Summarization of Contents

Welcome

Manual Reading Advice

Users must read the manual carefully before using the VoltHub, following all instructions.

Safety Information

Risk Assessment and Fire Safety

Ensure risk assessments, especially fire safety, are carried out before using the VoltHub.

Initial Charging and Tampering Warning

Plug in for 48 hours for backup charge. Do not tamper with the unit; this voids warranty and increases danger.

Fire Department Notification

Inform local fire department about VoltHub use during fire risk assessment.

General Safety Precautions

Keep doors shut and locked, ensure personnel know procedures, do not alter fire suppression system.

Battery Charging Guidelines

Charge batteries inside red lockers, do not exceed 350Wh per locker, use OEM certified equipment.

Lifting and Moving Safety

Examine unit before lifting, use qualified personnel, conduct risk assessment for lifting/lowering.

Extension Leads and Forklift Use

Do not run extension leads from locker sockets. Use fork pockets for forklift transport.

Unit Positioning and Ventilation

Position away from heat/flammables, maintain 1m distance, ensure outdoor ventilation when indoors.

Operating Temperature and Outdoor Use

Use within -10°C to +45°C. Keep out of direct sunlight outdoors for safety.

Locking Castors and Maintenance

Lock castors when static. Check castors regularly for fitness for purpose.

Locker Load Rating and Stability

Each locker has a 40kg UDL. Position on stable, even ground with castors locked.

Equipment Usage Restrictions

Not for use by persons with reduced capabilities without supervision. Children must not play with the equipment.

Damaged Supply Cord and Socket Usage

Damaged cords must be replaced by manufacturer. Sockets are for chargers only, not extension leads.

Charging Lead Management

Push leads to back of lockers before closing. Inspect power leads for damage before each use.

After a Fire

Waste Disposal and Neutralisation

Remove contaminated waste as per disposal requirements. Dispose of WEEE responsibly.

Fire Suppressant Containment

The suppressant will be contained in the VoltHub's bunded sump.

Re-commissioning After Fire

Return to Armorgard for re-commissioning. Ensure lockers are empty of batteries and chargers.

What's Included

VoltHub Unit and Keys

Includes 1x VoltHub unit and 2x keys.

Extension Lead and Connectors

Includes 1x IP67 extension lead and 1x SP21 male connector.

Castor Kit and Magnetic Studs

Includes 1x Castor kit and 4x magnetic studs.

Required Items

Padlocks and Spanner

Requires 16x padlocks (under 20mm depth) and a 13mm spanner/socket for castors.

SIM Card or Fire Alarm System

Requires 1x contract SIM card or pre-existing wireless fire alarm system for alert functionality.

Ducting and Sealant

Requires 1x intumescent sealant and 1x 150mm ducting flange/clamp for indoor use.

Screwdriver

Requires 1x PZ2 screwdriver for indoor use setup.

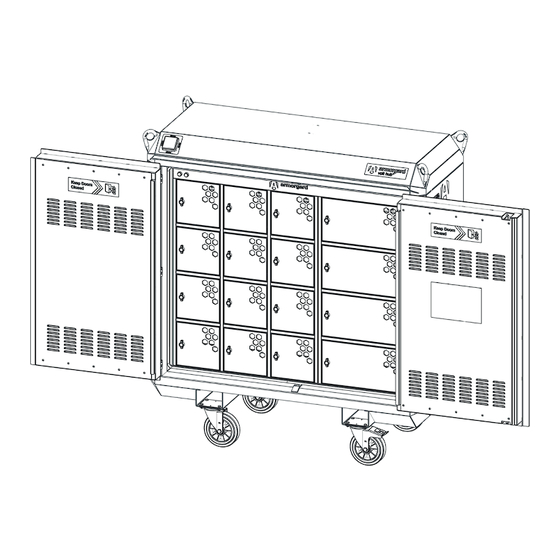

VoltHub Components Overview

Fire and Alarm Systems

Features local fire alert beacon, alarm system, SIM card alert functionality, and SP21 interface.

Charging and Control Features

Includes sockets, critical temperature alarm, on/off isolator switch, and crane lifting eyes.

Ventilation and Access

Features negative pressure ventilation system and forklift pockets/pallet truck access.

Castors and Power Supply

Equipped with heavy-duty castors and supports 240V/110V power supply.

Assembly Instructions

Unloading and Initial Inspection

Use forklift/pallet truck for unloading. Inspect for damage and note serial number.

Initial Charging Procedure

Unit MUST be plugged in for 48 hours to fully recharge the internal battery backup before use.

Fitting the Castors

Castor Plate Installation

Insert castor plates into forklift skids, place wheel, and tighten M8 nylocks with a 13mm socket.

Castor Type and Placement

Fit 2x fixed castors on the left and 2x swivel-braked on the right, same side as the handle.

Final Castor Check

Check all nuts are tight and braked castors swivel 360° before lowering the VoltHub.

Fire System Maintenance

Serviceable Condition and Information

Keep VoltHub serviceable per maintenance documentation. Scan QR for more information.

GSM Set-up

Programming the GSM System

Unit is plug-and-use. Scan QR for instructions on programming the GSM notification system.

Electrical Safety Information

Power Draw and Surge Protection

Do not exceed 32A total power draw. Ensure sufficient over-current and surge protection.

Hazard Assessment and User Training

Assess electrical hazards before use. Ensure users understand limitations and safety requirements.

Trip Hazards and Socket Overload

Ensure trailing cables are not trip hazards. Do not overload sockets with unfused adaptors.

RCD Testing and Wet Conditions

Test RCDs regularly. Do not handle equipment in wet conditions.

Appliance Checks and Safety Do's/Don'ts

Switch off appliances before cleaning. Check PAT tests. Follow stickers and manufacturer guidance.

Safe Battery Charging Conditions

Battery and Charger Inspection

Check batteries for damage, swelling, leaks, corrosion. Ensure batteries and cables are dry and undamaged.

Approved Chargers and Capacity Limits

Use only approved/certified OEM chargers and batteries. Do not charge batteries larger than 350Wh per locker.

Locker and Charger Spacing

Do not overload lockers. Space chargers at least 5cm apart. Do not stack batteries.

Fire Suppression System Maintenance

Fitted fire extinguisher and DLP system must be serviced per BS standards.

Fire Plan

Fire Department Awareness

Ensure fire department knows how VoltHub is used and its location.

Emergency Response Planning

For larger facilities, log VoltHub with fire department as a point of interest for clarity.

In the Event of a Fire

Fire Alarm Activation

If fire alarm/beacon activates and not connected to system, dial 999.

Safe Unit Interaction During Fire

Do not approach. Power is isolated. Disconnect lead if possible. Ensure indoor ventilation is clear.

Fire Department Instructions

System Features

VoltHub has 6Ltr DLP Fire Suppression, 12v battery backup fan.

Post-Fire Procedures

Unplug unit, allow cool down, dispose of remnants. Reset button behind SIM panel.

How to Use

Positioning and Locking

Place VoltHub on a stable surface and lock the castors.

Pre-use Inspections

Open doors before plugging in. Follow routine inspections as outlined on page 28.

Connecting to Power

Use supplied lead, connect to power supply, twist locking collar to secure. Ensure no trip hazard.

Powering On the Unit

Turn isolator switch to 'On'. Expect 2 beeps and flashes from the temp alarm.

Fire Beacon and System Confirmation

Red LED beacon remains lit for 5 seconds. If no confirmation, charge for 48 hours, then contact Armorgard.

Turning Off the Unit

Turn the isolator switch to 'off' to turn power off to the sockets.

GSM Call/Text Notification Setup

For call and text notification, follow GSM set-up instructions by scanning the QR code.

Continuous Monitoring and Backup

Safety systems monitor parameters. Keep unit plugged in to maintain 12v battery backup charge.

240V RCD Socket Operation

240V sockets have RCD protection. Test button (red) before use. Reset button (orange) after tripping.

110V Transformer and Plug Safety

For 110V, ensure transformer is RCD protected. Unclip appliance plug caps before removing from socket.

Connecting to Fire Alarm System

System Compatibility and Provider Contact

VoltHub is compatible with most systems. Contact Armorgard or your fire alarm provider for interface preparation.

SP21 Plug Termination

Terminate 2 core flex into SP21 plug. Wire terminals are 'normally open', 'normally closed', 'common'.

Existing Fire Alarm System Connection

Terminate the other end of the cable into the existing fire alarm system.

Interface Location and Mounting

Use rubber coated magnets to locate wireless interface onto VoltHub.

Isolator Switch and IP Rated Cap

Locate 3 pin socket under isolator switch and unscrew the IP rated cap.

Alarm Interface Connection and Reset

Connect alarm interface, tighten locking ring. Reset false alarms via SIM card cover button.

Continuous System Monitoring

Safety systems monitor charging and fire safety parameters. Keep unit plugged in for battery backup.

Indoor Use Setup

Indoor Ventilation Ducting Recommendation

Recommended to duct ventilation outside to avoid fume build-up indoors in case of fire.

Ventilation Panel Removal

Remove the ventilation panel at the rear of the VoltHub using a PZ2 screwdriver.

Ducting Flange Installation

Replace panel with a 150mm/6inch flange using existing screws. Seal with intumescent sealant.

Ducting Connection and Clamping

Connect 150mm/6inch diameter ducting using a suitable duct clamp to secure it in place.

Exhaust Routing to Outside Atmosphere

Route ducting to outside the indoor space, allowing exhaust gases to ventilate to an outside atmosphere.

Exhaust Location for Risk Assessment

Make a note of the exhaust location as part of the fire risk assessment.

Temperature Alert System Operation

Automatic Power Isolation

If internal temperature exceeds 60°C, power is automatically isolated from sockets, preventing charging.

Alarm Indicators and User Alert

Red LED flashes and audible beep alert the user when the VoltHub is above safe charging temperature.

Silencing the Alarm

Turn the isolator switch 'off' to silence the alarm. Unit needs time to cool down before charging resumes.

Resuming Charging

Turn isolator switch back 'on'. If alarm stops, power is restored. Charging can resume.

Extended Cooling Procedure

If alarm persists after turning 'on', turn 'off' again to allow more time for cooling. Repeat until deactivated.

Fan Operation Check

If critical temperature alarm sounds but fan is not heard, contact Armorgard.

Lifting the VoltHub

Pre-Lifting Checks

Ensure valid LOLER certificate, castors braked, and main doors locked closed before lifting.

Lifting Chain Attachment

Attach a 4-leg lifting chain or sling to all 4 lifting points on the top of the VoltHub.

Lifting Operation

Carefully lift off ground, checking balance, before moving to final location. Ensure no persons are in the lifting area.

Post-Lifting Inspection

After lowering, remove lifting equipment. Perform all unit inspections as a new unit.

Storing the Unit

Storage Location and Conditions

Position on level ground in a cool, dry area.

Maintaining Battery Backup Charge

Keep VoltHub plugged in to charge the internal battery backup. Unit does not need to be switched on.

Transporting the Unit

Lifting Eyes and Loading

Use crane lifting eyes for transport. Unit should never be lifted when loaded.

Forklift and Door Security

Always use forklift pockets for transport. Doors must be locked when transporting the VoltHub.

Securing During Transport

Secure the VoltHub to the carrier by strapping down the unit fully during transport.

Disconnecting Power Lead

Disconnect lead from mains by twisting locking collar clockwise, then pulling directly out.

Equipment Care

Weather Resistance and Sealing

VoltHub is IP55 rated. Seal and secure electrical equipment inside lockers with doors closed.

Outdoor Spacing and Data Plate

Keep 1m open space behind outdoors for gas dispersion. Keep data plate visible for serial number.

Ongoing Maintenance

Pre-use Damage Check

Check VoltHub for damage before every use.

Component Checks

Check locks, pockets, lifting eyes, sockets, seals every three months. Check integrity regularly under rigorous use.

Electrical Testing and Ventilation

Customer responsible for annual electrical testing. Keep ventilation clear and clean.

DLP Fire System Maintenance Record

Weekly Visual Inspection

Competent person to conduct weekly visual inspection of the fire suppression system.

Pressure Gauges and Hose Check

Check pressure gauges are green. Check detection hose for damage (gouges, cuts, creasing).

Hose Securing and Body Inspection

Ensure hose secured in clips. Inspect detached hose for damage. Check VoltHub body for excessive damage.

Door Seals and Reporting

Check condition of rubber door seals and replace if damaged. Report any potential problems immediately.

Warranty Information

Manufacturer's Warranty

Armorgard products have a 12-month manufacturer's warranty. Refer to terms and conditions.

Replacement Keys and Locks

Replacement keys/locks available up to five years old. Provide distributor, proof of purchase, and serial number.

Warranty and Modifications

Do not force entry. Contact Armorgard for replacements. Unauthorized modifications void warranty.

Spare Parts and Support

Available Spare Parts

Spare parts include replacement keys, castors, and deadlocks.

Product Registration

Register your product following the QR code for additional support and access to spare parts.

Need help?

Do you have a question about the volthub VH16-240 and is the answer not in the manual?

Questions and answers