Summarization of Contents

Safety Symbols and Definitions

Safety Alert Symbol

Symbol used to warn of potential personal injury. Read instructions carefully.

Signal Words and Safety Instructions

Understanding signal words (WARNING, CAUTION, NOTE) and following safety rules.

General Safety Precautions

Eye, Hearing, and Head Protection

Wear eye, hearing, and head protection where risks exist.

Protective Gloves and Footwear

Wear slip-resistant gloves and footwear for safety.

Cutting Attachment Guard

Always use the cutting attachment guard correctly to prevent accidents.

Fire and Flame Hazard

Avoid smoking or open flames near fuel or the unit due to fire hazard.

Carbon Monoxide Hazard

Do not start the engine indoors or in poorly ventilated areas due to carbon monoxide.

Operational Safety Precautions

Thrown Objects Hazard

Be aware of thrown objects; keep people/animals at least 15m away.

Blade Thrust (Kickback)

Avoid blade thrust (kickback) by not cutting with the right side of the blade or contacting hard objects.

Intended Use

Unit is designed for trimming grasses, weeds, or bushes, not other purposes.

Noise Exposure Warning

Serious Injury Warning

General warning to avoid serious injury. National regulations may limit use.

Noise Hazard Warning

Prolonged exposure to noise may exceed 85 dB(A), risking hearing damage.

Important Safety Instructions

General Safety Advice

Follow instructions carefully to avoid operational errors and accidents.

Safety Warnings and Definitions

Safety Alert Symbol

The safety alert symbol warns of potential personal injury.

Signal Words

Signal words (WARNING, CAUTION, NOTE) indicate levels of hazard and importance.

Prohibition Symbol

Circular band with diagonal slash means prohibition.

Safety Warnings and Definitions (Italian/Spanish)

Safety Symbol

Safety symbol warns of personal injury risk.

Signal Words

Signal words (ADVERTENCIA, PRECAUCIÓN, NOTA) indicate hazard levels.

Prohibition Symbol

Prohibition symbol indicates forbidden actions.

Safety Warnings and Definitions (Portuguese/Dutch)

Safety Alert Symbol

Safety alert symbol warns of personal injury.

Signal Words

Signal words (AVISO, ATENÇÃO, NOTA) indicate hazard levels.

Prohibition Symbol

Prohibition symbol indicates forbidden actions.

Safety Warnings and Definitions (Dutch)

Safety Alarm Symbol

Safety alarm symbol indicates personal injury risk.

Signal Words

Signal words (WAARSCHUWING, LET OP, OPMERKING) indicate hazard levels.

Prohibition Symbol

Prohibition symbol indicates forbidden actions.

General Safety Rules and Precautions

Read Manual and Familiarize

Read manual, familiarize with controls, learn to stop unit and unhook harness quickly.

Clothing and Equipment

Wear durable, light clothing and trousers with appropriate fit.

Personal Protective Equipment (PPE)

Eye Protection

Wear proper eye protection (EN166) and face shield for flying objects.

Hearing Protection

Wear hearing protection like earplugs or earmuffs to protect against loud noise.

Head Protection

Wear head protection if there's a risk of falling objects.

Gloves and Footwear

Wear slip-resistant gloves and footwear.

Additional Safety and Environmental Precautions

Children and Instruction

Never let children operate the unit. Ensure proper instruction for all users.

Alcohol, Drugs, Medications

Do not operate under the influence of alcohol, drugs, or medications affecting judgment.

Operating Area Safety

Thrown Objects Hazard Zone

Maintain a 15m distance from bystanders; the area is a danger zone due to thrown objects.

Footing and Stability

Maintain stable work posture with firm footing, especially on slippery or uneven ground.

Operational Safety and Fatigue Management

Footing and Obstacles

Work on the ground, avoid obstacles; never work on unstable supports like ladders.

Fatigue Management

Take regular rests and avoid becoming overly fatigued to reduce accident risk.

Fuel Handling and Fire Safety

Petrol Handling

Handle petrol with care; it is highly flammable.

Fueling and Spacing

Move at least 3 meters away from fueling point before starting the engine.

Sources of Sparks and Flames

Eliminate all sources of sparks or flames in areas where fuel is handled.

Fuel Safety and Storage

Hot Engine Fueling

Never refuel a hot engine; wait for it to cool down.

Spilled Fuel

Avoid spilling fuel or oil; wipe up any spills immediately.

Fuel Storage

Always store petrol in approved containers and well-ventilated areas.

Pre-Start Checks

Assembly Check

Ensure the unit is assembled properly before use.

Accessory and Attachment Usage

Use only manufacturer-supplied accessories and attachments.

Cutting Attachment Guard

Always attach the cutting attachment guard correctly to prevent injury or death.

Pre-Operation Checks

Handle and Footing

Hold handle firmly and check footing to avoid falling while working.

Harness Usage

Always use the harness if provided and balance the unit.

Blade Installation

Do not attach any blade without proper installation of all required parts.

Pre-Operation Safety Checks

Dull/Damaged Cutting Attachment

Never use a dull, cracked, or damaged cutting attachment to avoid injury.

Unit Condition

Keep the unit and attachments in good working condition, tighten fasteners regularly.

Safety Devices

Operate only with proper, connected safety devices; inspect them for condition and operation.

Pre-Operation Area and Unit Checks

Area Inspection

Inspect the area thoroughly and remove any objects that could be thrown.

Holding the Unit

Hold the unit down firmly while cranking to prevent loss of control.

Pre-Operation Unit and Load Checks

Cutting Attachment Stop

Ensure cutting attachment stops when throttle trigger is released and engine idles.

Unit Condition Check

Inspect the entire unit for worn, loose, or damaged parts before each use.

Unusually High Loads

Check unit condition after unusually high loads like heavy impact or a fall.

Handling Foreign Objects and General Operation

Foreign Object Impact

Stop engine, disconnect plug if unit strikes foreign object or vibrates abnormally.

Storage and Transport

Cover blade when storing or transporting. Secure unit on vehicle.

Muffler Position

Keep muffler side away from body to avoid arm burns.

Reasonable Operating Hours

Operate the unit during reasonable hours to avoid disturbing others.

Operation Safety and Cutting Hazards

Engine Stop and Rotation

Keep fingers and feet away from cutting attachment until rotation stops after engine shutdown.

Cutting Lines

Never use wire instead of nylon monofilament cutting lines; wire can break off.

Rotating Parts Hazard

Keep hands/feet away from rotating parts while the engine is running.

Cutting Techniques and Blade Safety

Blade Thrust (Kickback)

Blade thrust is dangerous; avoid contact with solid objects or internal contact.

Blade Thrust Zone

Understanding the blade thrust zone to prevent accidents.

Vibration Hazards and Health Effects

Prolonged Use Vibration

Prolonged use may cause vibration-induced circulation problems in hands (white finger disease).

Vibration Hazard Advice

Usage Duration Factors

Factors like hand protection, breaks, cold fingers, low temps, grip force affect usage duration.

Medical Examination

Users experiencing symptoms like tingling fingers should undergo a medical examination.

Ground Contact

Avoid cutting too close to the ground to prevent hitting small stones or debris.

Cutting Height

Keep the cutting attachment below waist level for safe operation.

Operational Advice

Engine Stop and Restart

Stop engine immediately if unit shakes or vibrates abnormally.

Handling Foreign Objects

Stop engine, disconnect plug if unit strikes foreign object or vibrates.

Operational Safety Procedures

Foreign Object Impact

Stop engine and disconnect plug if unit strikes a foreign object or vibrates.

Storage and Transport

Cover blade when storing or transporting. Secure unit on vehicle.

Muffler Position

Keep muffler side away from body to avoid arm burns.

Operating Hours

Operate the unit during reasonable hours to avoid disturbing others.

Fuel Storage Safety

Fuel in Tank Storage

Do not store unit with fuel in tank; allow engine to cool before storing.

Cleaning, Repair, Parts, and Storage Safety

Cleaning and Repair Safety

Ensure cutting attachment has stopped and disconnect spark plug cap before cleaning or repair.

Genuine Replacement Parts

Use only recommended genuine replacement parts to avoid hazards and warranty voidance.

Storage Environment

Store the unit in a dry area out of the reach of children.

Technical Specifications

Blade Speed and Cutter Details

Details on rated blade speed, standard blades, and nylon cutter specifications.

Dimensions and Weight

Specifications for unit dimensions (L x W x H) and weight.

Vibration and Noise Levels

Vibration and noise level data according to ISO standards.

Engine Specifications

Specifications for unit dimensions (L x W x H) and weight.

Technical Specifications (Continued)

Engine Specifications

Details on applicable engine, displacement, output, weight, and spark plug.

Noise Level Details

Measured and guaranteed sound power levels, including uncertainty.

Technical Specifications (Spanish/Portuguese)

Vibration and Noise Levels

Vibration and noise levels with uncertainty data.

Engine Specs

Engine specs: displacement, idle speed, max output, weight, spark plug, fuel tank.

Technical Specifications (Dutch)

Vibration and Noise Levels

Vibration and noise levels with uncertainty data.

Engine Specs

Engine specs: displacement, idle speed, max output, weight, spark plug, fuel tank.

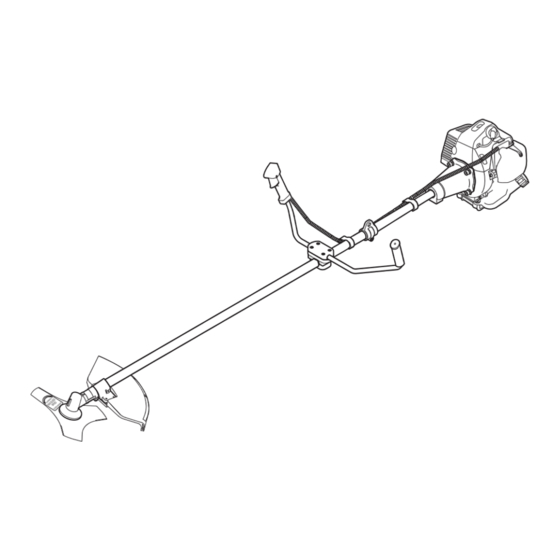

Parts Identification and Specifications

Blade and Transmission

Identification of blade, angle transmission, guard, shaft tube, and handle.

Controls and Harness

Identification of controls like throttle, switch, clutch, and harness.

Installation

Handle Installation

Instructions for installing the handle securely using four bolts.

Installation of Cutting Attachment Guard

Guard Installation Warning

Warning to always attach the cutting attachment guard correctly.

Blade Sharpness

Caution about the sharpness of the blade and handling it carefully.

Installation of Safety Guard (Spanish/Portuguese)

Guard Installation Warning

Warning to always attach the safety guard correctly to prevent accidents.

Blade Sharpness

Caution about blade sharpness; handle cutting tool carefully.

Installation of Cutting Attachment

Cutting Attachment Installation Procedure

Step-by-step procedure for attaching the cutting attachment (blade or nylon cutter).

Blade Sharpness and Handling

Warning about blade sharpness and careful handling.

Installation of Cutting Attachment (German/Italian)

Cutting Attachment Installation Procedure

Procedure for attaching the cutting attachment (blade or nylon cutter).

Blade Sharpness and Handling

Caution regarding blade sharpness and safe handling.

Installation of Cutting Attachment (Spanish/Portuguese)

Cutting Attachment Installation Procedure

Procedure for attaching the cutting attachment (blade or nylon cutter).

Blade Sharpness and Handling

Caution about blade sharpness; handle cutting tool carefully.

Installation of Cutting Attachment (Dutch)

Cutting Attachment Installation

Steps for mounting the cutting attachment (blade or nylon cutter).

Blade Sharpness

Warning about blade sharpness; handle the nylon cord cutter carefully.

Operating Instructions

Harness Adjustment

Adjust harness fit so the blade is almost flat on the ground.

Harness with Quick Release

Use harness with quick release for emergency protection (fire, etc.).

Starting and Stopping the Engine

Preparation Before Starting

Prepare for starting: check fuel system, fill tank with correct fuel mixture, check for leaks.

Fuel Mixture Warning

Warning: incorrect fuel mixture can cause low power or engine malfunction.

Throttle Wire Adjustment

Adjust throttle wire play to 0.5-1.0 mm; excessive play causes starting failure.

Starting and Stopping the Engine (German/Italian)

Preparation Before Starting

Prepare for starting: check fuel system, fill tank with correct fuel mixture, check for leaks.

Fuel Mixture Warning

Warning: incorrect fuel mixture can cause low power or engine malfunction.

Throttle Wire Adjustment

Adjust throttle wire play to 0.5-1.0 mm; excessive play causes starting failure.

Starting and Stopping the Engine (Spanish/Portuguese)

Preparation Before Starting

Prepare for starting: check fuel system, fill tank with correct fuel mixture, check for leaks.

Fuel Mixture Warning

Warning: incorrect fuel mixture can cause low power or engine malfunction.

Throttle Adjustment

Adjust throttle cable play to 0.5-1.0 mm; excessive play causes starting failure.

Starting and Stopping the Engine (Dutch)

Preparation Before Starting

Prepare for starting: check fuel system, fill tank with correct fuel mixture, check for leaks.

Fuel Mixture Warning

Warning: incorrect fuel mixture can cause low power or engine malfunction.

Throttle Cable Adjustment

Adjust throttle cable play to 0.5-1.0 mm; excessive play causes starting problems.

Starting Procedure

Set Engine Switch

Set the engine switch to the "I" (start) position.

Set Throttle Lock

Procedure to set the throttle lock by squeezing and moving the trigger.

Priming the Engine

Priming Pump Operation

Press priming pump several times until fuel comes out of the overflow tube.

Flooding Prevention

Press pump sufficiently; there is no possibility of flooding the engine.

Choke Lever Operation

Choke Lever Positions

Move choke lever to closed (N) or open (||) position based on fuel and engine status.

Recoil Starter Operation

Recoil Starter Grip

Grasp the recoil starter grip and pull it rapidly, but leave a margin.

Recoil Starter Caution

Do not pull recoil starter completely; return it slowly after pulling.

Post-Start Engine Monitoring

Engine Monitoring

After starting, monitor engine condition and slowly move choke lever to fully open position.

Engine Start Failure

If engine fires but won't start, move choke to open position and pull starter rapidly.

Engine Warm-up and Throttle Control

Lubrication and Engine Speed

Avoid rapid engine revolution increase after starting due to poor lubrication.

Engine Racing and Load

Do not race the engine or run at unnecessarily high revolutions.

Throttle Operation

Grip throttle trigger, warm up engine, then adjust to required speed.

Throttle Control and Engine Speed

Throttle Control Caution

Avoid rapidly increasing engine speed after starting due to poor lubrication.

Throttle and Engine RPM

Avoid high RPM, engine stalling, and unnecessary high RPM operation.

Throttle Operation Sequence

Operate throttle trigger, unlock, set to low speed, warm up, then adjust for operation.

Stopping the Engine and Fuel Tank Cap Precautions

Stopping the Engine

Release throttle trigger and turn engine switch to STOP position.

Summer Fuel Tank Cap

Caution: prevent fuel tank cap's inner packing from submerging in fuel in summer.

Fuel Tank Emptying for Storage

Fuel Tank Emptying Procedure

Evacuate fuel from tank, restart engine and run until it stops to empty carburetor.

Cutting Attachment Selection

Cutting Attachment Types

Select cutting attachment (nylon, 3/4/8 blade) based on weed type.

Cutting Attachment Warnings

Do not cut wood/twigs; use only company-designated cutters for safety.

Working Methods and Safety

General PPE for Operation

Wear safety glasses, ear protection, headwear, face shield, boots, and gloves during operation.

Nylon Cutter Use

Pull out 12cm nylon cutter cord; use for edging/scalping.

Blade Use and Safety

Use two-thirds of blade for cutting, clean periodically, avoid clogging.

Working Direction

Cut grass from right to left for efficiency as the blade rotates counter-clockwise.

Impact Warning

Stop engine and check blade if it hits a hard object or shows cracks.

Working Methods and Personal Protection

Operation PPE

Wear protective glasses, ear protection, headwear, face shield, and boots.

Blade Sharpness and Handling

Handle the sharp blade carefully to avoid injury.

Cutting Techniques

Use two-thirds of blade for cutting, clean periodically, avoid clogging.

Impact Warning

Stop engine and check blade if it hits a hard object or shows cracks.

Working Methods and Safety Precautions

Operation PPE

Wear protective glasses, ear protection, headwear, face shield, and boots.

Blade Sharpness and Handling

Handle the sharp blade carefully to avoid injury.

Cutting Techniques

Use two-thirds of blade for cutting, clean periodically, avoid clogging.

Impact Warning

Stop engine and check blade if it hits a hard object or shows cracks.

Inspection and Maintenance

Hot Engine Parts

Allow hot engine parts to stop and cool before checking or servicing.

Damaged or Faulty Parts

Replace damaged or faulty parts with new, genuine parts to prevent serious injury.

Maintenance Schedule

Periodically implement all tasks from the maintenance chart.

Liability for Non-Maintenance

User is liable for damage resulting from failure to implement maintenance work.

Idle Speed Adjustment

Adjust idle speed to differ sufficiently from clutch engaged speed (ratio >= 1.25).

Inspection and Maintenance (Italian/Spanish)

Hot Engine Parts

Allow hot engine parts to stop and cool before checking or servicing.

Damaged or Faulty Parts

Replace damaged or faulty parts with new, genuine parts to prevent serious injury.

Maintenance Schedule

Periodically implement all tasks from the maintenance chart.

Liability for Non-Maintenance

User is liable for damage resulting from failure to implement maintenance work.

Idle Speed Adjustment

Adjust idle speed to differ sufficiently from clutch engaged speed (ratio >= 1.25).

Inspection and Maintenance (Portuguese/Dutch)

Hot Engine Parts

Allow hot engine parts to stop and cool before checking or servicing.

Damaged or Faulty Parts

Replace damaged or faulty parts with new, genuine parts to prevent serious injury.

Maintenance Schedule

Periodically implement all tasks from the maintenance chart.

Idle Speed Adjustment

Adjust idle speed to differ sufficiently from clutch engaged speed (ratio >= 1.25).

Carburetor Adjustment

Carburetor Adjustment Necessity

Carburetor adjustment usually unnecessary; lean mixture can seize engine.

Idle Speed Screw Adjustment

Adjust low engine speed using the idle speed screw (turn right/left).

Carburetor Adjustment (Spanish/Portuguese)

Carburetor Adjustment Necessity

Carburetor adjustment generally not necessary; rich mixture can cause engine damage.

Idle Speed Adjustment

Adjust low engine speed using the idle adjustment screw (turn right/left).

Carburetor Adjustment (Dutch)

Carburetor Adjustment Necessity

Carburetor adjustment usually not necessary; lean mixture can seize engine.

Idle Speed Adjustment

Adjust low engine speed with the idle speed adjustment screw (turn right/left).

Maintenance Chart

Cutting Attachment Maintenance

Maintenance for cutting attachment: inspect, clean, sharpen, check tightness.

Controls Maintenance

Maintenance for controls: check operation of throttle trigger, switch, and lock.

Angle Transmission Maintenance

Maintenance for angle transmission: clean, check, lubricate.

Engine Components Maintenance

Maintenance for engine components: air filter, fuel filter, spark plug, carburetor.

Maintenance Chart (German/Italian)

Cutting Attachment Maintenance

Maintenance for cutting attachment: inspect, clean, sharpen, check tightness.

Controls Maintenance

Maintenance for controls: check throttle, lever, and safety guard operation.

Angle Transmission Maintenance

Maintenance for angle transmission: clean, check, lubricate.

Engine Components Maintenance

Maintenance for engine components: filters, fuel tank, cylinder, muffler, carburetor, spark plug.

Maintenance Chart (Spanish/Portuguese)

Cutting Attachment Maintenance

Maintenance for cutting attachment: inspect, clean, sharpen, check tightness.

Controls Maintenance

Maintenance for controls: check throttle, lever, and safety guard operation.

Angle Transmission Maintenance

Maintenance for angle transmission: clean, check, lubricate.

Engine Components Maintenance

Maintenance for engine components: filters, fuel tank, cylinder, muffler, carburetor, spark plug.

Maintenance Chart (Dutch)

Cutting Attachment Maintenance

Maintenance for cutting attachment: inspect, clean, sharpen, check tightness.

Controls Maintenance

Maintenance for controls: check throttle, lever, and safety guard operation.

Angle Transmission Maintenance

Maintenance for angle transmission: clean, check, lubricate.

Engine Components Maintenance

Maintenance for engine components: filters, fuel tank, cylinder, muffler, carburetor, spark plug.

Maintenance Procedures

Angle Transmission (Daily)

Daily maintenance for angle transmission: remove holder, clean and wipe components.

Rotary Blade Setting (Daily)

Daily maintenance for rotary blade: round the blade root with a file.

Screw Tightness Check (Daily)

Daily maintenance: periodically check and tighten screws.

Angle Transmission Lubrication (50 Hours)

Lubricate angle transmission every 50 hours by pulling spline sleeve to remove old grease.

Maintenance Procedures (German/Italian)

Gear Housing (Daily)

Daily maintenance for gear housing: clean and wipe components.

Sharpening Blades (Daily)

Daily maintenance for blades: sharpen 3, 4, or 8-blade blades.

Screw Tightness Check (Daily)

Daily maintenance: check and tighten screws periodically.

Gear Housing Lubrication (50 Hours)

Lubricate gear housing every 50 hours by removing the key sleeve.

Maintenance Procedures (Spanish/Portuguese)

Angle Transmission (Daily)

Daily maintenance for angle transmission: remove holder, clean and wipe components.

Rotary Blade Mounting (Daily)

Daily maintenance: check screw tightness.

Angle Transmission Lubrication (50 Hours)

Lubricate angle transmission every 50 hours by removing the casing.

Maintenance Procedures (Dutch)

Angle Transmission (Daily)

Daily maintenance for angle transmission: remove holder, clean and wipe components.

Mounting Rotary Blades (Daily)

Daily maintenance for rotary blades: round the blade foot with a file.

Check Screw Tightness (Daily)

Daily maintenance: check screw tightness periodically.

Angle Transmission Lubrication (Every 50 Hours)

Lubricate angle transmission every 50 hours by removing the housing.

Daily Maintenance

Air Filter Cleaning

Steps for cleaning the air filter: open cover, remove element, wash, replace.

Air Filter Cleaning (Italian/Spanish/Portuguese)

Instructions for cleaning the air filter element.

Air Filter Cleaning (Dutch)

Instructions for cleaning the air filter.

Maintenance Every 50 Hours

Fuel Filter Cleaning

Steps for cleaning the fuel filter: pull out, clean with gasoline, replace if dirty.

Maintenance Every 50 Hours (Spark Plug)

Spark Plug Cleaning and Adjustment

Clean spark plug: remove carbon deposit, adjust electrode gap to 0.6-0.7 mm.

Maintenance Every 50 Hours (Carbon Deposit Removal)

Carbon Deposit Removal

Remove carbon deposits from muffler, cylinder, and piston using special tools and techniques.

Troubleshooting and Storage

Machine Does Not Start

Troubleshooting: check fuel for water, check fuel intake if machine won't start.

Rotation Speed Does Not Increase

Troubleshooting: check choke, fuel mix, and fuel for water if rotation speed doesn't increase.

Insufficient Output

Troubleshooting: check air filter and exhaust ports for clogging if output is insufficient.

Machine Slows Down and Stops

Troubleshooting: check fuel vent, fuel system, and fuel for water if machine slows down.

Long Term Storage

Long-term storage procedures: clean, lubricate, empty fuel, store in dry place.

Troubleshooting and Storage (Italian/Spanish)

Machine Does Not Start

Troubleshooting: check fuel for water, check fuel intake if machine won't start.

Rotation Speed Does Not Increase

Troubleshooting: check choke, fuel mix, and fuel for water if rotation speed doesn't increase.

Insufficient Output

Troubleshooting: check air filter and exhaust ports for clogging if output is insufficient.

Machine Slows Down and Stops

Troubleshooting: check fuel vent, fuel system, and fuel for water if machine slows down.

Long Term Storage

Long-term storage procedures: clean, lubricate, empty fuel, store in dry place.

Troubleshooting and Storage (Portuguese/Dutch)

Machine Does Not Start

Troubleshooting: check fuel for water, check fuel intake if machine won't start.

Rotation Speed Does Not Increase

Troubleshooting: check choke, fuel mix, and fuel for water if rotation speed doesn't increase.

Insufficient Output

Troubleshooting: check air filter and exhaust ports for clogging if output is insufficient.

Machine Slows Down and Stops

Troubleshooting: check fuel vent, fuel system, and fuel for water if machine slows down.

Long Term Storage

Long-term storage procedures: clean, lubricate, empty fuel, store in dry place.

EC Declaration of Conformity

Product Designation and Standards

Declares product (Brush cutter) conforms to specified EU directives and standards.

EC Declaration of Conformity (Spanish/Portuguese/Dutch)

Product Designation and Standards

Declares product conforms to specified EU directives and standards.

Dealer Seal for Maintenance Records

Dealer Information

Ensure dealer's seal (name, address, phone, fax, signature) is placed in manual for maintenance.

Need help?

Do you have a question about the V440 and is the answer not in the manual?

Questions and answers