Summarization of Contents

1. Important Basic Information

1.1 Scope of Delivery

Details the standard basic equipment included with the roller brake tester.

1.2 Additional Equipment

Lists optional accessories and components available for the roller brake tester.

1.3 & 1.4 Manufacturer and Operator Responsibilities

Covers obligations of the manufacturer regarding directives and the operator's duties for safe use and compliance.

1.5 External Interfaces

Describes the connection points for external devices, primarily for computer linkage.

2. Safety

2.1 Safety Guidelines and Emergency Procedures

Provides essential safety rules, warnings, precautions, and emergency response actions for operating the brake tester safely.

2.3 Purpose, Use, and Personnel Requirements

Specifies the intended applications, limitations, and required qualifications for personnel operating the test stand.

2.5 Health and Safety at Work

Details specific health and safety measures related to the test stand's components and operation.

2. Safety (Continued)

2.6 Safety-Relevant Environmental Conditions

Addresses safety requirements for the installation environment, including pit covers and access.

2.8 Disposal and Manual Compliance

Provides guidelines for disposal and emphasizes the importance of following the operating manual.

2.11 Remaining Risks and Precautions

Lists residual risks and necessary precautions, such as rotating rollers and vehicle positioning.

3. Technical Information

3.1 Identification and System Specifications

Explains identification methods and details environmental, display, control box, and roller set specifications.

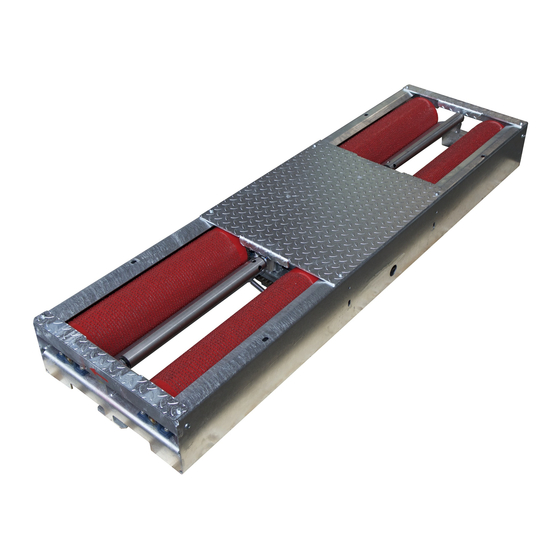

3.1.4 Set of Rolls Compact

Presents technical data for different compact roller set models, including dimensions, weight, and load capacity.

4. Description of the System

4.1 Range of Application and Directive Requirements

Defines application scope, certification, and requirements for Directive 10/2011 compliance.

4.1.5 Automatic All-Wheel Drive Detection

Explains the function and benefits of the automatic all-wheel drive detection option for testing complex drive systems.

4.3 Modes of Operation

4.3.1 Manual and Automatic Modes

Describes the manual operation via remote control/buttons and the automatic test run start functionality.

4.3.4 Automatic All-Wheel Drive Detection

Explains the automatic all-wheel drive detection mode and its operational indicators.

5. Installation Requirements

5.1 Installation of Main Components

Outlines the general requirements for installing the main components: roller sets, control box, and display.

5.2 Functional Description

Describes how the roller brake tester functions, including vehicle inspection certification and measurement principles.

5.3 Process Description: Roller Sets & Control Box

Explains the process of describing roller sets and connecting display units to the control box.

5. Installation Requirements (Continued)

5.5 Assembly Site and Delivery Requirements

Details site requirements for assembly and delivery, including accessibility and lifting equipment.

5.6.2 Environmental Conditions

Outlines environmental conditions for operation, including IP rating, temperature range, and protection against water.

5.7 Installation Plan Details

Refers to installation plans for roller sets, control box, and analogue display positioning.

6. Assembly and Installation, Initial Commissioning

6.1 & 6.2 Assembly Requirements and Safety

Lists prerequisites for assembly, emphasizing safety and the need for qualified personnel.

6.3 Assembly and Installation Steps

Provides step-by-step instructions for assembling display cabinet, screen, control box, and roller sets.

6.5 Initial Commissioning

Marks the point where initial commissioning procedures begin.

6.6 Option Lifting/Lowering Device

6.6.1 Description and Installation

Details the installation process for the lifting/lowering device and its pneumatic control system.

6.6.2 Application and Description

Explains the device's applications as step protection, for smooth vehicle entry, and its automatic operation.

6.7 Option Remote Control

6.7.1 View and Symbols

Shows a visual representation of the remote control, its buttons, and explains the meaning of the symbols.

6.7.4 Functions

Refers to a separate operating manual for detailed functions of the remote control.

7. Operation

7.1 Safety and Safety Devices

Highlights critical safety devices and general safety guidelines to be observed during operation.

7.2 Operating Elements: Control Box

Details the buttons, switches, and options on the control box for operating the test stand.

7. Operation (Continued)

7.2.2 & 7.2.3 Symbols and Switch Functions

Explains symbols for rotary switches and details operational functions based on different switch positions.

7.3 Display Units Overview

Describes visual output units, including analogue and imbalance displays, and their interpretation.

7. Operation (Continued)

7.4 Test Stand Operation

Provides instructions on switching the test stand on, preparing it, and general operating procedures.

7.5 Modes of Operation

Introduces the different operating modes available for the test stand.

7. Operation (Continued)

7.5.3 General Test Procedure

Guides through the general test procedure, including vehicle entry, braking, and automatic shutdown.

7.7 Motorcycle Brake Test

Details the procedure for conducting brake tests on motorcycles using specific options.

7.8 Automatic All-Wheel Drive Detection

Explains the automatic all-wheel drive detection option and its associated procedures.

7.9 Electronic Control Box - General View

7.9.1 Switch Possibilities

Lists the possible configurations for the rotary switches and their resulting operational modes.

7.9.2 Preparations for Testing

Details necessary preparations before initiating tests, especially for automatic all-wheel drive detection.

8. Brief Operating Manual

8.1 Start Up, Entry, and Brake Test

Covers powering on, driving into the test stand, and performing a brake test.

8.4 Leaving the Test Stand and Closing Down

Provides instructions on safely exiting the test stand and shutting down the equipment.

9. Trouble Shooting

9.1 Safety and Service Address

Emphasizes safety during troubleshooting and provides contact information for service.

9.3 Fuse Identification

Shows the location of fuses in the control box and identifies their ratings.

9.4 Error Type Detection

Explains how to detect errors based on LED indicators, needle displays, and computer error codes.

9. Trouble Shooting (Continued)

9.5 Error Checklist and Fault Clearance

Provides a comprehensive list of errors, their causes, and initial steps for fault clearance.

9. Trouble Shooting (Continued)

Warnings and Error Causes

Lists specific warnings and potential causes for errors with their remedies.

10. Maintenance and Repair

10.1 Safety and Proof of Maintenance

Emphasizes safety checks and the need for authorized personnel for maintenance and proof of work.

10.3 Control Process and Testing Devices

Outlines routine test requirements and lists specialized calibration devices according to ISO 17025.

10.4 Inspection and Maintenance Plan

Presents a plan for regular inspection and maintenance tasks, specifying frequencies.

11. Disassembly and Disposal

11.1 Safety and Disassembly Work

Stresses safety precautions, particularly disconnecting power lines by qualified personnel, and lists disassembly steps.

11.3 Description of Disposal Work

Outlines the overview and description of disposal procedures, emphasizing legal regulations and proper material handling.

12. Complementary Documents

12.1 to 12.6 Document Availability

Informs that various documents like drawings, plans, manuals, and test reports are available upon request.

12.7 Service Address

Provides the service address and contact details for Sherpa GmbH.

Need help?

Do you have a question about the BPS-Kompakt 6.0 and is the answer not in the manual?

Questions and answers