Advertisement

Quick Links

Advertisement

Summarization of Contents

Special Definitions

Understanding Safety Statements

Explains the meaning of WARNING, CAUTION, IMPORTANT, and NOTE statements.

Recommended Hydraulic Supply

Hydraulic Hose and Fitting Specifications

Specifies recommended hose sizes and fittings for different rotator models and functions.

Hose Reel System Types

Details the different hose reel groups for hydraulic supply system configurations.

Truck Requirements

Hydraulic System Settings

Specifies required truck hydraulic pressure (relief setting) and flow volume for rotator operation.

Carriage Mounting and Preparation

Covers carriage mounting dimensions and necessary cleaning/inspection before attachment installation.

Installation: Attaching Hoist and Removing Hooks

Hoist Attachment and Hook Removal

Procedure for attaching the overhead hoist and removing lower mounting hooks.

Installation: Unlocking Quick-Change Hooks

Quick-Change Hook Mechanism Operation

Steps to unlock and reposition quick-change lower mounting hooks, including guide adjustment.

Installation: Preparing Hydraulic Hoses

Hydraulic Hose Preparation and Connection

Guide to preparing, cutting, and connecting hydraulic hoses, including flushing requirements.

Installation: Hose Flushing and Lubricant Check

Hydraulic Hose Flushing Procedure

Procedure for flushing hydraulic hoses to remove air from the system.

Gearbox Lubricant Level Verification

Instructions for checking and refilling the gearbox lubricant level.

Installation: Mounting Attachment on Truck Carriage

Carriage Mounting and Hook Engagement

Steps to mount the attachment onto the truck's carriage, engaging hooks and centering tabs.

Installation: Engaging Lower Hooks

Securing Lower Hooks to Carriage

Procedure for installing and securing the lower hooks to the carriage bar.

Installation: Installing Fork Stop Block Kit

Fork Stop Block Installation Procedure

Instructions for installing the fork stop block kit to prevent fork swing during rotation.

Installation: Cycle Rotation Function Test

Rotation Function Testing Procedure

Tests the attachment's rotation function under no-load and maximum-load conditions.

Installation: Fork Welding Preparation

Preparing Forks for Middle Hook Welding

Procedures for cleaning forks and positioning the middle hook prior to welding.

Installation: Fork Middle Hook Welding

Welding the Middle Hook to Fork

Detailed welding process for attaching the middle hook to the fork.

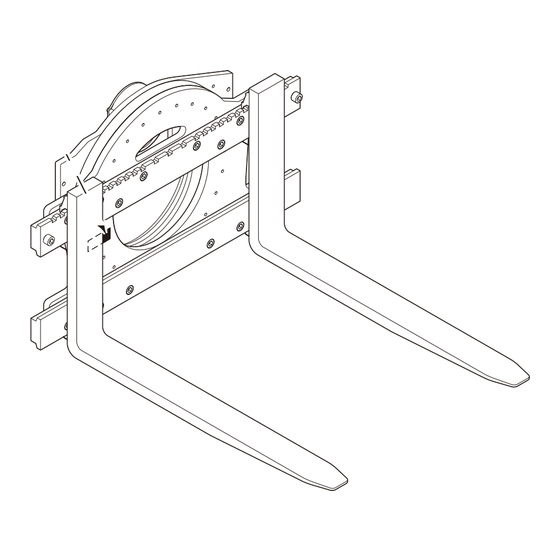

Installation: Installing Forks

Fork Installation and Locking

Steps for mounting forks onto the carriage, including releasing and securing locking mechanisms.

Prior to Operation: General Checks

Safety and Control System Alignment

Ensures safe truck control and attachment function alignment per industry standards.

Hydraulic System Bleeding and Leak Inspection

Bleeds air from the hydraulic system and inspects hoses/fittings for external leaks.

Prior to Operation: Load Testing and Adjustments

Maximum Load Rotation Testing

Tests attachment rotation with maximum load for smoothness and proper function.

180° Stop Group Adjustment Procedure

Adjusts stop bolt positions for the 180° rotation stop group if equipped.

Prior to Operation: Electronic Rotation Control

Electronic Rotation Control Testing

Verifies electronic rotation control stops correctly at vertical and horizontal positions.

Prior to Operation: Limit Switch Adjustment

Limit Switch and Stop Position Adjustment

Adjusts limit switches, ramps, and capscrews for precise stopping and continuous rotation.

Need help?

Do you have a question about the 45G and is the answer not in the manual?

Questions and answers