Summarization of Contents

Introduction

Machine Overview and Specifications

Covers intended use, pipe range, conditions, noise, gas, and hazards.

Safety

Machine and Personal Safety

Details machine safety, personal instructions, residual risks, and safety labels.

Machine Description

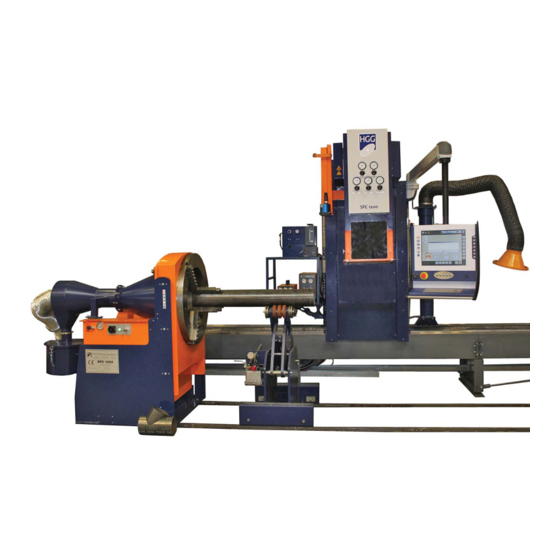

3.1 Introduction

Provides an overview of the SPC machines and their capabilities.

3.2 Axis Definition

Defines the different axes and movements of the machine.

3.3 Lay Out

Illustrates the main components and their arrangement on the machine.

Machine Frame

Describes the foundation frame essential for machine function and stability.

Main Drive

Details the main drive unit, including its chuck, motor, and clamping system.

Cutting Trolley

Explains the cutting trolley's function, movement, and integrated cutting head.

Cutting Head

Describes the biaxial cutting head, its torch, and rotation/tilt capabilities.

Spark and Fume Reversal Kit

Details the function of the spark and fume reversal kit for safety and fume management.

Remote Control

Explains the remote control interface for operating the machine.

Pipe Support: Pipe Trolleys

Describes the height-adjustable pipe trolleys used for supporting pipes.

Pipe Support: Rollerball Gutter

Details the rollerball gutter as an alternative pipe support system.

Fume Extraction (Optional)

Explains the optional fume extraction system for removing smoke and fumes.

Marking Unit (Optional)

Describes the optional marking units for applying marks on pipes.

The Controls

Main Drive Controls

Details the power key switch and clamping pressure adjustment for the main drive.

Remote Control Interface and Operation

Explains the remote control panel, its use, display, menus, and action buttons.

Screen-Based Operations

Covers Material Handling, Profiling, Settings, and Diagnostics screens for machine operation.

Component Controls

Details controls for the cutting trolley and main drive, covering movement and adjustment functions.

Profiling and Marking Controls

Covers settings, diagnostics, cutting tools, and marking controls for machine operation.

Operating the Machine

Control Elements Overview

Identifies and describes the main control elements of the SPC 500-1200 machine.

Pre-Operation Checks

Lists pre-operation checks and safety measures before starting the machine.

Starting and Homing the Machine

Provides steps for starting the machine and homing its axes for accurate positioning.

Stopping the Machine

Outlines procedures for safely stopping the machine and its associated systems.

Using the Main Drive

Details how to control the main drive for clamping, rotation, and height adjustments.

Pipe Handling Procedures

Provides safety instructions and procedures for loading and unloading pipes from the machine.

Profiling Process

Guides on initiating profiling, adjusting cutting parameters, and managing the cutting process.

Starting Oxyfuel Profiling

Provides detailed steps for starting the oxyfuel cutting profiling process.

Starting Plasma Profiling

Provides detailed steps for starting the plasma cutting profiling process.

Switching Cutting Torches

Explains how to switch between oxyfuel and plasma torches and adjust the plasma torch height.

Stopping and Resuming Profiling

Outlines procedures for stopping, pausing, resuming, and displacing the profiling process.

Cutting Near Main Drive and Behind Main Drive

Warns about cutting near the main drive and explains optional cutting behind it.

Emergency Stop and Safety Features

Explains the emergency stop system and safety features during operation.

Appendix A Maintenance and Grease Schedule

Periodic Maintenance Overview

Details the importance of periodic maintenance for machine reliability and safe operation.

Safety During Maintenance

Outlines safety precautions to be taken during maintenance procedures.

Replacing the Cutting Torch Nozzle

Details the procedure for replacing the cutting torch and preheat torch nozzles.

Weekly Maintenance Tasks

Outlines essential weekly checks for optimal machine performance and cutting quality.

Three-monthly Maintenance Tasks

Details maintenance procedures to be performed every three months.

Grease Types

Lists the types of grease, lubrication, and cleaning fluids used for machine maintenance.

Main Drive Unit Lubrication and Maintenance

Details greasing points and maintenance tasks for the main drive unit.

Cutting Trolley Lubrication and Maintenance

Details greasing points and maintenance tasks for the cutting trolley.

Cutting Head Lubrication and Maintenance

Details greasing points and maintenance tasks for the cutting head.

Pipe Trolley Lubrication and Maintenance

Details greasing points and maintenance tasks for the pipe trolleys.

Rollerball Gutter Lubrication and Maintenance

Details cleaning and greasing tasks for the rollerball gutter.

Machine Frame Cleaning

Details cleaning procedures for the machine frame's horizontal rails and pipe trolley rails.

Appendix B Calibration and Cutting Test Pieces

Calibration and Alignment Overview

Explains the importance of alignment and the process of calibrating machine components.

Cutting Test Pieces Procedure

Guides on cutting and evaluating test pieces for software offset calculation.

Safety During Calibration

Outlines safety precautions to be taken during calibration procedures.

Rear Frame Alignment

Provides detailed steps for ensuring the rear frame is correctly aligned horizontally and vertically.

Main Drive Alignment

Guides on aligning the main drive unit vertically and perpendicular to the machine centerline.

Pipe Trolley Adjustment

Details how to adjust pipe trolleys to align with the machine centerline and ensure proper fit.

Roller Ball Gutter Adjustment

Explains how to adjust roller ball gutter units for horizontal level and centerline alignment.

Mechanical Alignment of the Cutting Head

Guides on the mechanical alignment of the cutting head using pull and push bolts.

Cutting Head Rotation Alignment

Describes how to position the cutting arm and check its rotation axis for vertical level.

Software Calibration of the Cutting Head

Guides on performing software calibration for the cutting head, including tilt and torch angle adjustments.

Setting the Torch in the Centre of the Cutting Head

Explains how to mechanically center the torch within the cutting head.

Oxyfuel Cutting Test Pieces

Guides on cutting test pieces for oxyfuel profiling and evaluating results.

Cutting the First Test Piece

Provides instructions for cutting the first test piece for calibration.

Calculating Oscillation Offsets

Explains how to calculate oscillation offsets based on measurements from test pieces.

Cutting the Second Test Piece

Guides on cutting the second test piece, including bevel adjustments.

Calculating Virtual Burner Height

Explains how to calculate the virtual burner height based on test piece results.

Setting Kerf Width and Virtual Burner Height

Guides on setting kerf width and virtual burner height using caliper measurements.

Kerf Width Correction

Details how to correct kerf width based on test piece measurements for accurate cuts.

Virtual Burner Height Correction

Explains how to correct the virtual burner height based on test piece results for precise cutting.

Plasma Cutting Test Pieces

Guides on cutting test pieces for plasma profiling and evaluating results.

Plasma Angle Correction

Explains how to perform plasma angle correction based on ring measurements.

Calibrating the Marking Tool

Guides on calibrating the marking tool using test pieces and calculating offsets.

Appendix C Software Messages, Notifications and Errors

IO Director and Pmac Errors

Lists and explains errors related to IO Director and Pmac motion controller systems.

Max Controller Errors

Lists and explains errors related to the Max Controller system.

Axes and Safety Overrule

Describes software problems with axes and notifications for safety setting overrides.

Laser Measurement System Errors

Lists and explains messages and errors related to the Keyence laser measurement system.

Data Collector Messages

Explains messages related to the data collector's activity recording.

Digitax Drive Errors

Lists and explains errors related to the Digitax servo motor drive.

Plasma Service Counter Notifications

Explains notifications related to the plasma service counter for consumables.

HiFocus Plasma Unit Errors

Lists and explains messages and errors related to the HiFocus plasma unit.

REA Inkjet Printer Errors

Lists and explains communication problems with the REA Inkjet Printer driver.

Default Settings and General Errors

Explains default setting issues and general timeout/configuration errors.

General Notifications

Lists general notifications for the operator during machine startup and shutdown.

ProCAM Software Errors

Lists and explains errors related to starting ProCAM and its licensing.

Control Unit Errors

Lists and explains errors related to the control unit, including emergency stop and overheating.

Main Drive Rotation Errors

Lists and explains errors related to main drive rotation during profiling or automatic mode.

Main Drive Height Errors

Lists notifications for the operator regarding main drive height encoder status.

Main Drive CNC Clamping Errors

Lists and explains errors related to CNC clamping on the SPC 330 main drive.

Cutting Trolley Errors

Lists and explains errors related to cutting trolley longitudinal movement and conditions.

Main Drive Hydraulic Motor Errors

Explains errors related to the main drive hydraulic motor overload.

Cutting Trolley Height Errors

Lists and explains timeout errors for cutting trolley height systems.

Cutting Trolley Height Sensor Errors

Lists and explains errors related to the cutting trolley height sensor.

Gas Cutting Errors

Lists and explains timeout errors related to gas cutting operations like piercing.

Plasma Cutting Errors

Lists and explains timeout errors related to plasma cutting operations.

Software Errors

Lists and explains general software configuration errors.

Fume Extraction Unit Notifications

Lists notifications for the operator regarding fume extraction status.

Profiling Errors

Lists and explains errors related to data file calculation, loading, and profiling parameters.

Cutting Head Rotation Errors

Lists and explains notifications related to cutting head rotation calibration.

Cutting Head Pitch Errors

Lists and explains notifications related to cutting head pitch calibration.

Cutting Head Tilt Errors

Lists and explains notifications related to cutting head tilt calibration.

Main Drive Longitudinal Errors

Lists and explains notifications for main drive longitudinal movement limits.

Main Drive Transversal Errors

Lists and explains errors and notifications for main drive transversal movement.

Diabolo Conveyor Controller Errors

Lists and explains errors and notifications for the Diabolo Conveyor controller.

Plasma Fine Marker Errors

Lists and explains timeout errors for the plasma fine marker.

Punch Marker Errors

Lists and explains timeout errors for the punch marker.

HiFocus Plasma Unit Errors

Lists and explains timeout errors for the HiFocus plasma unit.

REA Inkjet Printer Errors

Lists and explains timeout errors for the REA inkjet printer.

Main Drive Clamping Errors

Explains errors related to main drive clamping on SPC 1500-3000 machines.

Control Unit Errors

Lists and explains errors related to the control unit, specifically emergency stop fuses.

Approach Errors (Prior to Profiling)

Lists errors that occur before profiling, related to approaching sets or main drive areas.

REA Inkjet Printer Controller Errors

Lists and explains communication errors with the REA inkjet printer controller.

Diabolo Conveyor Errors

Explains errors related to the Diabolo conveyor motor overload.

Conveyor Lever Height Errors

Lists notifications for conveyor lever height status.

Roller Bed Bogie Errors

Lists notifications for roller bed bogie height status.

Roller Bed Hydraulic Motor Errors

Explains errors related to roller bed hydraulic motor overload.

Frequency Regulator Faults

Describes faults related to frequency regulators and emergency stop procedures.

Diameter Check Errors (RBPC Machines)

Lists and explains timeout errors during diameter checks on RBPC machines.

Transversal Platform Errors (SPC-RB Machines)

Lists and explains timeout errors for the transversal platform movement.

Diabolo Conveyor Height Errors

Lists notifications for diabolo conveyor height status.

Settings Errors

Covers errors encountered when opening, creating, or modifying settings files and parameters.

Axis Definition

Axis Labels and Diagrams

Defines the machine's axes and their corresponding labels with visual diagrams.

Amplifier Errors

Checking the Amplifier

Provides guidance on checking the amplifier status and potential causes of errors.

Amplifier Errors for MDR, CTL, CTH, MDH Motors

Describes the status LEDs and display modes of M'Ax drives used for these motors.

Amplifier Checks for CHT and CHR Motors

Details amplifier checks for CHT and CHR motors, including power and LED status.

Amplifier Checks for MDC Motor (SPC 1500-2500)

Describes amplifier checks for the MDC motor, including status LEDs and power issues.

Following Errors

Motor Position Display Issues

Addresses issues where motor position display doesn't update despite motor movement.

Motor Does Not Move

Covers scenarios where the motor fails to move, indicating mechanical blockage or defects.

Motor Overload Errors

Discusses errors occurring when the motor cannot keep up with commanded speed or acceleration.

Troubleshooting Unlocated Errors

Provides further troubleshooting steps when initial checks fail to identify the error cause.

Height Sensor Following Errors

Addresses following errors related to the height sensor and pipe surface following.

End Switch Errors

Software End Switches

Explains software-defined end positions and their role in error reporting.

CHT Motor End Switch Errors

Discusses end switch errors for the CHT motor, noting the absence of physical switches.

CHR Motor End Switch Errors

Covers end switch errors for the CHR motor, including hardware and software aspects.

CTL Motor End Switch Errors

Details end switch errors for the CTL axis, including safety features related to the main drive.

False End Switch Error Messages

Guides on identifying and troubleshooting false end switch error messages.

Missing End Switch Error Messages

Addresses situations where the machine hits a mechanical stop without an end switch error.

Double End Switch Errors

Discusses troubleshooting double end switch errors possibly caused by power supply issues.

Homing Errors

CTL Axis Home Error

Explains home errors for the CTL axis and checks for its functioning.

Cutting Head Home Errors

Covers general home errors for the cutting head axes and troubleshooting steps.

CHT Axis Home Error

Details home errors for the CHT axis and checks for its home switch functionality.

CHR Axis Home Error

Explains home errors for the CHR axis and checks for its home and limit switches.

General Home Search Errors

Addresses general home search timeout errors and checks for other motor errors.

Sensor System Errors

General Sensor Check

Guides on performing a general check of the sensor system and its components.

Sensor Value Not Changing

Provides troubleshooting steps when the sensor value does not change during operation.

Height Sensor Blocked

Addresses issues where the height sensor system becomes mechanically blocked.

Floating Mode and Deviation Errors

Explains errors occurring during floating mode and deviation issues related to the sensor system.

Emergency Stop

False Emergency Stop Message

Discusses potential causes and checks for false emergency stop messages.

Main Drive Unit Errors

SPC 330 Main Drive Unit Errors

Details errors specific to the SPC 330 main drive unit, including clamping and rotation.

Clamping Errors SPC 330

Covers clamping errors for the SPC 330, including cylinder and switch checks.

SPC 500-1200 Main Drive Unit Errors

Explains errors related to the SPC 500-1200 main drive unit, including hydraulic height and clamping.

SPC 1500-2500 Main Drive Unit Errors

Details errors for the SPC 1500-2500 main drive unit, including fixed height and electric clamping.

Pipe Jammed in Chuck

Addresses issues with pipes jammed in the chuck and potential causes.

Clamping Side Setting Importance

Explains the importance of the clamping side setting for pipe release.

Jamming Due to Improper Clamping

Discusses jamming caused by improper clamping or height adjustments.

Manual Pipe Removal from Chuck

Provides methods for manually removing a pipe jammed in the chuck.

Encoder Signal Check

Checking MDR, MDH, CTH, CTL Motor Encoder Signals

Guides on checking encoder signals for MDR, MDH, CTH, and CTL motors.

Checking CHT and CHR Motor Encoder Signals

Details checking encoder signals for CHT and CHR motors.

Height Sensor Encoder Signal Check

Explains how to check the encoder signal for the height sensor system.

Encoder Failure Troubleshooting

Discusses steps to take if the encoder signal does not change during motor movement.

MDR Motor Resolver Feedback Check

Details checks for the MDR motor's resolver feedback and amplifier.

CTH, CTL, MDH Motor Checks

Explains checks for CTH, CTL, and MDH motors with resolver feedback.

Encoder Voltage and Status Check

Explains how to check encoder signal voltage and status using a multimeter.

Resolver Check

Resolver Functionality and Amplifier Diagnosis

Guides on checking the resolver's functionality and diagnosing issues with the amplifier.

Motor Check

MDR, MDH, CTL, CTH Motor Checks

Details checks for MDR, MDH, CTL, and CTH motors, including coil impedance and earthing.

CHT and CHR Motor Checks

Explains checks for CHT and CHR motors, including fuse status and coil impedance.

MDC Motor Checks (SPC 1500-2500)

Details checks for the MDC motor, including cable earthing and coil impedance.

Motors Overloaded

MDR Motor Overload Causes

Discusses potential causes of MDR motor overload and how to locate system blocks.

CTL Motor Issues

Addresses common problems with the CTL motor, sliders, and guiding rail.

CHT Motor Issues

Discusses CHT motor issues related to gearbox grease and mechanical checks.

CHR Motor Issues

Covers CHR motor problems related to gearbox grease and checks of the cutting head components.

CTH Motor Issues

Details CTH motor issues, including guide rails, spindle, and bearing checks.

MDC Motor Issues (SPC 1500-2500)

Addresses MDC motor overload, slider box, chuck, and gearbox checks.

MDH Motor Issues

Covers MDH motor checks, including gearbox, spindle, and bearing inspections.

Appendix D Software Restore

Introduction to Software Restore

Introduces the process of restoring machine software using a USB stick.

Software Locations

Identifies where to find necessary software on the HGG Customer Portal and USB drive.

Bootable USB Key Preparation

Explains how to prepare a bootable USB key with snapshot software and disk images.

Machine Image Location

Specifies the location of the latest machine images for different computer types.

ProCAM Software Location

Indicates the location of the latest ProCAM software version.

UPC Software Location

Specifies the location of the latest UPC machine software.

ProCAD Software Information

Discusses ProCAD software installation and compatibility requirements with AutoCAD/Tekla.

Creating a Bootable USB Key

Guides on preparing the USB key by starting Snapshot and selecting 'Restore disk from file'.

Copying Software to USB Key

Explains how to copy Windows images, UPC, and ProCAM software to the USB drive.

UPC Machine Configuration Copy

Guides on copying UPC machine backup files to the USB drive for settings.

ProCAD Connection and Manuals Copy

Explains how to copy ProCAD installers and manuals to the USB drive.

Restoring the Hard Disk

Details the process of installing the Windows image from the USB stick by booting from it.

Restoring UPC Machine Software

Guides on installing the UPC machine software from the USB drive.

Replacing Settings

Explains how to import settings files after installing the UPC software.

Restoring ProCAM Software

Guides on installing the ProCAM software from the USB drive.

BIOS Settings

FPC-7100 BIOS Configuration

Details BIOS setup adjustments for the FPC-7100, including power configuration.

FPC-7300 BIOS Configuration

Details BIOS setup adjustments for the FPC-7300, including SuperIO and USB configuration.

FPC-7700 BIOS Configuration

Details BIOS setup adjustments for the FPC-7700, focusing on Super IO configuration.

Appendix E Cutting Quality

Oxyfuel Cutting Quality Issues

Discusses oxyfuel cutting quality issues, their causes, and correction methods.

Plasma Cutting Quality Issues

Discusses plasma cutting quality issues, their causes, and correction methods.

Appendix F Terminology

Glossary of Technical Terms

Defines key technical terms used throughout the manual related to cutting and machine operation.

Need help?

Do you have a question about the SPC 1200 and is the answer not in the manual?

Questions and answers