

Operation

9.1 Welding current calibration

Guide for calibrating welding current based on wire extension.

9.2 "NO CRATER"

Operation sequence for the "No Crater" function.

9.3 "CRATER"

Detailed operation for the "Crater" welding function.

9.4 "INI. &CRATER"

Operation for initial and crater welding sequences.

9.5 "Crater repeat" operation

How to perform repeated crater welding operations.

9.6 "ARC SPOT"

Procedure for performing arc spot welding.

Maintenance and inspection

10.1 Daily check

Daily inspection tasks for the welding machine.

10.1.1 Welding machine (This product)

Specific daily checks for the welding machine itself.

10.1.2 Cables

Daily checks for cables and connections.

10.1.3 Other devices

Daily checks for related devices like torch and gas regulator.

10.2 Periodic check

Regular maintenance checks for the welding equipment.

10.3 Precautions for withstand voltage test and insulation resistance measurement

Safety precautions for electrical testing procedures.

10.3.1 Test preparation

Steps for preparing the machine for voltage and insulation tests.

10.3.2 After completion of the test

Procedures after completing voltage and insulation tests.

Troubleshooting

11.1 Error indication

Explains error codes and their meanings displayed on the panel.

11.2 Troubleshooting table

A table listing common welding errors and their probable causes.

Parts list

12.1 Parts list for 350GL5/350GR5

Lists parts for the 350GL5/350GR5 models with diagrams.

12.2 YD-350GL5/ YD-350GR5 parts diagram

Detailed diagram and part numbers for 350GL5/350GR5 models.

12.3 Parts list for 500GL5

Lists parts for the 500GL5 model with diagrams.

12.4 YD-500GL5 parts diagram

Detailed diagram and part numbers for the 500GL5 model.

12.5 Parts list for 500GR5

Lists parts for the 500GR5 model with diagrams.

12.6 YD-500GR5 parts diagram

Detailed diagram and part numbers for the 500GR5 model.

Circuit diagram

13.1 Circuit diagram for YD-350GL5, YD-350GR5

Provides the circuit diagram for 350GL5 and 350GR5 models.

13.2 Circuit diagram for 500GL5

Presents the circuit diagram specific to the 500GL5 model.

13.3 Circuit diagram for 500GR5

Details the circuit diagram for the 500GR5 model.

Appendix

14.1 CO2 welding conditions table: Solid wire (Reference)

Reference table for CO2 welding conditions with solid wire.

14.2 MAG welding conditions table: Solid wire (Reference)

Reference table for MAG welding conditions with solid wire.

14.3 Arc spot welding conditions table (Reference)

Reference table for arc spot welding conditions.

【The standard of the product】

Information regarding product standards and compliance.

【ATTENTION: The disposal of the product】

Guidelines for proper disposal of the product.

【NOTICE: Machine export to Europe】

Information on European export requirements and product compliance.

Need help?

Do you have a question about the YD-500GL5 and is the answer not in the manual?

Questions and answers