Summarization of Contents

Section 1: Preface

Preface

Introduction to the Honeywell X Series recorder, its features, and the manual's scope.

Documentation

Information on available manuals for software and recorders, and supplementary documents.

Notes

Important notes regarding manual accuracy, updates, and copyright.

Trademarks

List of registered trademarks for Microsoft and Compact Flash.

Safety

Information on safety compliance with BS EN 61010-1:2001 and UL 61010C-1 standards.

Symbols

Explanation of safety symbols that may appear on the recorder labelling.

Static Electricity

Precautions for handling components susceptible to electrostatic discharge.

Protocols used in this manual

Defines symbols and warnings used in the manual for safety and clarity.

Safety and Symbol Identification

Defines warning, caution, and notice symbols and their meanings.

Warnings and Safety Precautions

Details critical safety advice and handling procedures.

Do’s and Don’ts

Essential installation and handling guidelines for safe operation.

Hazardous Voltage

Defines hazardous voltage levels and safety precautions for operators.

Section 2: Installation

Damage checks

Instructions for reporting any damage to the recorder or its contents.

Unpacking

Steps for unpacking the recorder and verifying contents.

Contents

List of standard items included with the recorder package.

Re-packing

Guidance on proper repacking procedures to maintain warranty.

Environment and Location

Recommendations for suitable installation environment and location.

Mechanical Installation

Details on mounting, viewing angles, and panel cut-out sizes for recorders.

Panel Mounting Clamp Installation

Instructions for installing panel clamps for secure mounting.

Electrical Installation

Guidance on electrical installation, including category, fuses, and cables.

Installation Category

Specifies installation category and pollution degree requirements.

Fuses

Information on fuse replacement for the DC input power supply.

Cables

Requirements for using screened cable and low impedance earth connections.

Signal Wiring

Guidelines for safe signal wiring and ensuring safety earth connection.

Section 4: Recorder Setup

Power up

Initial steps after powering up the recorder, including splash screen and language.

Menu Access

Guide to accessing the recorder's menu system via the touch screen.

Log On/Off

Procedure for logging into and out of the recorder's system.

Local Settings

Configuration of local settings like language, time zones, and units.

Time and Date Settings

Instructions for setting the recorder's time and date.

Firmware Options

Enabling firmware options by checking credits and selecting desired features.

Menu Path

Explanation of how the menu path indicates the user's current location in the system.

Setup Menu

Edit Setup

Access to sub-menus for configuring Field IO, Pens, Comms, etc.

Save Setup

Procedure for saving the recorder setup configuration.

Load Setup

Procedure for loading previously saved setup configurations.

Back Button

Functionality of the back button to return to the previous menu.

Edit Setup

Field IO

Configuration of Analogue In, Analogue Out, Alarm/Digital IO, and Pulse Inputs.

Pens

Configuration of pens including scales, maths, alarms, and logging.

Comms

Configuration of communication services like Modbus, Web, and Email.

Events/Counters

Configuration of events and counters for logging occurrences.

General

Configuration of general recorder information like identity and alerts.

Screen

Configuration of screen saver, chart speed, and brightness settings.

Recording

Setup of scheduled recording and storage bias.

Reports

Configuration for generating and running reports.

Field IO Menu

Analogue In

Configuration of each Analogue Input channel.

Analogue Out

Configuration of each Analogue Output channel.

Alarm/Digital IO

Configuration of Relay Alarm Output or Digital Input/Output cards.

Pulse Inputs

Configuration of each Pulse Input channel.

Linearisation Tables

User-defined tables for non-linear input signal display.

Pens Menu

Enabled

Toggle to enable or disable individual pens.

Tag

Assign an identifier for the pen.

Description

Provide a description for the pen displayed on custom screens.

Maths Type

Select the type of mathematical calculation for the pen signal.

Edit Maths

Edit the mathematical expressions for a specific pen.

Scale

Configure scale parameters including units, span, and zero.

Logging

Setup the logging configuration for each pen.

Alarms

Setup the alarm profile for each pen.

Totaliser

Setup the totalising profile for each pen.

RAV

Display the Rolling Average for the pen.

Group

Allocate pens to groups for batch control or report generation.

Colour

Set the default pen colour for display.

Trace Width

Set the trace width for the pen on a chart.

Scale Menu

Units

Set measurement units for the scale.

Span

Define the highest value of the scale.

Zero

Define the bottom of the scale.

Scale Type

Toggle between Linear or Logarithmic scale types.

Divs Select

Select Auto or User Defined divisions for linear scales.

Logging Menu

Enabled

Activate or deactivate logging for the pen.

Type

Select logging type: Continuous or Fuzzy.

Rate Units

Set the units for the logging rate.

Rate

Specify the data logging speed.

Alarm Rate Units

Set units for the alarm logging rate.

Alarm Rate

Define the logging rate when the pen enters an alarm state.

Method

Select logging method: Sample, Average, or Max/Min.

Align

Align logging at specified intervals.

Auto Fit

Log last data point before signal goes out of tolerance.

Band 1 %

Set tolerance band percentage for input signal.

Fuzzy Band 2

Set a tighter tolerance band, used with Autofit.

Band 2 %

Specify tighter tolerance band percentage.

Totaliser Menu

Enabled

Activate or deactivate totalising for the pen.

Comms Menu

Services

Access Modbus, Web, Email, SNTP, FTP, and Peers settings.

TCP/IP

Configure Transmission Control Protocol/Internet Protocol settings.

Network Admin

Setup network printing and emailing parameters.

Web Browser

Web Browse

Enable/disable web browsing function for recorder information.

Email

General operation of the e-mail system

How the recorder sends messages via an e-mail server using SMTP.

Standard Communication Interfaces

Rear Ethernet Communication port

Details of the Ethernet port supporting Modbus TCP/IP, OPC, and Web Browser.

Rear RS485 port

Information on the RS485 port for eZtrend QXe and Minitrend/Multitrend recorders.

Front and Rear USB Communication Ports

Interface options for USB devices like keyboards, storage, and printers.

Hardware Installation

Device and PC Ethernet connections

Diagram illustrating Ethernet connections between devices and PCs via hubs/switches.

Hubs or Switches

Explanation of hubs and switches as common connection points in networks.

Getting connected - IP Address

Stand alone system

Connecting a device directly to a PC using an Ethernet crossover cable.

Local Area Network setup

LAN Setup

Diagram illustrating a Local Area Network setup.

Links to Remote Networks

Data Logging and Transfer

How to transfer data using TrendServer software via various methods.

Comms and Trend Manager Suite

TrendServer

Network-aware software for real-time viewing, archiving, and communication.

TrendManager Pro

Advanced data analysis and archiving software for recorder configuration.

TrendViewer

Standard software for displaying and printing imported data.

System Requirements

Minimum system specifications for PC software packages.

Software Installation

Upgrades

Information on upgrading software packages like TrendViewer and TrendServer.

Start Up

Import recorders

Procedure for importing recorder setups into TrendServer Pro.

External Import

Find Device button

Utility to find X Series recorders on the network.

Modbus profile tool, data update

Updating Modbus profiles automatically or manually.

Communications Server

Comms Server Overview

Overview of the Communications Server and its functions.

Start up

Procedure for starting the Communications Server.

Comms Server Setup

Add a Device

Methods for adding a device to the comms server.

Add a Device via Ethernet

Procedure for adding a device via Ethernet connection.

Comms Server Setup

Add a Device

Steps to add a device to a comms port.

Delete a Device

Procedure for deleting a device from the comms server.

Comms ports

Database Servers

Listing and accessing databases and devices within them.

Add a Database

Add a Database Server

Steps to add a database server.

Connect to a Database Server

Connecting to a database server using its IP address.

Delete a Database Server

Procedure for removing a database server.

Realtime Graphing

Drag and Drop Recorder from the list onto the graph area

Instructions for adding recorders and pens to the graph.

Comms Database Server

System Setup

Ways to set up the system for device logging.

Modbus Capabilities

Details on Modbus master capabilities and limitations.

OPC Interface - Open Process Control

OPC limitations

Technical limitations of OPC DA and OPC A&E servers.

OPC DA Server

Details on OPC DA server group and item limits per client.

OPC A&E Server

Information on OPC A&E server alarm and event subscription limits.

How OPC works

Explanation of how OPC enables interoperability between devices and software.

OPC Clients

Using OPC clients for real-time interface with servers.

Web Browser

Web Browse

Enabling/disabling the web browse function and remote viewer access.

IP Address Troubleshooting

Internet Security Settings

Configuring web browser security and firewall settings for network access.

Section 9: PC Software Suite

The TrendManager Pro Software Suite

Overview of the software suite and its components.

System Requirements

Minimum system requirements for PC software packages.

Section 10: Spares List

Minitrend QX Recorder

List of spare parts for the Minitrend QX recorder.

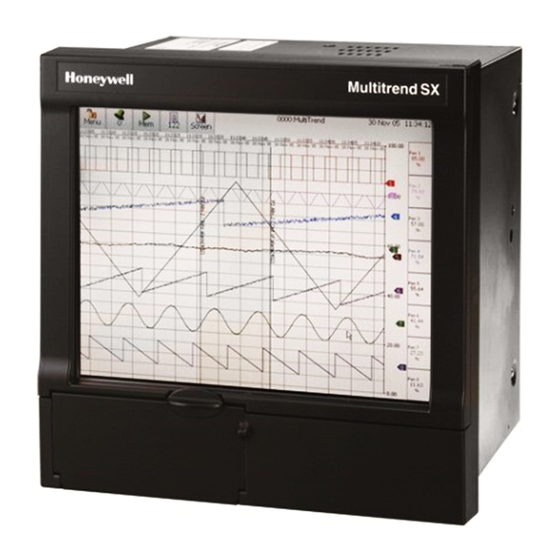

Multitrend SX Recorder

List of spare parts for the Multitrend SX recorder.

eZtrend QXe Recorder

List of spare parts for the eZtrend QXe recorder.

Section 11: Instrument Care and Maintenance

Instrument Care and Manintenance

General guidelines for maintaining the recorder's hardware.

Cleaning Instructions

Safe procedures for cleaning the recorder's touch screen and unit.

Backlights

Information on backlight MTTF and factors affecting its lifespan.

Operating Temperature

Recommendations for operating temperatures to prevent display degradation.

Touch Screen

Care and cleaning guidelines for the touch screen.

Calibration

Recommendation for regular recorder calibration to ensure accuracy.

Section 12: Technical Data & Specifications

Field IO Specification

Specifications for Analogue Output and Pulse Input cards.

Analogue Input

Details on user-defined maximum input ranges.

Relay Alarm/Digital Input Specification

Specifications for relay alarm and digital input/output cards.

Relay/Alarm Output Card Options

Description of 4 and 8 Channel Relay Alarm Card options.

Common Alarm Output

Details on the common alarm output relay.

Digital Input Cards

Information on 8 and 16 Digital Input options.

Digital Input Functions

Functions and actions that digital inputs can perform.

Failsafe Relay Positions

Table showing relay positions for normal and failsafe states.

Specification Tables

Compilation of various technical specifications and design attributes.

Specification Design Attributes

Details on digital indicators, display, communications, and math.

Specification Analogue Inputs

Technical specifications for analogue input parameters.

Specification Logging

Specifications related to logging methods, types, and rates.

Input Range Performance Accuracy Table

Table detailing input ranges, accuracy, and temp stability.

Specification Options

Details on optional features like Pulse Input and Alarm Outputs.

Firmware Options

List of available firmware options and their credit values.

Data Storage

Information on internal memory and removable media storage.

Power Requirements

Specifications for recorder power requirements.

Common Relay Output (SPNC)

Details on the common alarm output relay.

Battery

Information on the clock backup battery type and life.

Password Protection

Overview of password protection levels and user management.

Languages

List of supported language prompts for the recorder.

Temperature Units

Selection of temperature units for measurement.

Recorder Identification

Status bar information for recorder ID and screen name.

Clock

Accuracy and synchronization methods for the recorder's clock.

Alarm Set Points

Configuration of alarm set points and effects.

Appendix B: Maths Expressions

Full Maths & Script Processing

Explanation of basic and advanced math functions and scripting.

Maths Credit Options

Information on firmware credit options for math functions.

Maths Variable and Function Tables

Maths Variables

Table of available maths variables and their syntax.

Maths Function Table

List of available maths functions and their descriptions.

Functions for Scripts

Else

Scripting keyword for conditional execution.

Elseif

Scripting keyword for conditional testing.

First run

Scripting keyword to check if the script is running for the first time.

If

Scripting keyword for conditional execution.

Set Changed

Scripting keyword to check if setup has been changed.

Time Changed

Scripting keyword to check if time has been changed.

Appendix C: Thermocouple Connections

How Thermocouples work

Explanation of how thermocouples generate voltage based on temperature gradients.

Thermocouple CJC Compensation

Internal Automatic

Method using the recorder's internal temperature sensor for compensation.

Appendix D: Alarms

Alarms Menu

Functions for acknowledging, configuring, and viewing alarms.

Appendix E: Ethernet

Ethernet

Explanation of Ethernet technology and its operation in local area networks.

Email

General operation of the e-mail system

How the recorder sends messages via an e-mail server using SMTP.

Appendix F: Fuzzy Logging

What is Fuzzy Logging?

Definition of Fuzzy Logging as a real-time data compression technique.

What’s it for?

Benefits of Fuzzy Logging for scan rate, disk capacity, and recording time.

How does it work?

Explanation of Fuzzy Logging's adaptive technique for data capture.

Appendix G: F sub zero Sterilisation

The significance of F0

Explanation of the F0 value used in sterilisation processes.

Appendix H: Calibration

AI Calibration and CJC Calibration

Procedures for factory and user calibration of AI and CJC.

Sensor Compensation

Adjusting signal input for improved accuracy on sub ranges.

Appendix I: Battery Data

Location: Processor Board

Identifies the battery location for clock backup.

Safety Guidelines

Important safety precautions for handling and disposing of batteries.

Appendix J: Function Codes and Memory Maps

Modbus Memory Map Supplement:

Reference for Modbus serial communications user manual.

Totalisers

Information on totaliser values and Modbus registers.

Input Text message

Facility for passing text messages for chart annotation and logging.

Section 9: PC Software Suite

The TrendManager Pro Software Suite

Overview of the software suite and its components.

System Requirements

Minimum system requirements for PC software packages.

Section 10: Spares List

Minitrend QX Recorder

List of spare parts for the Minitrend QX recorder.

Multitrend SX Recorder

List of spare parts for the Multitrend SX recorder.

eZtrend QXe Recorder

List of spare parts for the eZtrend QXe recorder.

Section 11: Instrument Care and Maintenance

Instrument Care and Manintenance

General guidelines for maintaining the recorder's hardware.

Cleaning Instructions

Safe procedures for cleaning the recorder's touch screen and unit.

Backlights

Information on backlight MTTF and factors affecting its lifespan.

Operating Temperature

Recommendations for operating temperatures to prevent display degradation.

Touch Screen

Care and cleaning guidelines for the touch screen.

Calibration

Recommendation for regular recorder calibration to ensure accuracy.

Section 12: Technical Data & Specifications

Field IO Specification

Specifications for Analogue Output and Pulse Input cards.

Analogue Input

Details on user-defined maximum input ranges.

Relay Alarm/Digital Input Specification

Specifications for relay alarm and digital input/output cards.

Relay/Alarm Output Card Options

Description of 4 and 8 Channel Relay Alarm Card options.

Common Alarm Output

Details on the common alarm output relay.

Digital Input Cards

Information on 8 and 16 Digital Input options.

Digital Input Functions

Functions and actions that digital inputs can perform.

Failsafe Relay Positions

Table showing relay positions for normal and failsafe states.

Specification Tables

Compilation of various technical specifications and design attributes.

Specification Design Attributes

Details on digital indicators, display, communications, and math.

Specification Analogue Inputs

Technical specifications for analogue input parameters.

Specification Logging

Specifications related to logging methods, types, and rates.

Input Range Performance Accuracy Table

Table detailing input ranges, accuracy, and temp stability.

Specification Options

Details on optional features like Pulse Input and Alarm Outputs.

Firmware Options

List of available firmware options and their credit values.

Data Storage

Information on internal memory and removable media storage.

Power Requirements

Specifications for recorder power requirements.

Common Relay Output (SPNC)

Details on the common alarm output relay.

Battery

Information on the clock backup battery type and life.

Password Protection

Overview of password protection levels and user management.

Languages

List of supported language prompts for the recorder.

Temperature Units

Selection of temperature units for measurement.

Recorder Identification

Status bar information for recorder ID and screen name.

Clock

Accuracy and synchronization methods for the recorder's clock.

Alarm Set Points

Configuration of alarm set points and effects.

Appendix B: Maths Expressions

Full Maths & Script Processing

Explanation of basic and advanced math functions and scripting.

Maths Credit Options

Information on firmware credit options for math functions.

Maths Variable and Function Tables

Maths Variables

Table of available maths variables and their syntax.

Maths Function Table

List of available maths functions and their descriptions.

Functions for Scripts

Else

Scripting keyword for conditional execution.

Elseif

Scripting keyword for conditional testing.

First run

Scripting keyword to check if the script is running for the first time.

If

Scripting keyword for conditional execution.

Set Changed

Scripting keyword to check if setup has been changed.

Time Changed

Scripting keyword to check if time has been changed.

Appendix C: Thermocouple Connections

How Thermocouples work

Explanation of how thermocouples generate voltage based on temperature gradients.

Thermocouple CJC Compensation

Internal Automatic

Method using the recorder's internal temperature sensor for compensation.

Appendix D: Alarms

Alarms Menu

Functions for acknowledging, configuring, and viewing alarms.

Appendix E: Ethernet

Ethernet

Explanation of Ethernet technology and its operation in local area networks.

Email

General operation of the e-mail system

How the recorder sends messages via an e-mail server using SMTP.

Appendix F: Fuzzy Logging

What is Fuzzy Logging?

Definition of Fuzzy Logging as a real-time data compression technique.

What’s it for?

Benefits of Fuzzy Logging for scan rate, disk capacity, and recording time.

How does it work?

Explanation of Fuzzy Logging's adaptive technique for data capture.

Appendix G: F sub zero Sterilisation

The significance of F0

Explanation of the F0 value used in sterilisation processes.

Appendix H: Calibration

AI Calibration and CJC Calibration

Procedures for factory and user calibration of AI and CJC.

Sensor Compensation

Adjusting signal input for improved accuracy on sub ranges.

Appendix I: Battery Data

Location: Processor Board

Identifies the battery location for clock backup.

Safety Guidelines

Important safety precautions for handling and disposing of batteries.

Appendix J: Function Codes and Memory Maps

Modbus Memory Map Supplement:

Reference for Modbus serial communications user manual.

Totalisers

Information on totaliser values and Modbus registers.

Input Text message

Facility for passing text messages for chart annotation and logging.

Section 9: PC Software Suite

The TrendManager Pro Software Suite

Overview of the software suite and its components.

System Requirements

Minimum system requirements for PC software packages.

Section 10: Spares List

Minitrend QX Recorder

List of spare parts for the Minitrend QX recorder.

Multitrend SX Recorder

List of spare parts for the Multitrend SX recorder.

eZtrend QXe Recorder

List of spare parts for the eZtrend QXe recorder.

Section 11: Instrument Care and Maintenance

Instrument Care and Manintenance

General guidelines for maintaining the recorder's hardware.

Cleaning Instructions

Safe procedures for cleaning the recorder's touch screen and unit.

Backlights

Information on backlight MTTF and factors affecting its lifespan.

Operating Temperature

Recommendations for operating temperatures to prevent display degradation.

Touch Screen

Care and cleaning guidelines for the touch screen.

Calibration

Recommendation for regular recorder calibration to ensure accuracy.

Section 12: Technical Data & Specifications

Field IO Specification

Specifications for Analogue Output and Pulse Input cards.

Analogue Input

Details on user-defined maximum input ranges.

Relay Alarm/Digital Input Specification

Specifications for relay alarm and digital input/output cards.

Relay/Alarm Output Card Options

Description of 4 and 8 Channel Relay Alarm Card options.

Common Alarm Output

Details on the common alarm output relay.

Digital Input Cards

Information on 8 and 16 Digital Input options.

Digital Input Functions

Functions and actions that digital inputs can perform.

Failsafe Relay Positions

Table showing relay positions for normal and failsafe states.

Specification Tables

Compilation of various technical specifications and design attributes.

Specification Design Attributes

Details on digital indicators, display, communications, and math.

Specification Analogue Inputs

Technical specifications for analogue input parameters.

Specification Logging

Specifications related to logging methods, types, and rates.

Input Range Performance Accuracy Table

Table detailing input ranges, accuracy, and temp stability.

Specification Options

Details on optional features like Pulse Input and Alarm Outputs.

Firmware Options

List of available firmware options and their credit values.

Data Storage

Information on internal memory and removable media storage.

Power Requirements

Specifications for recorder power requirements.

Common Relay Output (SPNC)

Details on the common alarm output relay.

Battery

Information on the clock backup battery type and life.

Password Protection

Overview of password protection levels and user management.

Languages

List of supported language prompts for the recorder.

Temperature Units

Selection of temperature units for measurement.

Recorder Identification

Status bar information for recorder ID and screen name.

Clock

Accuracy and synchronization methods for the recorder's clock.

Alarm Set Points

Configuration of alarm set points and effects.

Appendix B: Maths Expressions

Full Maths & Script Processing

Explanation of basic and advanced math functions and scripting.

Maths Credit Options

Information on firmware credit options for math functions.

Maths Variable and Function Tables

Maths Variables

Table of available maths variables and their syntax.

Maths Function Table

List of available maths functions and their descriptions.

Functions for Scripts

Else

Scripting keyword for conditional execution.

Elseif

Scripting keyword for conditional testing.

First run

Scripting keyword to check if the script is running for the first time.

If

Scripting keyword for conditional execution.

Set Changed

Scripting keyword to check if setup has been changed.

Time Changed

Scripting keyword to check if time has been changed.

Appendix C: Thermocouple Connections

How Thermocouples work

Explanation of how thermocouples generate voltage based on temperature gradients.

Thermocouple CJC Compensation

Internal Automatic

Method using the recorder's internal temperature sensor for compensation.

Appendix D: Alarms

Alarms Menu

Functions for acknowledging, configuring, and viewing alarms.

Appendix E: Ethernet

Ethernet

Explanation of Ethernet technology and its operation in local area networks.

Email

General operation of the e-mail system

How the recorder sends messages via an e-mail server using SMTP.

Appendix F: Fuzzy Logging

What is Fuzzy Logging?

Definition of Fuzzy Logging as a real-time data compression technique.

What’s it for?

Benefits of Fuzzy Logging for scan rate, disk capacity, and recording time.

How does it work?

Explanation of Fuzzy Logging's adaptive technique for data capture.

Appendix G: F sub zero Sterilisation

The significance of F0

Explanation of the F0 value used in sterilisation processes.

Appendix H: Calibration

AI Calibration and CJC Calibration

Procedures for factory and user calibration of AI and CJC.

Sensor Compensation

Adjusting signal input for improved accuracy on sub ranges.

Appendix I: Battery Data

Location: Processor Board

Identifies the battery location for clock backup.

Safety Guidelines

Important safety precautions for handling and disposing of batteries.

Appendix J: Function Codes and Memory Maps

Modbus Memory Map Supplement:

Reference for Modbus serial communications user manual.

Totalisers

Information on totaliser values and Modbus registers.

Input Text message

Facility for passing text messages for chart annotation and logging.

Need help?

Do you have a question about the Multitrend SX and is the answer not in the manual?

Questions and answers