Table of Contents

Advertisement

Steinert GmbH

Widdersdorfer Straße 329-331 • D-50933 Köln

Postfach 45 11 60 • D-50886 Köln

Phone:

Switchboard

Spare parts

Service / Repairs

Fax

E-mail

INSTRUCTIONS OF INCORPORATION (EN)

Machine

Type

Serial no.

Job no.

Customer

KKS no.

Order no.

Order date

Project name

Final customer

Year of manufacture

+49-(0)221 / 49 84 - 0

+49-(0)221 / 49 84 - 177

+49-(0)221 / 49 84 - 132

+49-(0)221 / 49 84 - 102

sales@steinert.de

www.steinert.de

Over-belt magnetic separator

UME 115 150 C

18 0077 060 01 + 18 0077 090 01 +

18 0077 100 01

A1180077

WTT B.V.

Münsterstraat 14

NL - 7575

ED Oldenzaal

1020AT203

WTT 20180031

2018-01-24

14246 Jieyang Project

2018

Advertisement

Chapters

Table of Contents

Summary of Contents for steinert UME 95 110 C

- Page 1 +49-(0)221 / 49 84 - 102 E-mail sales@steinert.de www.steinert.de INSTRUCTIONS OF INCORPORATION (EN) Over-belt magnetic separator Machine Type UME 115 150 C 18 0077 060 01 + 18 0077 090 01 + Serial no. 18 0077 100 01 A1180077 Job no. Customer WTT B.V.

-

Page 3: Over-Belt Magnetic Separator Ume

Over-belt magnetic separator UME … C Implementation example Read the instructions and the supplier's documentation in the Appendix before starting any work! - Page 4 Translation of the original Operating Instructions Printed in Germany © Copyright Steinert GmbH. All rights reserved. Manufacturer and customer service If you have technical questions or are in need of spare parts, please contact: Steinert GmbH Widdersdorfer Straße 329-331 •...

-

Page 5: Table Of Contents

Over-belt magnetic separator UME … C Overview Overview ................. 9 Information about the installation instructions ....9 Restricted liability ............9 Copyright ..............10 Spare parts ..............10 Warranty conditions ............. 10 Customer service ............10 Symbols ................11 Warnings ..............11 Notes –... - Page 6 Over-belt magnetic separator UME … C Overview Construction and function ..........27 Overview ..............27 Brief description ............27 Transport, packaging and storage ........28 Safety instructions for transport ........28 Symbols on the packaging ...........29 Transport inspection.............30 Packaging ..............30 Transport ..............31 7.5.1 Transporting packages / modules ....31 7.5.2 Weight of the machine ........32 Storage .................33...

- Page 7 Over-belt magnetic separator UME … C Overview 11 Disassembly ................. 57 11.1 Disassembly ..............58 11.2 Disposal ............... 58 12 Appendix ................59 12.1 Dimension sheet ............59 12.2 Belt change device ............61 12.3 3-phase motor .............. 63 12.4 Gearbox ............... 65 12.5 STUME operating instructions ........67 12.6 Wiring diagram .............

- Page 8 Over-belt magnetic separator UME … C Overview GB_UME 75-135 ... C-03-US...

-

Page 9: Overview

Over-belt magnetic separator UME … C Overview Overview 1.1 Information about the installation instructions These instructions provide important information on how to operate the machine. Compliance with all safety and work instructions is an essential prerequisite for safe working. Store the instructions as follows: −... -

Page 10: Copyright

Over-belt magnetic separator UME … C Overview 1.3 Copyright These instructions are confidential. They are intended solely for persons operating the machine. The instructions must not be passed to third persons without the written approval of the manufacturer. The information, texts, drawings, pictures and other illustrations are protected by copyright and subject to industrial property rights. -

Page 11: Symbols

Over-belt magnetic separator UME … C Symbols Symbols 2.1 Warnings Warnings are indicated by symbols in these instructions. Signal words preceding the warnings indicate the extent of the risk. Nature and source of danger! SIGNAL WORD! Possible consequences of ignoring the warning Measures to avoid the risk. -

Page 12: Other Symbols

Over-belt magnetic separator UME … C Symbols 2.4 Other symbols Work instructions Structure of the work instructions: Instructions for work. Indicates result if applicable. Lists Structure of unnumbered lists: List level 1 − List level 2 GB_UME 75-135 ... C-03-US... -

Page 13: Safety

Over-belt magnetic separator UME … C Safety Safety This section gives an overview of all the most important safety aspects for optimum protection of staff and for safe and fault-free operation. The non-observation of the handling and safety instructions listed in this manual can lead to considerable risks. - Page 14 Over-belt magnetic separator UME … C Safety Dynamic and static load! DANGER! Risk to life! The suitability of the foundation and the installation location must be checked by a structural engineer. For self-supporting structures, pay attention to the dynamic stresses caused by vibration and the movements of the machine.

-

Page 15: Magnetic Field Strength Limits For The Protection Of Persons

Over-belt magnetic separator UME … C Safety 3.1 Magnetic field strength limits for the protection of persons Protection against magnetic fields The maximum permissible limit value for persons with active medical implants is 1 mT (corresponds to 10 Gauss). This value is not exceeded at distances≥ 5 m from the strongest magnet. -

Page 16: Responsibility Of The Owner

Over-belt magnetic separator UME … C Safety 3.3 Responsibility of the owner The machine is used in an industrial environment. The owner is therefore subject to legal health and safety obligations. Heed the safety, accident prevention and environment protection regulations applicable to the area of operation of the machine. -

Page 17: Staff Requirements

Over-belt magnetic separator UME … C Safety 3.4 Staff requirements 3.4.1 Qualification Reduced responsiveness! WARNING! Risk of injury. Make sure that no one works on the system with reduced responsiveness due to medication, alcohol or drugs. W_ER_01_EN-US-00 Incorrect handling may result in severe bodily injuries and extensive property damage. -

Page 18: Personal Protective Equipment (Ppe)

Over-belt magnetic separator UME … C Safety 3.5 Personal protective equipment (PPE) Make sure the necessary protective equipment is used for the respective task whenever working on the machine. Heed the instructions regarding PPE on display in the work area. Do not wear rings, chains or other jewelery. -

Page 19: Safety Devices

Over-belt magnetic separator UME … C Safety 3.6 Safety devices Malfunctioning safety devices! DANGER! Risk to life! Make sure that the safety devices are properly installed. Make sure that all safety devices are intact. Never disable safety devices. Make sure that the safety devices are accessible at all times. - Page 20 Over-belt magnetic separator UME … C Safety Stop machine movements and switch off the power supply as fast as possible in case of an emergency. Proceed as follows in an emergency: Initiate an EMERGENCY STOP immediately by pressing the nearest EMERGENCY STOP button. Evacuate any persons from the danger area.

-

Page 21: Environmental Protection

Over-belt magnetic separator UME … C Safety 3.8 Environmental protection Lubricants! NOTE! Environmental damage. Have disposal carried out by authorized specialist companies. If substances that are harmful to the environment are released: Remove contamination. Inform the responsible local authority. H_SSF_01_EN-US-00 Electric scrap, electronic components, lead NOTE! components! -

Page 22: Labeling

Over-belt magnetic separator UME … C Safety 3.9 Labeling There are following symbols and information signs in the work area. They refer to the immediate vicinity of the place where they are affixed. Illegible safety signs! WARNING! Risk of injury. Replace unreadable safety signs immediately. -

Page 23: Intended Use

Over-belt magnetic separator UME … C Intended use Intended use The machine is used solely for sorting of bulk material at high belt speeds and defined working distances. For the properties of the bulk goods please refer to the order confirmation. -

Page 24: Technical Data Ume

Over-belt magnetic separator UME … C Technical data UME … … C Technical data UME … … C UME 75-115 … C 5.1 Technical data UME … 75 90 C 75 110 C 95 110 C 95 130 C 115 130 C 115 150 C Magnet Power (cold) approx.. -

Page 25: Operating Conditions

Over-belt magnetic separator UME … C Technical data UME … … C 5.2 Operating conditions Surroundings Specification Value Unit Temperature range -20 to +40 °C Max. relative humidity 60 % Duration Specification Value Unit Maximum operating duration 24 hours without interruption 5.3 Emissions Specification Value Unit... -

Page 26: Consumables

Over-belt magnetic separator UME … C Technical data UME … … C 5.5 Consumables Lubricating Consumable Type Filling quantity Unit point Shell Gadus S2 V220 2 Per bearing Tension bearing - For re-lubrication: PHUSE 50-N - For initial lubrication: approx. Lithium grease DIN 51502 Shell Gadus S2 V220 2... -

Page 27: Construction And Function

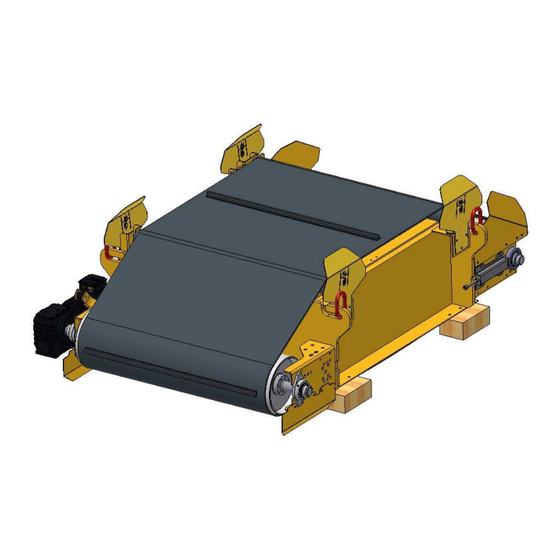

Over-belt magnetic separator UME … C Construction and function Construction and function 6.1 Overview Fig. 2: General view 1 Suspension (optional – see purchase agreement) 2 Discharge belt 3 Magnet 4 Discharge belt drive 5 GLR rectifier (optional – see purchase agreement) 6.2 Brief description Over-belt magnetic separators are suspended at a defined working distance above a conventional conveyor belt system or are... -

Page 28: Transport, Packaging And Storage

Over-belt magnetic separator UME … C Transport, packaging and storage Transport, packaging and storage 7.1 Safety instructions for transport Suspended loads! DANGER! Risk of severe injuries or even death. Never stand beneath suspended loads. Make sure there are no persons in the danger area. -

Page 29: Symbols On The Packaging

Over-belt magnetic separator UME … C Transport, packaging and storage 7.2 Symbols on the packaging Marks the top Keep dry Attachment point (packing unit) Center of gravity Weight of slung load Industrial trucks prohibited GB_UME 75-135 ... C-03-US... -

Page 30: Transport Inspection

Over-belt magnetic separator UME … C Transport, packaging and storage 7.3 Transport inspection Upon receipt immediately check the delivery for completeness and transport damage. If external transport damage can be identified, proceed as follows: Do not accept the delivery or only accept it under reserve. Note the extent of the damage on the transport documents or on the shipping agent’s delivery note. -

Page 31: Transport

Over-belt magnetic separator UME … C Transport, packaging and storage 7.5 Transport 7.5.1 Transporting packages / modules Only lift and transport using the lifting eyes. Preferably with a traverse. Unsuitable hoisting gear and lifting WARNING! accessories! Risk of injury. Pay attention to the markings on the packing units. -

Page 32: Weight Of The Machine

UME 95 130 C ..........approx. 2,450 kg UME 115 130 C ..........approx. 3,350 kg UME 115 150 C ..........approx. 3,850 kg UME 135 150 C ..........approx. 5,300 kg UME 135 170 C ..........approx. 5,900 kg Fig. -

Page 33: Storage

Over-belt magnetic separator UME … C Transport, packaging and storage Forklift transport of pallets Machines fastened to pallets can be directly transported with a forklift truck under the following conditions: The forklift must be designed to match the weight of the transport units. -

Page 34: Installation And Commissioning

Over-belt magnetic separator UME … C Installation and commissioning Installation and commissioning Electrical power! DANGER! Danger of life from electric shock. Before starting any work: Switch off. Secure against being reactivated. All work on the electrical system must be carried out by trained electricians. G_ES_01_EN-US-00 Improper installation and commissioning! WARNING! -

Page 35: Installation Location

Over-belt magnetic separator UME … C Installation and commissioning 8.1 Installation location If necessary, request "Technical data sheet". − Over-belt magnetic separator UME ... C − Installation suggestion for UME ... C lengthwise over the belt − Installation suggestion for UME ... C transverse over the belt −... -

Page 36: Installation

Over-belt magnetic separator UME … C Installation and commissioning 8.2 Installation Incorrect suspension! WARNING! Risk of injury. Never use a chain suspension as a loop between two attachment points. Over belt magnetic separators are intended for use within an overall system. Plant parts in the area of the magnetic field must be made of nonmagnetic material. -

Page 37: Commissioning

Over-belt magnetic separator UME … C Installation and commissioning 8.3 Commissioning Missing consumables! NOTE! Material damage. Check all filling levels. Top up with suitable consumables. H_FB_01_EN-US-00 After completion of installation and prior to commissioning: Ensure that rotating components are provided with suitable safety devices by the owner. -

Page 38: Power Supply

Over-belt magnetic separator UME … C Installation and commissioning 8.4.1 Power supply Direct current is required to excite the magnets. For the current and voltage ratings, please refer to the type plate next to the terminal box. For the number of coils, please refer to the spare parts list. Three-coil variant Four-coil variant Coil 4... -

Page 39: Inspections

Over-belt magnetic separator UME … C Installation and commissioning 8.5 Inspections After setting up or connection of the machine within the complete plant: Test the entire plant in line with applicable local regulations. In subsequent running: Check the entire plant for technical defects in line with applicable local regulations at specified intervals. -

Page 40: Faults

Over-belt magnetic separator UME … C Faults Faults Electrical power! DANGER! Danger of life from electric shock. Before starting any work: Switch off. Secure against being reactivated. All work on the electrical system must be carried out by trained electricians. G_ES_01_EN-US-00 Falls from heights! DANGER! -

Page 41: Behaviour In Case Of Malfunctions

Over-belt magnetic separator UME … C Faults If malfunctions occur more frequently: Reduce the maintenance intervals according to the actual requirements. If malfunctions cannot be eliminated by following the hints below: Contact the manufacturer. 9.1 Behaviour in case of malfunctions Press the EMERGENCY STOP button immediately in case of malfunctions which cause immediate danger to personnel or material assets. -

Page 42: List Of Mechanical Faults

Over-belt magnetic separator UME … C Faults 9.2 List of mechanical faults Fault Possible cause Elimination Elimination by Discharge belt does Belt torn Stop plant, Specialist not move perform belt change Belt tension too high Reduce belt tension Operator Belt tension too low Increase belt tension Operator Belt magnetically blocked... -

Page 43: Maintenance

Over-belt magnetic separator UME … C Maintenance 10 Maintenance 10.1 Safety Electrical power! DANGER! Danger of life from electric shock. Before starting any work: Switch off. Secure against being reactivated. All work on the electrical system must be carried out by trained electricians. G_ES_01_EN-US-00 Falls from heights! DANGER! -

Page 44: Cleaning

Over-belt magnetic separator UME … C Maintenance If not specified otherwise, the maintenance work can be performed by the operator. Work on the electrical system must only be performed by a qualified electrician. Personal protective equipment (PPE) Always use the following protective equipment when working on the plant: −... -

Page 45: Maintenance Schedule

Over-belt magnetic separator UME … C Maintenance 10.3 Maintenance schedule Insufficient qualifications! WARNING! Risk of injury. Make sure all work is carried out by appropriately qualified staff. W_UQ_01_EN-US-00 To ensure safe and trouble-free operation, perform the following maintenance work at the specified intervals. When regular checks reveal an increased wear: Reduce the maintenance intervals according to the actual wear. - Page 46 Over-belt magnetic separator UME … C Maintenance Interval Maintenance step Remarks To be done by Monthly Check for fault-free Off-track running sensor (optional) Specialist operation Check for fault-free Speed sensor rotation check (optional) Specialist operation Excess oil escaping at the drives Visual inspection Operator Check oil and oil level of the drive motor...

-

Page 47: Checking/Replacing The Discharge Belt

Over-belt magnetic separator UME … C Maintenance 10.4 Checking/replacing the discharge belt Unauthorized reactivation! DANGER! Risk of severe injuries or even death. Before starting any work: Switch off. Secure against being reactivated. Ensure that only authorized personnel can switch on the system. Make sure there are no persons in the danger area. -

Page 48: Replacing The Discharge Belt

Over-belt magnetic separator UME … C Maintenance 10.4.1 Replacing the discharge belt Replacement of the discharge belt! DANGER! Risk to life! Always remove the over belt magnetic separator from the customer provided device. Never perform a belt change at the place of use within the plant. - Page 49 Over-belt magnetic separator UME … C Maintenance Fit the lifting device (4). Raise the magnetic separator. Remove wooden supports(1) Fig. 13: Attaching lifting devices Fit the belt changing device (5). Fig. 14: Belt change device Position a new discharge belt (6) on the belt change device (5).

- Page 50 Over-belt magnetic separator UME … C Maintenance Tension the new discharge belt (6) and align on the machine. Fig. 17: Aligning the discharge belt Fit the lifting device (A) on the machine. Thereafter remove the lifting device (B) from the belt change device (5).

-

Page 51: Adjusting/Tensioning The Discharge Belt

Over-belt magnetic separator UME … C Maintenance Fit the guards (2). Pretension the discharge belt at the tension bearings (3) of the belt drum. Machine ready for installation at the place of use in the plant. Further adjustment of the discharge belt occurs at the place of use. -

Page 52: Setting The Maximum Permissible Discharge Belt Tension

Over-belt magnetic separator UME … C Maintenance 10.4.3 Setting the maximum permissible discharge belt tension Extract from the work instruction AA KO 11-01 of 6/25/2006 Fig. 22: Belt slack Axis separation A–A s = min. conveyor belt slack (less than or equal to in (mm) 1 000 2 000... -

Page 53: Adjustment Instructions For Central Running Of The Discharge Belts

Over-belt magnetic separator UME … C Maintenance 10.4.4 Adjustment instructions for central running of the discharge belts Extract from the work instruction AA KO 13-01 of 9/25/2006 Item 1 – drive belt Item 2 – belt drum/ tensioning drum Item 3 – support roller Fig. -

Page 54: Lubrication

Over-belt magnetic separator UME … C Maintenance 10.5 Lubrication Lubricants! NOTE! Environmental damage. Have disposal carried out by authorized specialist companies. If substances that are harmful to the environment are released: Remove contamination. Inform the responsible local authority. H_SSF_01_EN-US-00 Mixing of different grease! NOTE! Material damage. - Page 55 Over-belt magnetic separator UME … C Maintenance Relubrication Information! Use lithium saponified grease with the same walk penetration for re-lubrication. Avoid mixing different types of grease. If grease mixing is unavoidable, contact the grease manufacturer immediately! I_W_01_EN-US-00 use lithium saponified grease of same walk penetration. Inject approx.

-

Page 56: Lubricating The Drives

Over-belt magnetic separator UME … C Maintenance In case of repairs: fill not more than 30 - 50% of the bearing with grease. Do not use more than 60 cm grease for all 4 lubricating points. Apply a generous amount of grease on all sealing lips. Mixing of different grease! NOTE! Material damage. -

Page 57: Disassembly

Over-belt magnetic separator UME … C Disassembly 11 Disassembly Once the end of the useful life is reached, the plant must be disassembled and disposed of in an environmentally friendly manner. Electrical power! DANGER! Danger of life from electric shock. Before starting any work: Switch off. -

Page 58: Disassembly

Over-belt magnetic separator UME … C Disassembly 11.1 Disassembly Before starting disassembly: Switch off the plant and secure it against switching on. Physically disconnect the machine power supply. Discharge stored residual energies. Uncouple the machine for disassembly. Ensure environmentally responsible disposal of operating and auxiliary media in line with local regulations. -

Page 59: Appendix

Over-belt magnetic separator UME … C Appendix 12 Appendix 12.1 Dimension sheet GB_UME 75-135 ... C-03-US... - Page 60 Over-belt magnetic separator UME … C Appendix GB_UME 75-135 ... C-03-US...

-

Page 63: 3-Phase Motor

Optional - Suspension for overband magnetic separator Length Screw Bearing Weight thread capacity per peace Type total [mm] [kg] [mm] [mm] max. approx. AHG 24 130 1300 12,5 AHG 24 170 1700 14,0 AHG 24 210 2100 15,5 AHG 36 160 1600 21,5 AHG 36 200... - Page 64 GB_Aufhängung AHG -02...

-

Page 65: Gearbox

Over-belt magnetic separator UME … C Appendix 12.2 Belt change device Drawing V03 3043 10 00 3 GB_UME 75-135 ... C-03-US... - Page 66 Over-belt magnetic separator UME … C Appendix GB_UME 75-135 ... C-03-US...

-

Page 69: Wiring Diagram

Over-belt magnetic separator UME … C Appendix 12.3 3-phase motor GB_UME 75-135 ... C-03-US... - Page 70 Over-belt magnetic separator UME … C Appendix GB_UME 75-135 ... C-03-US...

-

Page 71: Spare Parts List

Over-belt magnetic separator UME … C Appendix 12.4 Gearbox GB_UME 75-135 ... C-03-US... - Page 72 Over-belt magnetic separator UME … C Appendix GB_UME 75-135 ... C-03-US...

-

Page 73: Declaration Of Incorporation

Over-belt magnetic separator UME … C Appendix 12.5 STUME operating instructions GB_UME 75-135 ... C-03-US... - Page 74 Over-belt magnetic separator UME … C Appendix GB_UME 75-135 ... C-03-US...

-

Page 75: Index

Over-belt magnetic separator UME … C Appendix 12.6 Wiring diagram GB_UME 75-135 ... C-03-US... - Page 76 Over-belt magnetic separator UME … C Appendix GB_UME 75-135 ... C-03-US...

- Page 77 Over-belt magnetic separator UME … C Appendix 12.7 Spare parts list GB_UME 75-135 ... C-03-US...

- Page 78 Over-belt magnetic separator UME … C Appendix GB_UME 75-135 ... C-03-US...

- Page 79 Spare parts list UME 75-115 … C 6,(11) 9,(10) Please indicate manufacturer's no. and our commission no. for any spare parts order! UME … … C Spare part Item Piece 75 90 C 75 110 C 95 110 C 95 130 C 115 130 C 115 150 C BWAME 00170 BWAME 00176 BWAME 00189 BWAME 00168 BWAME 00154...

- Page 80 GB_Ersatzteil UME 75-115 ... C-01...

- Page 81 Over-belt magnetic separator UME … C Appendix 12.8 Declaration of incorporation GB_UME 75-135 ... C-03-US...

- Page 82 Over-belt magnetic separator UME … C Appendix GB_UME 75-135 ... C-03-US...

- Page 83 Annex VII Part B, and we commit to communicate these documents to the authorities on demand. Type of machine / no: UME 115 150 C 18007706001 STUME 115 150 C (108V/70A) 18007710001 Order no.:...

- Page 85 Over-belt magnetic separator UME … C Index 13 Index Faults ..............40 3-phase motor ............ 63 troubleshooting ..........41 Accident .............. 19 Gearbox ..............65 Adjusting/tensioning the discharge belt ....51 GLR operating instructions .........67 Adjustment instructions for central running of the discharge belts ..........53 Guards ..............19 Authorized electrician .........

- Page 86 Over-belt magnetic separator UME … C Index in the danger area .......... 22 Reasonably foreseeable misuse......23 Symbols Replacing the discharge belt ......47 on the packaging ..........29 Replacing the discharge belt ......48 Technical data ............ 24 Safety ..............13 Technical data UME 75-115 …...

Need help?

Do you have a question about the UME 95 110 C and is the answer not in the manual?

Questions and answers