Summary of Contents for Magnetic HWR 100 plus

- Page 1 ® regulator HWR 50/100 plus Operating manual Anodenstrom magnetic ® ...einfach besser...

- Page 2 GmbH & Co. KG Am Richtbach 5 D-74547 Untermünkheim Tel. +49 7944 94199-0 Fax +49 7944 94199-19 info@magnetic-online.de www.magnetic-online.de Managing director Shareholder: Michael Bader VAT ID No.: DE 255 018 730 Trade Register: HRA 571362 Registered court: Stuttgart Version 2019/10 BA HWR 50/100 plus EN...

-

Page 3: Table Of Contents

® regulator HWR 50/100 plus Operating manual Inhalt 1. General / Safety information 1.1 General information 1.2 Area of application 1.3 Safety information 1.4 Safety regulations 1.5 Exclusion of liability 1.6 Specific safety and handling instructions 1.7 Specific operating instructions 1.8 Conformity declaration... - Page 4 5. Installation of the connection set / Delivery contents 6. Success monitoring 7. Maintenance 7.1 Functional check - flow rate 7.2 Functional check - Anode function 7.3 Backwashing, desludging, container cleaning 7.4 Monitoring water quality 7.5 Anode replacement 8. Troubleshooting 8.1 What you should do if...

-

Page 5: General / Safety Information

In addition, regulators are more commonly used in lower temperature systems (e.g. heat pumps) or within the context of so-called “low-salt” operation of heating systems, mostly to stabilise the pH value. Corrosion in heating systems is caused by the interaction of several factors. The magnetic Heating Water Regulator is not ®... -

Page 6: Safety Information

Make sure that you comply with applicable national and international safety regulations. Each operator is personally respon- sible for complying with the applicable regulations and must endeavour to comply with the most recent regulations. 1.4 Safety regulations The magnetic Heating Water Regulator may only be operating by specialist personnel. Please comply with the manufacturer’s ®... -

Page 7: Specific Operating Instructions

Please pay attention to information on the filling water quality on the following pages of the user manual. Do not use treated soft water as filling water in combination with a magnetic Heating Water Regulator. -

Page 8: Location Of Installation

3. Location of installation Main return flow system group floor heating System group flow-flow Preferred installation variants with several heating circuits Bypass installation using the circulating pump. dueto proximity to source of oxygen intake. Anodenstrom Anodenstrom System group flow-return flow System group return flow-return flow Classic bypass installation using the main circulating pump. - Page 9 • Supply line = nominal diameter of main line or 1” Anodenstrom • Connection from below with immersion pipe • Connection from above or attached laterally • Connection from below or laterally in case of large quantity of circulating impurities magnetic ® ...einfach besser...

-

Page 10: Filling Water Quality

Silt build-up In our experience, using the HWR reduces existing silt build-up over a longer period. However, in order to remove existing hydraulic problems the system should be rinsed using the magnetic water demineralisation clea- ® ner for heating systems. -

Page 11: Necessity For Treating The Filling Water

HWR. A residual conductivity of 50 - 100 μS/cm must be retained. When using a heating water regulator, the filling water should not be softened using ion exchange. 4.4 Use of antifreeze agents No classic antifreeze agents should be used with heating water regulators from magnetic , as these agents often contain ®... -

Page 12: Success Monitoring

5. Assembly of the connection set / Delivery contents In general, the associated connection set should be used to connect the magnetic Heating Water Regulator to the system. ® The connection set contains: (3) Ball valve 1” (4) T-piece 1” x 1” x 1/2”... -

Page 13: Maintenance

After that, the construction phase is concluded. After this, it is sufficient to service the device once a year. Functional check The magnetic regulators have a display device which displays the anode activity. This display must be checked regularly. Professional use... -

Page 14: Functional Check - Anode Function

If the water metre is not working or flow is not occurring despite taking the abovementioned points into account, it is necessary to rinse the HWR. If an automatic control valve is used for flow regulation, particles can impact its function. In this case, the valve must be opened and cleaned. -

Page 15: Backwashing, Desludging, Container Cleaning

5. Open the ball valve slowly (Figure 2 - ) and raise the magnet on the magnetic flux filter using the chain (Figure 2-). If no water comes out, carefully stick a wire (e.g. a welding rod) through the ball valve (3) into the device in order to loosen impurities. -

Page 16: Anode Replacement

7.5 Anode replacement 1. Opening the HWR reaction vessel to replace anodes Once the display indicator of the regulator is on the left in the “0” range during the heating phase, you must check the installed anode and replace it where applicable. To do this, follow the steps below: - Close the inlet and outlet on the HWR - Place a bucket or other collecting vessel under the emptying valve... -

Page 17: Troubleshooting

This will provide you with a long-term statistic and you can determine the corrosion protection function by means of the improved values. The regular water analysis also serves as a warning system if problems occur. magnetic ® ...einfach besser... -

Page 18: Maintenance Record

9. Maintenance record Installer Object Installation date: pH value upon initial operation: Conductivity upon initial operation: Serial number: Colour of Anode replace- Water residue free yes/ Metre reading, if Conductivity Date rinsing pH-value mA metre ment Executor available μS/cm water yes/no Note: Keep this document on the device and record properly. -

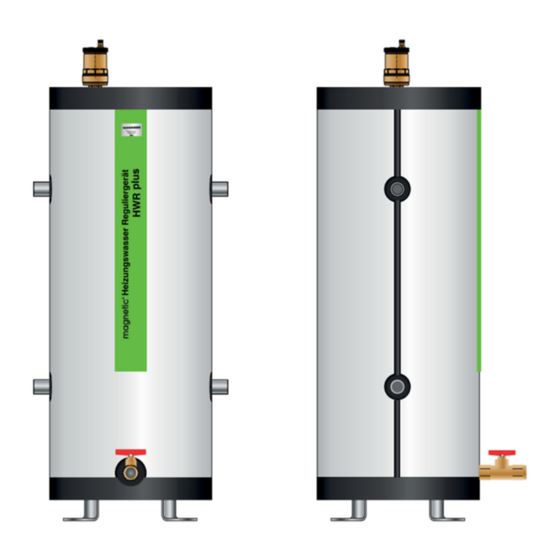

Page 19: Data And Dimensions

10. Data and dimensions Boiler material: Chrome steel v4A Dimensions in mm HWR 50 plus HWR 100 plus A Diameter B Width including connection pipe 403.5 403.5 C Total height 1060 1210 D Floor - Centre inflow 295.5 295.5 E Floor - Centre outflow 745.5... - Page 20 GmbH & Co. KG Am Richtbach 5 D-74547 Untermünkheim Tel. +49 7944 94199-0 Fax +49 7944 94199-19 info@magnetic-online.de www.magnetic-online.de Managing director Shareholder: Michael Bader VAT ID No.: DE 255 018 730 Trade register: HRA 571362 Registered court: Stuttgart www.magnetic-online.de...

Need help?

Do you have a question about the HWR 100 plus and is the answer not in the manual?

Questions and answers