Summary of Contents for RockHound BrushHound 30EX

- Page 1 EX Series PO Box 220 | 2507 Tully Road| Hughson, CA 95326 USA | 800 426-5615 www.Valleytoolmfg.com...

- Page 3 EX Series Delivery Report Form Prior to acceptance of the equipment, thoroughly check and mark off the items outlined in the de- livery checklist below with your sales representative. Make sure you fully understand the opera- tion, adjustment and safety rules as outlined in the operator’s manual. The sales representative is Customer Information Last Name Street Address...

-

Page 5: Table Of Contents

EX Series Table of Contents Introduction Thank You Warranty Information Safety Operational Safety Maintenance Safety Basic Operation Attaching to the Power Unit Starting Procedure Shut Down Procedure Running Your Attachment Basic Guidelines for Running Your Attachment Transport, Removal & Storage Adjustments &... -

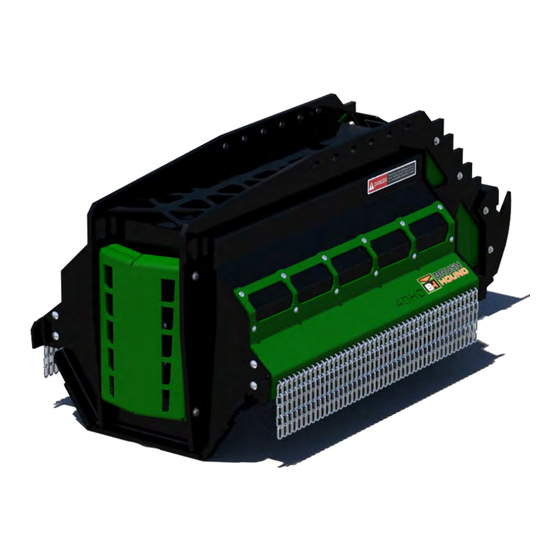

Page 6: Thank You

ATTENTION The safety of the operator was one of the primary concerns of RockHound Attachments when de- signing this shredder. Shielding, simple adjustments and other safety features were built into this shredder whenever possible. You can make your home, orchard or farm a safer place by observing the precautions noted in this manual. - Page 7 RockHound Attachments. Such being subject to the warranty of their respective man- ufacturers. No expressed, implied, or statutory Warranty other than herein set forth is made or authorized to be made by us. RockHound Attachments shall not be liable for consequential damages of any kind, including but not...

-

Page 8: Safety

In the event that a failure does occur during operation or if the machine begins to produce excessive noise or vibration, shut the machine down immediately and repair before any continued use. www.rockhound.com... -

Page 9: Maintenance Safety

Be sure to inspect all safety devices before each use. If safety devices are worn in such a way that they can no longer properly perform their guarding function contact your nearest RockHound dealer for replacements. Maintain all safety decals and make sure they are visible to the operator. If decals are worn, contact your nearest RockHound dealer for replacements. -

Page 10: Basic Operation

3) Slowly bring the throttle up to maximum flow. If the Attachment produces excessive noise or vibration, disengage the auxiliary hydraulics and shut down the Power Unit immediately. Determine the cause of the problem and correct it before continuing with its operation. 4) Attachment is ready for operation. www.rockhound.com... -

Page 11: Shut Down Procedure

EX Series Some examples of Model Specific Mounts III) Shut Down Procedure 5) When work is completed, disengage auxiliary hydraulics and position it for storage or transport (See the “Storage and Transport” section for details on proper storage). Shut off Power Unit and set parking brake. Wait for the Attachment to stop rotating and allow hydraulic circuits to bleed back to reservoir, as they can still be pressurized even when turned off, before approaching or allowing others to approach the Attachment. -

Page 12: Running Your Attachment

Power Unit, a significant portion of the horsepower available is directed towards movement which is why it is not recommended to drive the Power Unit and shred simultaneously. All heavy shredding with the EX Series should be performed while stationary. www.rockhound.com... - Page 13 EX Series House Rotation Shredding Top Down Shredding...

-

Page 14: Basic Guidelines For Running Your Attachment

If the attachment is being transported on the Power Unit, disengage the auxiliary hydraulic circuit and position the attachment at a reasonable driving height and position to maximize Power Unit’s balance. Wait for the drum to stop rotating before transport. www.rockhound.com... - Page 15 EX Series b) Transporting Attachment and Power Unit If the Power Unit is being transported with the Attachment (e.g. transporting on a trailer between jobsites), follow the Power Unit manufacturer’s recommendations for transport and be sure to comply with all local regulations. c) Removal To remove the Attachment from the Power Unit: 1) Find a suitable, flat location to leave the Attachment where it will not fall over.

-

Page 16: Adjustments & Maintenance

The disk itself has a lifetime of over 1000 hours, but should be inspected regularly for excessive wear. If the disk appears worn thin or torn it should be replaced. It should also be replaced whenever the cutter drum is removed. www.rockhound.com... - Page 17 EX Series Grease Fitting Locations b) Hydraulic Hoses The hydraulic hoses located within the motor guards have been placed to minimize their wear caused by rubbing against metal surfaces. However, due to heavy vibration their positions can shift so regular inspection for excessive wear should be performed.

-

Page 18: Knife Maintenance

Attachment by 4 provided 1” bolts, simply line up the holes on the mount with the corresponding holes on the Attachment, insert the bolts and secure with the provided nuts and washers. Check with your local Brush hound Dealer before changing Power Units to verify compatibility. www.rockhound.com... - Page 19 EX Series Cleaning Locations: Debris can collect on bearings, in the motor area, on top or on the rear deflection guard. Use a power washer to keep these areas clean.

-

Page 20: Hydraulic Plumbing Diagram

Pressure Out (shown as female quick connect) - Connect to the return side of your Power Unit’s hydraulic circuit. c) To Reverse cutting direction, You would need to switch the Male/ Female hose location or the Male/ Fe- male quick couple location. In addition the check valve location will need to be switched as well. www.rockhound.com... - Page 21 EX Series Pressure In (Male Quick Pressure Out (Female Connect) Quick Connect) Plug Check Valve On quick couplers, the male end is usually the pressure in. Quick couplers may need to be ex- changed on hose ends depending on the power unit. If oil is flowing and there is no movement, this may be due to coupler orientation.

-

Page 22: Frequently Asked Questions

A. Be careful! Make sure the hoses are pressed all the way into their corresponding fittings on the power unit. Turn the female coupler collar past bump to cock. Give them a slight tug to make sure they are se- www.rockhound.com... - Page 23 EX Series Serial Number Plate...

-

Page 24: Parts Catalog

EX Series - Brush Shredder Parts Catalog www.rockhound.com... -

Page 26: Cutter Drum & Drive Assembly

www.rockhound.com... - Page 28 EX Series PO Box 220 | 2507 Tully Road| Hughson, CA 95326 USA | 800 426-5615 www.Valleytoolmfg.com...

Need help?

Do you have a question about the BrushHound 30EX and is the answer not in the manual?

Questions and answers