Table of Contents

Summary of Contents for BRADEN BG4B

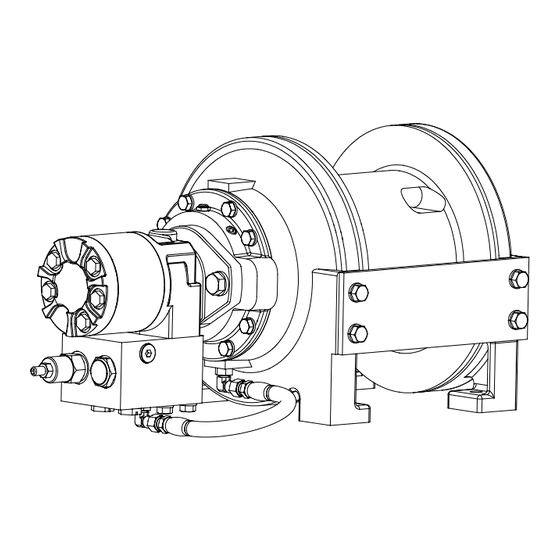

- Page 1 BRADEN BG4A & BG4B HYDRAULIC HOIST INSTALLATION, MAINTENANCE AND SERVICE MANUAL PACR WINCH DIVISION P.O. BOX 547 BROKEN ARROW, OK U.S.A. 74013 LIT2193 R4 3/2008 PHONE (918) 251-8511 FAX (918) 259-1575 Printed in U.S.A. www.paccarwinch.com...

-

Page 3: Table Of Contents

TABLE OF CONTENTS FOREWORD…...………………………………………..…......……….…..…1 PARTS AND SERVICE…………………………………...…......……...…...2 GENERAL SAFETY RECOMMENDATIONS…………..…......……..…..3 THEORY OF OPERATION………………………………...…......………..….4 DIMENSIONAL DATA………………………………………......…………..6 HOIST AND WIRE ROPE INSTALLATION………...………......………...…7 PREVENTATIVE MAINTENANCE……………..……………......………..…8 RECOMMENDED GEAR OIL………………….……………......…………...10 HOIST EXPLODED VIEW DRAWING…..............11 PARTS KEY.........................11 TROUBLE SHOOTING……………………………………..……......……...13 HOIST SERVICE……………………………………………...…......…..……16 HOIST DISASSEMBLY………………………………….…..…......…..16 DRUM ASSEMBLY SERVICE………………………….…..……….......…17 PLANET GEAR SERVICE………………………......……....17 BRAKE CYLINDER ENDPLATE SERVICE…………......…….…….18 HOIST ASSEMBLY………………………………….........……..….19... -

Page 4: Foreword

Continuing product improvement may cause changes in your hoist which may not be included in this manual. When a ques- tion arises regarding your hoist or this manual, contact your nearest BRADEN dealer or the factory Service Department. Provide the complete hoist model number and serial number when making inquiries. The model and serial numbers are stamped into the data plate attached to the tie plate as shown below. -

Page 5: General Safety Recommendations

23. The BRADEN wire rope anchors are capable of sup- 4. Assure that personnel who are responsible for hand sig- porting the rated load only when installed properly. For... -

Page 6: Theory Of Operation

The shuttle valve directs oil to the internal brake from both directions, releasing the brake during both raising and lowering operations. Note: Early BG4A hoists included (2) counterbalance car- tridges in the valve block. When servicing, one cartridge may be replaced with the check valve cartridge currently in use. -

Page 7: Hoist And Wire Rope Installation

ISO VG 32 (SAE10W); for applications colder than 10°F stopping the load. The friction brake will engage and hold (-12°C), contact the BRADEN Product Support Department. the load after the cartridge is closed. The use of multi-viscosity oils is generally not recommend-... - Page 8 5. The hydraulic oil filter should have a 10 micron nominal rating and be full flow type. 6. The vent plug in the motor adapter must be located as close to top dead center as possible. If the hoist is mounted on a pivoting surface, the vent plug must remain above the centerline of the cable drum to prevent gear oil leakage.

- Page 9 If there is interference or the wedge does not seat firmly, wire rope manufacturer on the proper treatment of the dead contact the BRADEN Product Support Department at end of the wire rope. Some rope manufacturers recommend 1-918-251-8511 to determine the proper wedge size.

-

Page 10: Preventative Maintenance

The oil should be level with the bottom of this The user of BRADEN hoist products is responsible for hoist opening. If additional oil is needed, refer to “Recommended inspection, testing, operator training and maintenance noted Planetary Gear Oil”... - Page 11 The gear oil should also be changed whenever the ambient 6. Mounting Bolts temperature changes significantly and an oil from a different Tighten all hoist base mounting bolts to recommended temperature range would be more appropriate. Oil viscos- torque after the first 100 hours of operation, then every 1000 ity with regard to ambient temperature is critical to reliable operating hours or six (6) months, whichever occurs first.

-

Page 12: Recommended Gear Oil

RECOMMENDED PLANETARY GEAR OIL RECOMMENDED PLANETARY GEAR OIL PREVAILING AMBIENT TEMPERATURE PREVAILING AMBIENT TEMPERATURE F -40 F -40 MOBILGEAR 600 XP 220 OR EQUIVALENT AGMA 5 EP, ISO VG 220 AGMA 5 EP, ISO VG 220 MOBILGEAR 600 XP 150 OR EQUIVALENT AGMA 4 EP, ISO VG 150 AGMA 4 EP, ISO VG 150 MOBILGEAR SHC 150... - Page 13 BG4 Components NOTE: BG4 version “A” features splined brake discs, pictured left. The “B” version features lobed discs as shown in explosion above. Addition- ally spring count and brake disc count (items 27, 34, & 36) may vary from depiction above; consult the appropriate Material List for your particualr hoist model for accurate brake spring and brake disc quantities.

-

Page 14: Troubleshooting

TROUBLESHOOTING The following troubleshooting section is provided as a general guide. You may also need to contact the Original Equipment Manufacturer (OEM) for additional information. If a hoist exhibits any sign of: - Erratic operation such as poor load control, load creeping down or chattering. - Unusual noise. - Page 15 PROBABLE CAUSE TROUBLE REMEDY 1. Same as A2. Same as A2. Oil leaks from vent plug 2. Motor seal may be defective as a Hydraulic System back pressure must result of high back pressure in the mo- not exceed 100 psi (690 kPa.) Inspect tor case drain circuit or contaminated hydraulic system for a restriction in the oil.

- Page 16 PROBABLE CAUSE TROUBLE REMEDY Trouble “D” Continued From 3. Check valve or counterbalance valve Remove the counterbalance or check Previous Page may be clogged or stuck. BG4 hoists valve cartridge and clean for inspection. use a check valve which requires the Reseal or replace as required.

- Page 17 PROBABLE CAUSE TROUBLE REMEDY Hoist “chatters” or surges while raising 1. Same as D2. Same as remedies for Trouble D2. rated load. 2. Same as D3 Same as remedies for Trouble D3 3. Hydraulic oil flow to motor may be too Same as remedies for Trouble E2.

-

Page 18: Hoist Service

Remove wire rope prior to removing hoist from crane. Inspect all replacement parts, prior to installation, to detect any damage which might have occurred in shipment. Use only genuine BRADEN replacement parts for optimum results. Never reuse expendable parts such as oil seals and O-rings. -

Page 19: Drum Assembly Service

DRUM ASSEMBLY SERVICE Likewise, the cage should be inspected for unusual wear or 1. Remove the bearing and seal from each end of the drum. deformation, particularly the cage bars. If there is any dam- Check the ring gear teeth (machined into the inside surface age that will impair the cage’s ability to separate, retain and of the drum) for nicks, spalling or excessive wear. -

Page 20: Brake Cylinder Endplate Service

BRAKE CYLINDER ENDPLATE SERVICE DISASSEMBLY AND INSPECTION. 3. Place each friction disc on a flat surface and check for distortion with a straight edge. Friction material should ap- pear even across entire surface with groove pattern visible. Replace friction disc if splines are worn to a point, disc is dis- torted, friction material is worn unevenly or groove pattern is worn away. -

Page 21: Hoist Assembly

(8) friction and nine (9) steel discs have been installed. Finish with a steel disc on top. BG4A units with splined discs: Install a brake spacer (33) into the motor support. Insert a steel disc (35) against the 5. - Page 22 6. Loosely attach the two tie plates (4) to the bearing support end plate using capscrews (4) and lockwashers (6.) 9. Lubricate the bearing support and sealing surface on the CAUTION brake cylinder endplate and install the endplate assembly onto the drum. Make certain the snap ring is installed on the bearing sup- port.

- Page 23 WARNING CAUTION Be certain the snap ring (30) is seated in the groove in the 12. Install a new gasket (37) on the motor pilot and lubricate splined bore of the brake coupling (29). This snap ring will with petroleum jelly or gear oil. Install the motor onto the keep the brake coupling correctly positioned in the center motor adapter with two (2) capscrews (50) and lockwashers of the friction brake pack.

- Page 24 RECOMMEND FASTENER TORQUE The general purpose torque shown in the chart applies to SAE Grade 5 bolts, studs and standard steel full, thick and high nuts. Higher or lower torques for special applications will be specified such as the use of spanner nuts, nuts on shaft ends, jam nuts and where distortion of parts or gaskets is critical.

-

Page 26: Metric Conversion Table

METRIC CONVERSION TABLE English to Metric Metric to English LINEAR inches (in.) X 25.4 = millimeters (mm) millimeters (mm) X 0.3937 = inches (in.) feet (ft.) X 0.3048 = meters (m) meters (m) X 3.281 = feet (ft.) miles (mi.) X 1.6093 = kilometers (km) kilometers (km)

Need help?

Do you have a question about the BG4B and is the answer not in the manual?

Questions and answers