Table of Contents

Advertisement

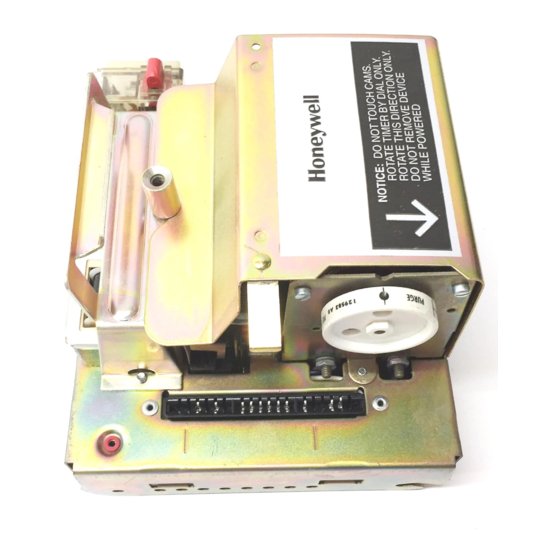

Flame Safeguard Programming Controls

OPTIONAL

202050C

COVER

OPTIONAL HEAVY DUTY

COVER (PART NO.

202050C OR 139695C)

IMPORTANT

Applications, Features, Specifications (including

dimension drawings), Operation (including

schematics and bar charts), and Wiring Diagrams

are included in these Specifications for models of

the R4140G, L, and M: R4140G—60-2337;

R4140L—60-2339; R4140M—60-2340.

Copyright © 1996 Honeywell Inc. • All Rights Reserved

RESET BUTTON

TIP JACK

PLUG-IN

AMPLIFIER

RELAY/TIMER

COVER

Fig. 1. Components of R4140G and R4140M Programmers.

RESET BUTTON

PLUG-IN

FLAME SIGNAL

AMPLIFIER

FLAME SIGNAL

METER JACK

RELAY/TIMER

COVER

Fig. 2. Components of R4140L Programmers.

R4140G,L and M

HANDLE

TIMER

TIMER DIAL

RELAY

FLAME SIGNAL

2K

METER JACK

CHASSIS RETAINING

HANDLE

TIP JACK

SCREW

TIMER

TIMER DIAL

RELAY

2K

RELAY 1K

Installation ........................................................................... 2

Checkout ............................................................................. 11

Troubleshooting .................................................................. 18

Service Information ............................................................. 27

Testing and Maintenance .................................................... 28

INSTALLATION INSTRUCTIONS

CHASSIS RETAINING

SCREW

SAFETY SWITCH

BUTTON

CHASSIS

HINGE

TIMER

BRACKET (2)

MOTOR

RELAY

1K

M10053

RELAY 4K

SAFETY SWITCH

BUTTON

CHASSIS

HINGE

BRACKET (2)

TIMER

RELAY

MOTOR

M7959

3K

Contents

60-0770-2

Advertisement

Table of Contents

Troubleshooting

Summarization of Contents

Honeywell R4140 Flame Safeguard Programming Controls Installation

Location Considerations for Installation

Guidance on selecting an appropriate installation site for the R4140 based on environmental factors like temperature and humidity.

Weather Protection Requirements

Information regarding protection requirements for outdoor installations of the R4140.

Mounting the Wiring Subbase

Instructions on how to physically mount the subbase for the R4140 programmer, including orientation constraints.

Wiring to Subbase

Details and precautions for connecting wires to the R4140 subbase, including wire type and safety notes.

Installing the Flame Detector

Guidance on the proper installation of flame detectors for reliable operation and safety.

Special Considerations for C7012E or F Detectors

Specific installation advice for C7012E or F ultraviolet flame detectors, including power requirements.

Using Redundant Parallel C7012E or F Detectors

Instructions for wiring multiple C7012E or F detectors in parallel for improved flame detection reliability.

Static Checkout Procedures

Equipment Required for Static Checkout

List of tools and equipment needed for performing static checkout procedures.

General Instructions for Static Checkout

Important guidelines and steps to follow before and during the static checkout process.

Programmer Installation and Removal Procedures

Installing the Programmer

Step-by-step guide for physically installing the R4140 programmer onto its subbase.

Removing the Programmer

Instructions on how to safely detach the R4140 programmer from its subbase.

Programmer Servicing Procedures

Removing and Replacing the Relay/Timer Cover

Steps for accessing internal components by removing and reinstalling the programmer's cover.

Installing a Plug-in Flame Signal Amplifier

Guide on how to insert and secure a flame signal amplifier module into the programmer.

Installation Instructions for Special Features

Information on special features available on certain R4140 models.

Programmer Configuration and Upgrades

Installing Jumper on Back of Programmer

Instructions for installing a jumper to extend the main burner flame-establishing period.

Upgrading Systems

Information on selecting R4140 models for different application requirements and system upgrades.

Model Replacement and Wiring Diagrams

Replacing an R4140M with an R4140G

Wiring diagrams and instructions for replacing an R4140M with an R4140G model.

Replacing an R4140M or G with an R4140L

Wiring diagrams and instructions for replacing an R4140M or G with an R4140L model.

Checkout Procedures

Equipment Required for Checkout

List of tools and instruments necessary for performing checkout tests.

Checkout Summary

Overview of all checkout tests required for various installation types.

Preliminary Inspection (All Installations)

Initial checks to perform on all installations to prevent common problems.

Flame Signal Measurement

Procedure for measuring flame signal strength using test equipment.

Initial Lightoff Check for Proved Pilot

Test procedure to verify pilot ignition and signal before main burner operation.

Initial Lightoff Check for Direct Spark Ignition of Oil

Checkout procedure for oil burners without a pilot, focusing on direct spark ignition.

Pilot Turndown Test

Procedure to test pilot flame stability by reducing gas pressure until relay dropout.

Ignition Interference Test

Verifies that ignition spark does not falsely trigger the flame signal.

Hot Refractory Saturation Test

Checks if hot refractory radiation masks the flame signal.

Hot Refractory Hold-In Test

Ensures hot refractory does not keep the flame relay energized after flame loss.

Ultraviolet Response Tests

Tests response of ultraviolet detectors to ignition spark and other light sources.

Flame Signal with Hot Combustion Chamber

Measures flame signal under hot conditions and checks response time.

Safety Shutdown Tests (All Installations)

Verifies system safety shutdown occurs correctly under various failure conditions.

Troubleshooting Procedures

Troubleshooting Equipment Required

Lists essential tools and equipment for diagnosing and resolving system issues.

Preliminary Check for Troubleshooting

Initial checks to perform to rule out common causes of programmer malfunction.

Troubleshooting Chart and Procedures

Guidance on diagnosing and resolving specific system symptoms using the troubleshooting chart.

Flame Relay (2K) Hold-In Check

Procedure to test if the flame relay stays energized after flame loss.

Service Information and Maintenance

Scheduled Inspection and Maintenance

Recommended schedule for inspecting, maintaining, and testing controls.

Contact Cleaning Guidelines

Guidelines and warnings regarding the cleaning of relay and timer contacts.

Testing and Maintenance Schedule

Minimum Inspection and Testing Schedule

A table outlining recommended inspection and testing frequencies for boiler controls.

CM-102 Minimum Schedule Details

Detailed breakdown of inspection tasks by frequency (Daily, Weekly, Monthly, etc.).

Cm-103 General Guidance

General guidance emphasizing adherence to manufacturer's specific instructions.

Need help?

Do you have a question about the R4140L and is the answer not in the manual?

Questions and answers